Patents

Literature

111results about How to "The removal process is smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual positioning system according to semantic meaning in dynamic environment and method thereof

ActiveCN107833236AResolve consistencyHigh precisionImage analysisNeural architecturesObject detectionMonocular image

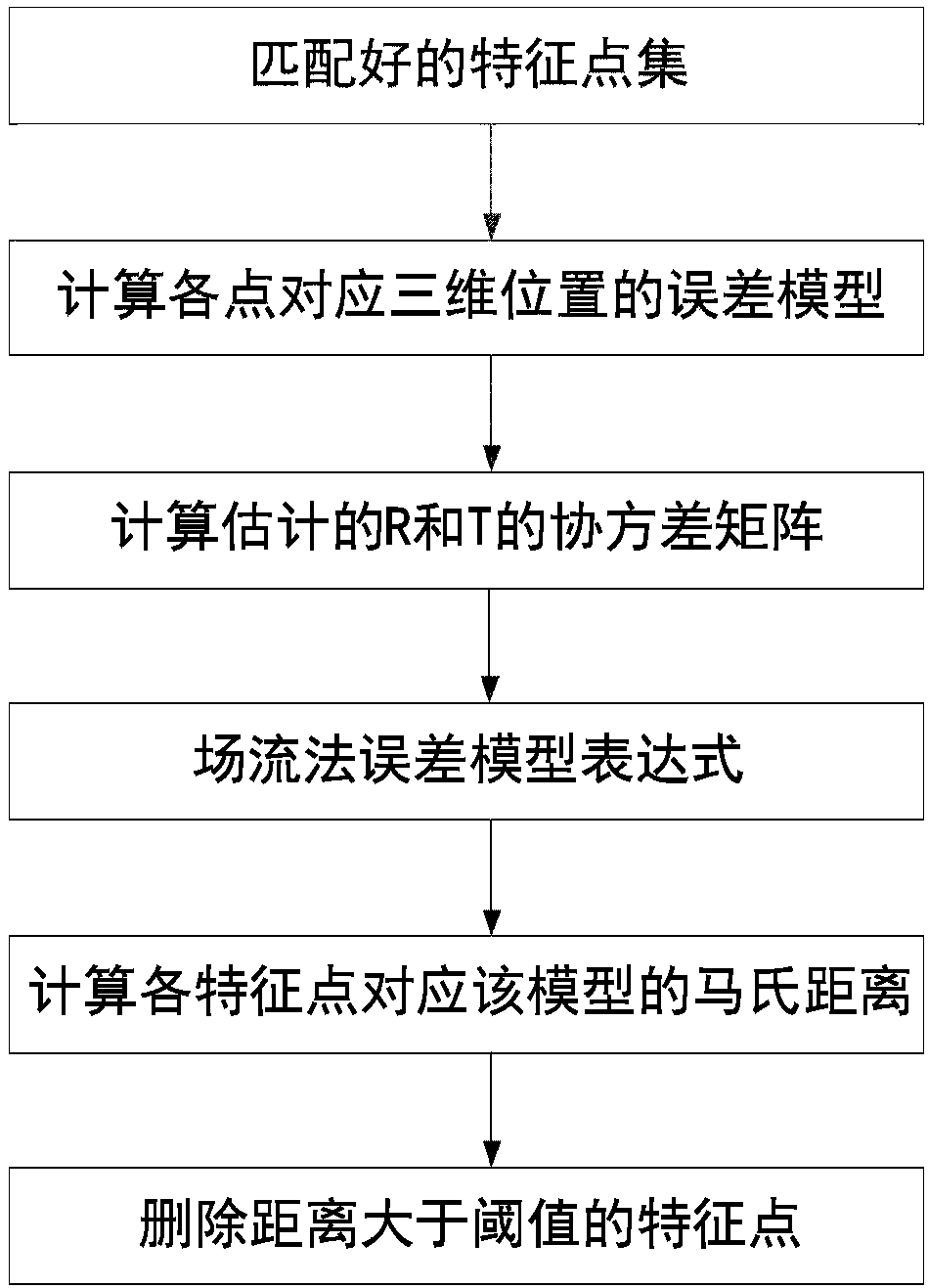

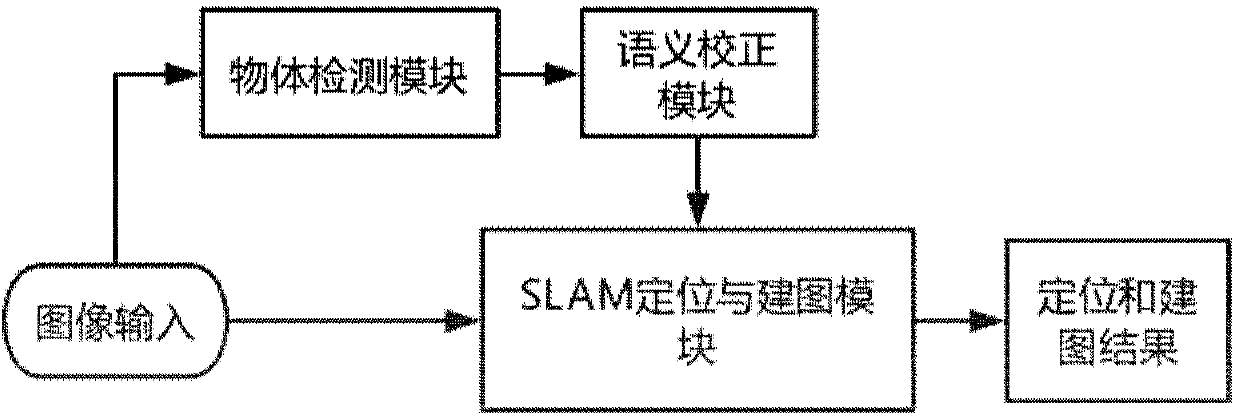

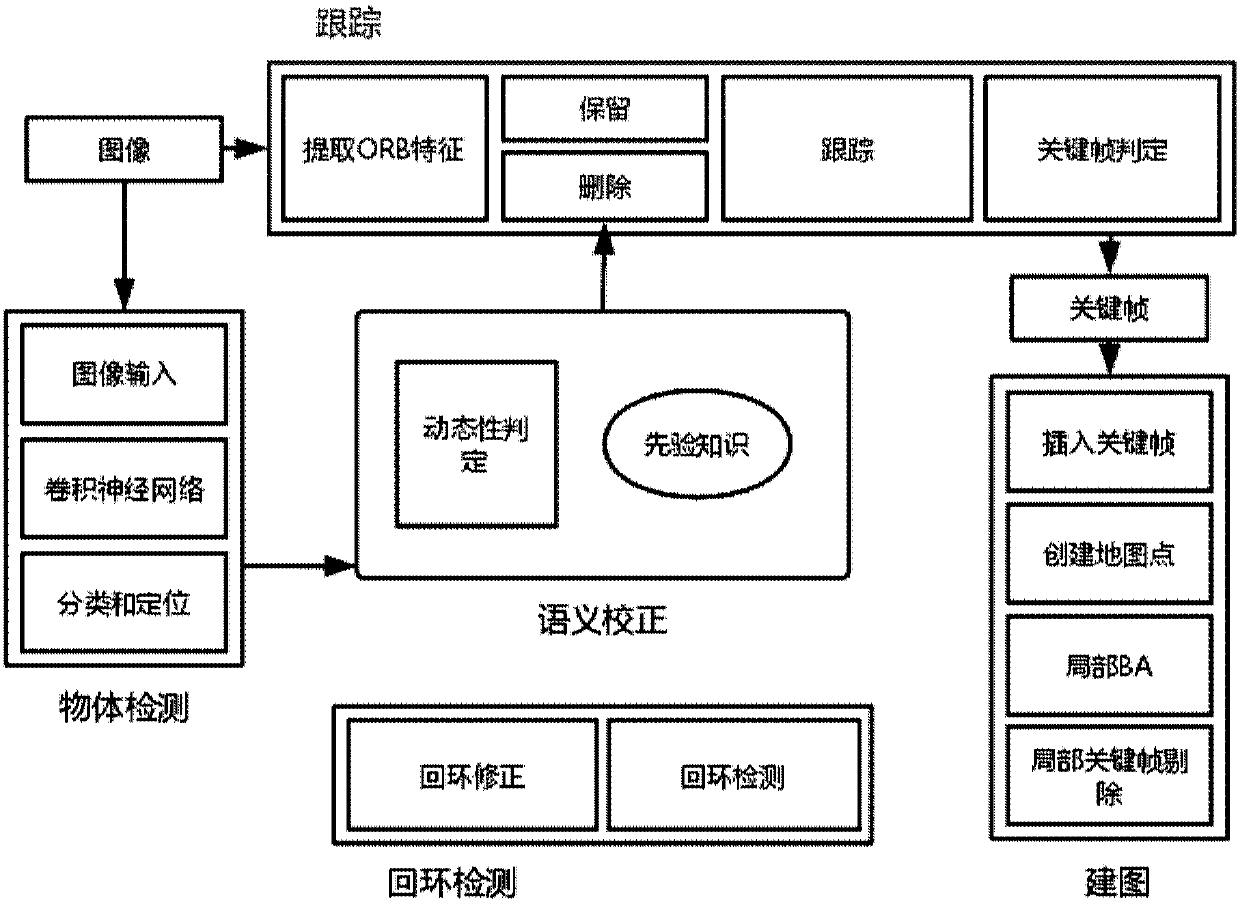

The invention discloses a monocular vision positioning system in a dynamic environment and a method thereof. According to semantic meaning, elimination of a dynamic object characteristic is realized.An environment image is acquired in real time through a monocular image camera. In the image, object detection is realized through a convolutional neural network, thereby obtaining the semantic meaning of the object. Furthermore determination of a dynamic object is realized according to priori knowledge. The characteristic in the image is extracted by means of an ORB algorithm, and furthermore thecharacteristic points of the dynamic object are eliminated according to the position of the dynamic object. Local bundle adjustment is performed on the gesture and the 3D point coordinate of the camera, thereby eliminating influence of the characteristic points of the dynamic object and improving positioning precision.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

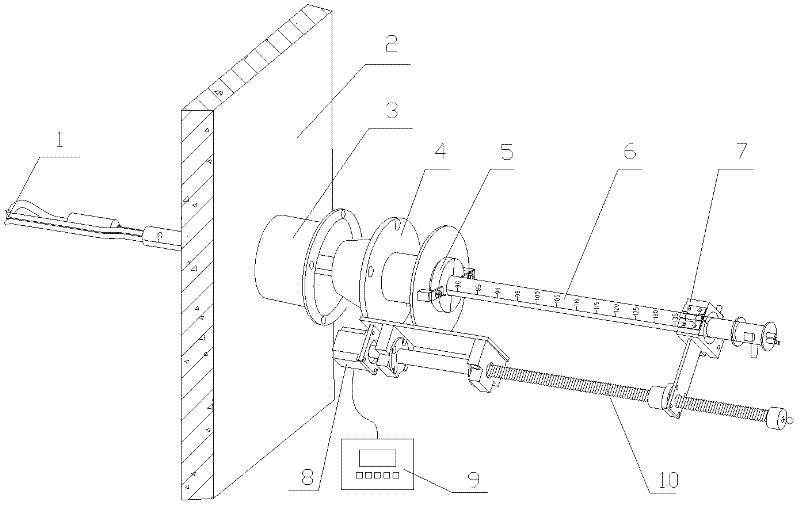

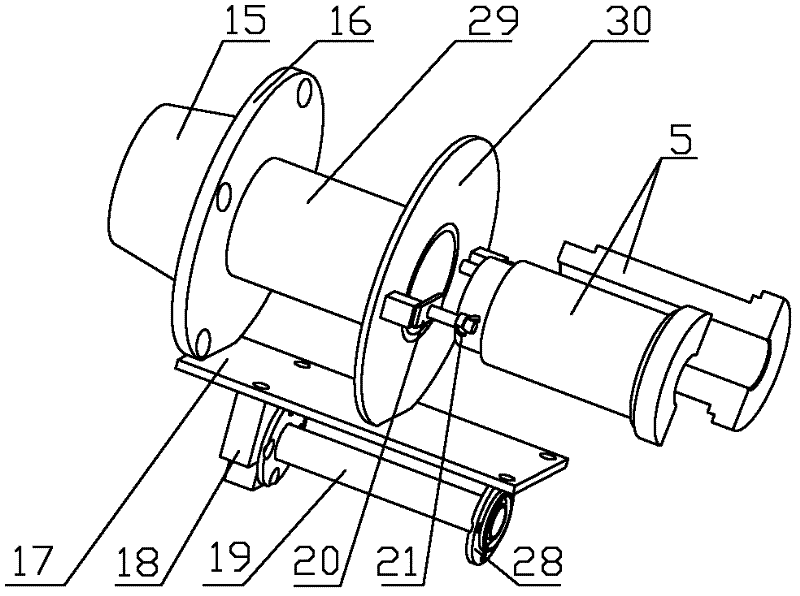

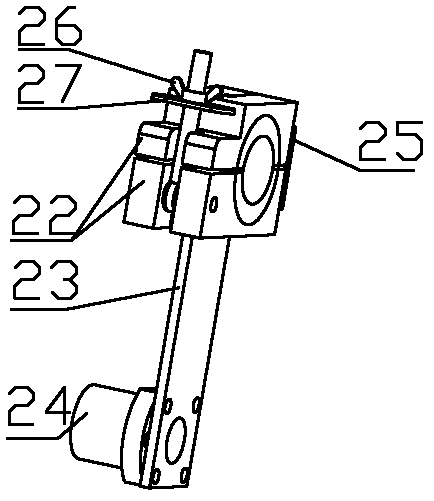

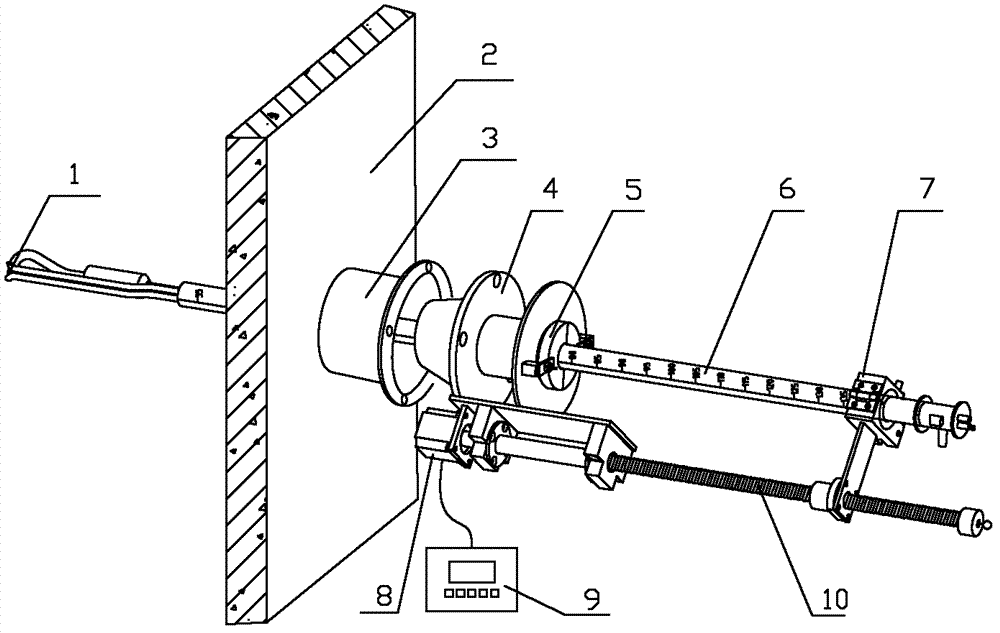

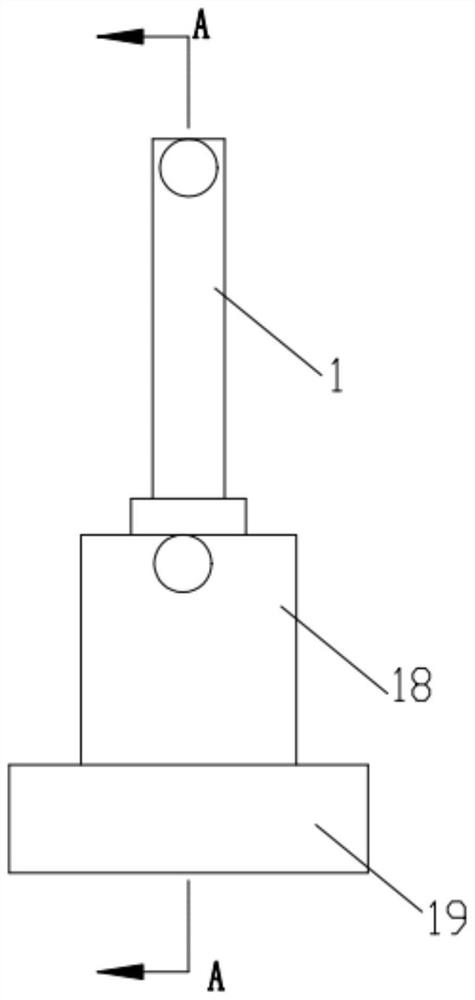

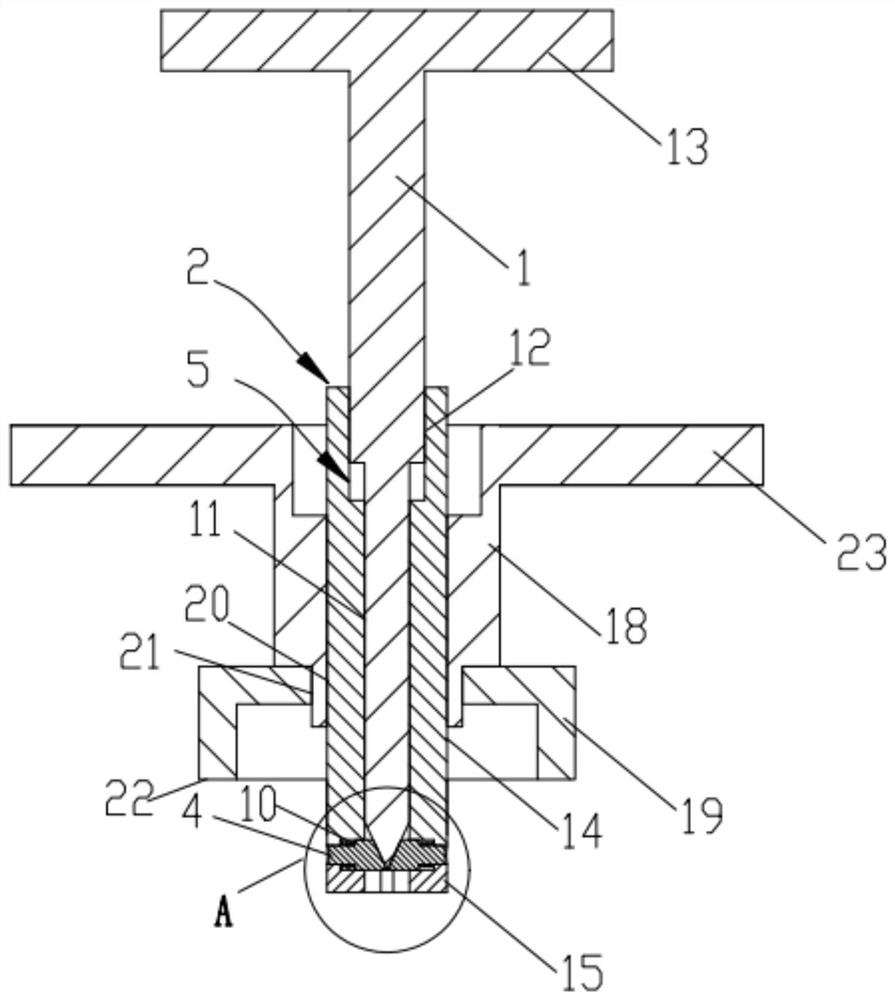

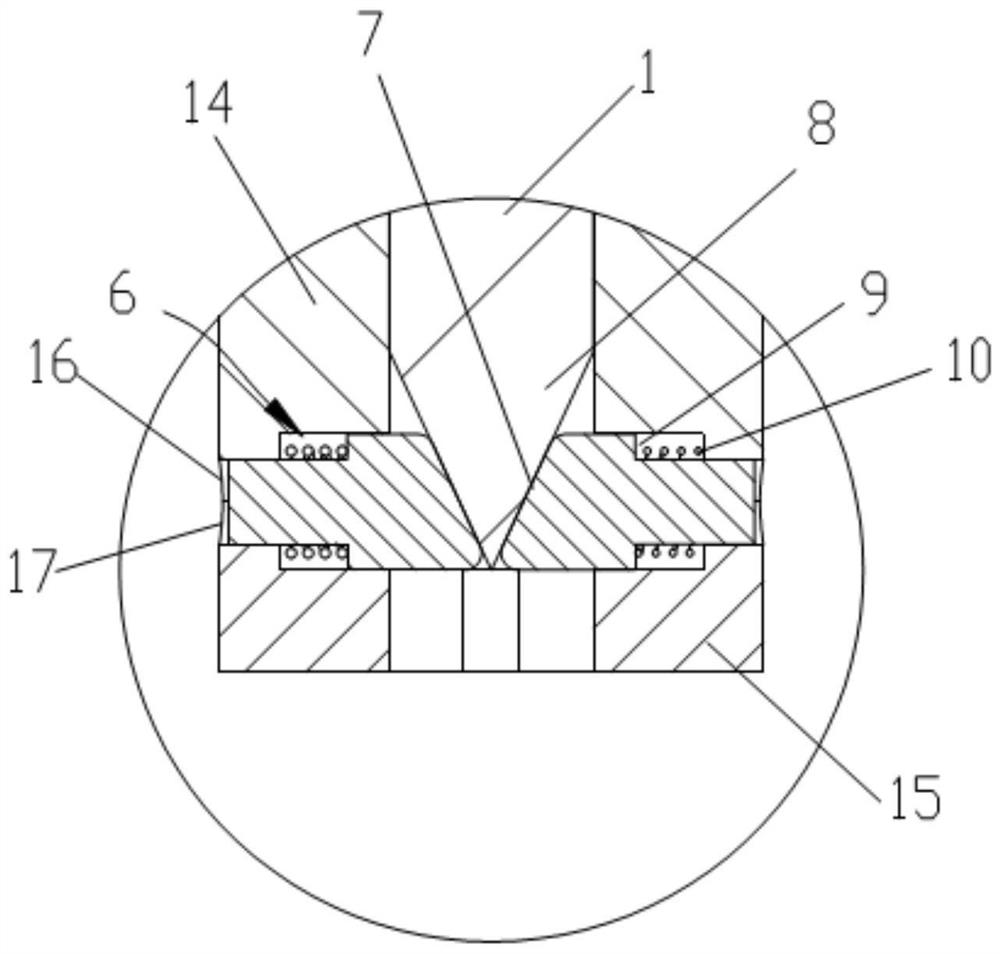

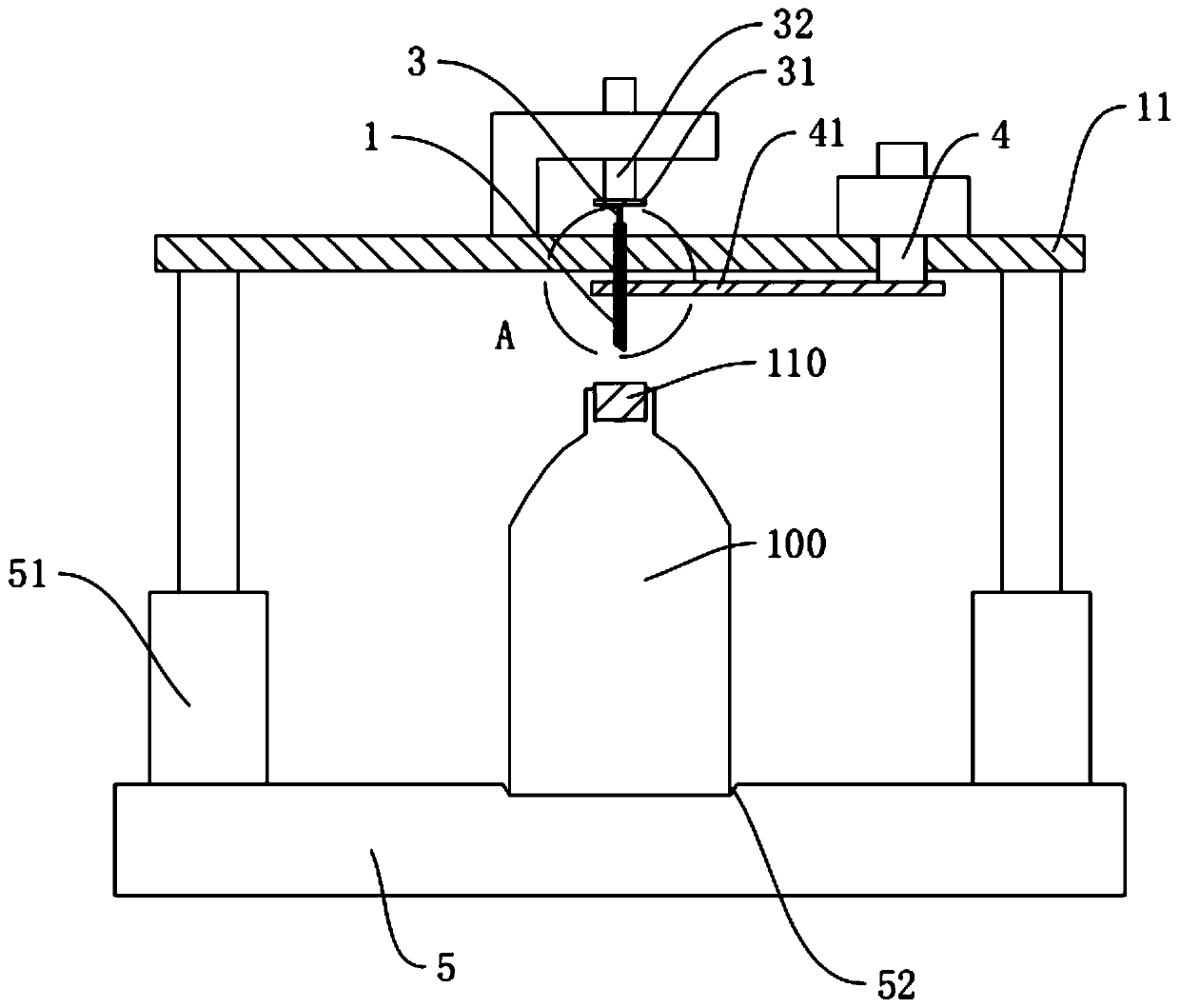

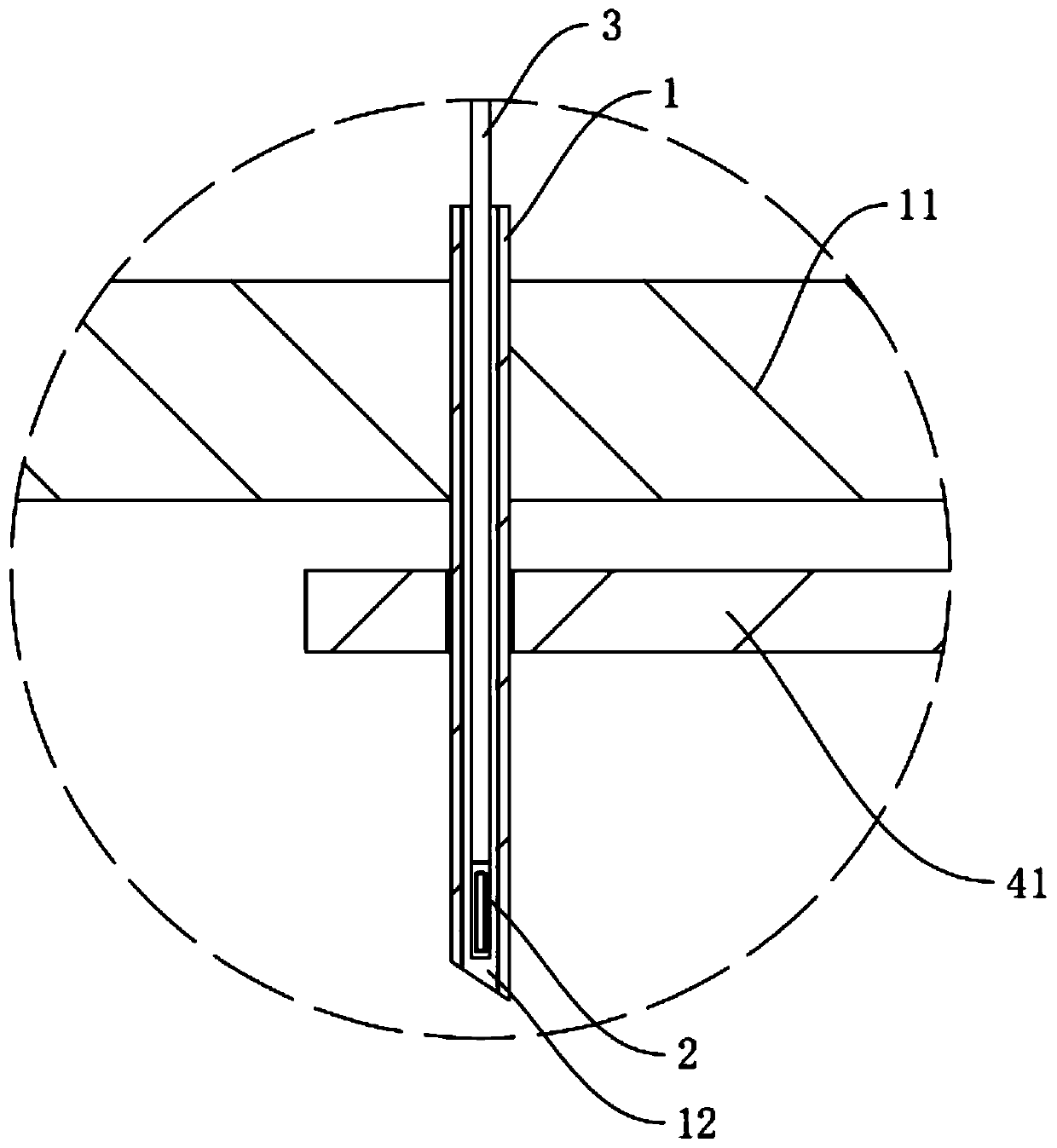

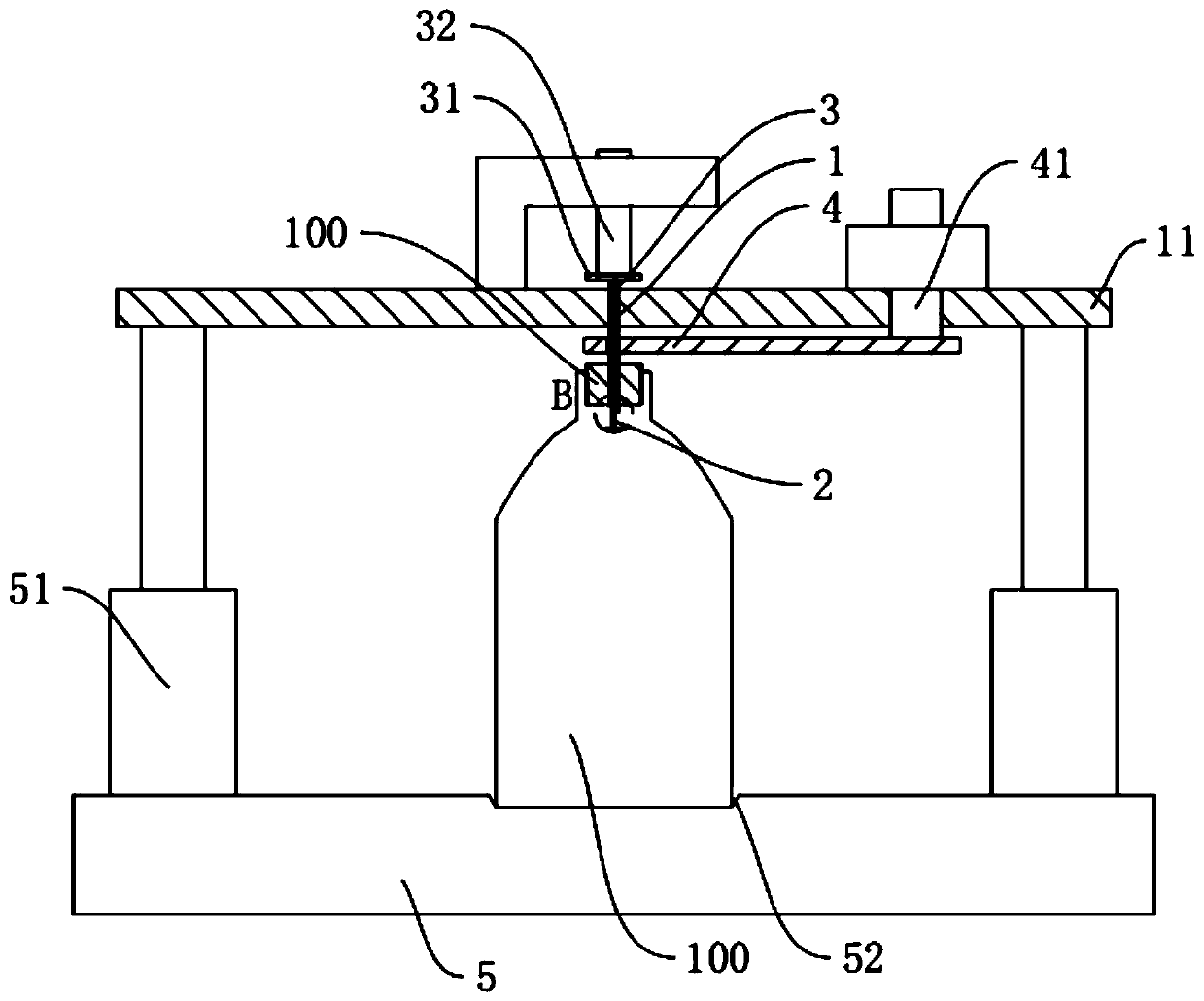

A smoke sampling device for automatically locating and measuring points

InactiveCN102297787AHigh positioning accuracyReduce sampling errorWithdrawing sample devicesMeasurement pointEngineering

The invention discloses a sampling device of smoke and dust with automatically positioning detecting point, comprising a sampling mouth, a fixing unit, a Teflon axle sleeve, a sampling pipe of smoke and dust, a connecting piece of the sampling pipe, a stepping motor, a main engine of the sampling device of smoke and dust, a screw rod, and a rigid bearing unit, wherein, the fixing unit is connected with a sampling hole through a flange, the Teflon axle sleeve comprising two half circle cylinders are embedded in the center of the fixing unit, the sampling pipe of smoke and dust is slidingly arranged in the Teflon axle sleeve, one end of the sampling pipe of smoke and dust is provided with the sampling mouth, the connecting piece of the sampling pipe is fixed on the other end of the samplingpipe of smoke and dust, one end of the screw rod is arranged in a screw rod retainer, the other end of the screw rod is connected with the stepping motor through the rigid bearing unit arranged on the fixing unit, and the stepping motor is connected with the main engine of the sampling device of smoke and dust through signal lines and power lines. According to the invention, the whole process of sampling smoke and dust is accomplished automatically, so that the damage probability of operating personnel in operation process is reduced. The sampling mouth does not shake or incline when being used for positioning, the positioning is accurate and rapid, and the installation and dismounting of the sampling pipe are convenient.

Owner:武汉境辉环保科技有限公司

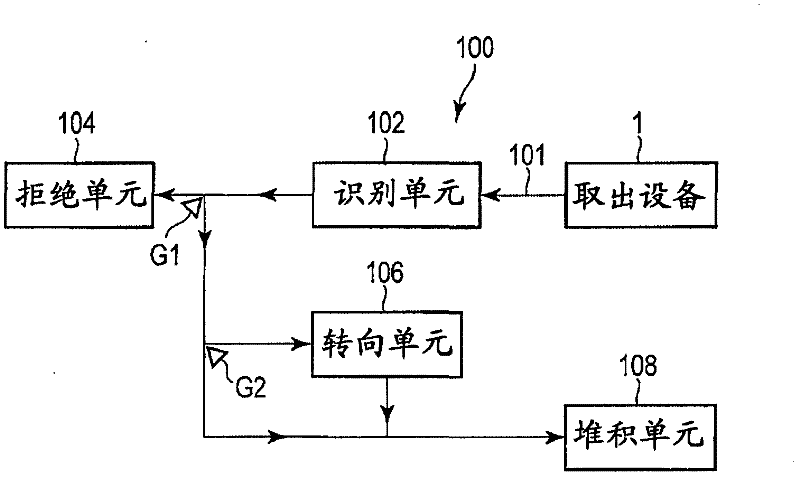

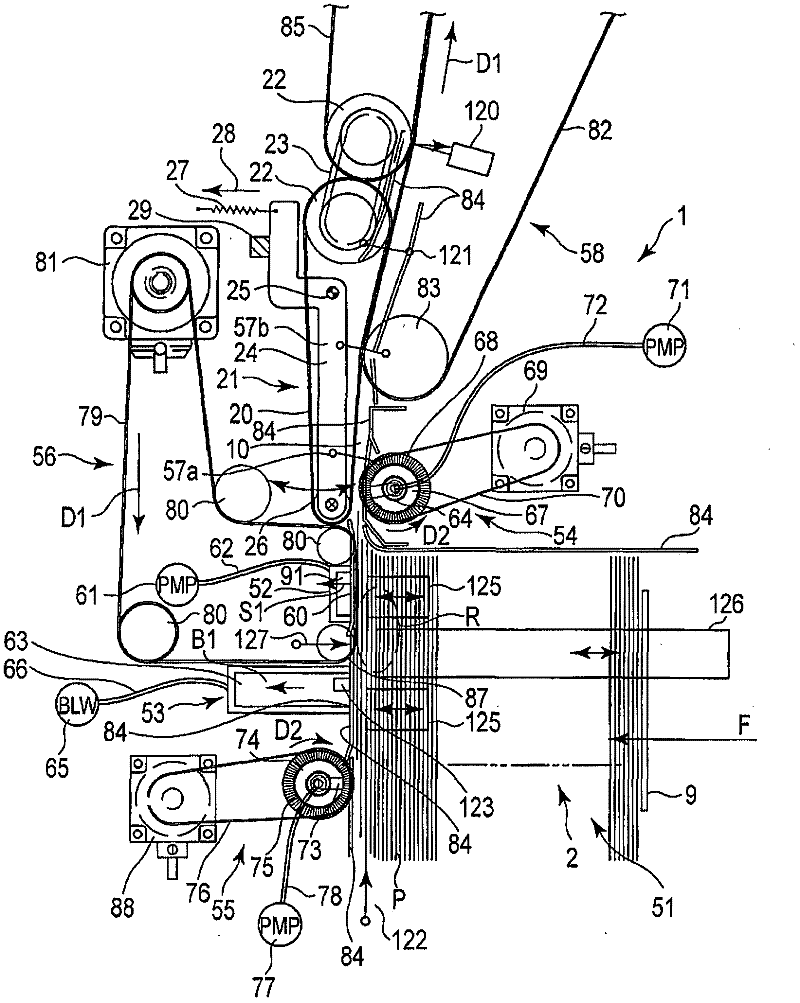

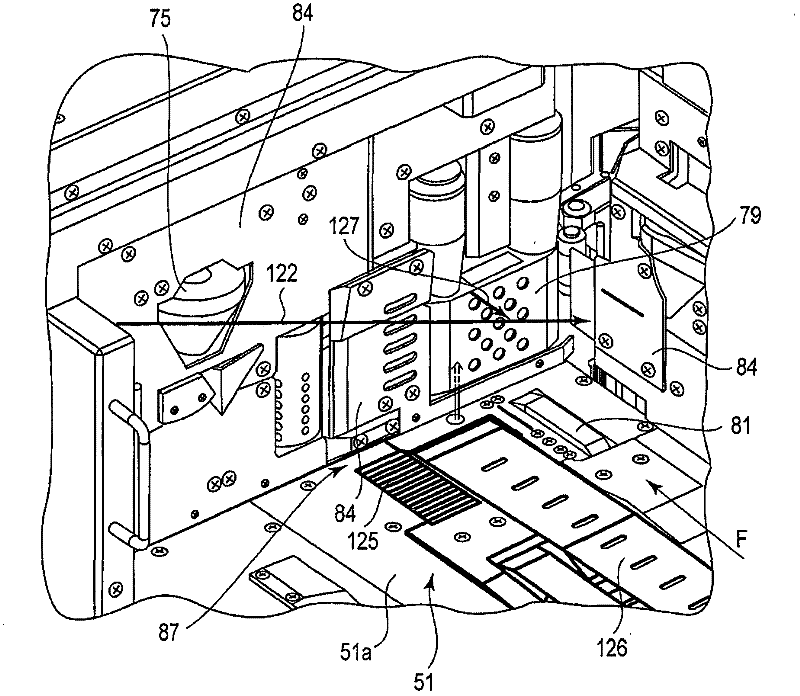

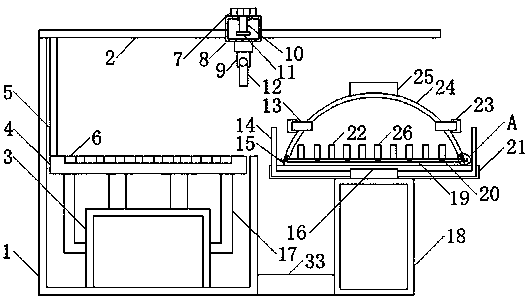

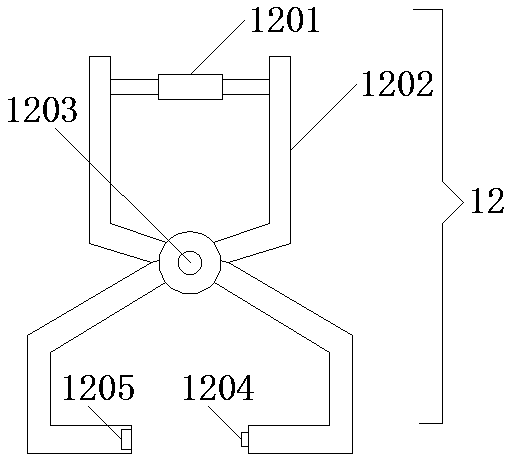

Paper sheet take-out device and paper sheet processing apparatus with the same

InactiveCN102653349ASuppression of operational defectsThe removal process is smoothFunction indicatorsSortingEngineeringPaper sheet

According to one embodiment, a paper sheet take-out device includes a supply unit (51), a supply mechanism (2) configured to supply a paper sheet to a take-out position in the supply unit, a take-out mechanism (56) configured to take-out the paper sheets at the take-out position from the supply unit, sensors (122, 127) including at least one optical sensor and configured to detect absence / presence of the paper sheets at the take-out position, and a control unit configured to control a supply operation of the supply mechanism in accordance with detection information from the sensors, monitors a relationship between signal information from the optical sensor and signal information from the other sensor, and retract the signal information from the optical sensor and use the signal information from the other sensor alone if there is generated a signal relationship that is not normal with respect to a signal relationship at the time of normal take-out operation.

Owner:KK TOSHIBA

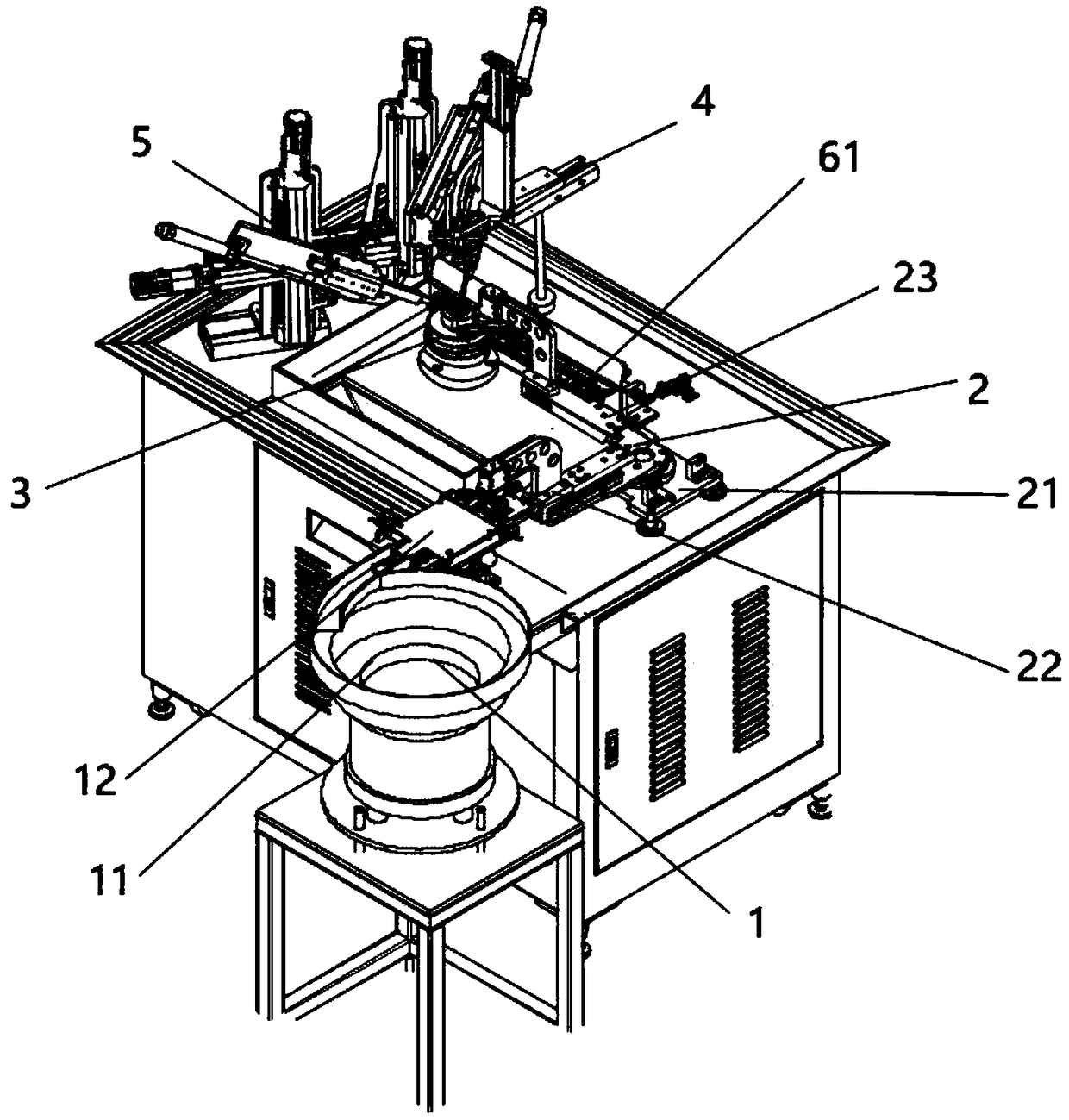

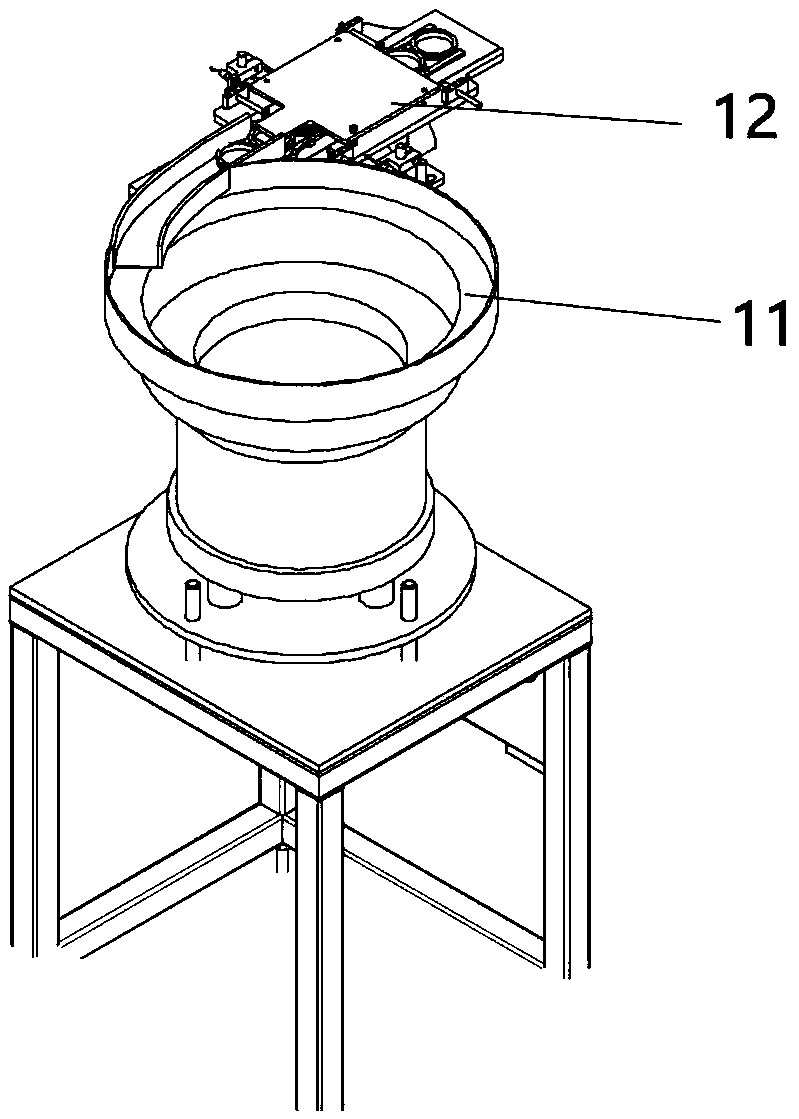

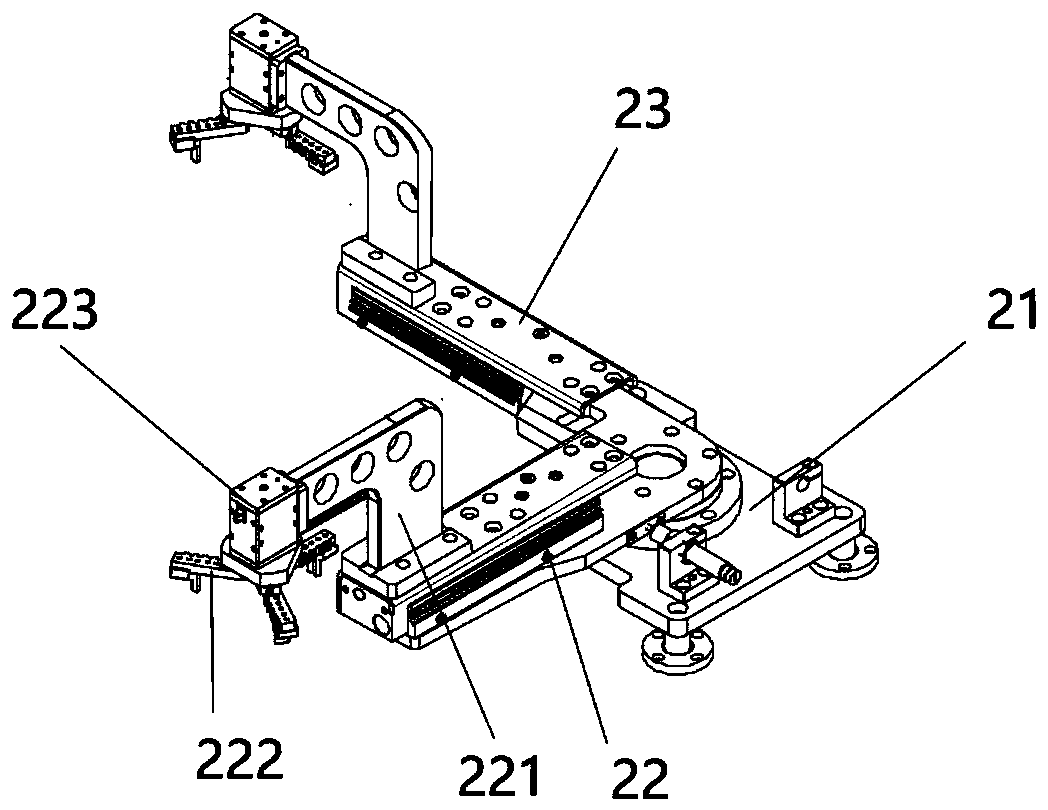

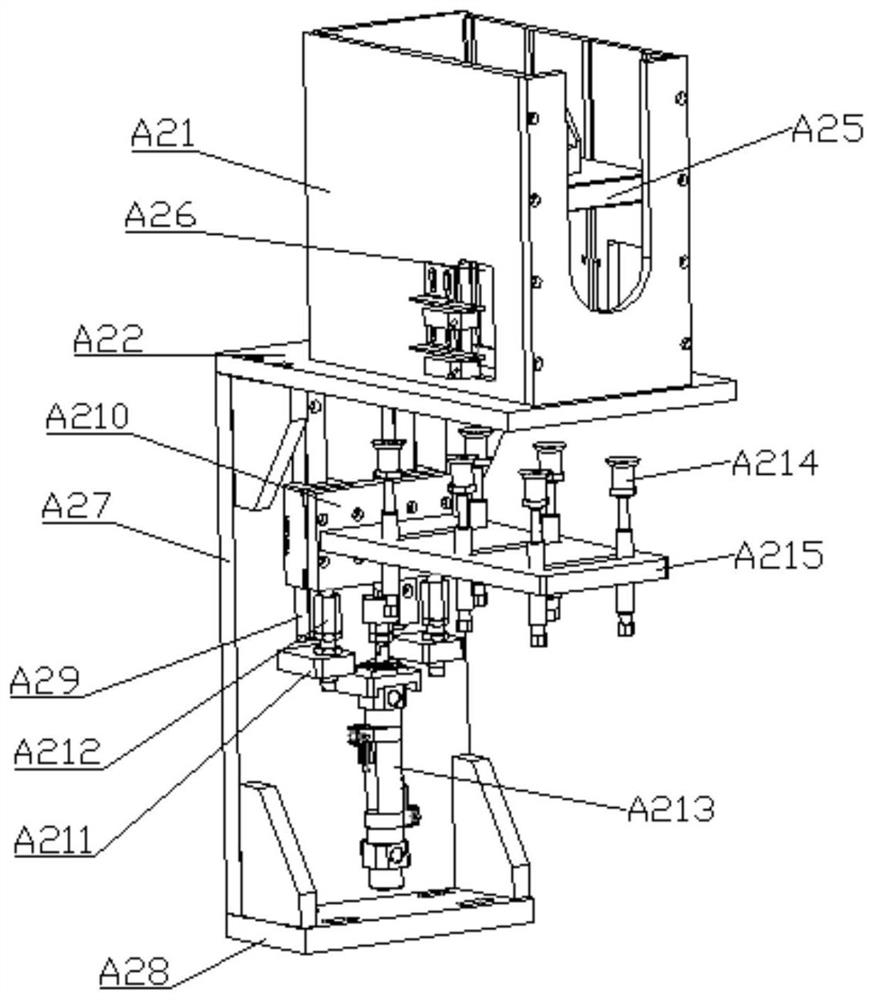

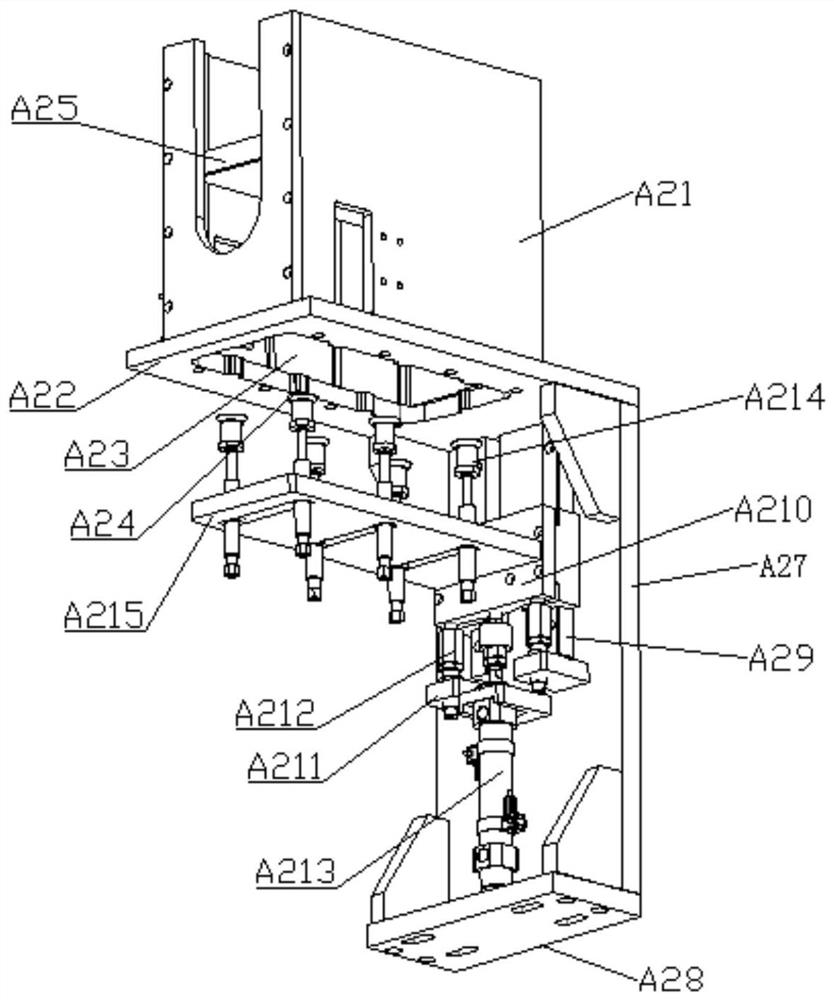

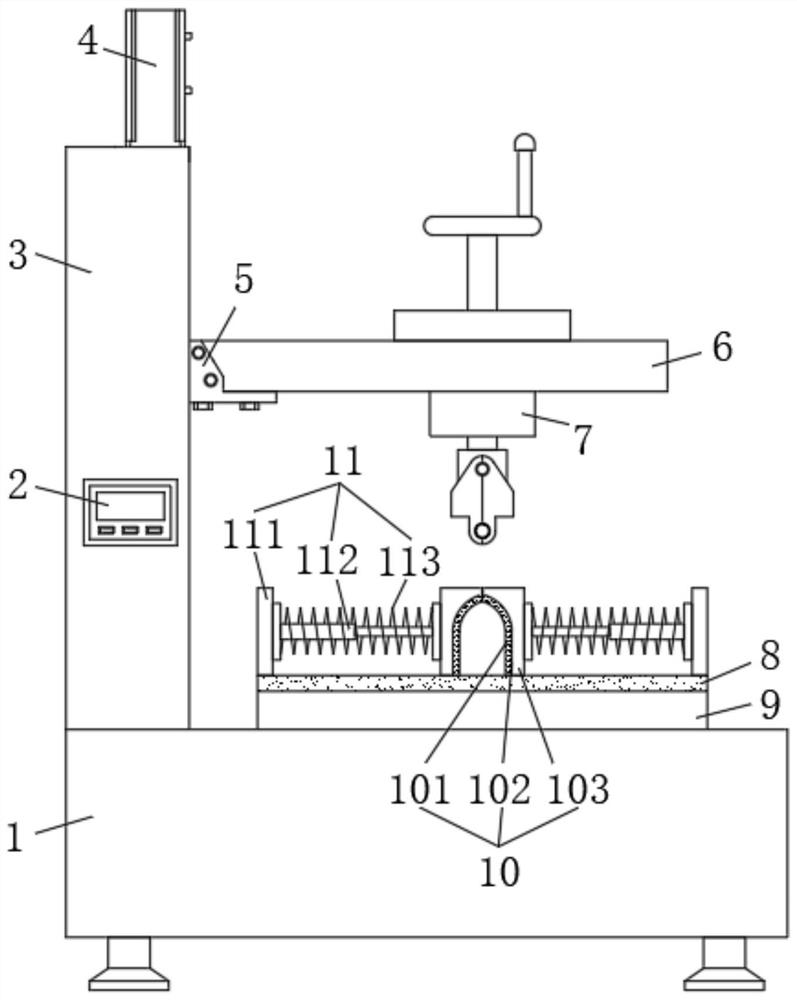

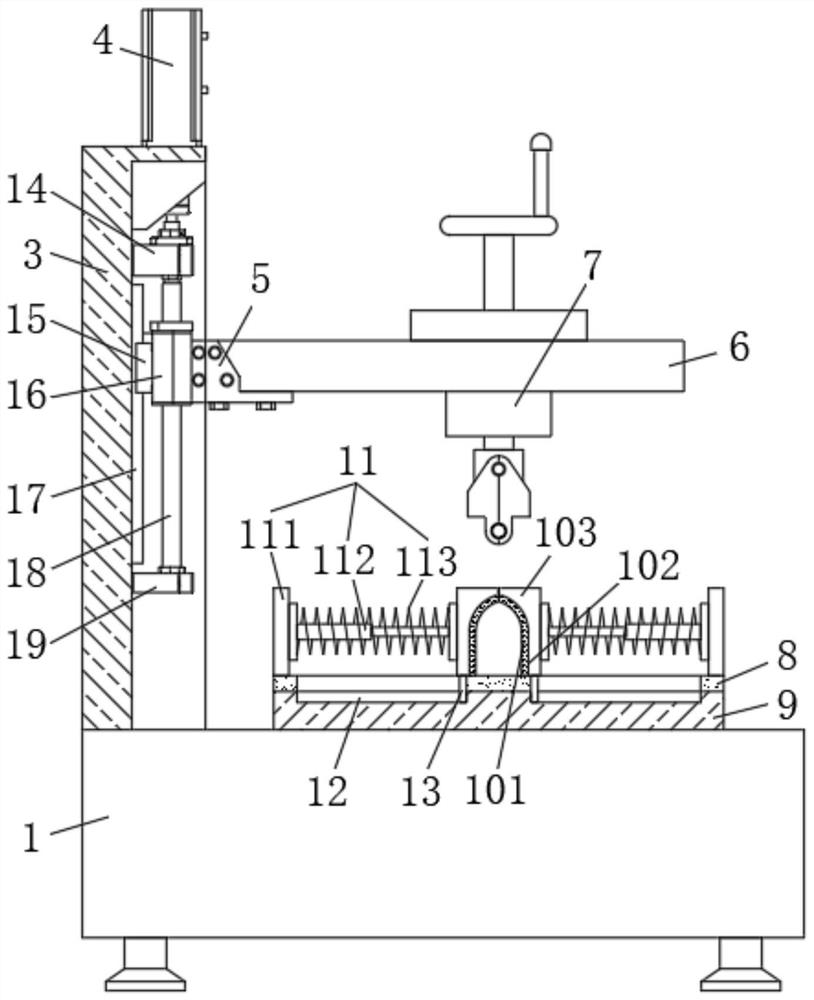

Full-automatic seal ring edge repairing machine

ActiveCN109291344AReduce labor costsImprove work efficiencyDomestic articlesPositive pressureRepair material

The invention discloses a full-automatic seal ring edge repairing machine. The full-automatic seal ring edge repairing machine comprises a clamping device, a mold, a pressing wheel device, an edge repairing device and a waste collecting device; the clamping device comprises a feeding clamping claw and a discharging clamping claw, the feeding clamping claw is used for clamping materials and placingthe materials into the mold, the discharging clamping jaw is used for clamping materials, subjected to edge repairing, in the mold, the mold comprises a groove, the groove is used for placing the materials, at least two air holes and at least two ejector pins are arranged in the groove, the air holes blow out or absorb the materials through leading of positive pressure or negative pressure, and the ejector pins are used for ejecting the repaired materials; the pressing wheel device is used for fixing the materials; the edge repairing device comprises two sets of edge repairing tool combinations and is used for repairing the inner side and the outer side of the materials; and the waste collecting device is used for collecting the waste generated in the edge repairing process. Unmanned operation is achieved on real meaning, complete mechanical operation is achieved, and manual cost is greatly saved.

Owner:JIANGSU ZUNSION AUTOMOBILE TECH CO LTD

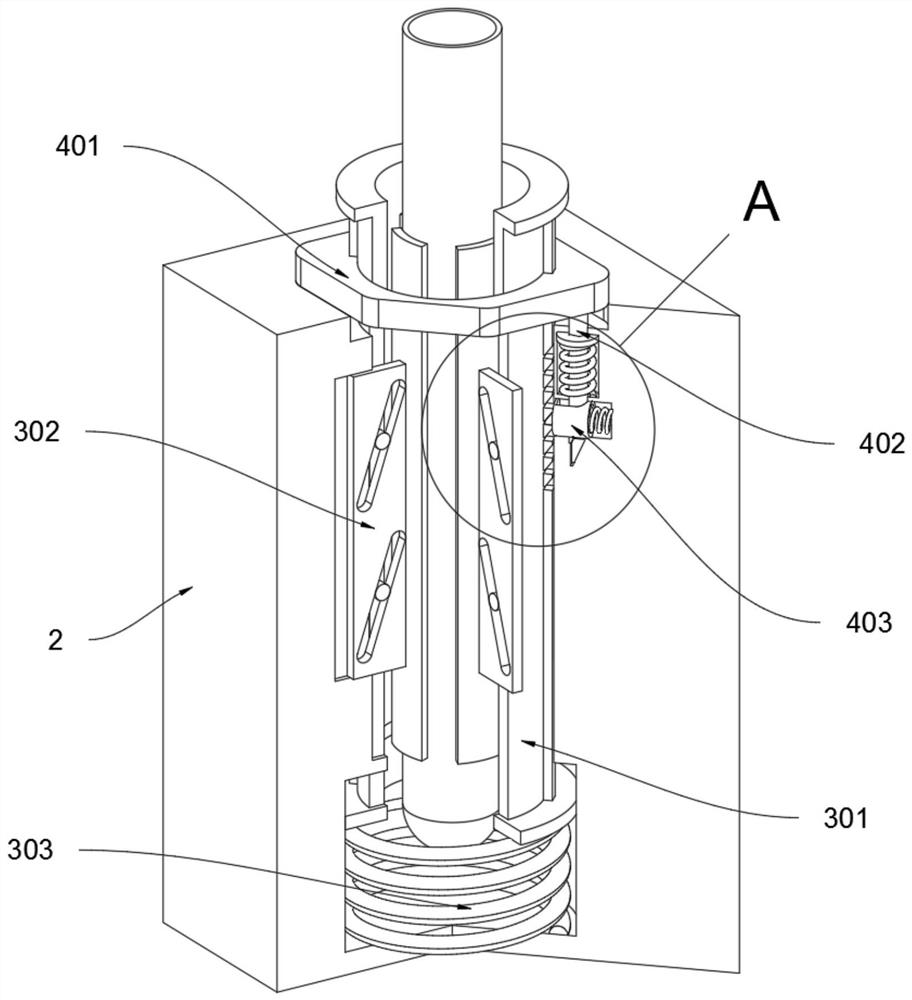

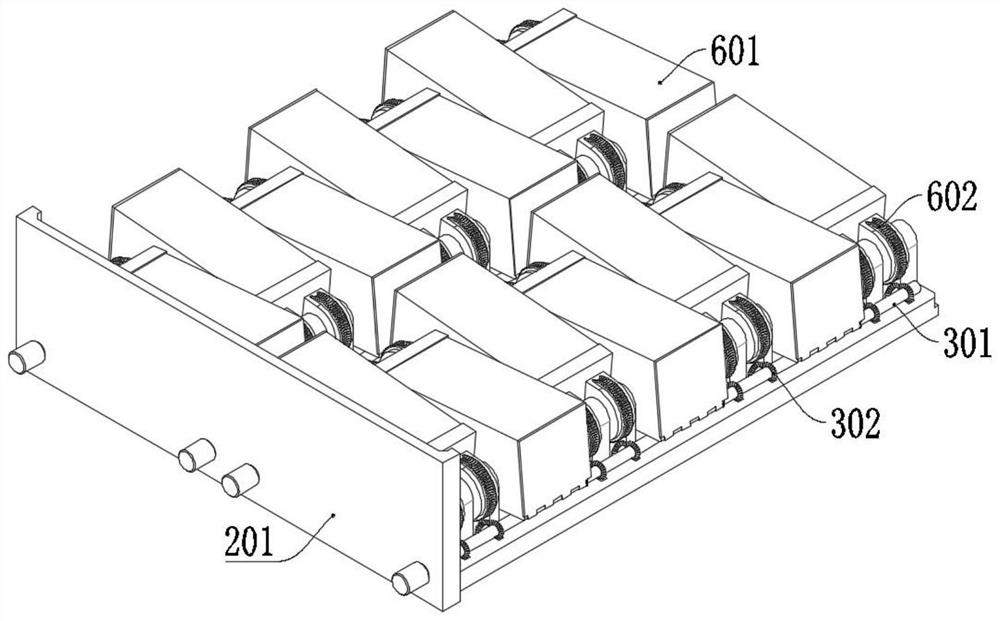

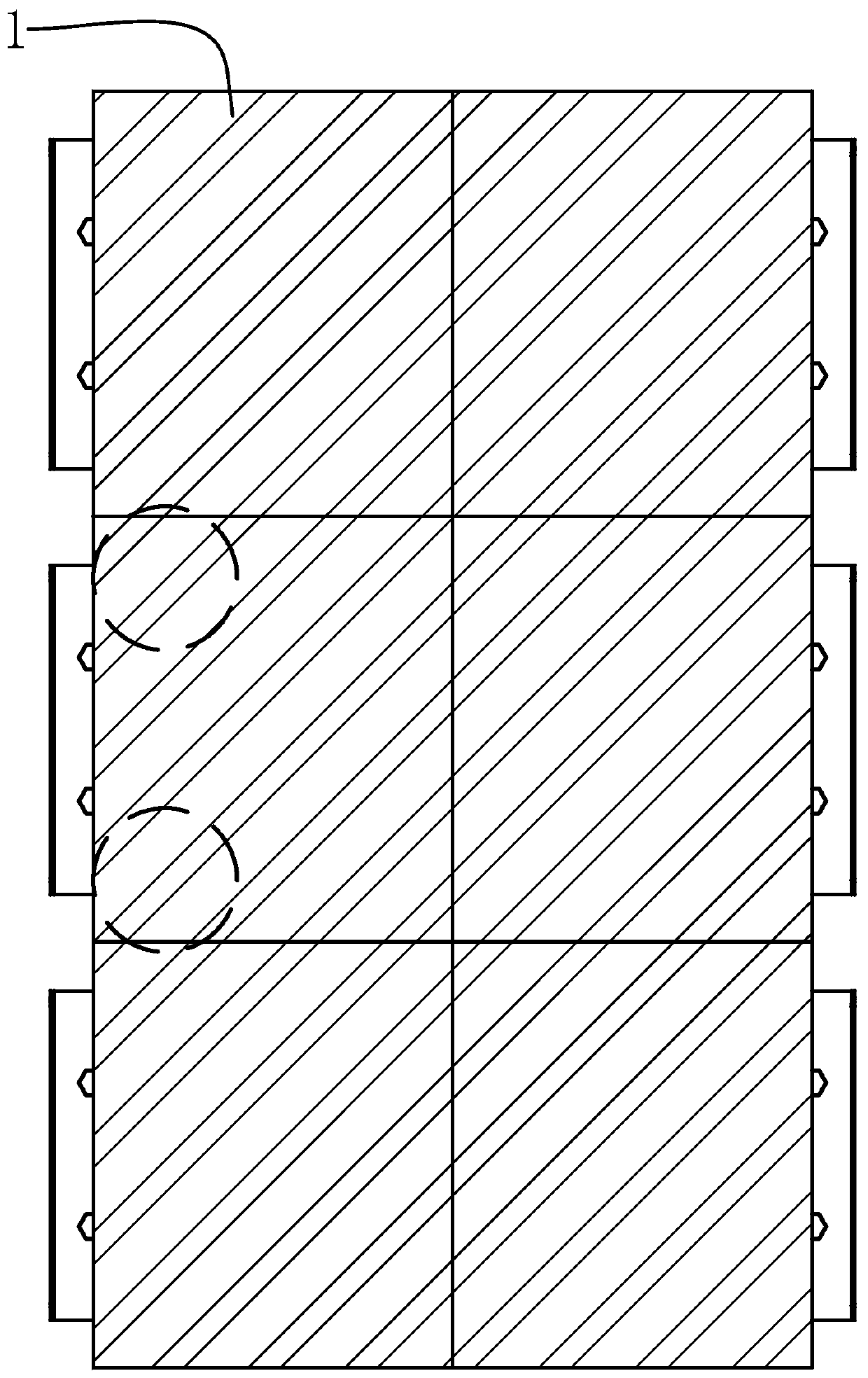

Chemical fiber bobbin yarn transferring and placing mechanism

InactiveCN109205393ARealize continuous feedingEasy and efficient replacementFilament handlingYarnFiber

The invention discloses a chemical fiber bobbin yarn transferring and placing mechanism, and belongs to the field of chemical fiber conveying and processing machine equipment. A bobbin transferring mechanism is vertically arranged on a fixing support between a bobbin guiding mechanism and a yarn placing mechanism. A discharging material pipe is obliquely downwards arranged on the upper side of thefixing support. The output end of a lifting air cylinder is vertically and fixedly provided with a lifting support. A bobbin transferring rotation rod is vertically and rotationally connected to a rotation rod sleeve. One end of the lower side of a reciprocating rotating plate is fixedly connected with the upper end of the bobbin transferring rotation rod. A bobbin taking mechanism is fixedly arranged at the other end of the lower side of the reciprocating rotation plate. A plurality of bobbin placing circular plates are evenly arranged at the outer end of the upper side of a yarn guiding rotation disc. A plurality of yarn guiding mechanisms are evenly arranged on the upper side of the yarn guiding rotation disc. The bobbin placing circular plates and the yarn guiding mechanism are sequentially arranged in the radial direction of the yarn guiding rotation disc from exterior to interior. The chemical fiber bobbin yarn transferring and placing mechanism is reasonable in structural design, a plurality of chemical fiber bobbin yarns can be continuously transferred and replaced conveniently and efficiently, a plurality of strands of chemical fiber filaments can be stably, accurately and synchronously conveyed, the automation degree is high, and the production and usage requirements are met.

Owner:桐乡市宏力纺织股份有限公司

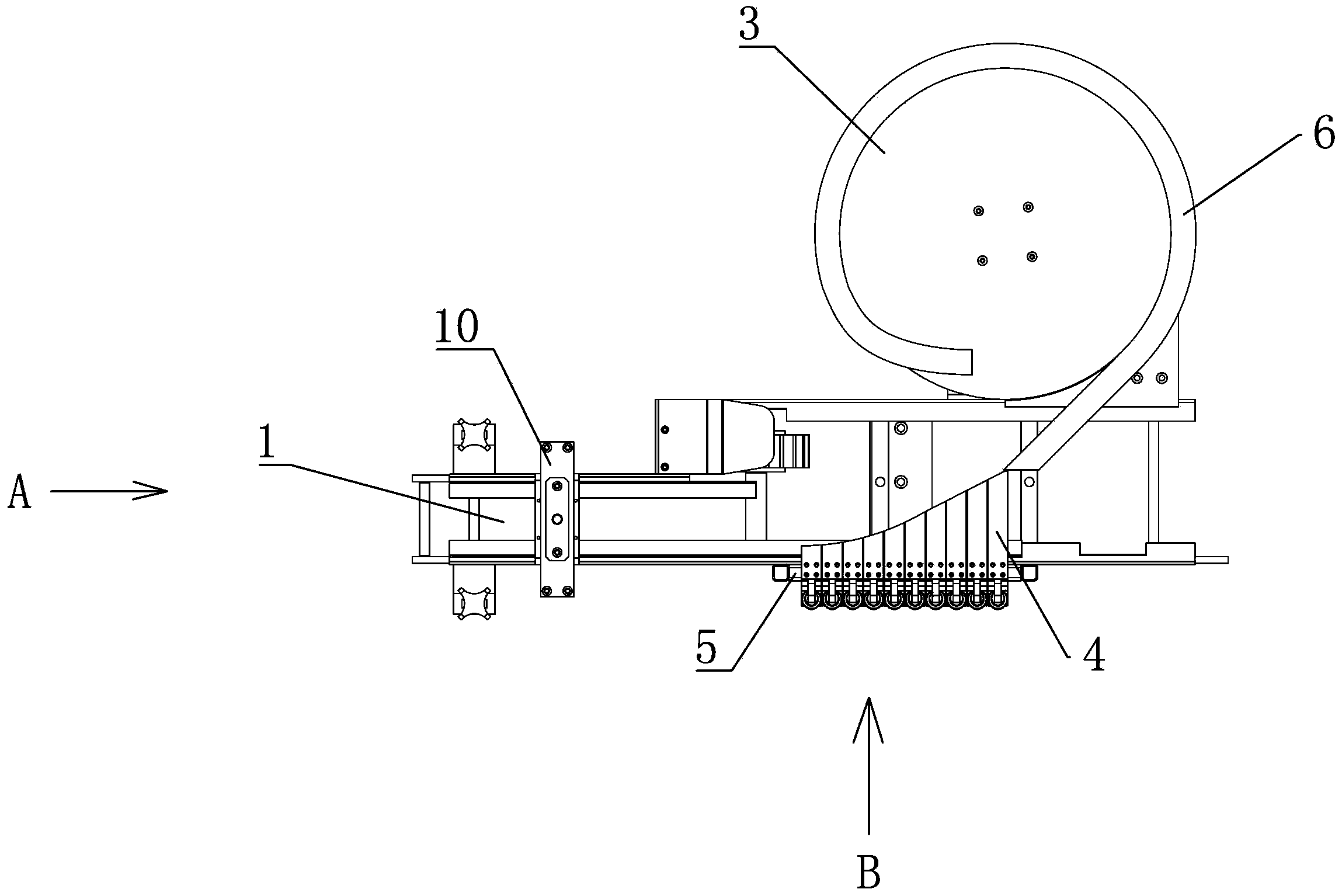

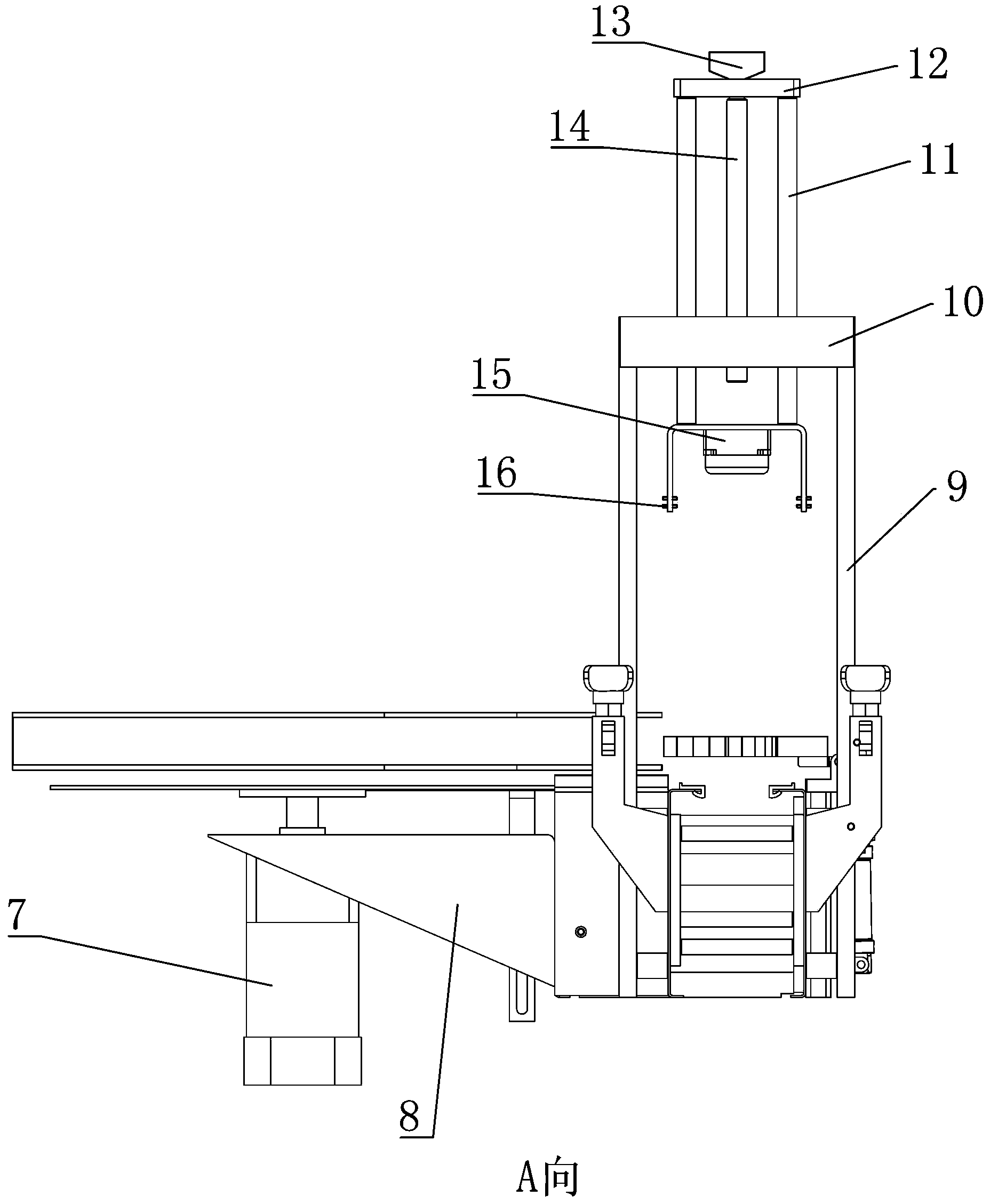

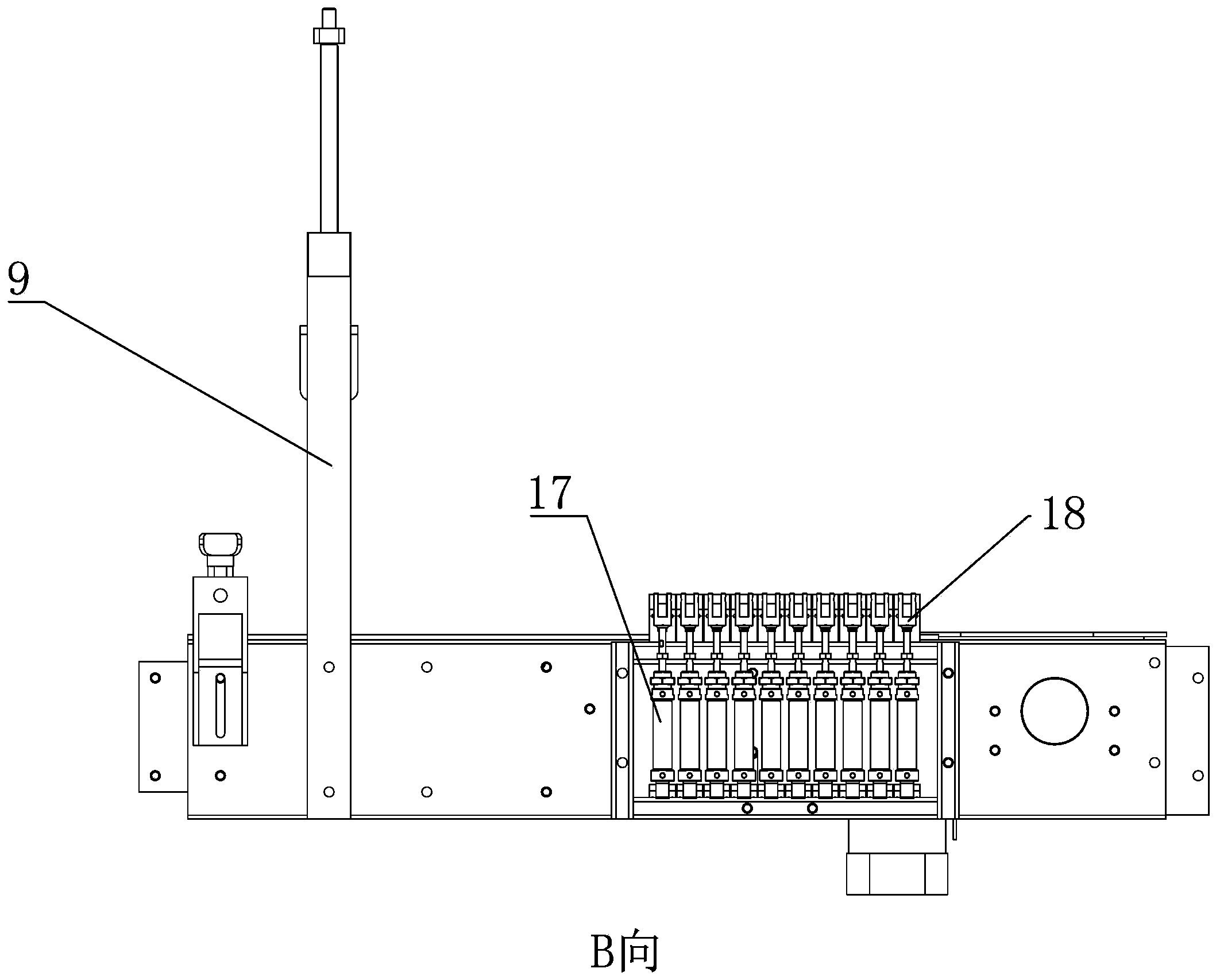

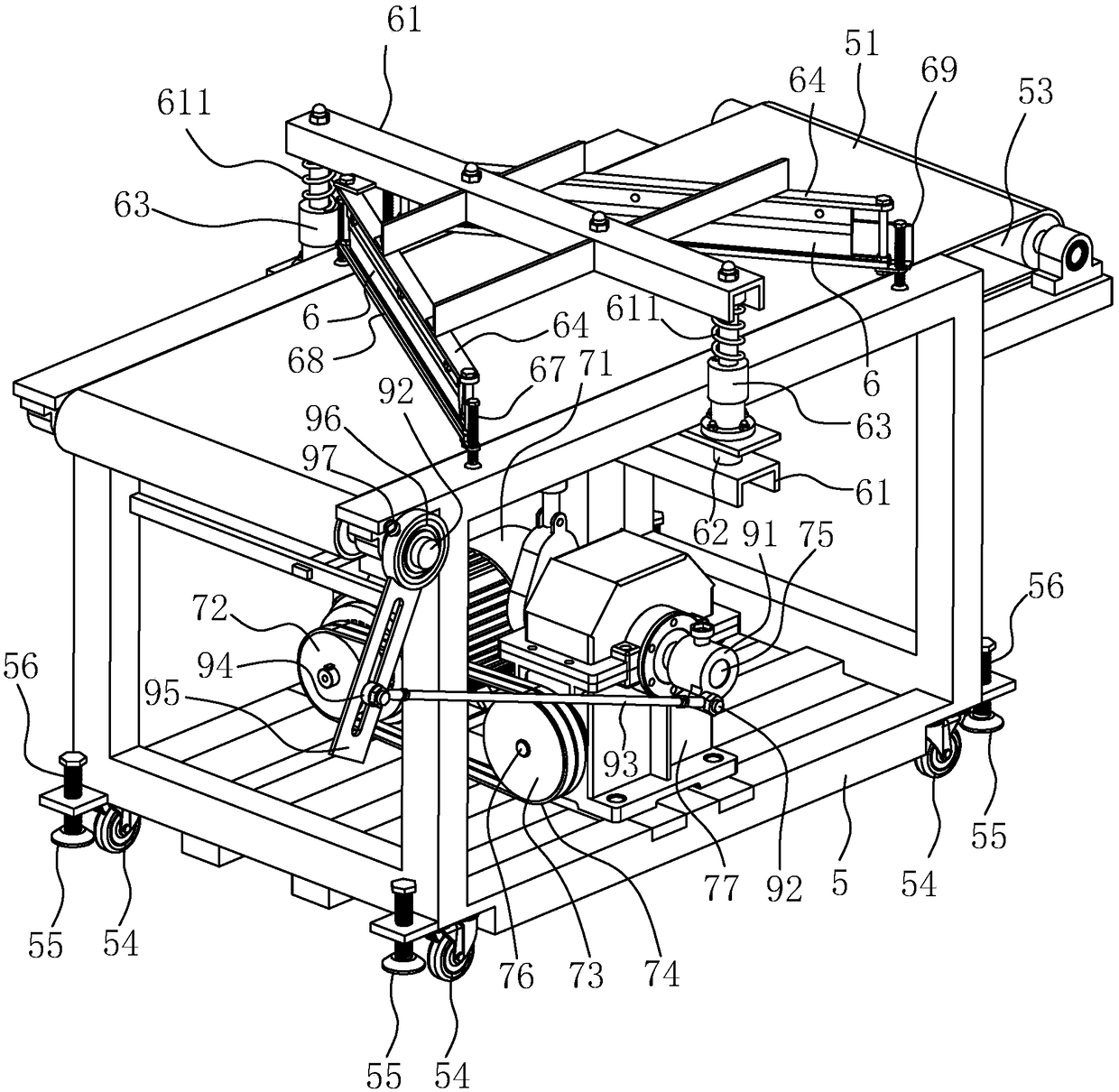

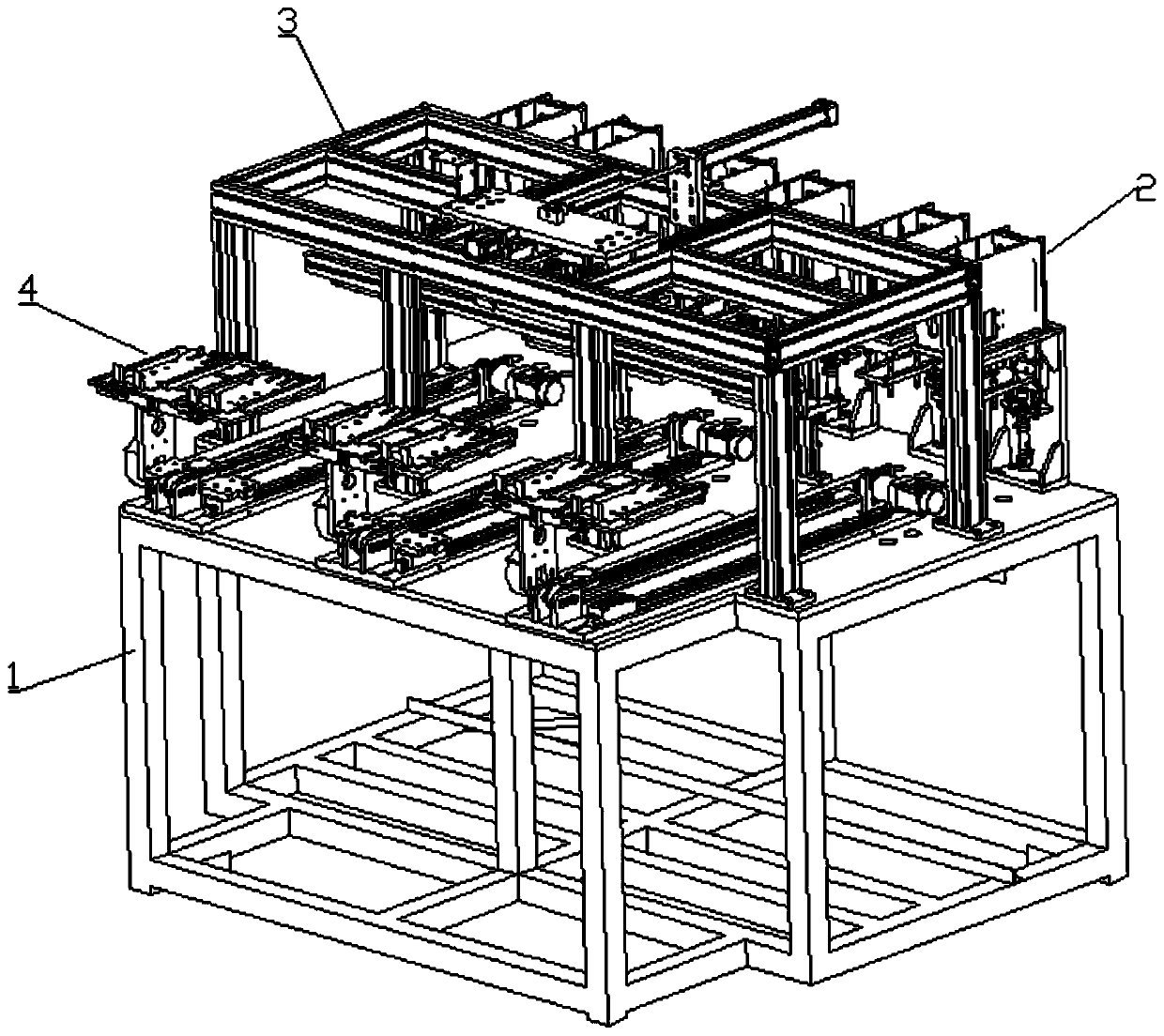

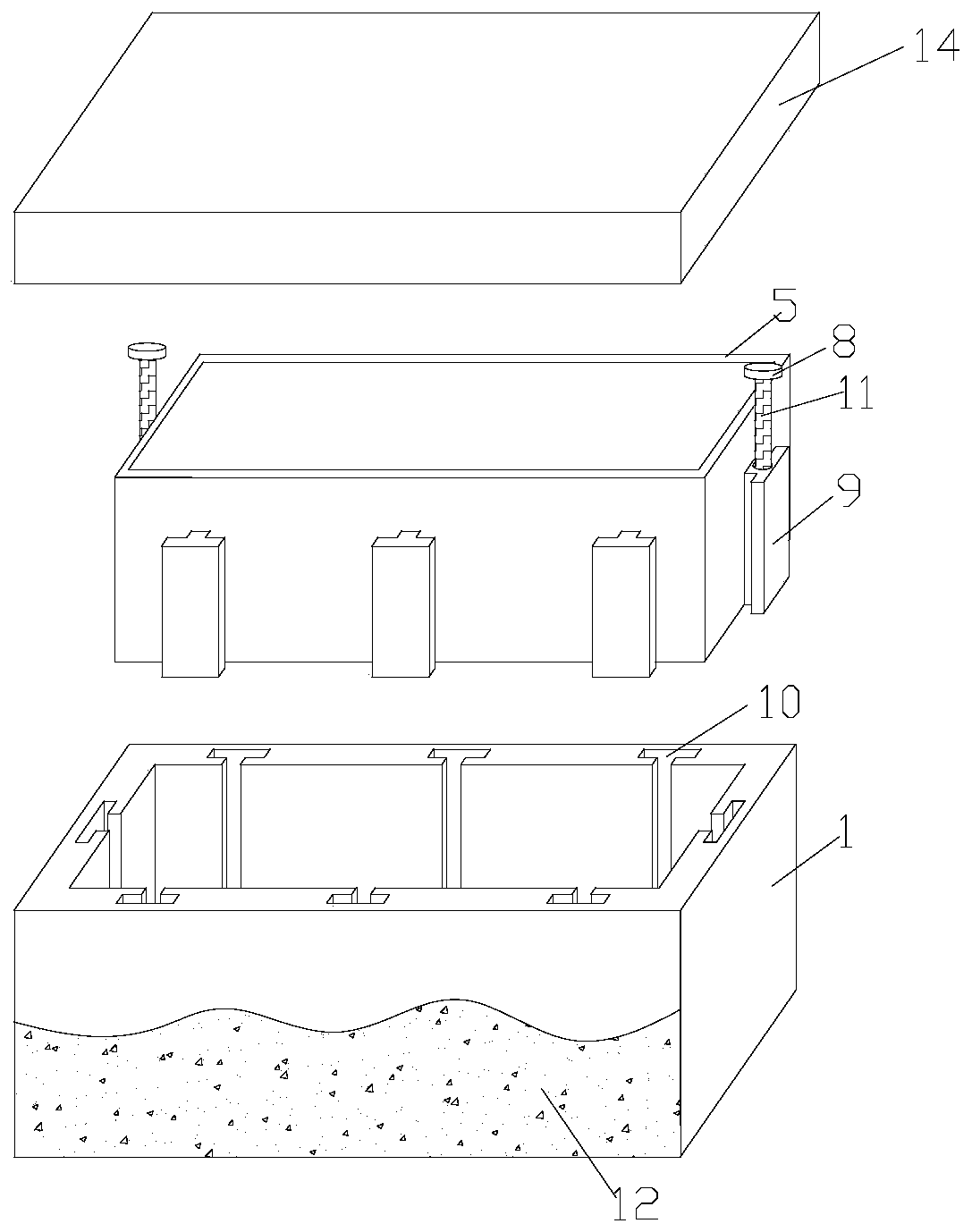

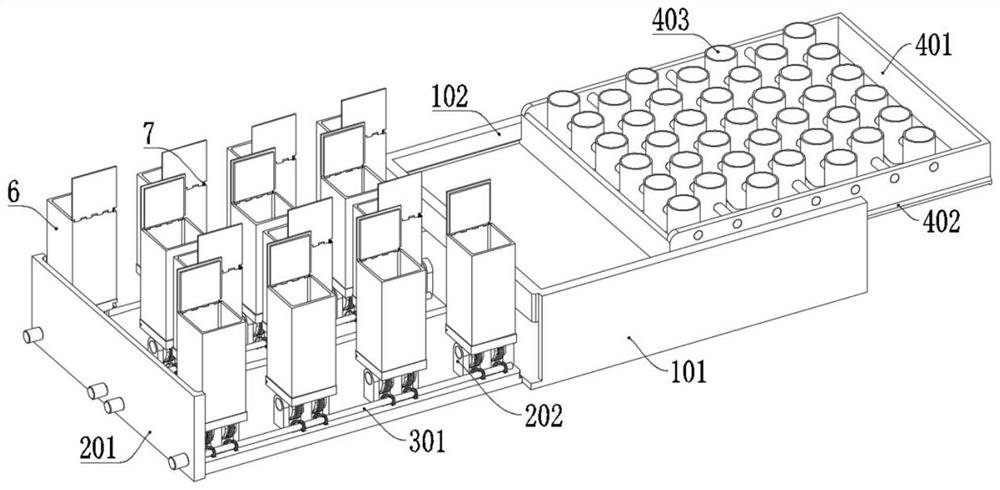

Automatic infusion apparatus packaging production line

PendingCN111717469AEvenly loadedNeatly coiledWrapper twisting/gatheringIndividual articlesInfusion setProcess engineering

The invention relates to the technical field of packaging equipment, in particular to an automatic infusion apparatus packaging production line. The automatic infusion apparatus packaging production line comprises automatic packaging bag feeding and position correcting equipment, automatic packaging bag transferring and opening equipment, automatic packaging bag taking, winding and bagging equipment and automatic packaging bag sealing equipment; the automatic feeding and position correcting equipment is arranged in front of the automatic packaging bag transferring and opening equipment in theX-axis direction; the automatic packaging bag taking, winding and bagging equipment is arranged behind the automatic packaging bag transferring and opening equipment in the X-axis direction; and the automatic packaging bag sealing equipment is arranged on one side of the automatic packaging bag transferring and opening equipment in the Y-axis direction. The automatic infusion apparatus packaging production line is reasonable in overall structure arrangement, high in structural operation relation continuity, high in process continuity, high in automation degree, high in packaging efficiency andhigh in packaging success rate.

Owner:YANTAI KAIBO AUTOMATION TECH

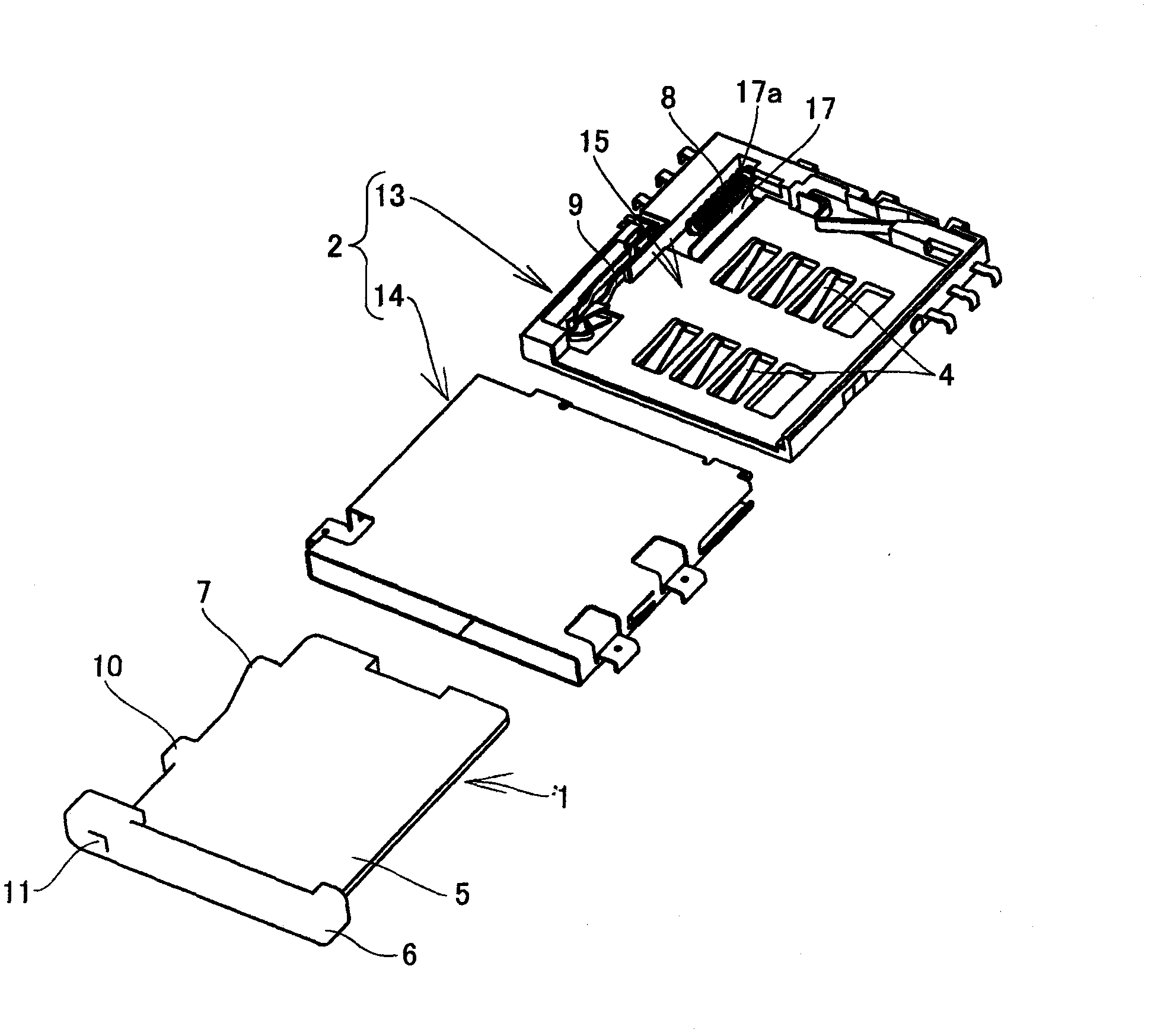

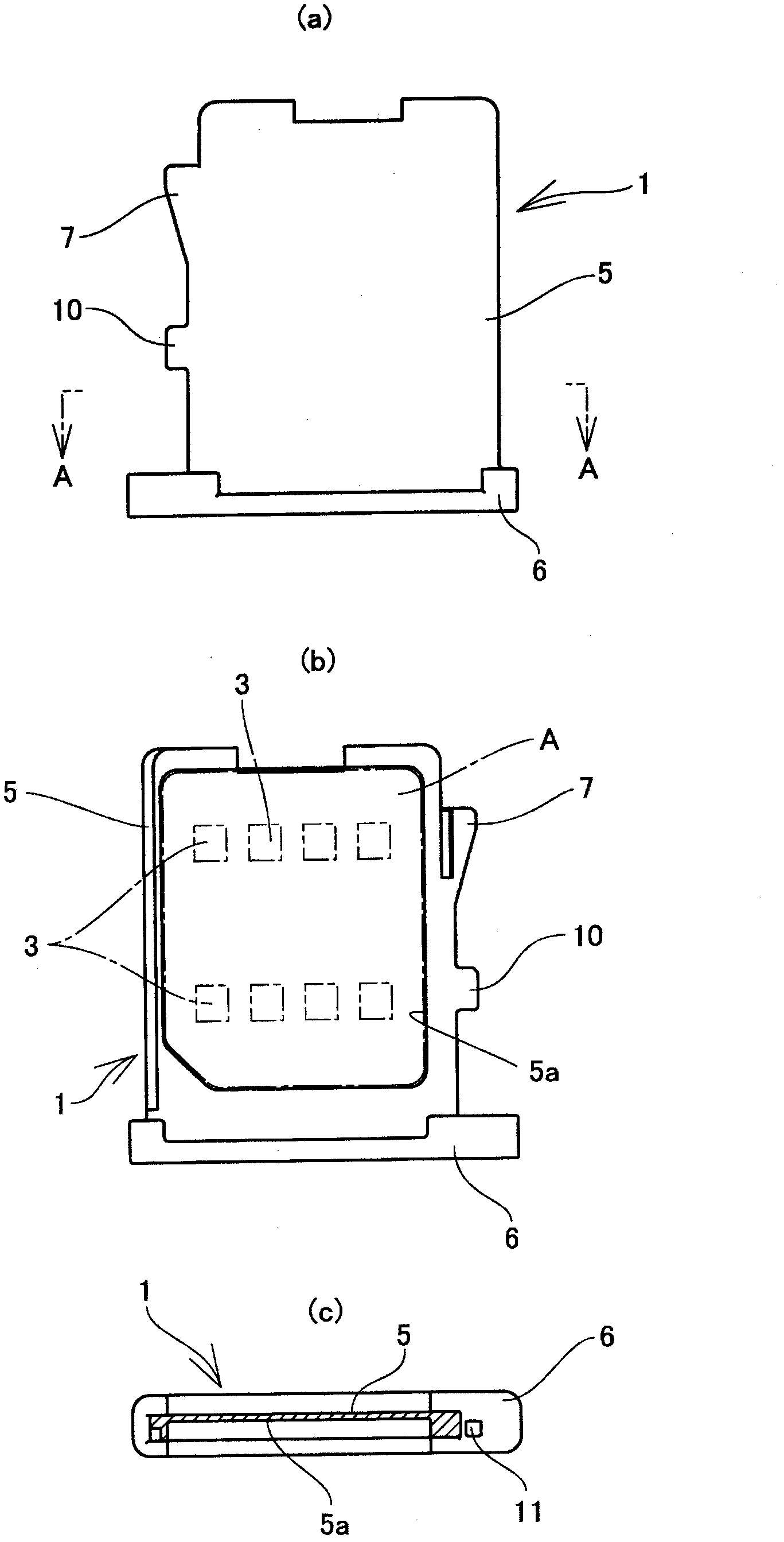

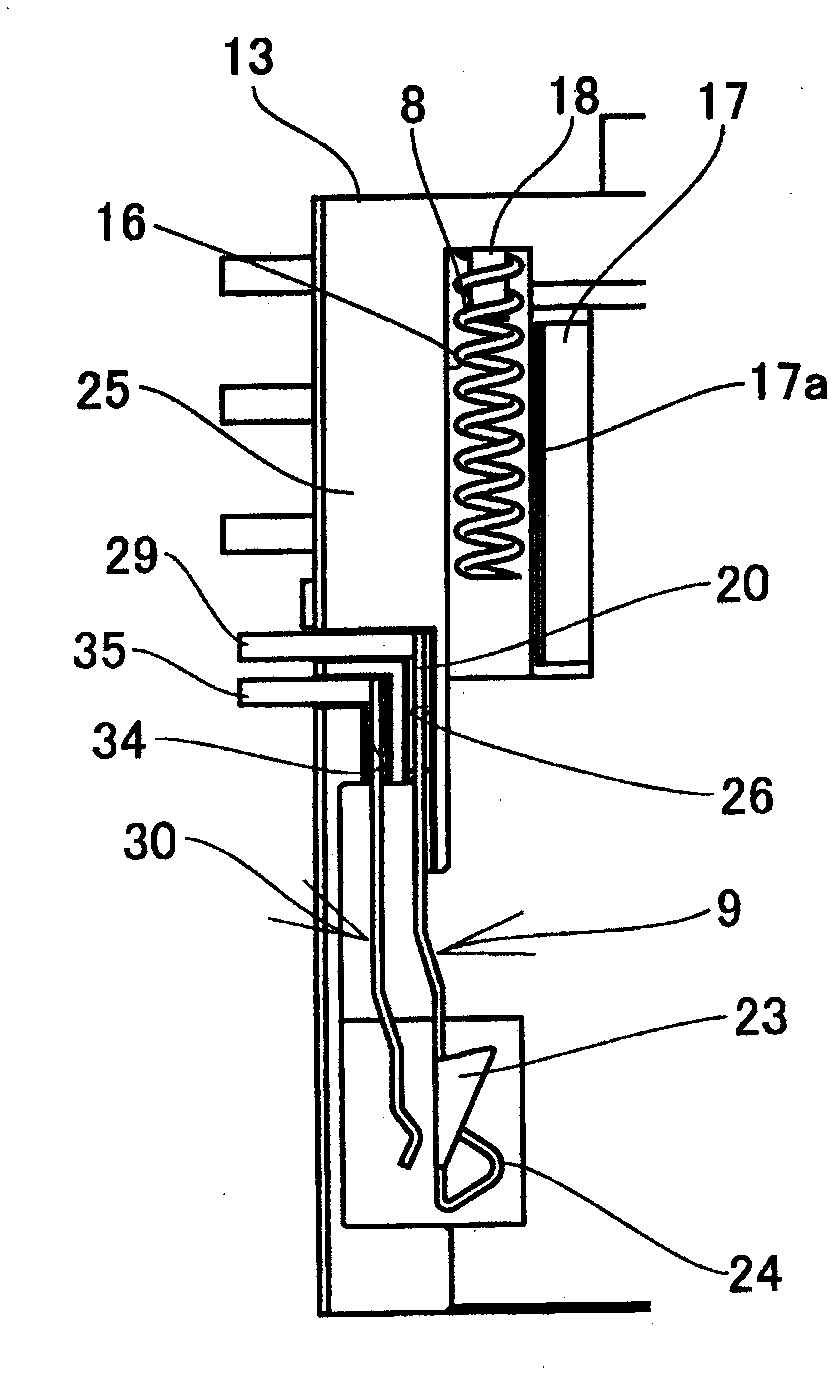

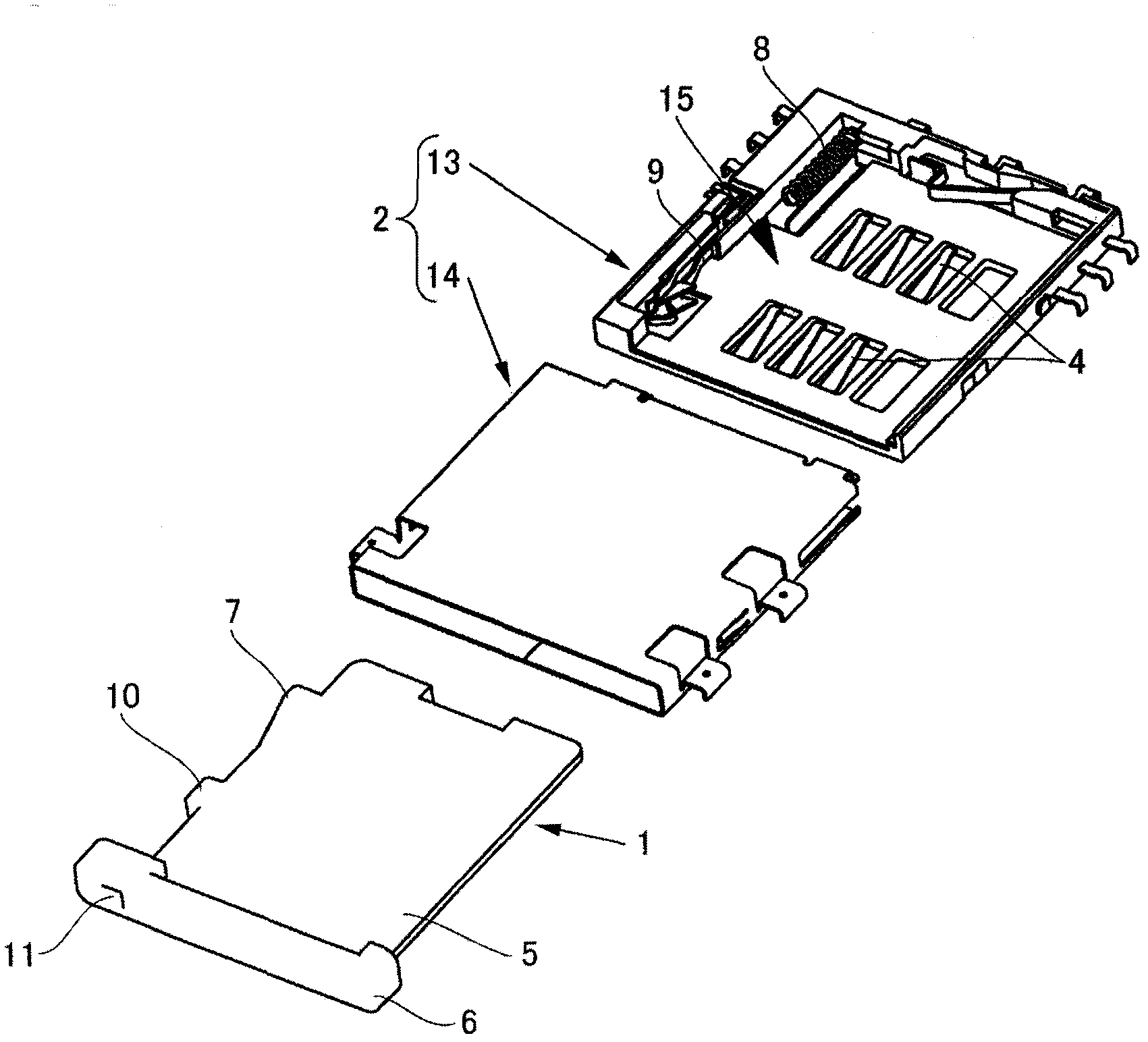

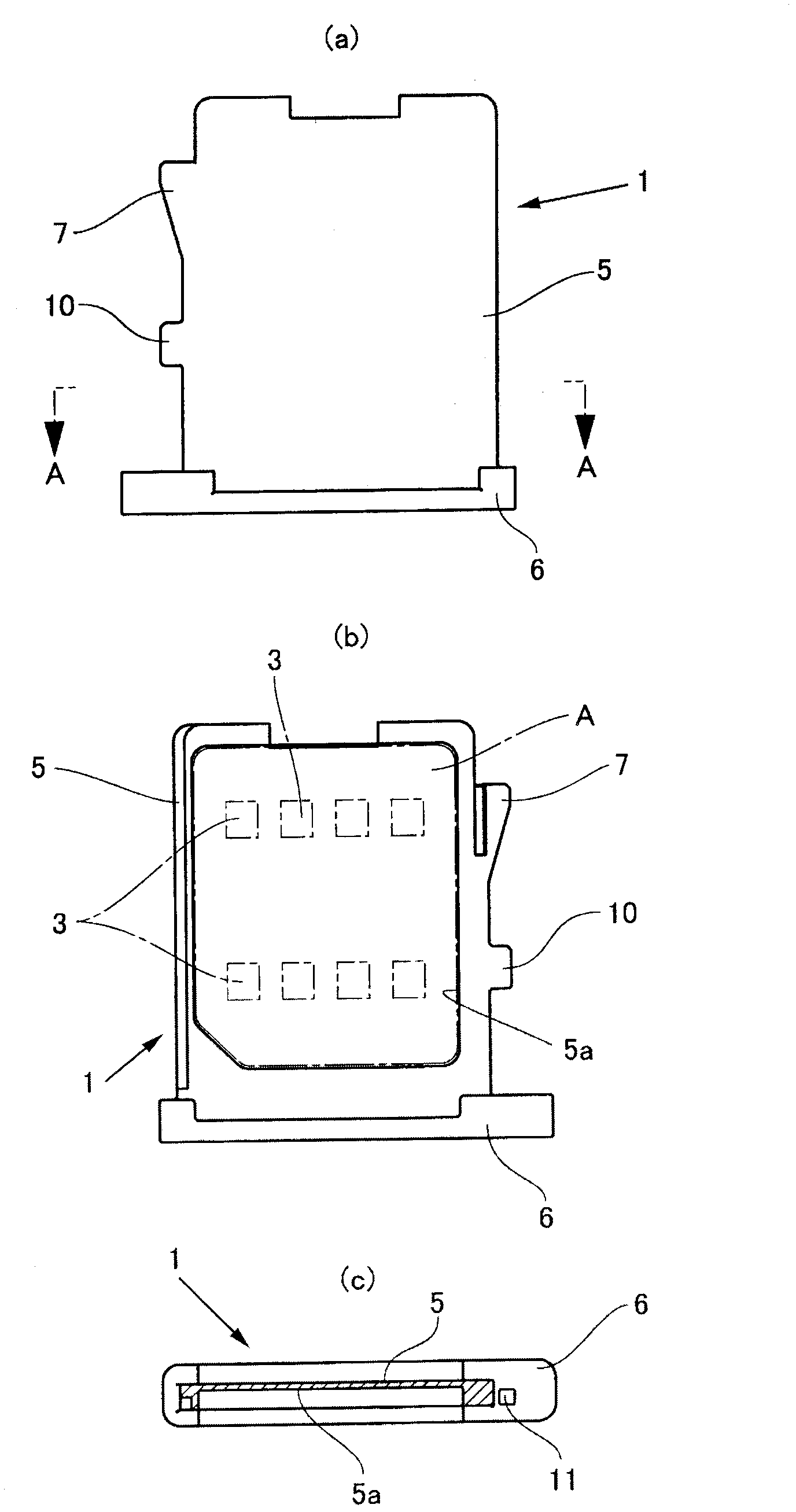

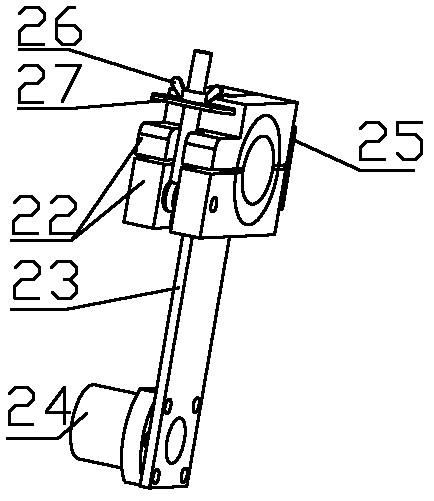

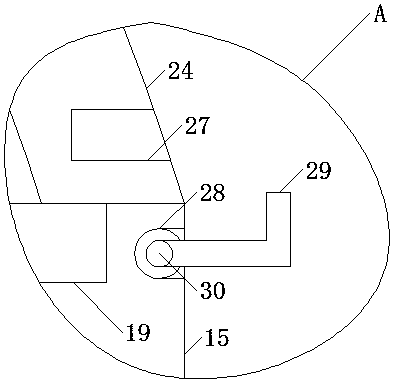

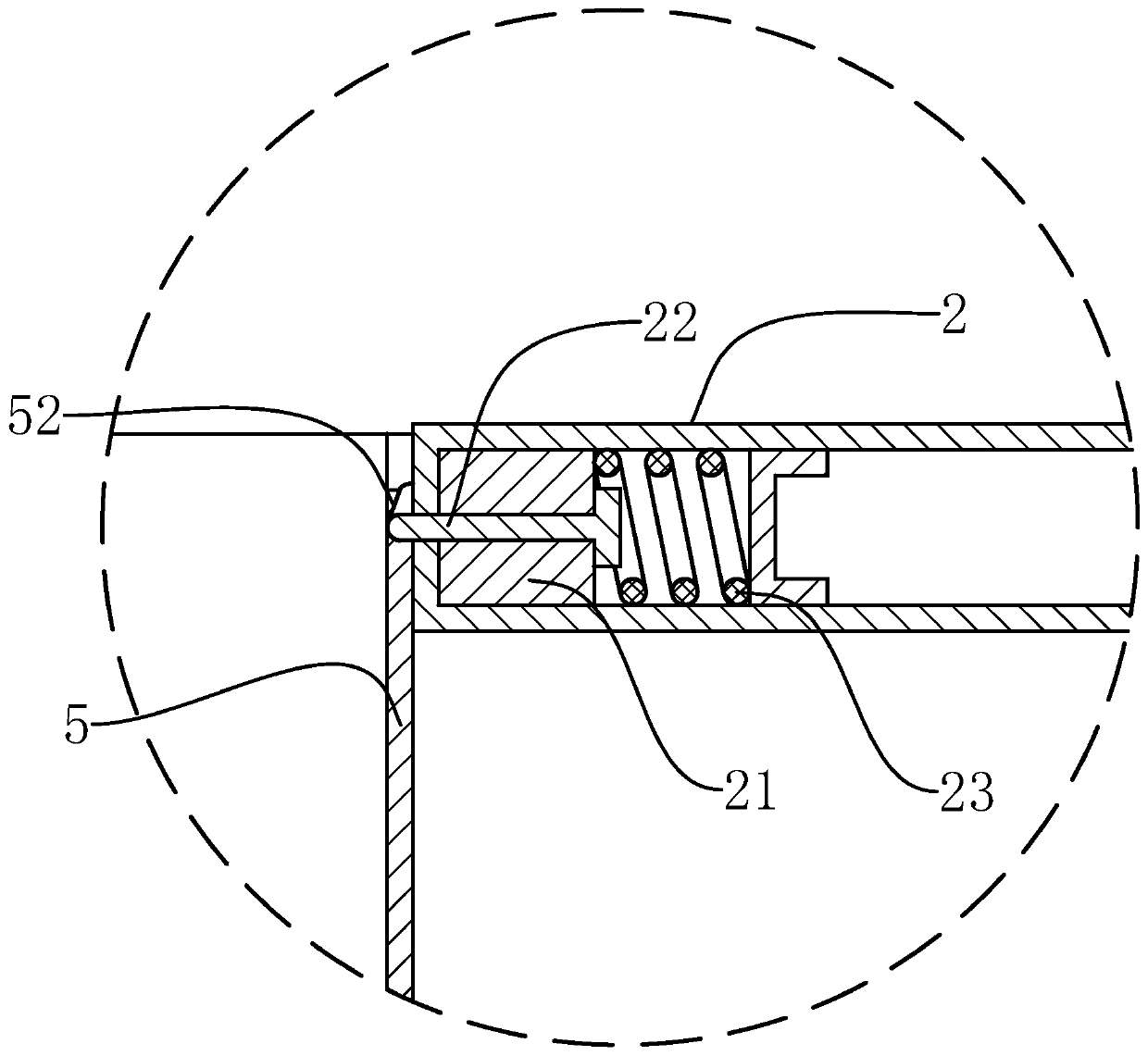

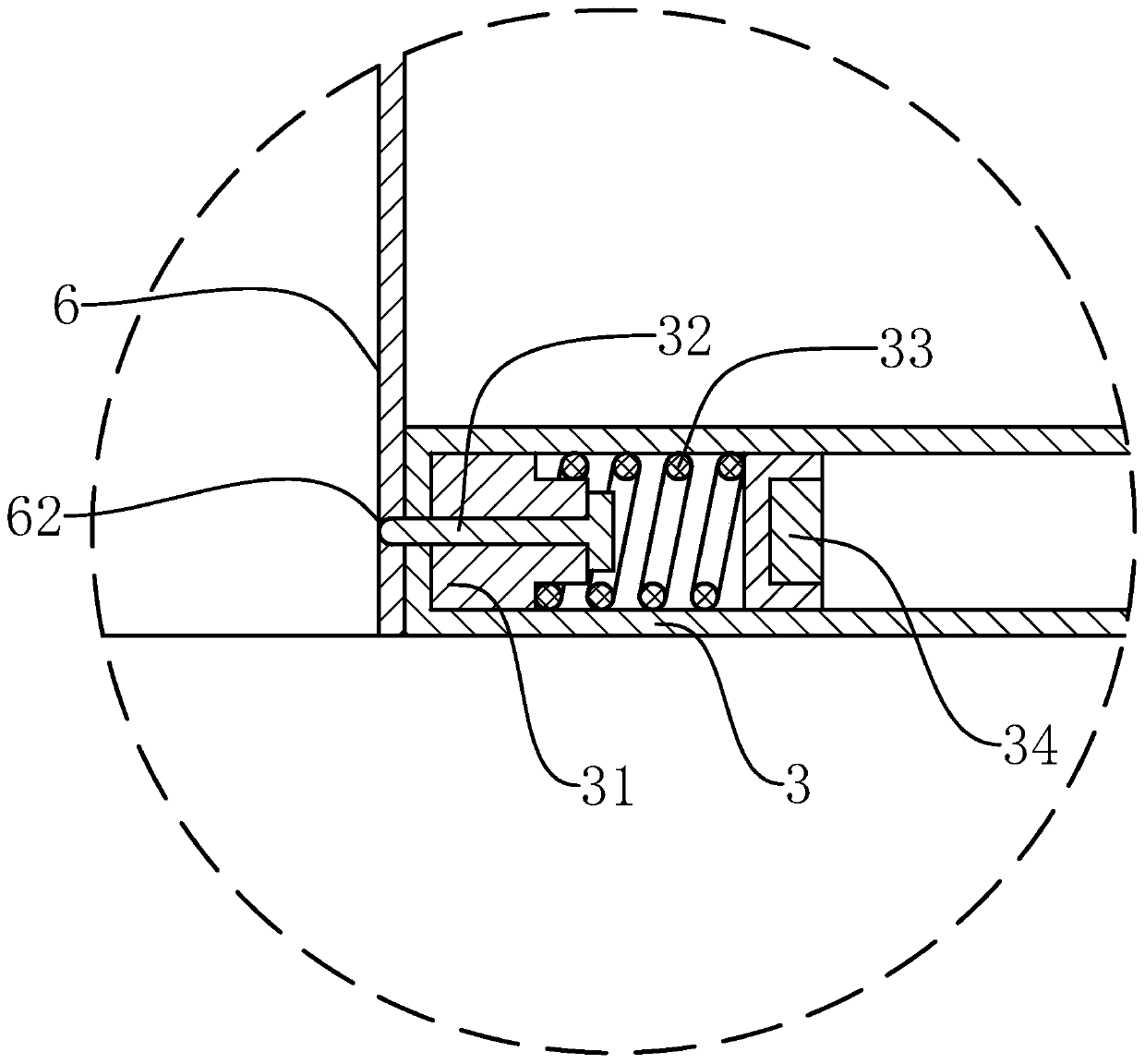

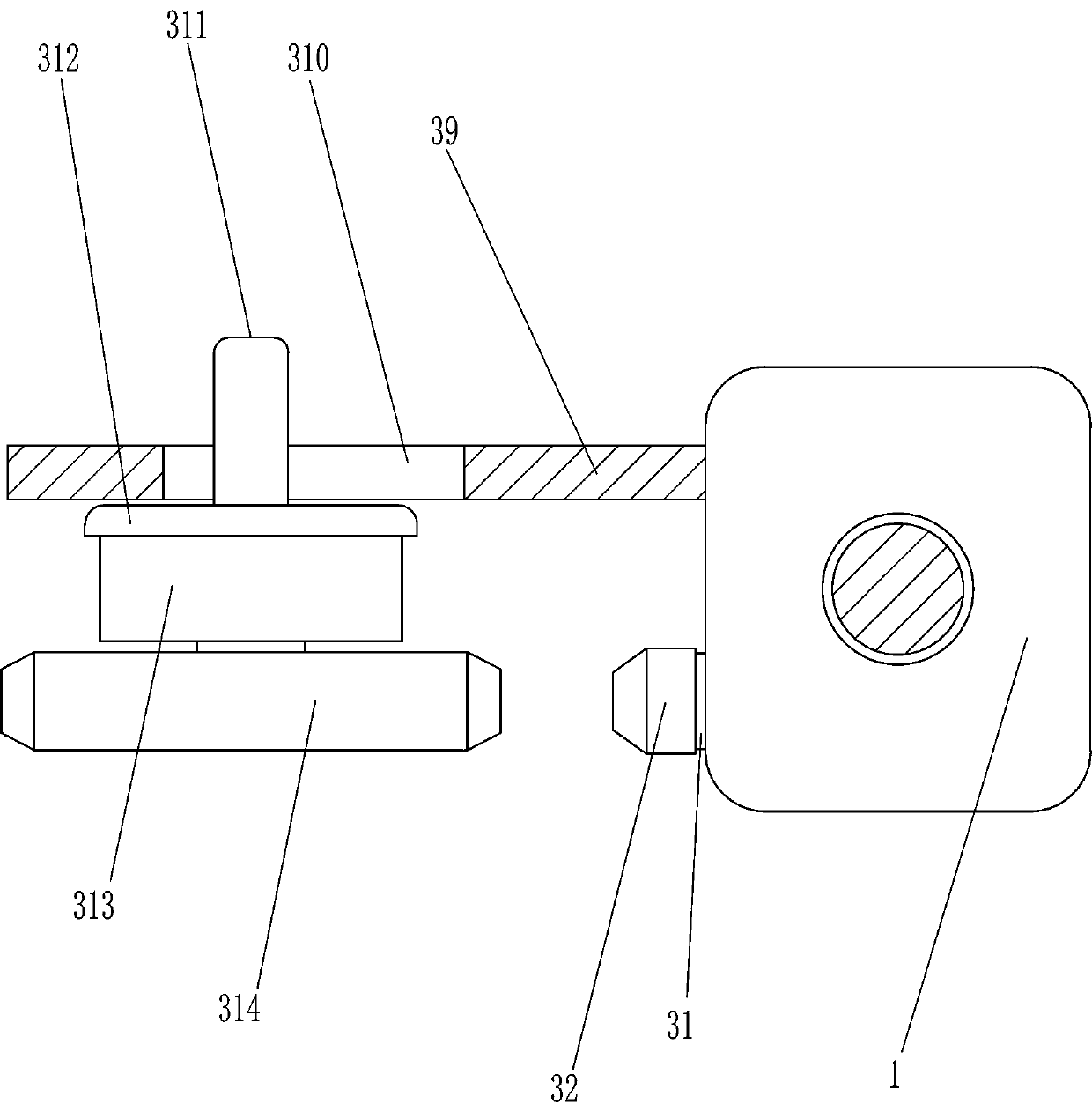

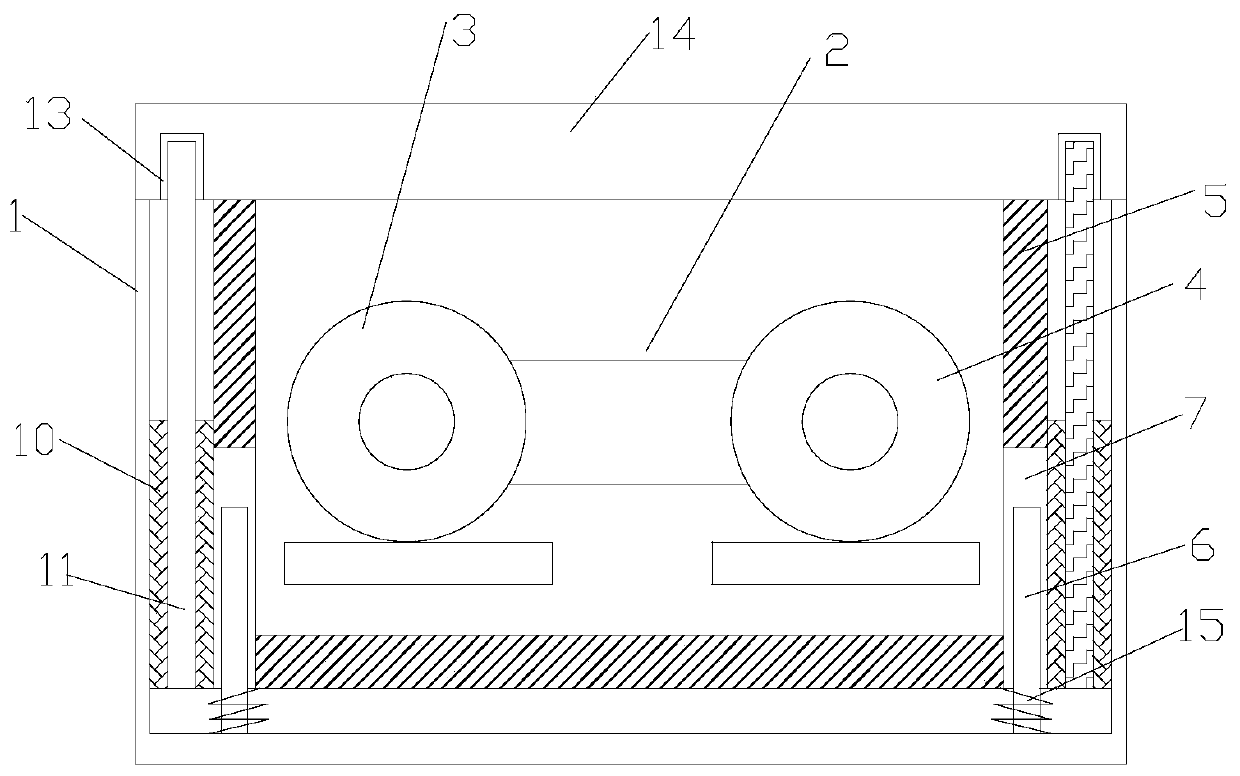

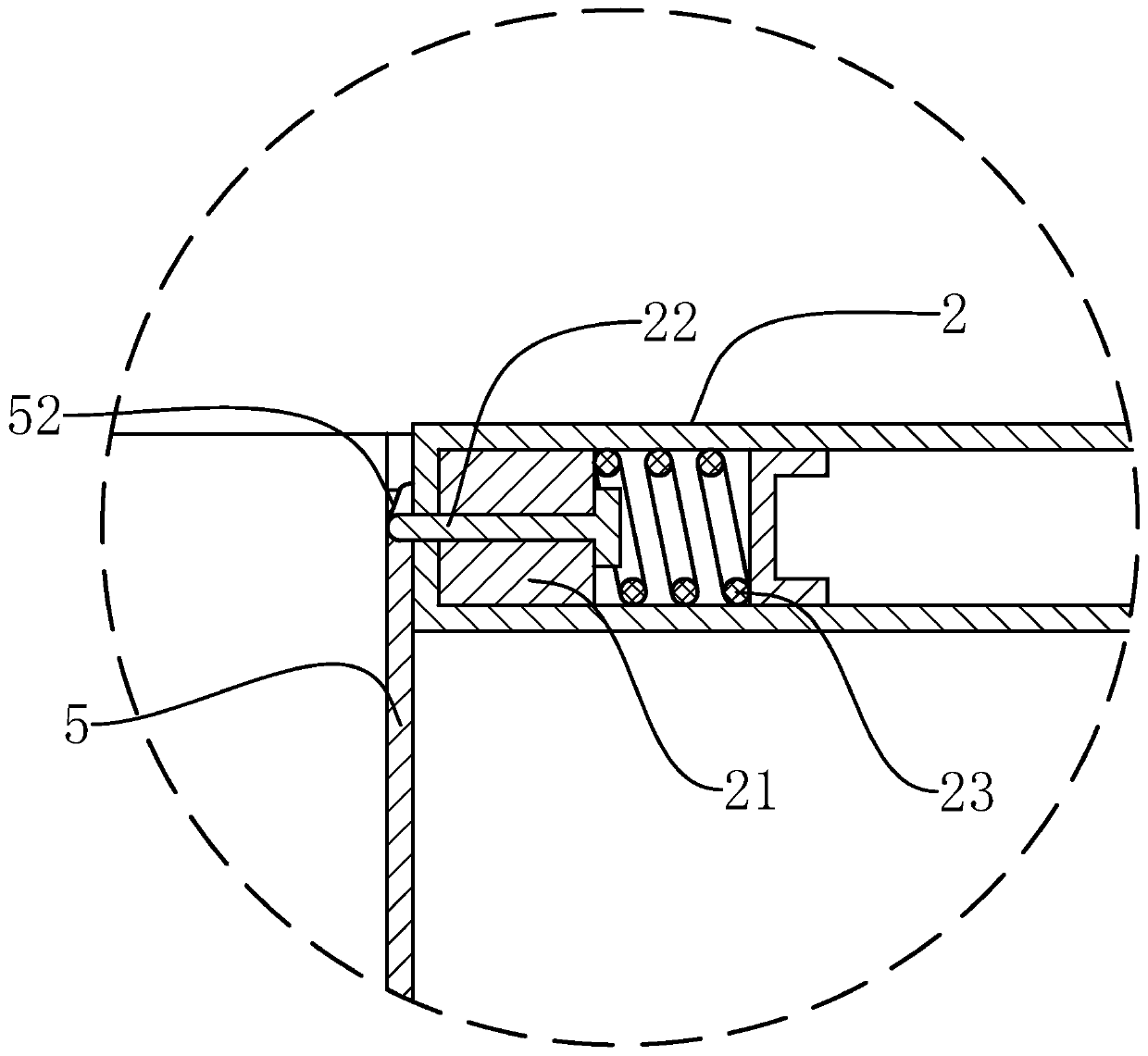

Card connector with removing function

InactiveCN102593660AThe removal process is smoothMiniaturizationCoupling device detailsLocking mechanismMiniaturization

The invention provides a card connector with a removing function. The card connector can act stable card removing operations, realize miniaturization, and can be manufactured with a low cost. A locking mechanism possesses a locking part at one side of a housing (2), wherein the locking part faces the access direction of a card type part (1). The locking part possesses the components as following: a fixing sheet portion fixed arranged on the housing (2); a spring sheet portion extended from one end of the fixing sheet portion to the access direction of the card type part; and a cooperation portion (32) supported at the front end of the spring sheet portion and detachably matched with the side edge portion of the card type part (1). The spring sheet portion possesses an operation convex portion utilizing an extraction operation part (8) to extract at the traverse direction, the convex portion is extruded with the insertion of the extraction operation part, the cooperation part acts at the direction released from the card type part.

Owner:SMK CO LTD

Bottle inspection and elimination device and working method thereof

The invention relates to a bottle inspection and elimination device which can rapidly and stably eliminate unqualified bottles and does not influence the passing of qualified bottles. The bottle inspection and elimination device comprises a plurality of elimination fingers which are sequentially and adjacently arrayed along the conveying direction of bottles from short to long, wherein when bottles are detected to have no cover, have inclined covers or have no aluminum film, the plurality of elimination fingers are forwards turned to be in the horizontal state from the vertical state in sequence and then are reset; the longest elimination finger is used for conveying the bottles into an entrance of a rotary table type recycling mechanism so as to stably and rapidly eliminate the unqualified bottles and prevent the bottles from falling down; meanwhile, the subsequent passing of qualified bottles is not influenced.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

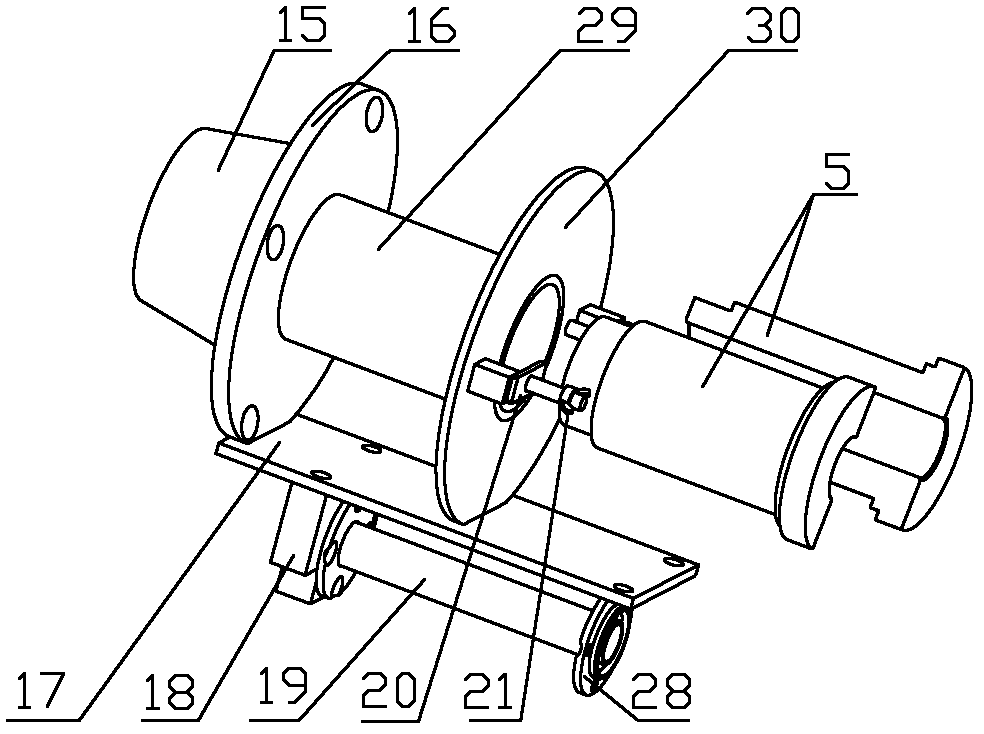

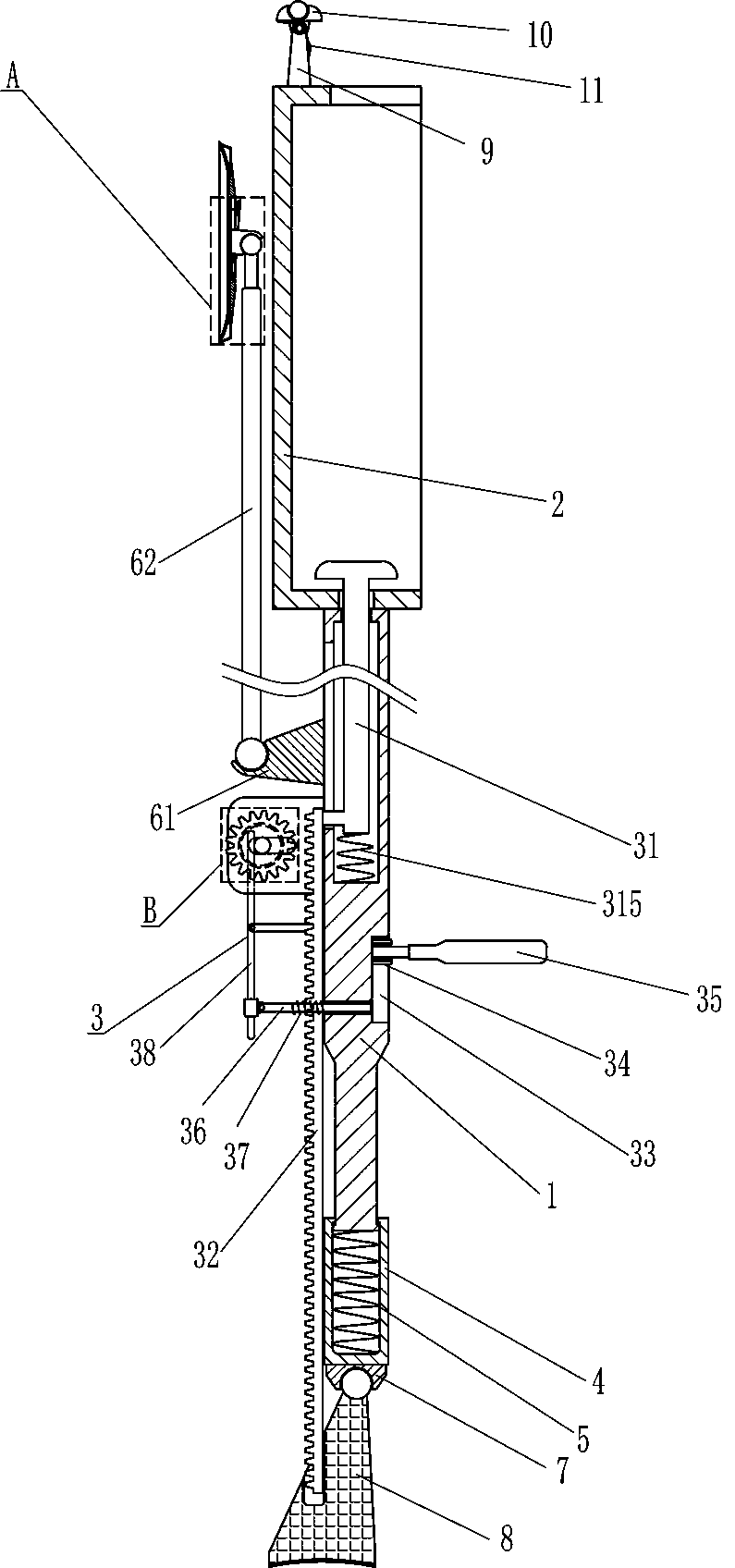

Intelligent inclination measuring system and monitoring method thereof

ActiveCN110359440AImprove human-computer interactionRegression is accurateIn situ soil foundationData acquisitionDeformation monitoring

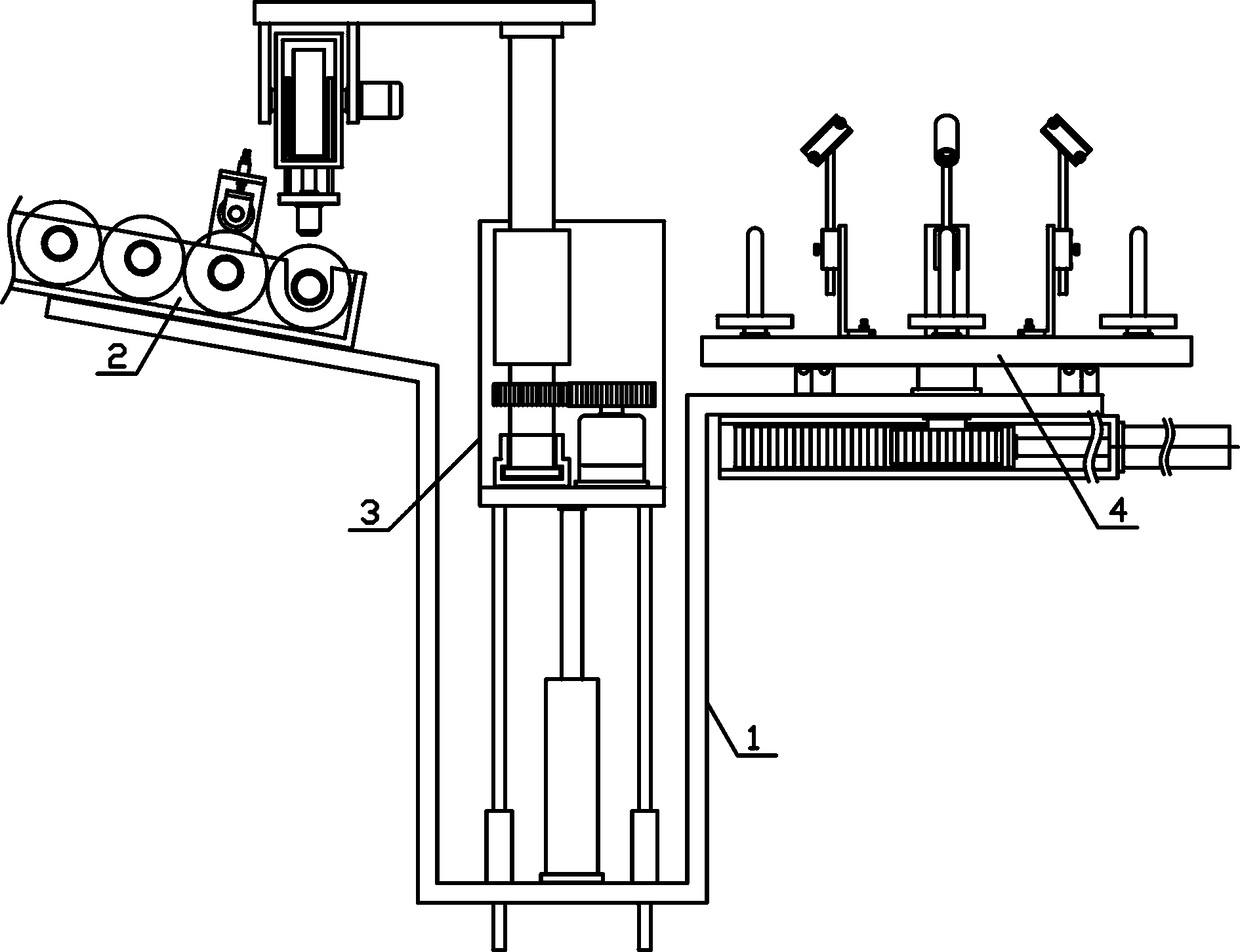

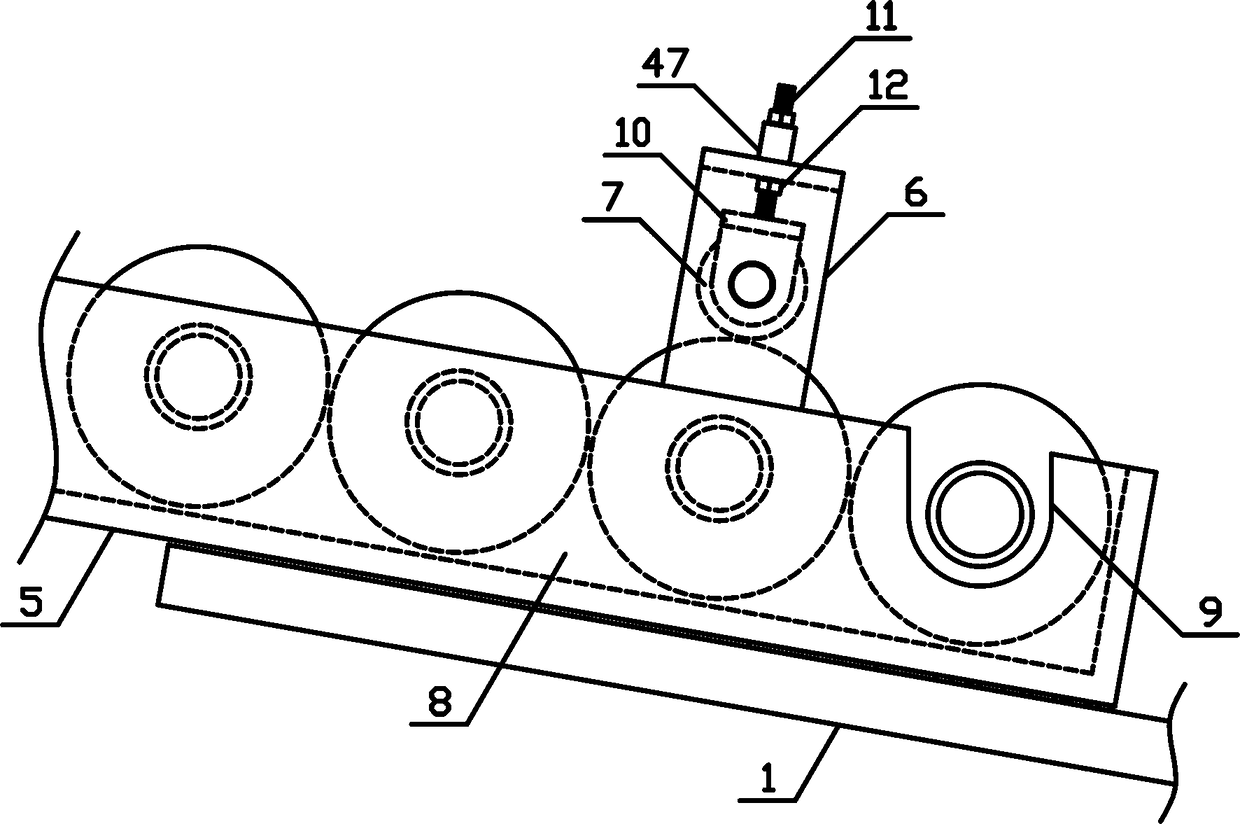

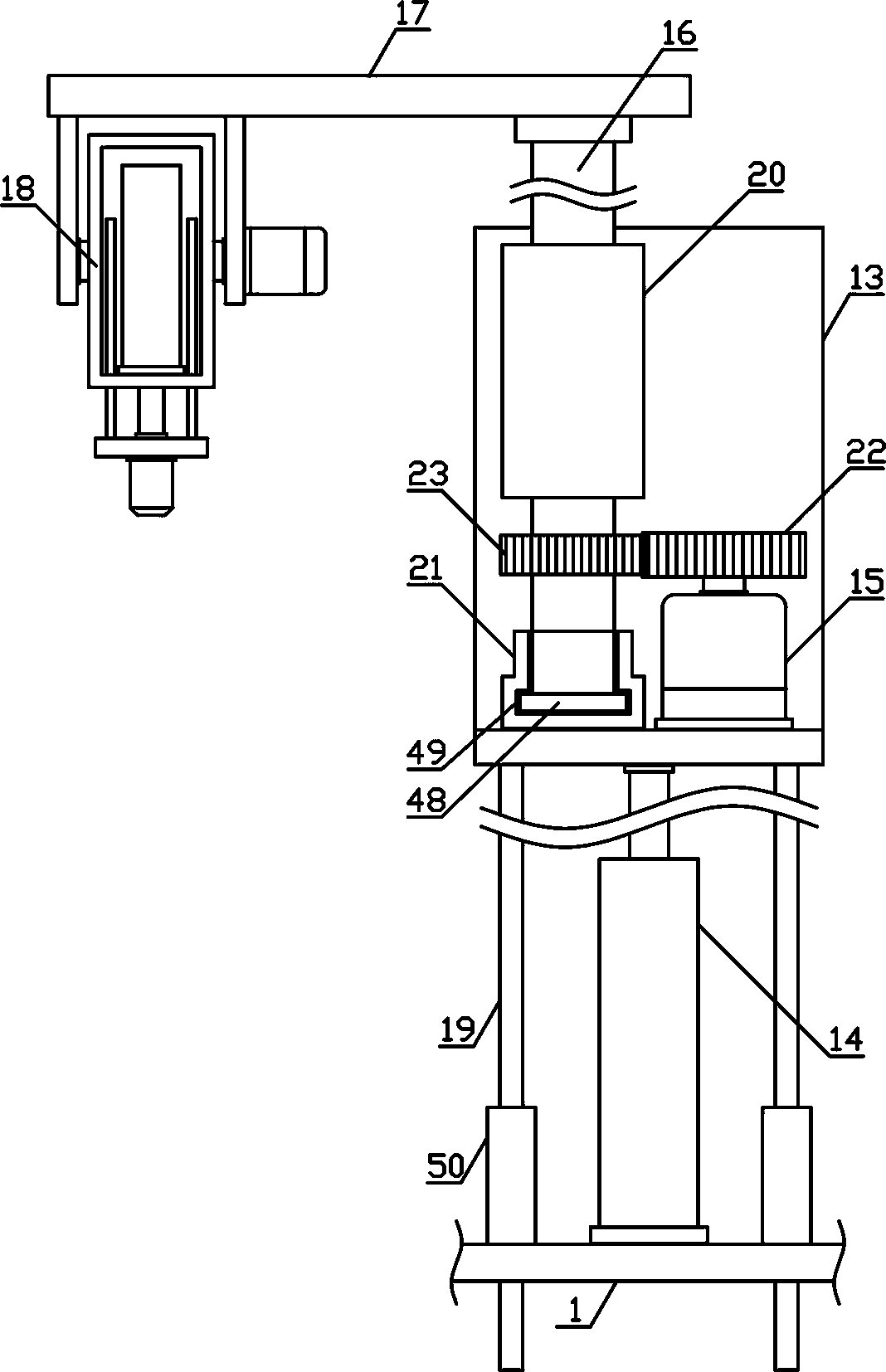

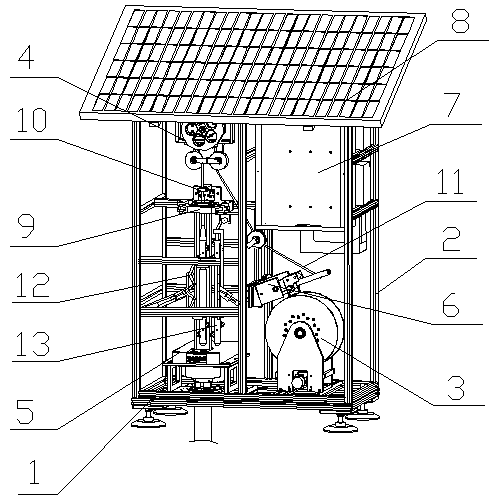

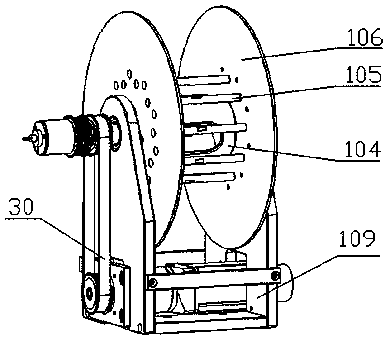

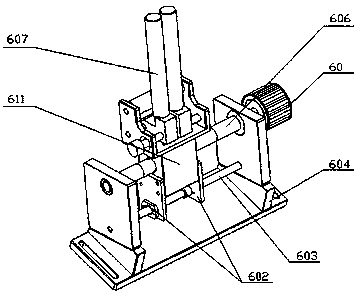

The invention provides an intelligent inclination measuring system and a monitoring thereof method. The intelligent inclination measuring system comprises an automatic inclination measuring machine, adata acquisition terminal, a cloud monitoring management system and a power supply system. The automatic inclination measuring machine comprises a machine frame, an unwinding device, a cable arranging device, a meter counting device, a reversing device, a correcting device, an in-place detecting device, an electric control system, a gripping device and a trial winding device; the intelligent inclination measuring system is simple in structure and convenient to maintain, assemble and disassemble, and does not have a safety hazard; an inclination measuring pipe is detected by simulating automatic trial winding of an inclination measuring device; the damage of an inclination measuring sensor, inaccurate data and the like are avoided; the operating state of equipment can be monitored in realtime by arranging a tension sensor; automatic measurement is realized in the overall process; measuring point data are automatically acquired through the data acquisition terminal and are transmittedto the cloud monitoring management system in real time; event information in the operating process of the equipment is displayed through the cloud monitoring management system; the intelligent inclination measuring system processes and gives an alarm when an abnormity appears; the measurement precision is high; and the equipment is stable and reliable, and can be applied to deformation monitoringon a sliding surface in a soil body of a landslide mass, dangerous rock, high side slope and the like.

Owner:广州日昇岩土科技有限公司

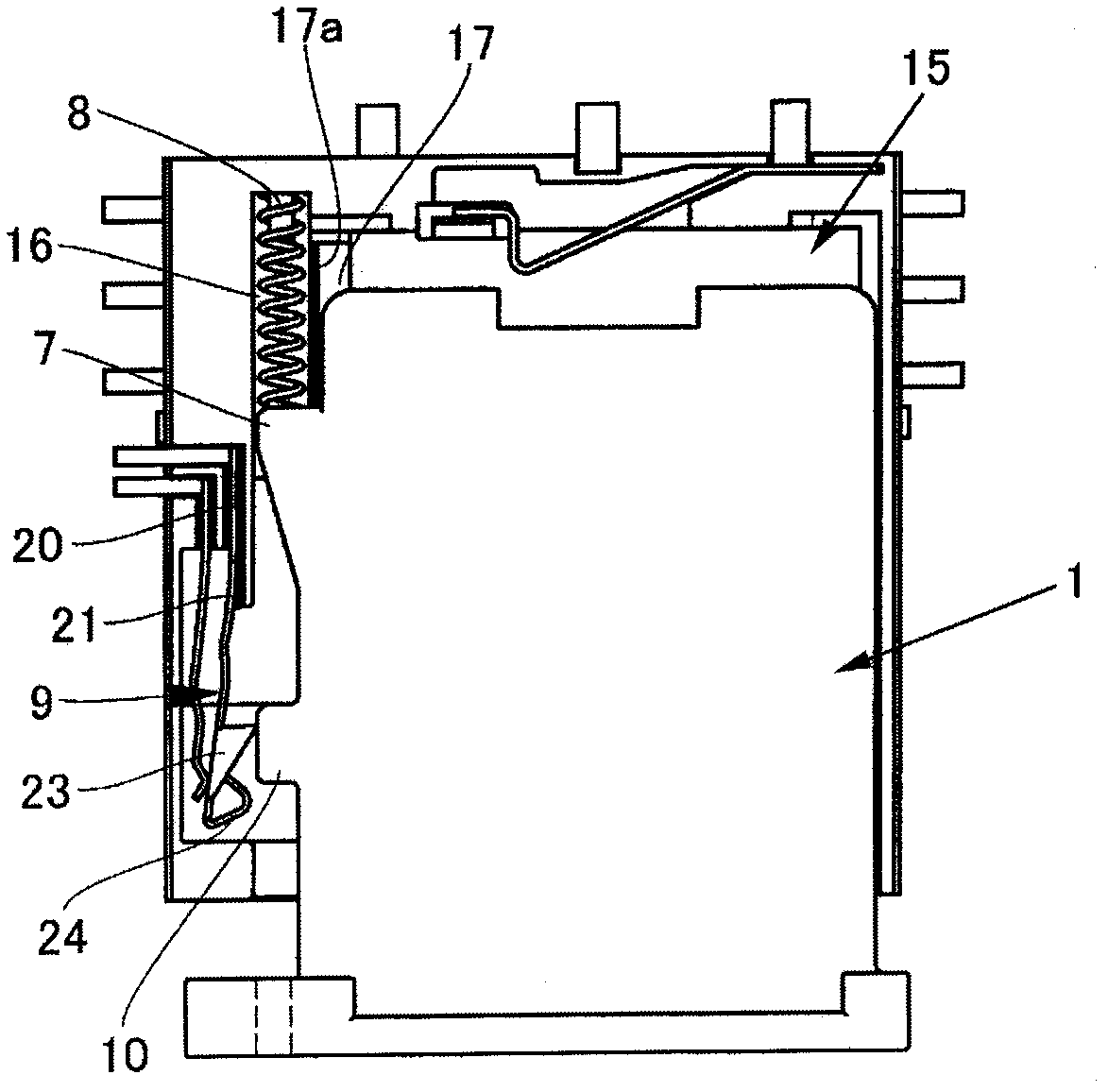

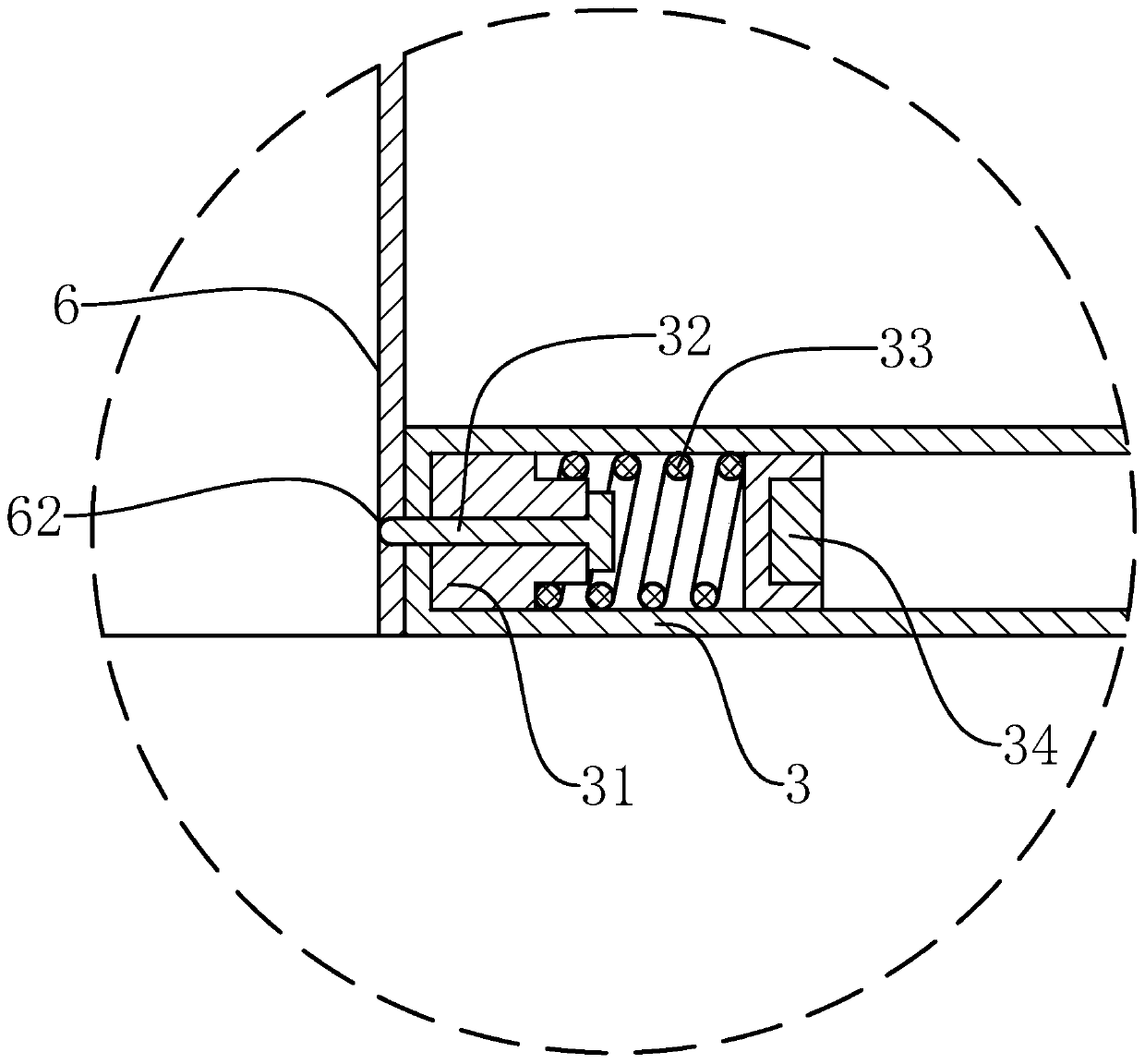

Card connector with removing function

InactiveCN102593658AThe removal process is smoothMiniaturizationCoupling device detailsLocking mechanismMiniaturization

The invention provides a card connector with a removing function. The card connector can act stable card removing operations, realize miniaturization, and can be manufactured with a low cost. The card connector with a removing function possesses a housing (2) for inserting a card type part (1), and a locking mechanism at a predetermined embedding position for restricting the movement of the card type part (1), the restriction of the locking mechanism is released through the action of the discharge operation part inserted in the housing (2), and the card type part (1) is removed, the card type part (1) possesses a force applying part (7), which is supporting against the other end of a reset spring (8) with one end fixedly arranged on the housing (2). With the pressing in action of the card type part (1), the reset spring (8) is pressed at the compression direction, and the card type part (1) is provided with a force by the reset spring (8) at the pressing-out direction.

Owner:SMK CO LTD

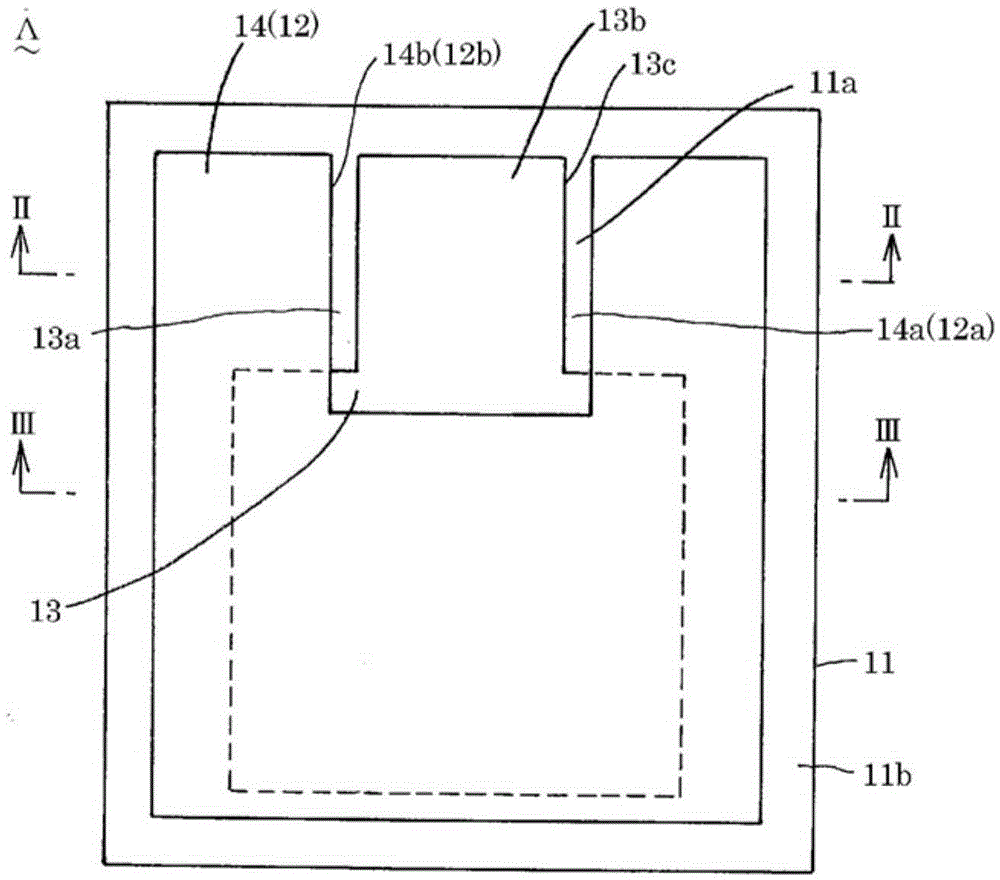

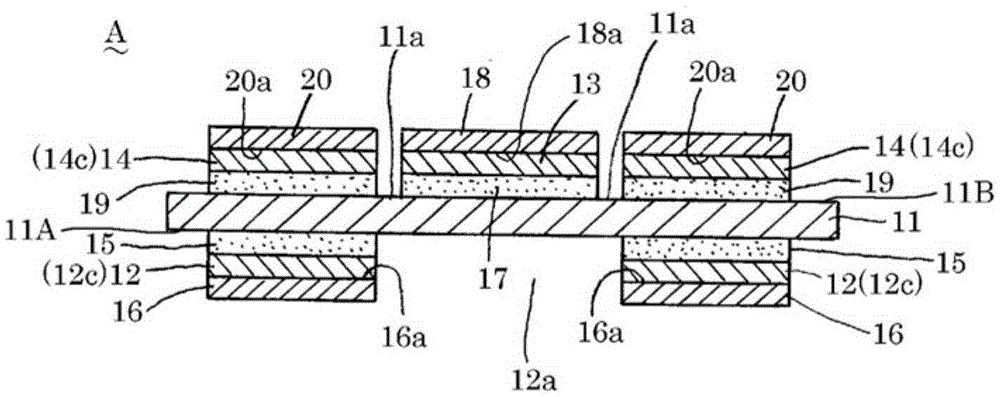

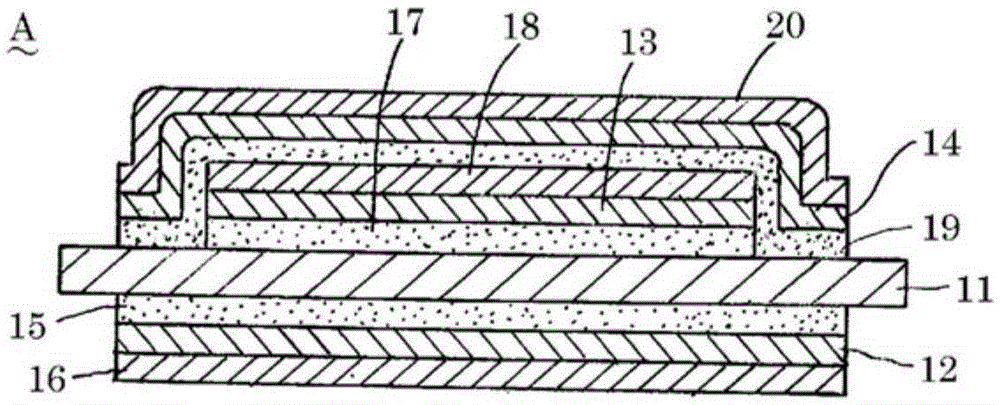

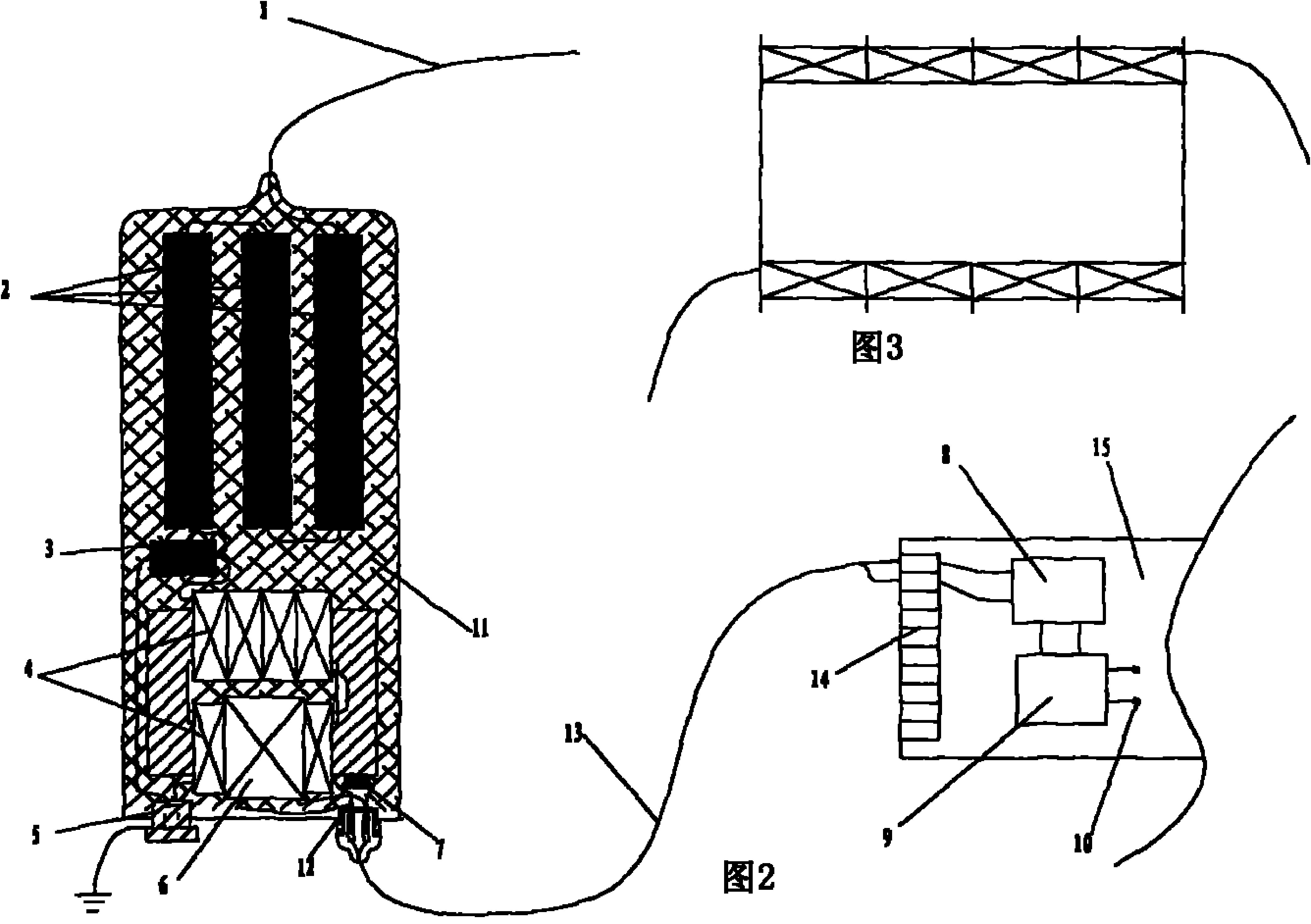

Piezoelectric sensor

ActiveCN105358950AGood piezoelectricityEasy electrical connectionFluid pressure measurement using piezo-electric devicesAcceleration measurement using interia forcesElectrical and Electronics engineeringGrounding electrodes

This piezoelectric sensor has: a piezoelectric sheet; a first ground electrode integrally laminated upon a first surface of the piezoelectric sheet and having a first cut-out section; a signal electrode integrally laminated upon a second surface of the piezoelectric sheet and having a third cut-out section; and a second ground electrode integrally laminated upon the signal electrode, in a state electrically insulated from the signal electrode, and having a second cut-out piece. The cut-out sections of the signal electrode, the first ground electrode, and the second ground electrode are at least partially overlapping in the thickness direction of the piezoelectric sheet. The section of the piezoelectric sheet exposed from the cut-out sections of the first ground electrode, the second ground electrode, and the signal electrode that overlap in the thickness direction of the piezoelectric sheet serves as an exposed section.

Owner:SEKISUI CHEM CO LTD

Sampling device of smoke and dust with automatically positioning detecting point

InactiveCN102297787BHigh positioning accuracyReduce sampling errorWithdrawing sample devicesEngineeringFlange

The invention discloses a sampling device of smoke and dust with automatically positioning detecting point, comprising a sampling mouth, a fixing unit, a Teflon axle sleeve, a sampling pipe of smoke and dust, a connecting piece of the sampling pipe, a stepping motor, a main engine of the sampling device of smoke and dust, a screw rod, and a rigid bearing unit, wherein, the fixing unit is connected with a sampling hole through a flange, the Teflon axle sleeve comprising two half circle cylinders are embedded in the center of the fixing unit, the sampling pipe of smoke and dust is slidingly arranged in the Teflon axle sleeve, one end of the sampling pipe of smoke and dust is provided with the sampling mouth, the connecting piece of the sampling pipe is fixed on the other end of the samplingpipe of smoke and dust, one end of the screw rod is arranged in a screw rod retainer, the other end of the screw rod is connected with the stepping motor through the rigid bearing unit arranged on the fixing unit, and the stepping motor is connected with the main engine of the sampling device of smoke and dust through signal lines and power lines. According to the invention, the whole process of sampling smoke and dust is accomplished automatically, so that the damage probability of operating personnel in operation process is reduced. The sampling mouth does not shake or incline when being used for positioning, the positioning is accurate and rapid, and the installation and dismounting of the sampling pipe are convenient.

Owner:武汉境辉环保科技有限公司

Paper board stack separating device

PendingCN109516248AThe removal process is smoothReliable removalBox making operationsPaper-makingCardboardPulp and paper industry

The invention discloses a paper board stack separating device. The device comprises baffles located at the feed ends of conveying belts. The intervals between the lower edges of the vertically-arranged baffles and the conveying belts are larger than the thickness of one paper board and smaller than the thicknesses of two paper boards, the lower portions of the baffles are in transition from rear to front and from top to bottom as arc curved surfaces, pushing parts are arranged behind the baffles, and the lower portions of the platy or rodlike pushing parts are inclined from top to bottom and from rear to front. Paper boards are put at the feed ends of the conveying belts in a stacked manner and abut against the baffles, the paper boards on the lower layers are stacked in a staggered manneralong the inclined pushing parts and the arc curved surfaces of the baffles, and the paper boards on the lowest layer run forwards along with the conveying belts to pass through the lower edges of the baffles. The intervals between the lower edges of the baffles and the conveying belts are larger than the thickness of one paper board and smaller than the thicknesses of two paper boards, only onepaper board passes through the lower edges of the baffles every time, and the printing paper boards are stably and reliably taken out of a paper board stack one by one from bottom to top and conveyeddownstream.

Owner:安徽华艺包装科技有限公司

Preparation method and processing equipment of traditional Chinese medicine medicated leaven

ActiveCN108653419AHigh degree of automationEasy to operateDigestive systemMetal working apparatusTraditional Chinese medicinePhaseolus

The invention discloses a preparation method of traditional Chinese medicine medicated leaven. The preparation method is characterized by comprising the following steps of: S1: grinding phaseolus calcaratus and semen armeniacae amarae into coarse powder A, S2: mixing flour and the sieved coarse powder A to form a powder medicine B, S3: cutting cocklebur, sweet wormwood and red-knees herb into small sections, adding water for decocting, performing filtration to prepare filtrate C, S4: putting the powder medicine B in a mixer for premixing to form a uniform mixture D, S5: mixing the filtrate C and the mixture D in the mixer to form a medicine composition E, S6: preparing the medicine composition E into a medicated leaven block F, S7: putting the medicated leaven block F in a fermentation tank for fermentation, S8: dicing the fermented medicated leaven block F, and S9: putting the cut cubical blocks G into an oven. High-efficiency preparation of the medical traditional Chinese medicine medicated leaven is achieved; the production efficiency of the medicated leaven is improved; and the quality of the medicated leaven in modernized production is ensured.

Owner:BEIJING SHENGSHILONG PHARMA

Gypsum artwork drying device convenient to pick and place and gypsum artwork drying method

The invention discloses a gypsum artwork drying device convenient to pick and place and a gypsum artwork drying method. The gypsum artwork drying device comprises a fixing bracket; the top of the bottom end of the fixing bracket is provided with a drier; the drier is provided with a heat flow tube; the top of the heat flow tube is provided with a supporting plate; a baffle is arranged at the top end of the left side of the supporting plate; a connecting rod is arranged at the top of the baffle; the connecting rod is provided with a movable box body; a motor is arranged at the top of the movable box body; an electric telescopic rod is arranged at the bottom of the movable box body; a clamping device is arranged at the bottom of the electric telescopic rod; a fixing plate is arranged at thetop of a supporting column; a base plate is arranged at the top of the fixing plate; a sealing cover is arranged at the top of the base plate; a fan is arranged in an inner chamber of the fixing plate; gypsum artworks are heated uniformly; the drying speed is increased; the gypsum artworks can be taken out more easily; the safety in work is improved; the cooling speed of the gypsum artworks is increased; and the work efficiency is improved.

Owner:苏州盛迪通电子科技有限公司

Seamless building curtain wall structure and demounting and mounting method thereof

The invention provides a seamless building curtain wall structure and a demounting and mounting method thereof and belongs to the field of building curtain walls. The problems that existing glass curtain wall demounting and mounting are troublesome and low in efficiency, and potential safety hazards exist are solved. The seamless building curtain wall structure comprises a wall face and face plates. The face plates are connected to the wall face through connecting components. Each connecting component comprises a connecting seat fixed to the wall face and a connecting part fixed to the inner side face of the corresponding panel. Each connecting part comprises two upper connecting pipes and two lower connecting pipes. Upper sliding blocks and upper insertion rods are arranged in the upper connecting pipes, upper insertion holes are formed in the pipe walls of the upper connecting pipes, upper reset springs are arranged in the upper connecting pipes, lower sliding blocks and lower insertion rods are arranged in the lower connecting pipes, lower insertion holes are formed in the pipe walls of the lower connecting pipes, lower reset springs are arranged in the lower connecting pipes, and positioning blocks are fixed to the pipe walls of the inner ends of the lower connecting pipes. Each connecting seat comprises two upper connecting plates and two lower connecting plates, wherein the upper connecting plates are provided with upper mounting grooves and demounting grooves, and the lower connecting plates are provided with lower mounting grooves and insertion grooves. By means ofthe curtain wall structure, mounting and demounting operation is safe, convenient and efficient.

Owner:江苏锦上装饰设计工程有限公司

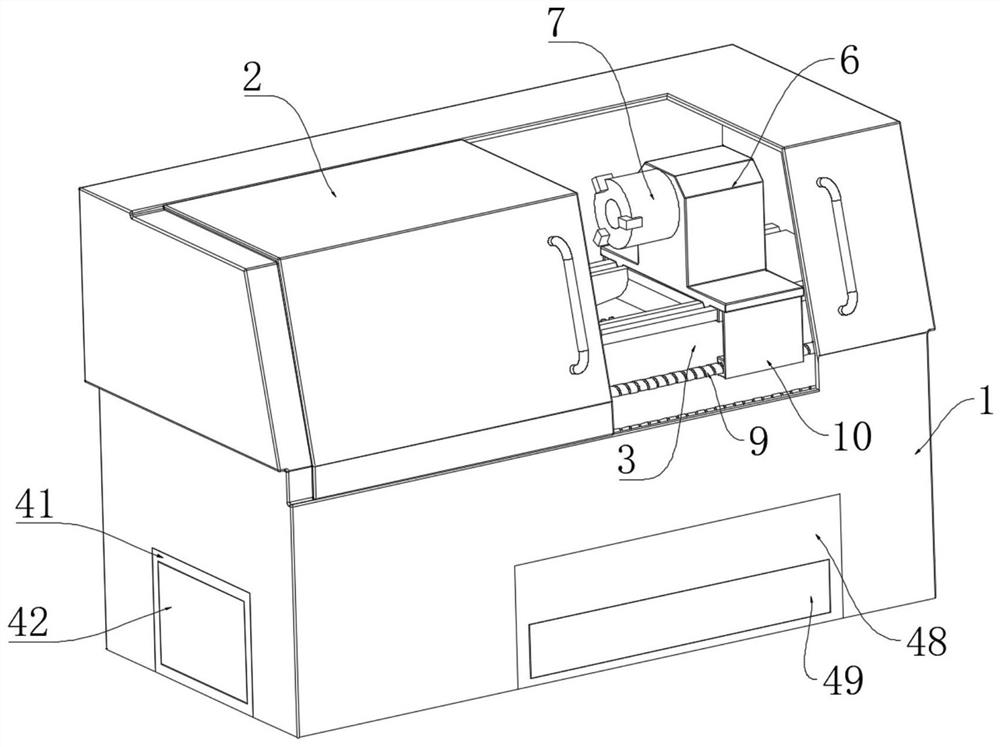

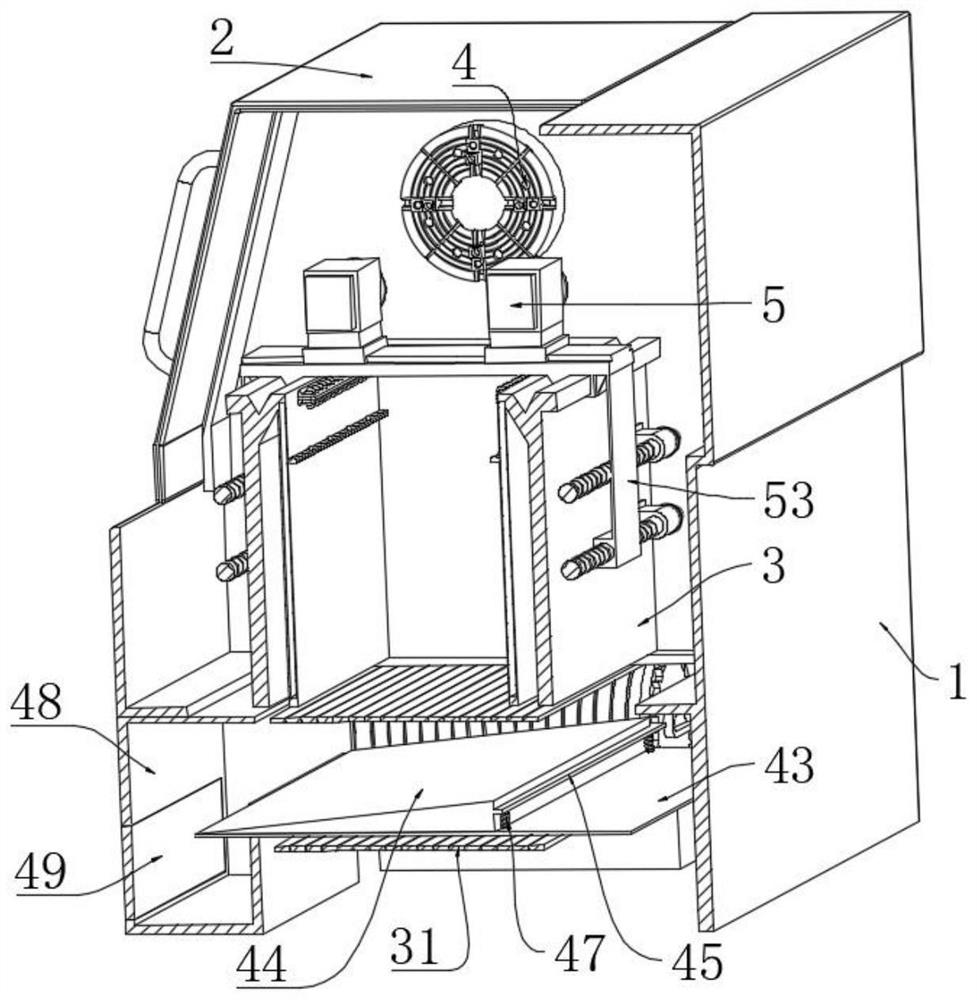

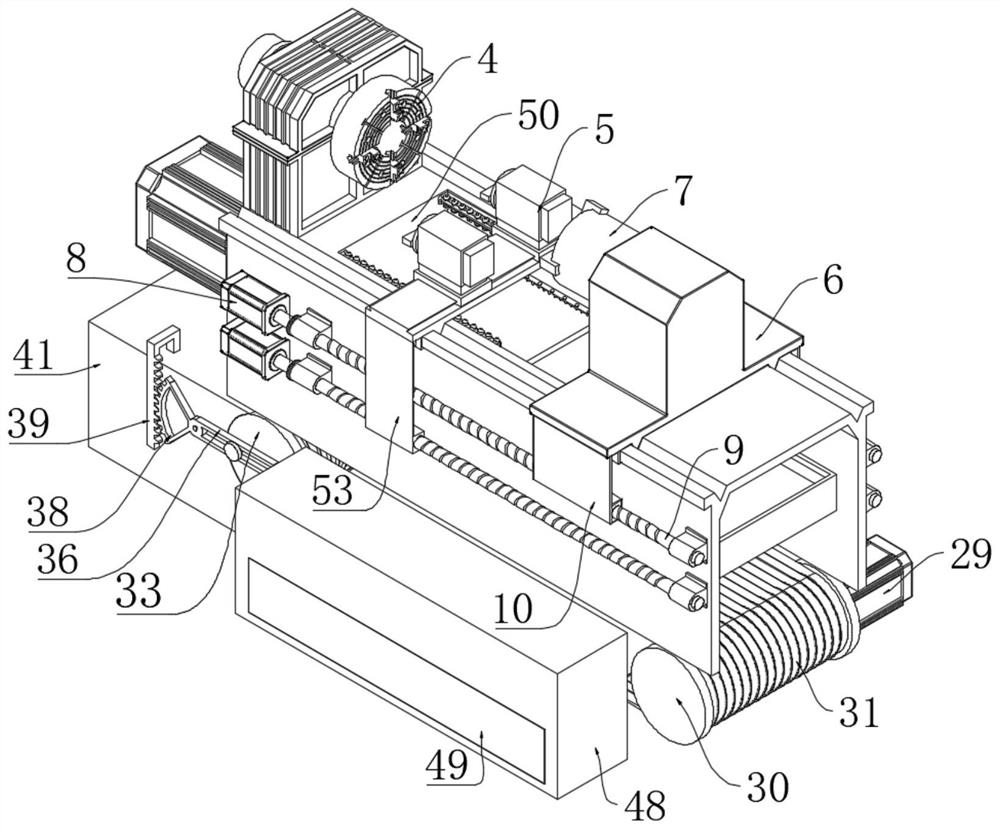

Multi-station numerical control machining tool

ActiveCN113334133AEasy to drop and recycleTake out stableMaintainance and safety accessoriesNumerical controlEngineering

The invention relates to the technical field of numerical control machine tools, in particular to a multi-station numerical control machining tool. The multi-station numerical control machining tool comprises a box body, wherein a movable door is slidably installed on one side of the box body, a workbench is fixedly installed in the box body, a material receiving opening is formed in the workbench in a penetrating mode, a four-jaw chuck is fixedly installed on the workbench through bolts, a moving frame and a moving table are slidably installed at the top of the workbench, and the moving frame is located between the moving table and the four-jaw chuck. According to the device, through the arrangement of strip-shaped conveying belts and an inclined receiving plate, spiral threadlike fragments generated in the machining process of the device can be conveyed and collected along with the strip-shaped conveying belts, and heavy leftover materials cut away in the machining process penetrate through the strip-shaped conveying belts to fall onto the inclined receiving plate to be collected, so that the device can classify and collect different waste materials generated in the machining process, different waste materials can be subjected to recycling treatment in different ways, and the material utilization rate is increased.

Owner:YUNNAN ZHENGCHENGGONG PRECISION MACHINERY

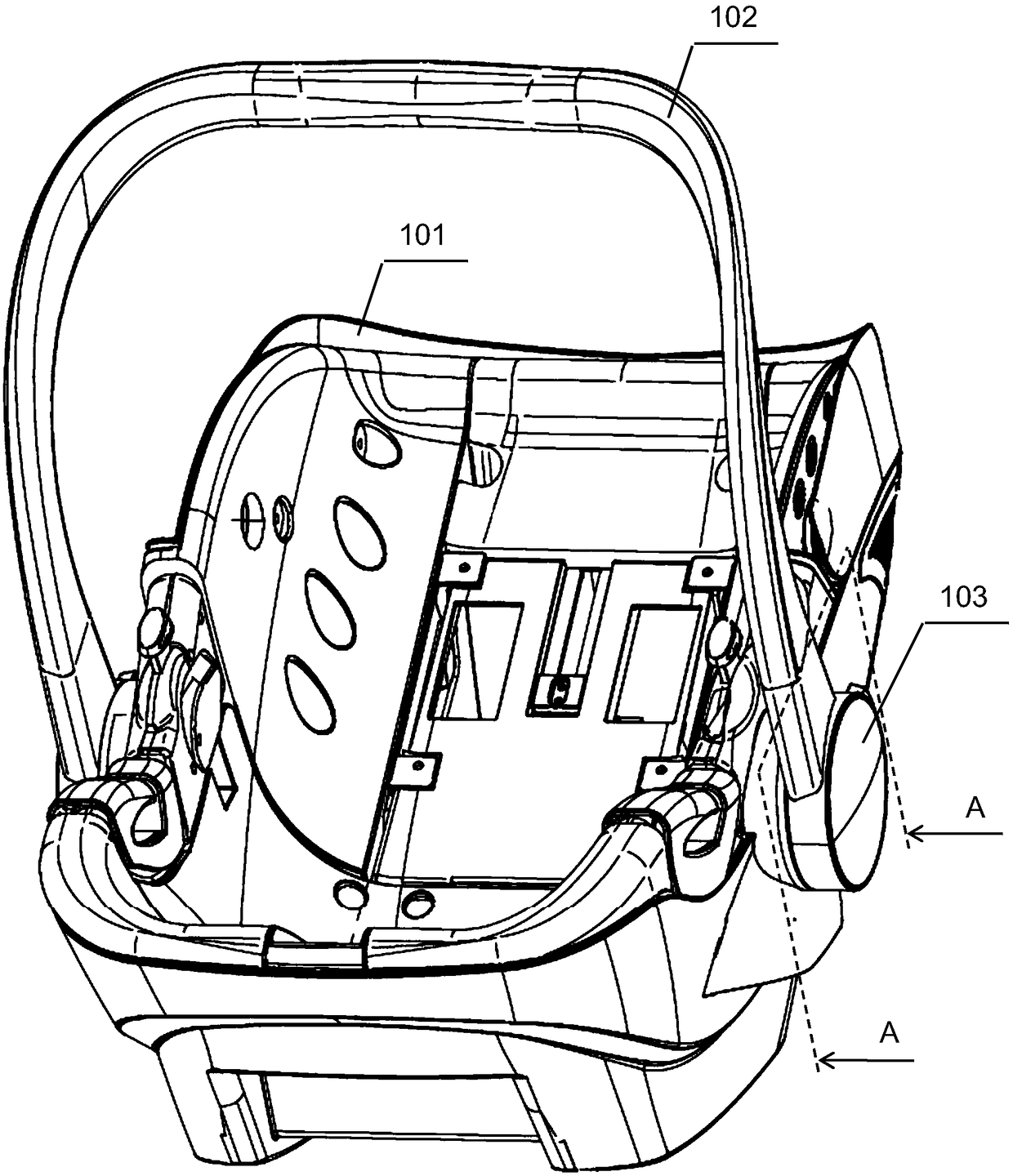

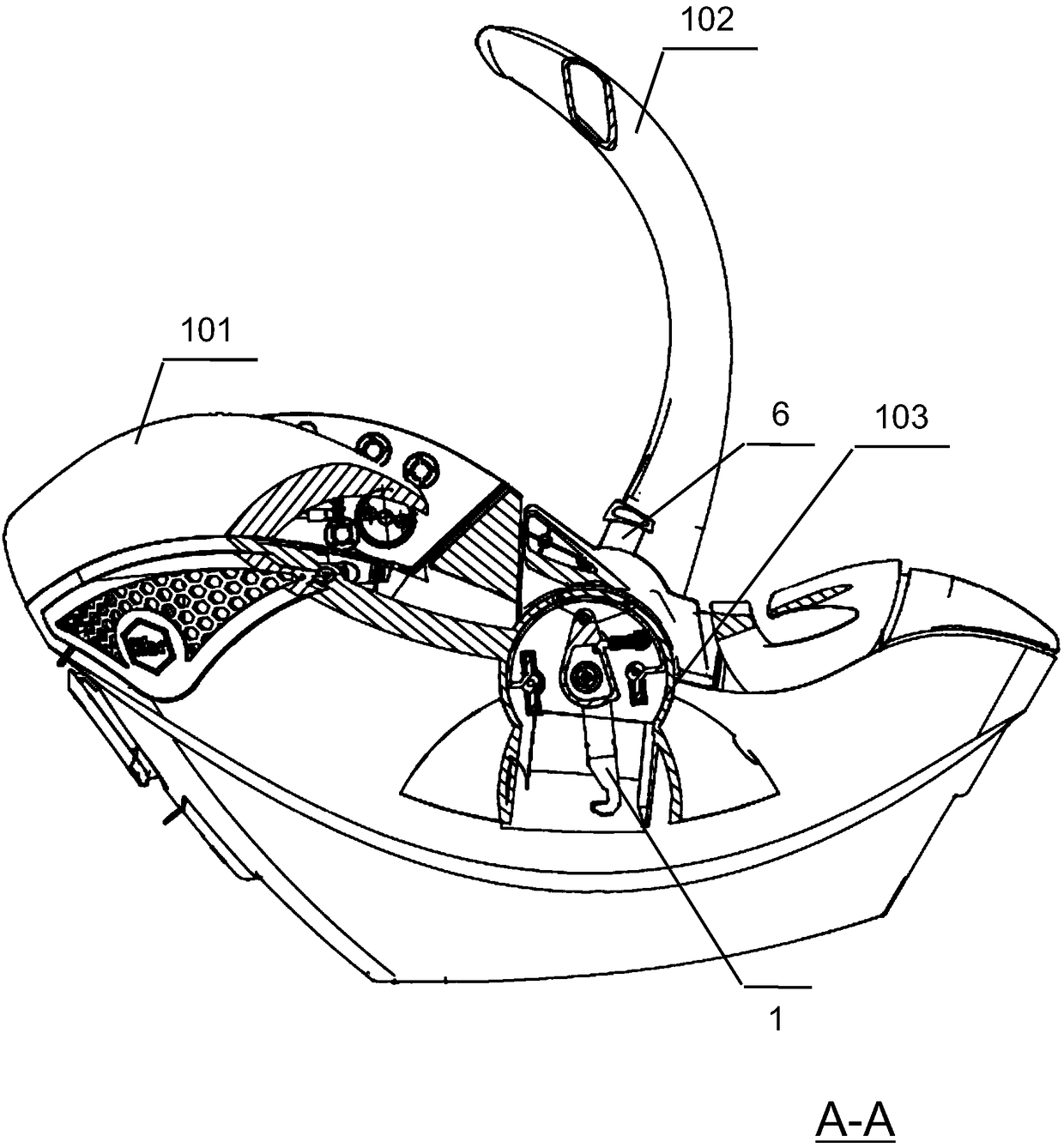

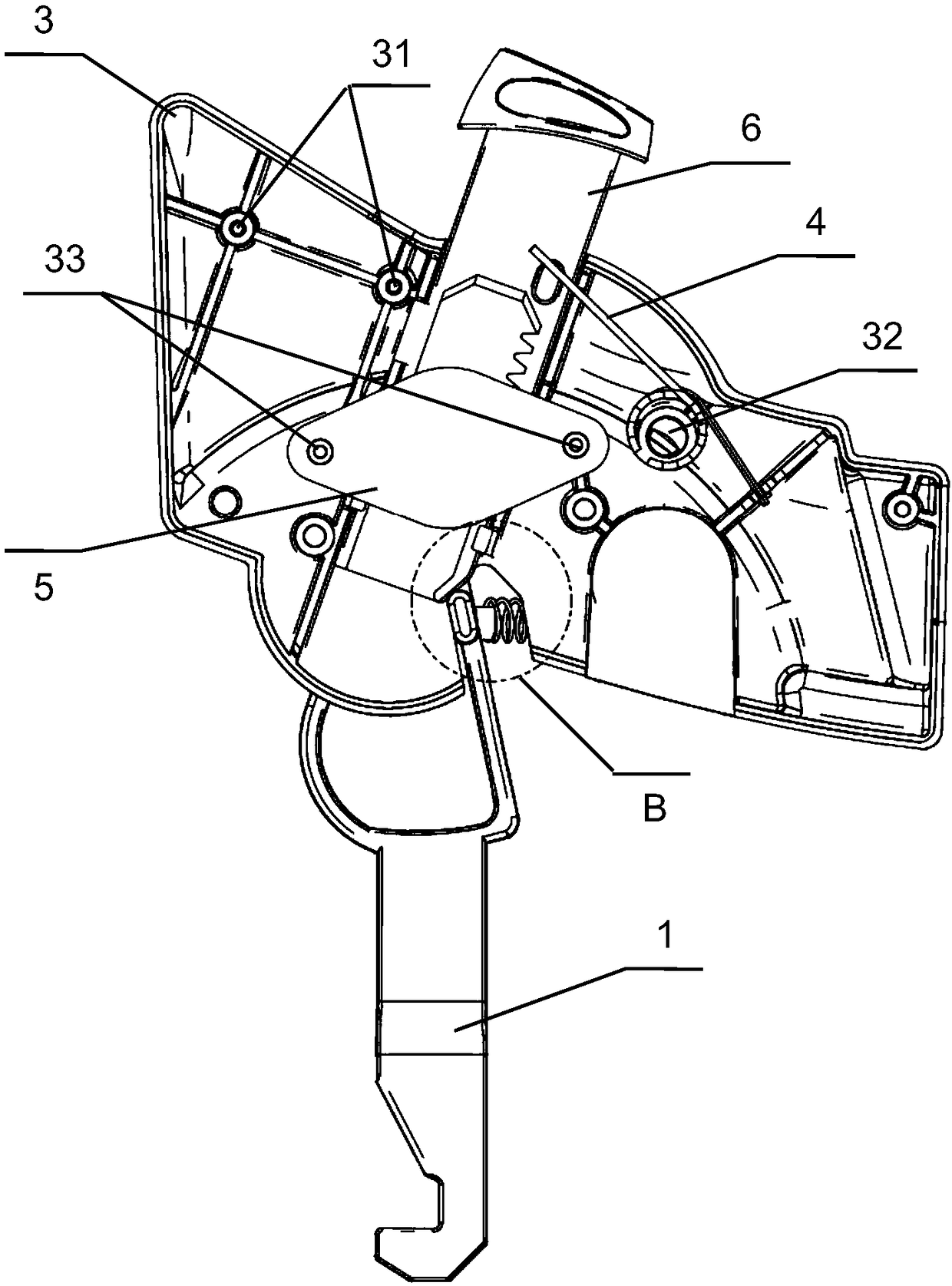

Infant carrying basket with slow rebound unlocking mechanism

PendingCN109229197ATake out stableTo achieve the effect of locking delayCarriage/perambulator accessoriesSufficient timeEngineering

The invention discloses an infant carrying basket with a slow rebound unlocking mechanism, which comprises a base, a carrying basket frame body, a carrying basket handle, a rotary connecting seat andan unlocking mechanism. The carrying basket frame body is arranged on the base so as to form a concave cavity structure of the carrying basket. A handle of that carry basket is arranged in the shape of an invert U, and both ends of the handle are connected with the carrying basket frame through a rotary connecting seat; An unlock mechanism is arranged in that rotary connecting seat, and the unlocking mechanism comprises a hook, a hook compression spring, a cover plate, a torsion spring, a damper, a trigger bar and a rear plate. The unlocking mechanism has the effect of slowly rebounding and locking, so that after the connection between the basket and the trolley is unlocked, the basket can be lifted with both hands in sufficient time. The invention makes the unlocking mechanism on the basket have the effect of delaying and rebounding, realizes the liberation of hands, and conveniently and stably removes the basket.

Owner:上海五虎婴童用品有限公司

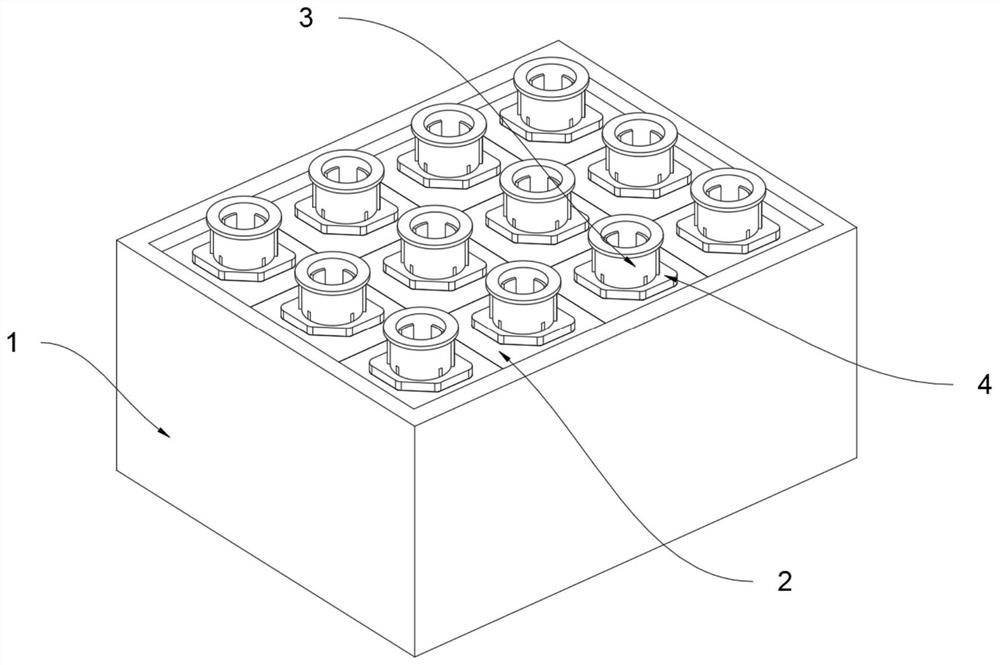

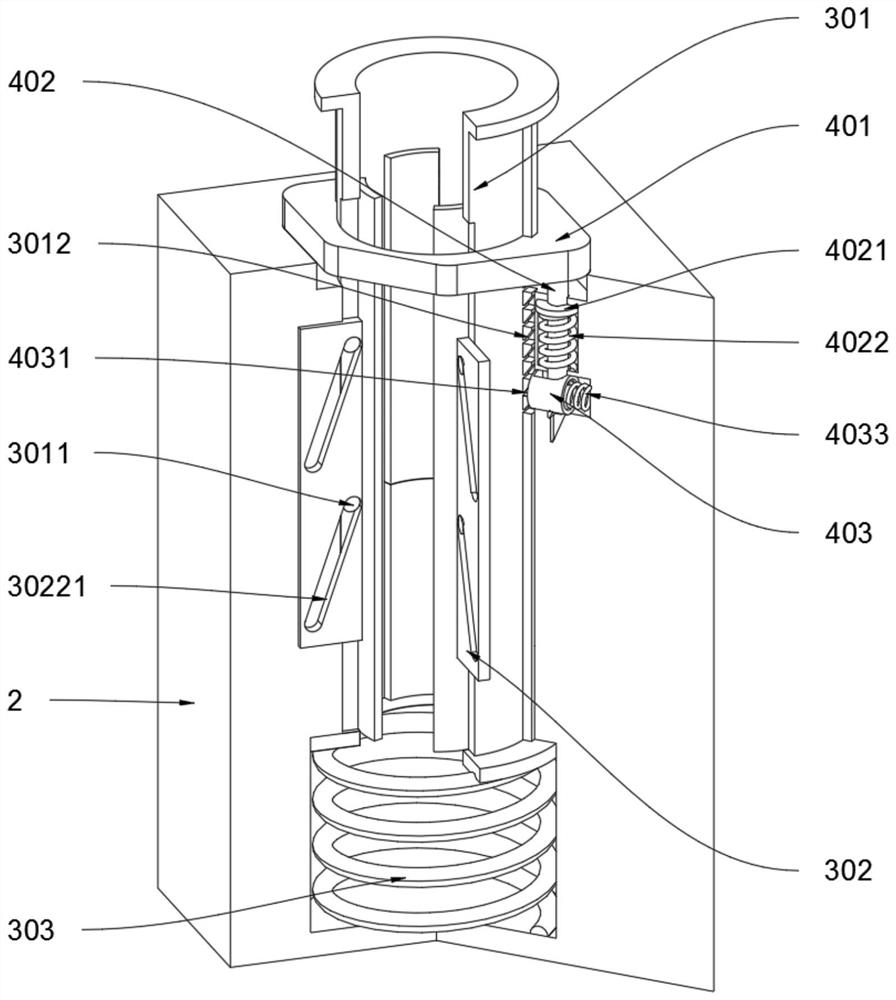

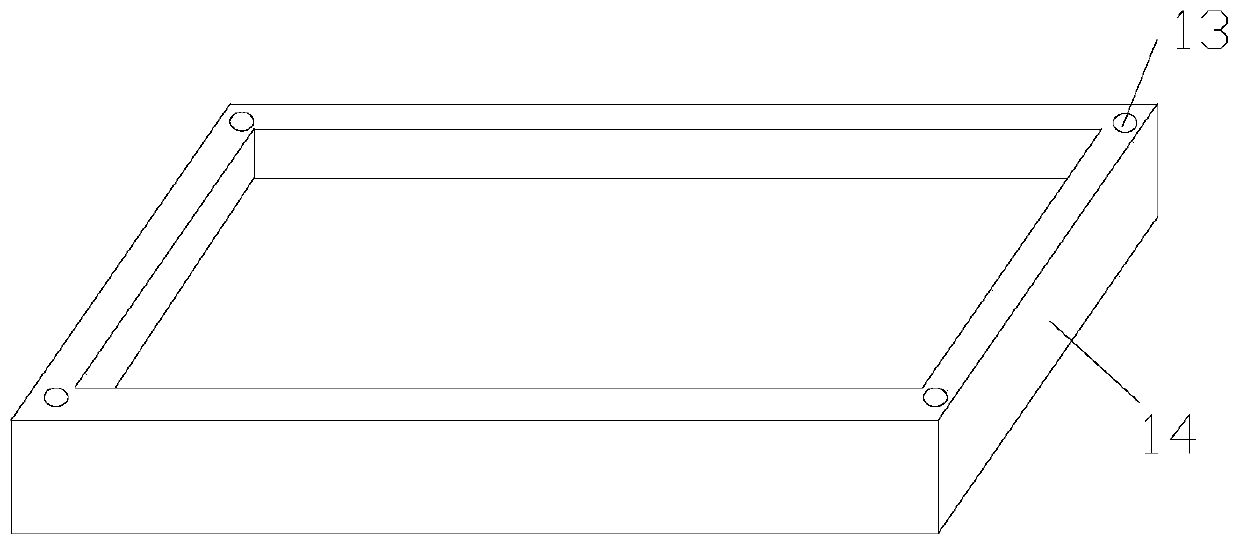

Transfer tank for molecular biological experiments

ActiveCN113335730AReduce use costFlexible and convenient to useContainers to prevent mechanical damageDischarging meansExperimental laboratoryProcess engineering

The invention discloses a transfer tank for molecular biological experiments, relates to the technical field of biological experiment appliances, and solves the problems that the inner diameter of a tank body of an existing transfer tank cannot be changed, so that the transfer tank of one specification can only stably store and transfer test tubes of the same specification, the adaptability is poor, transfer tanks of various specifications need to be prepared, and the experiment cost is increased. The transfer tank for the molecular biology experiments comprises a transfer box body; and a transfer tank component is mounted in the transfer box body. Transfer tank assemblies of the device can stably store and transfer test tubes of different specifications, calibers, lengths and sizes, and all the transfer tank assemblies can be independently used and do not interfere with one another, so that the device can store and transfer the test tubes of various specifications at a time, use is convenient and flexible, the use cost of a laboratory is saved, and adaptability is high.

Owner:龙超

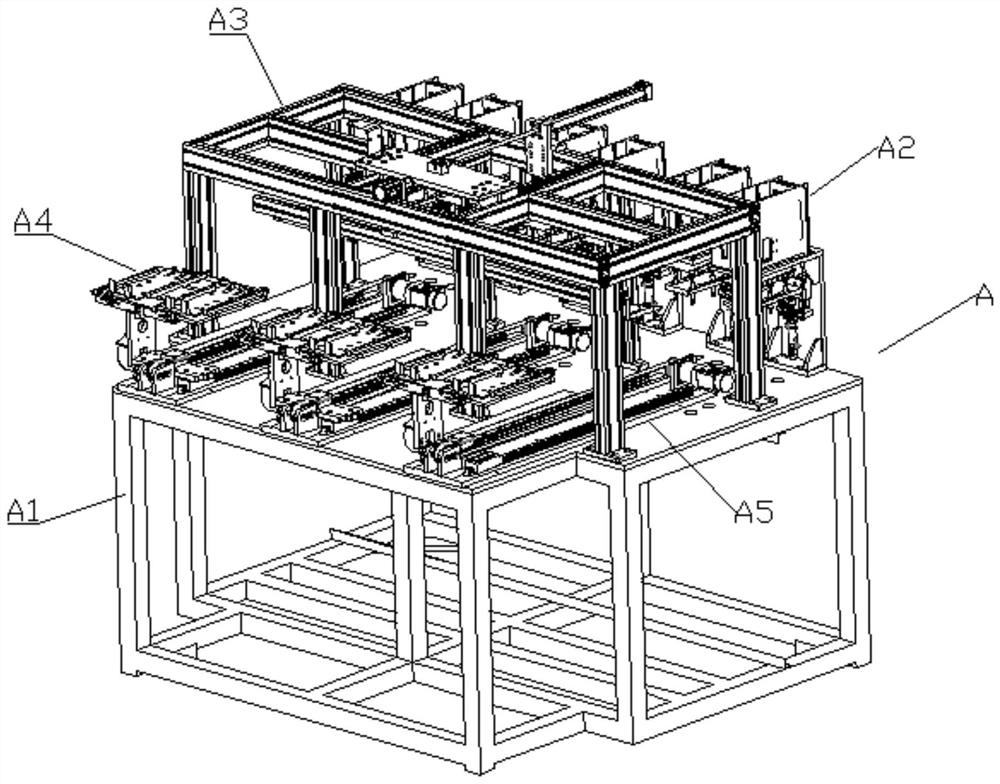

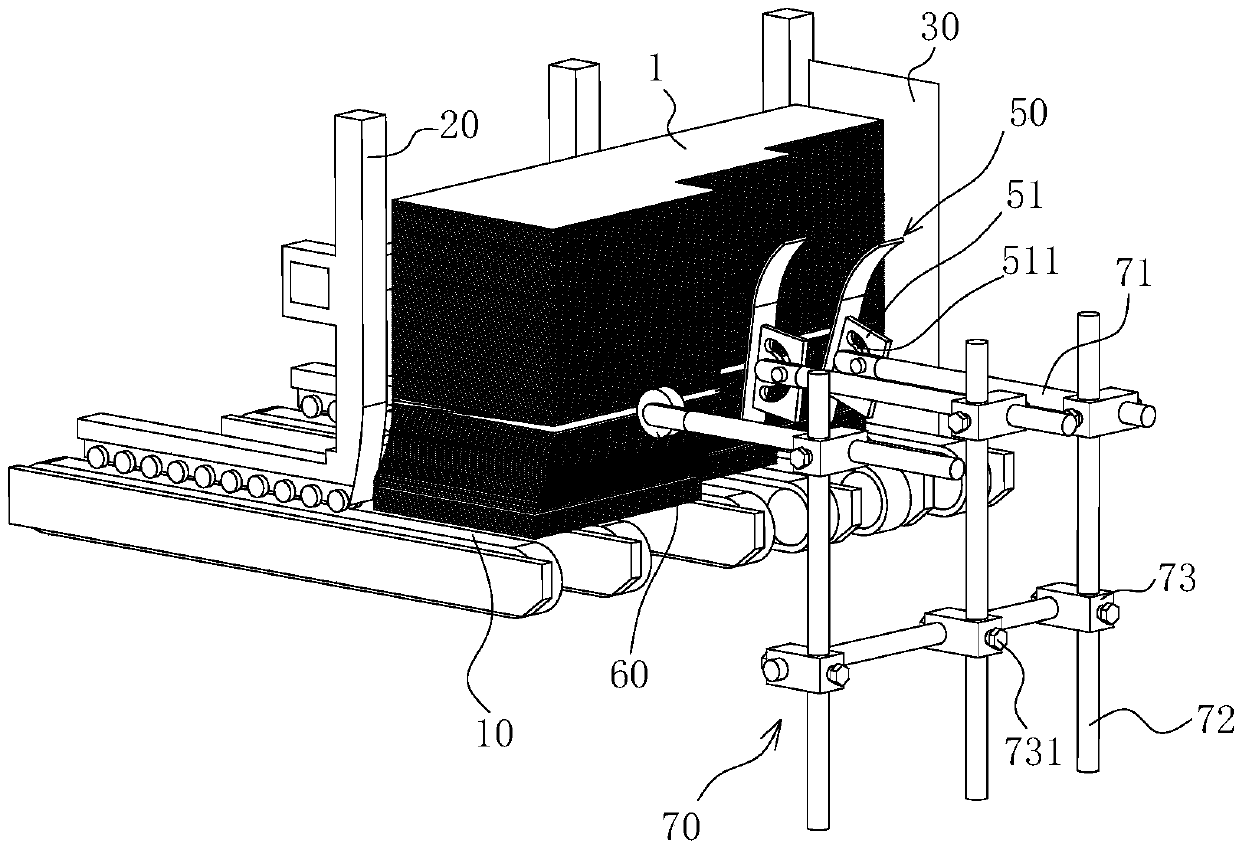

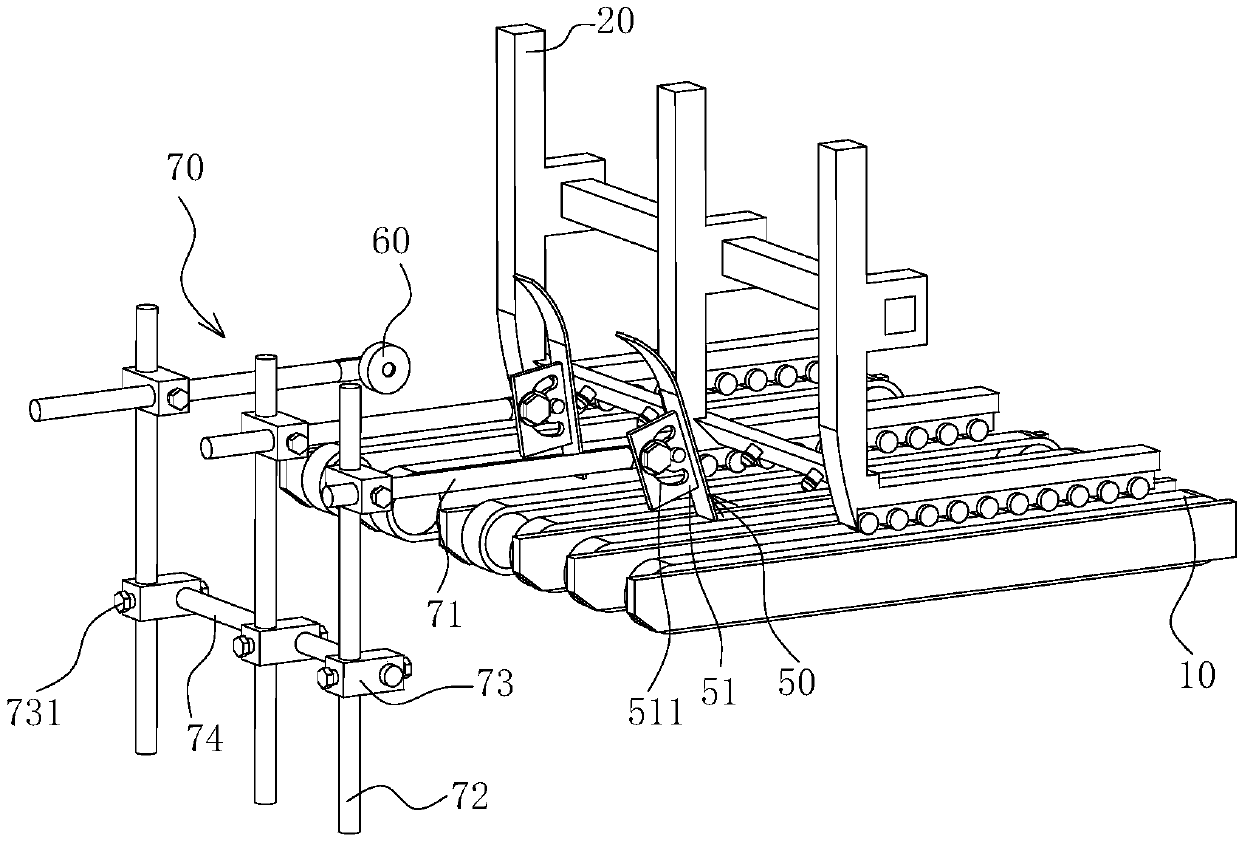

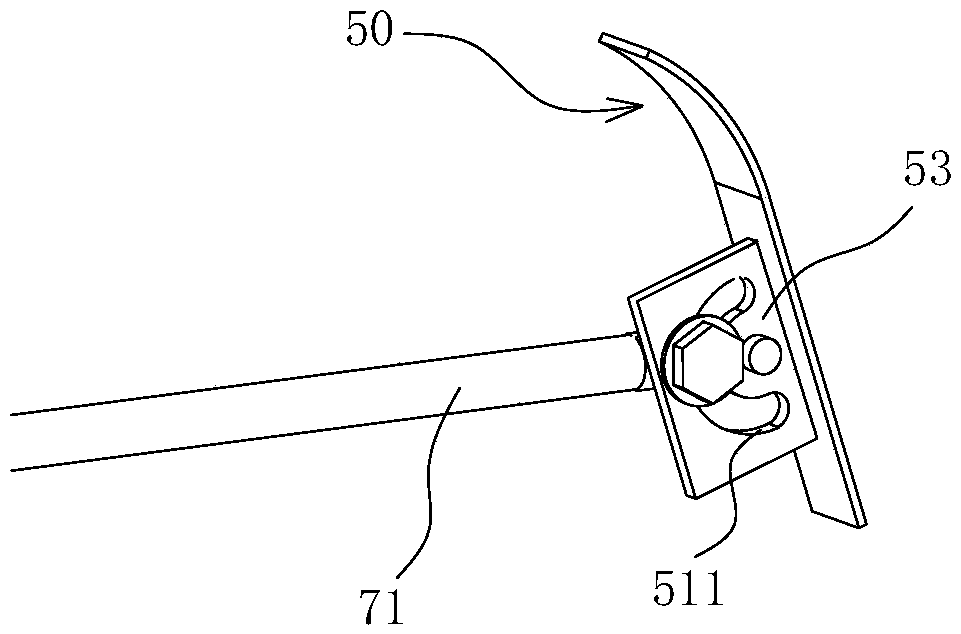

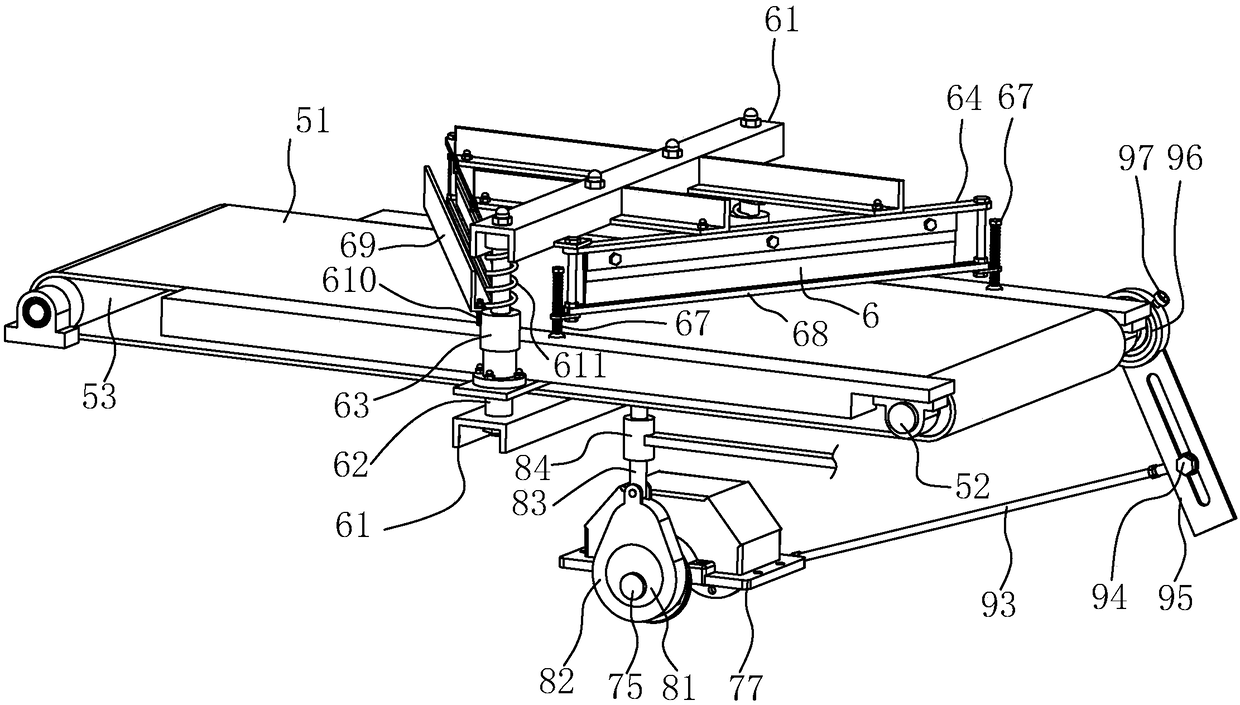

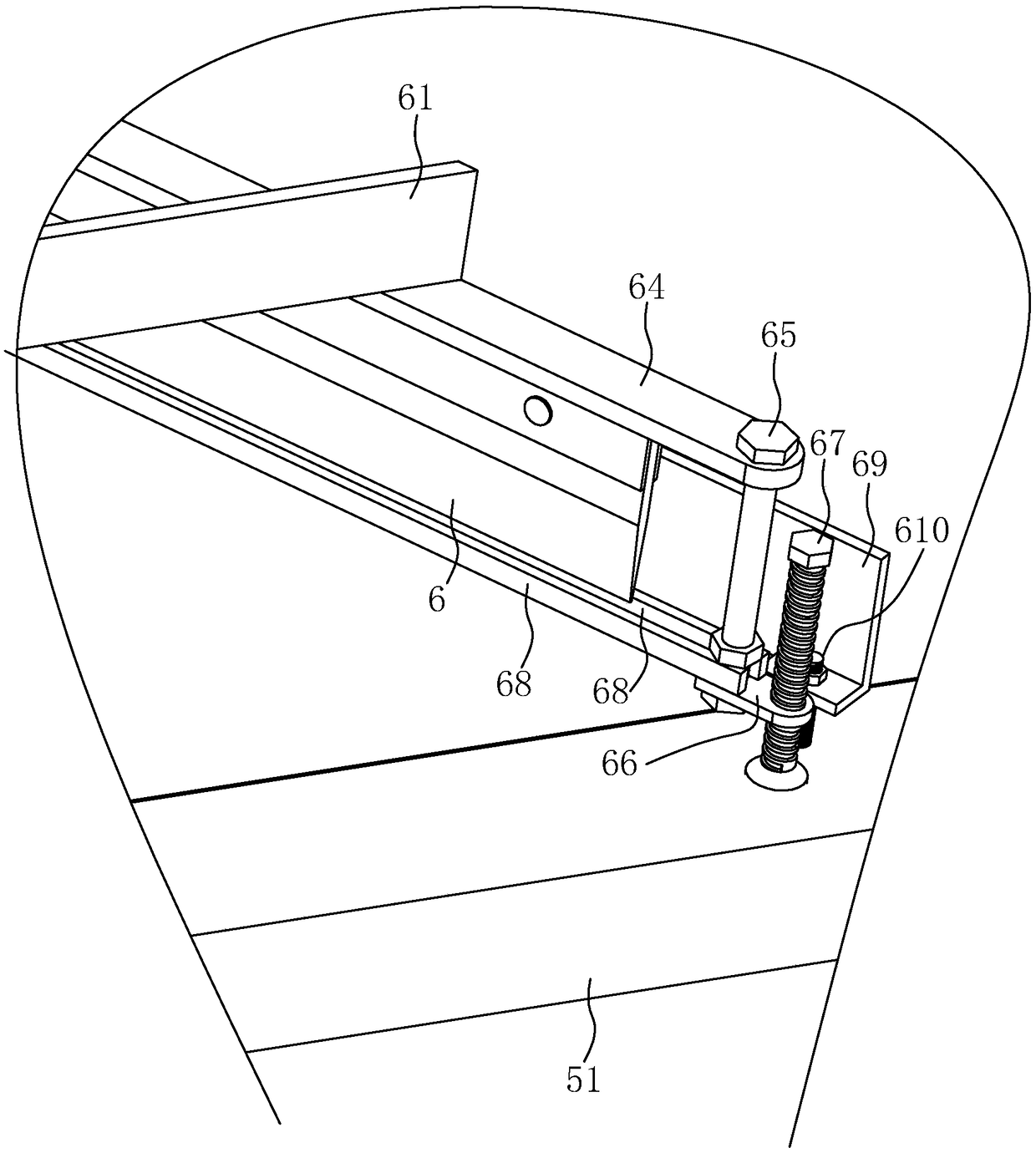

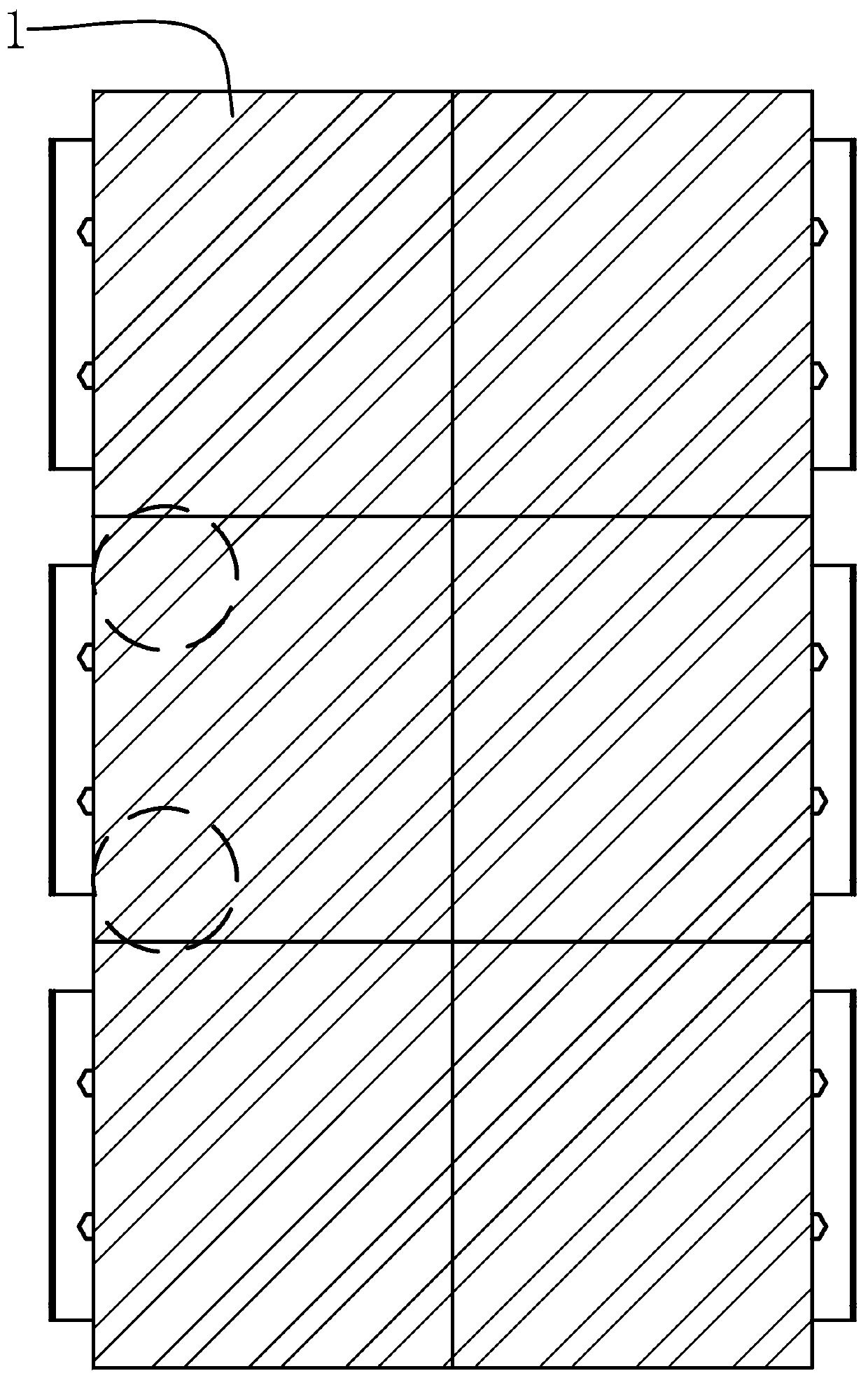

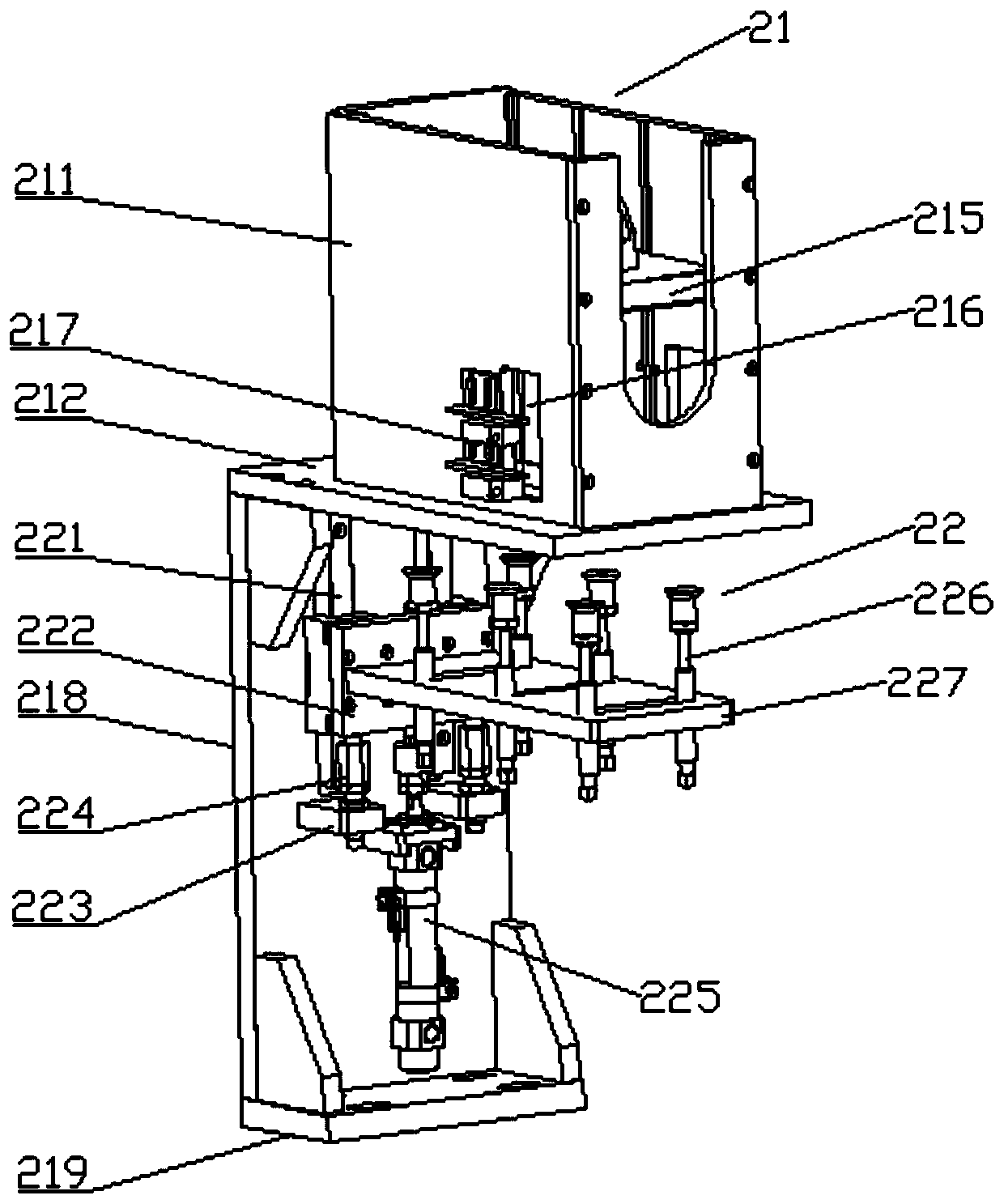

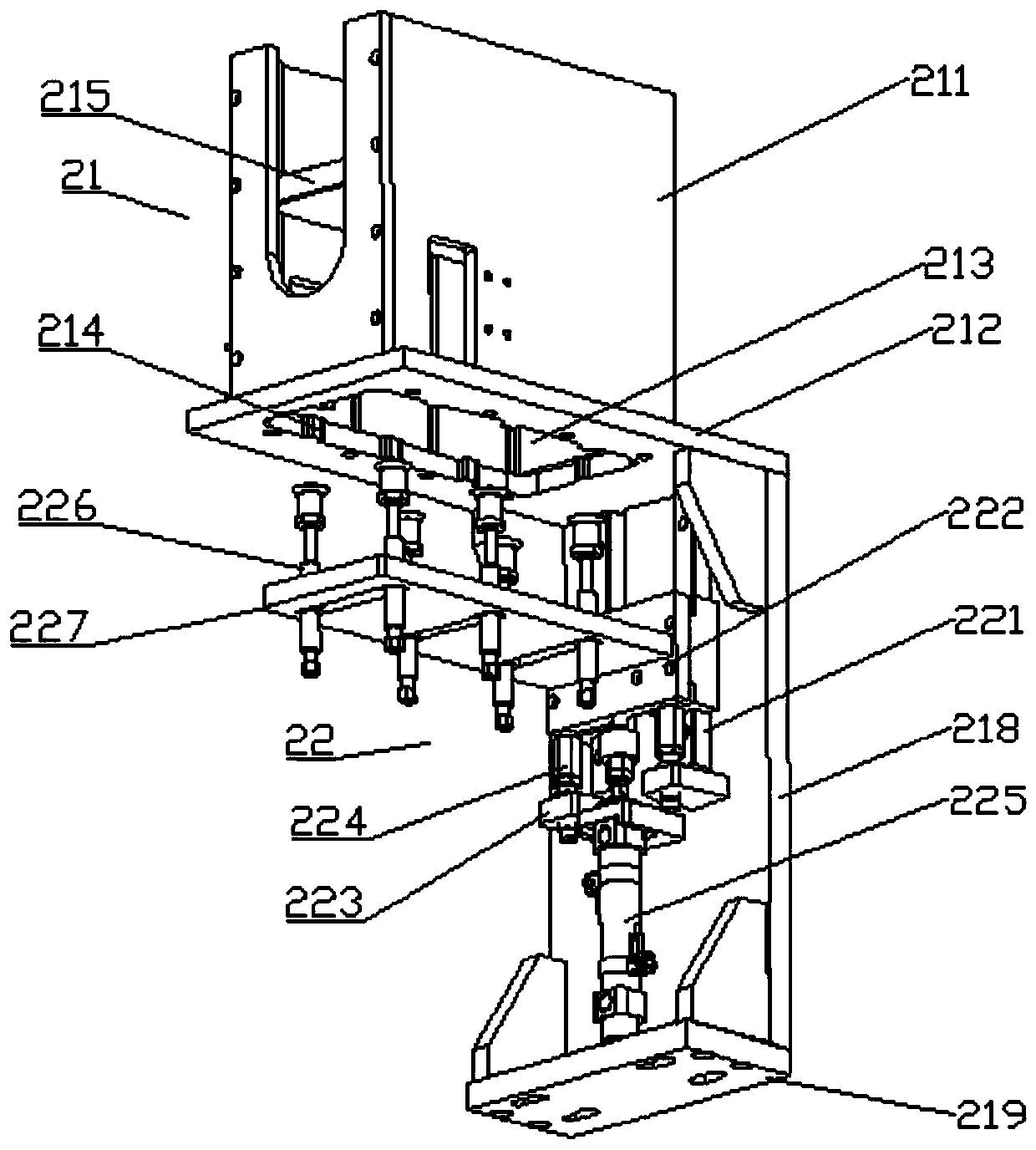

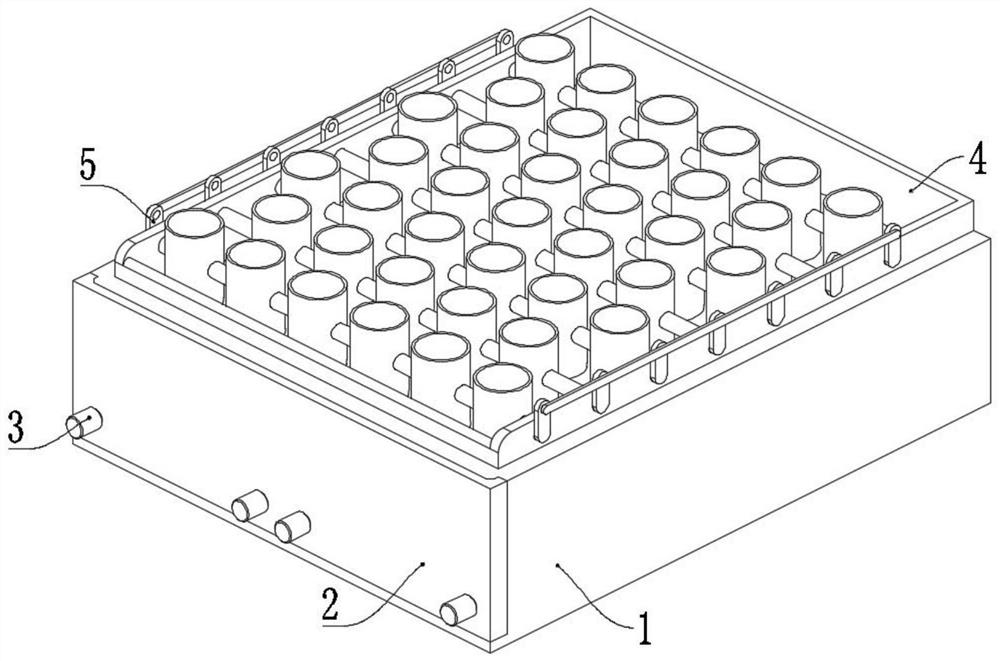

Automatic feeding and position correcting device for packaging bags

PendingCN111348258AThe removal process is smoothStable and flat take outPackagingTransfer mechanismEngineering

The invention relates to the technical field of packaging equipment, in particular to an automatic feeding and aligning device for packaging bags. The device comprises a support, an automatic bag taking mechanism, a packaging bag transferring mechanism and a packaging bag position correcting mechanism, and the automatic bag taking mechanism, the packaging bag transferring mechanism and the packaging bag position correcting mechanism are sequentially installed on the table top of the support; the automatic bag taking mechanism comprises a bag bin used for containing the packaging bags and a bagtaking assembly used for sucking the packaging bags from the bag bin, the packaging bag transferring mechanism clamps the packaging bags sucked by the bag taking assembly and horizontally moves the packaging bags to the packaging bag position correcting mechanism, and the packaging bag position correcting mechanism is provided with an X-direction bag position correcting assembly and a Y-directionbag position correcting assembly to adjust the front-back positions and the left-right positions of the packaging bags. The device is reasonable in overall structure arrangement and strong in structural operation relation continuity, and the automation degree of the equipment is improved; the automatic bag taking mechanism is stable in bag taking, the bag transferring mechanism is high in structural stability degree, and after the packaging bags are subjected to position correcting adjustment of the X-direction bag position correcting assembly and the Y-direction bag position correcting assembly, the positions of the packaging bags taken out each time are consistent and smooth, and the packaging bags can be stably conveyed to the next procedure.

Owner:YANTAI KAIBO AUTOMATION TECH

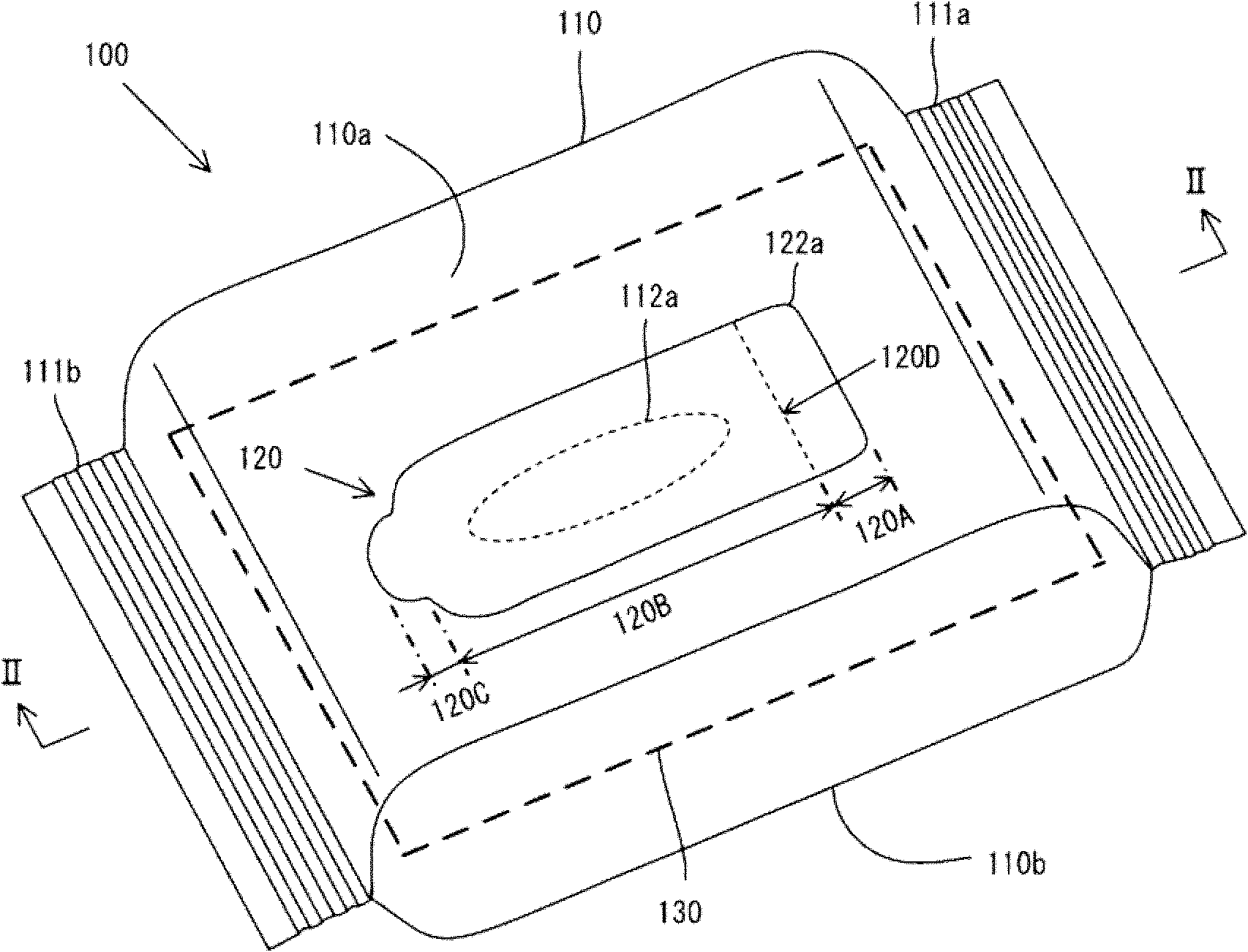

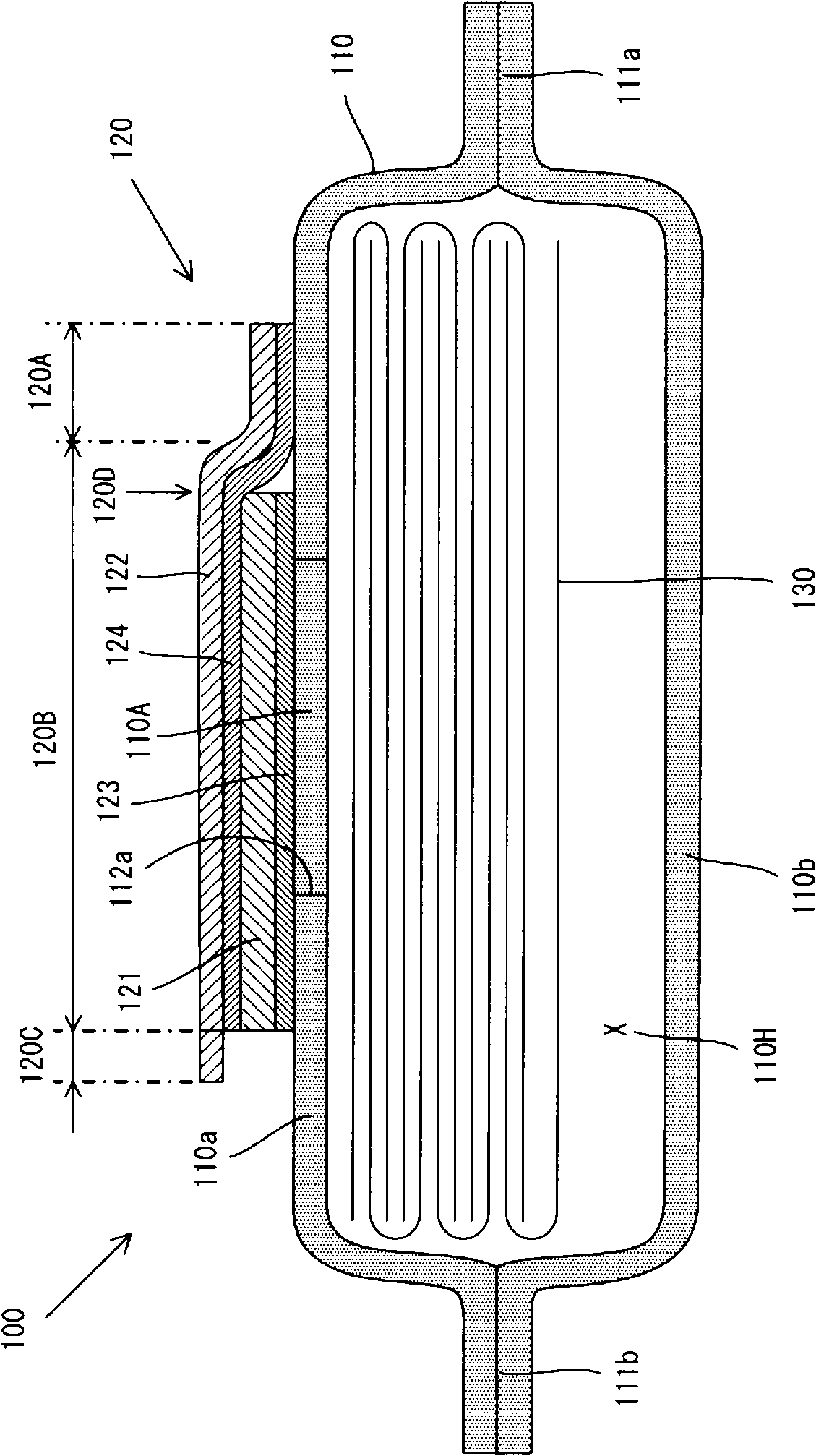

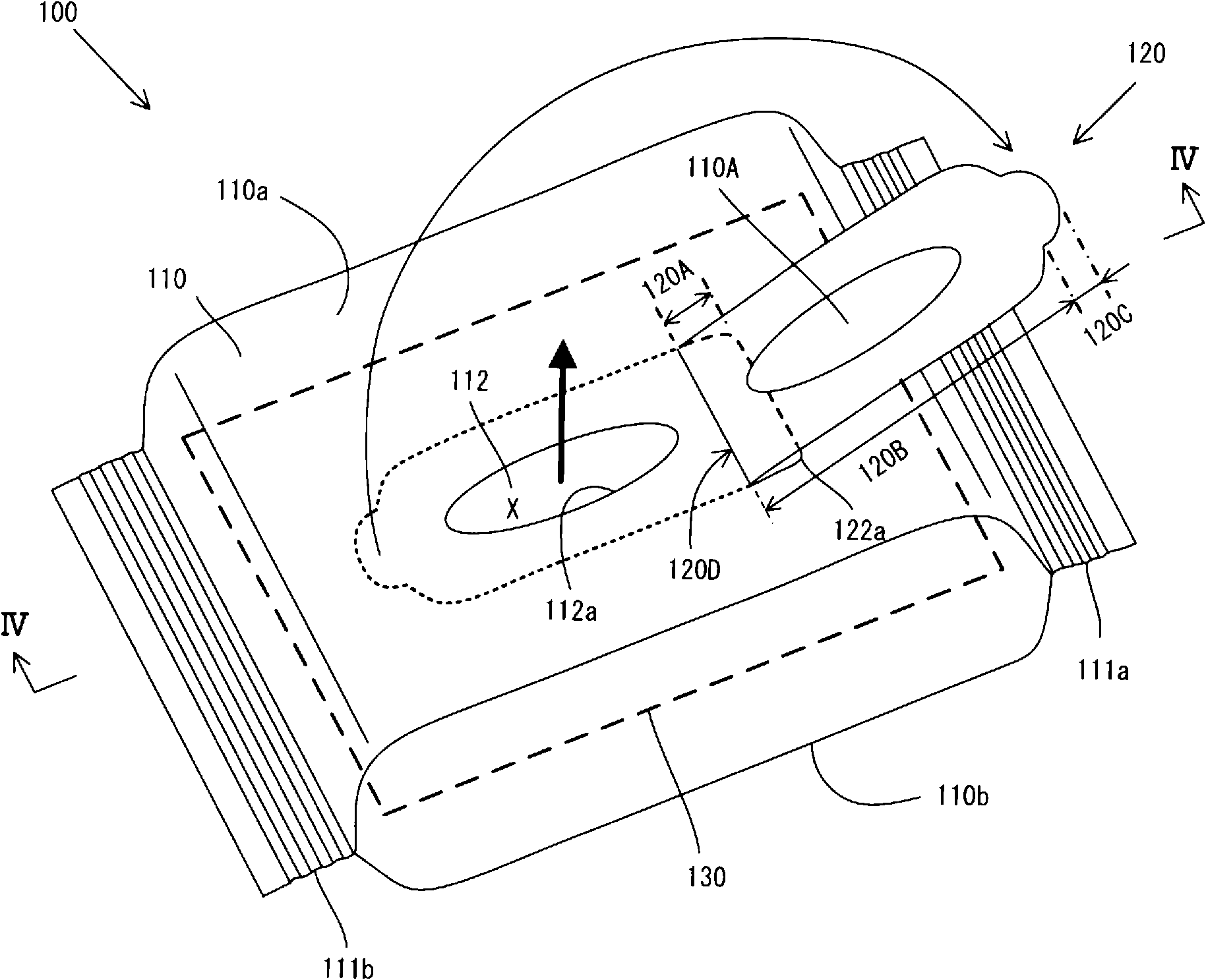

Containing device

ActiveCN102076576AThe removal process is smoothBathroom accessoriesFlat article dispensingEngineeringMechanical engineering

A technique for allowing smooth drawing of an article out of a package body housed in a container. Wet tissues (130) are housed in a package body (100), and the package body (100) is housed in a container (200). A lid (120) of the package body (100) has an opening and closing section (120B) constructed from a stack portion having a first sheet (121) and a second sheet (122) stacked on each other, and also has a base section (120A) constructed from that portion of the second sheet (122) which extends from the first sheet (121). One surface of the first sheet (121) is separably bonded to the front surface of a body (110) by a first bonding agent (123). One surface of the second sheet (122) is bonded by a second bonding agent (124) to the other surface of the first sheet (121) and to the front surface of the body (110). The package body (100) is housed in the container (200) with the opening and closing section (120B) of the lid (120) separated from the front surface of the body (110), folded back, and bonded to the rear surface of the body (110) by the first bonding agent (123).

Owner:UNI CHARM CORP

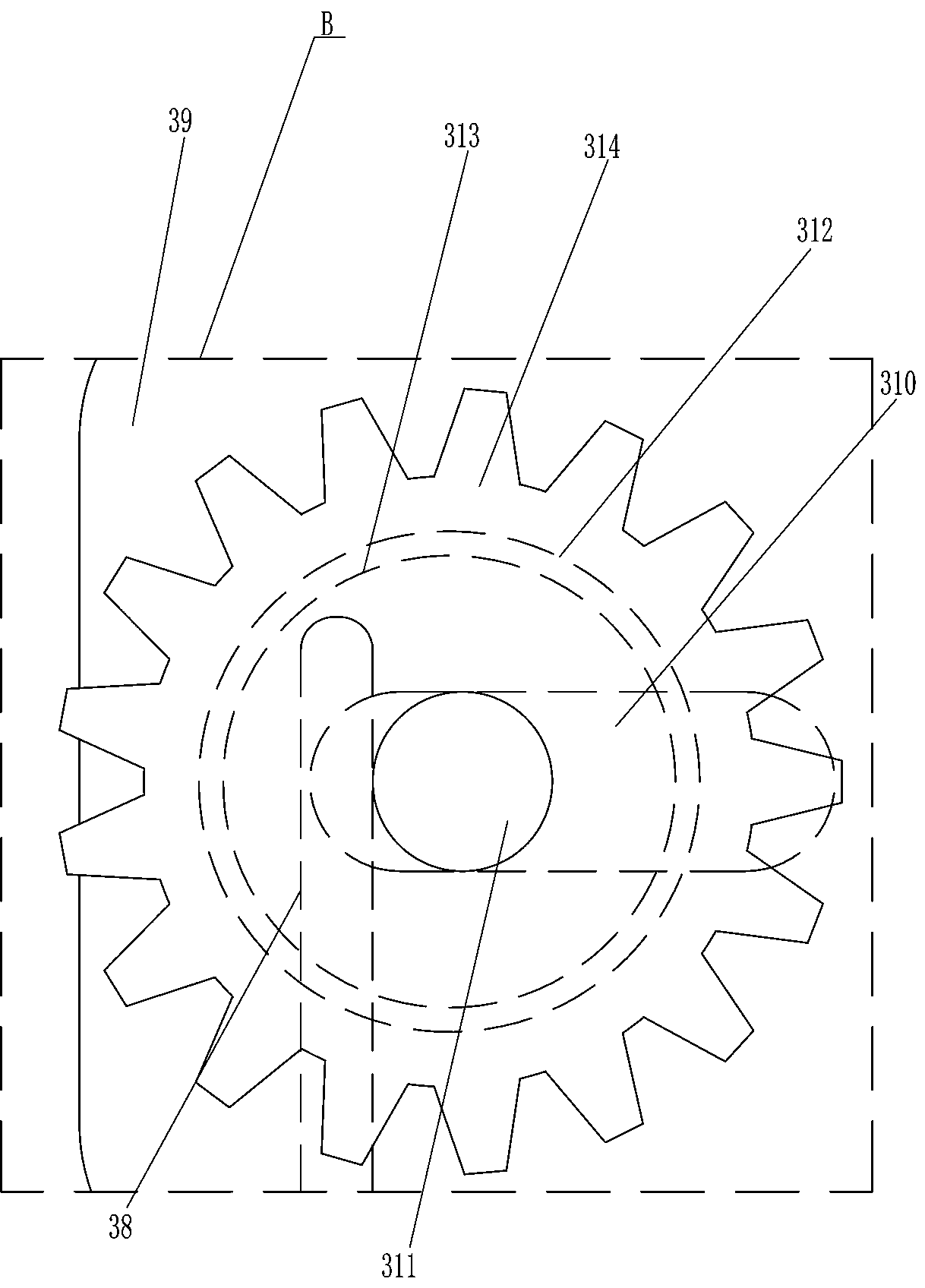

Glass cement applying device for high-place glass window frame

InactiveCN110756406ATake it out and save effortTake out stableLiquid surface applicatorsCoatingsStructural engineeringHollow core

The invention relates to a glass cement applying device, in particular to a glass cement applying device for a high-place glass window frame. The technical problem to be solved is how to provide a glass cement applying device for a high-place glass window frame with high safety factor, no cement breakage when glass cement is applied, no restriction on the construction area of an operator, uniformglass cement application on the glass window frame, and convenient use. The glass cement applying device for the high-place glass window frame comprises a hollow branch pipe, a placing frame and the like; the top of the hollow branch pipe is provided with the placing frame. According to the invention, a sliding rod can be driven to move through a clamping rod, a vertical swing rod can be driven toswing through the sliding rod, so that a gear is driven to contact and mesh with a rack through the vertical swing rod, and then a T-shaped pushing rod is driven by the rack to push out the glass cement, and meanwhile, the air in a sucking disc can be drained through the cooperation of an L-shaped swing rod and the sucking disc without pressing the sucking disk manually and strongly, and the workload is reduced.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

Nail removing device for orthopedics

InactiveCN111759448AReduce labor intensityHigh degree of automationInstruments for stereotaxic surgeryOsteosynthesis devicesMedical equipmentOrthopedic department

The invention discloses a nail removing device for orthopedics, and relates to the technical field of medical equipment. The nail removing device for orthopedics includes a base and a supporting platform installed at the top of the base. The nail removing device further includes an installation platform, a lifting mechanism installed inside the installation platform, a nail removing platform, a translation mechanism and a nail removing mechanism, wherein the translation mechanism and the nail removing mechanism are installed in the nail removing platform. The lifting mechanism and the nail removing platform are fixedly connected by a connecting assembly. The height and horizontal position of the nail removing mechanism can be adjusted through the arrangement of the lifting mechanism and the translation mechanism, manual adjustment does not needed, the whole device automation degree is high, time and effort are saved, and the labor intensity of medical staff is effectively reduced; andthe positioning is accurate after the position of the nail removing mechanism is adjusted, it is effectively ensured that the nail removing mechanism corresponds to the limbs of a patient, so that thenail removing mechanism can remove nails quickly, and improving of the nail removing efficiency is facilitated.

Owner:岳靓

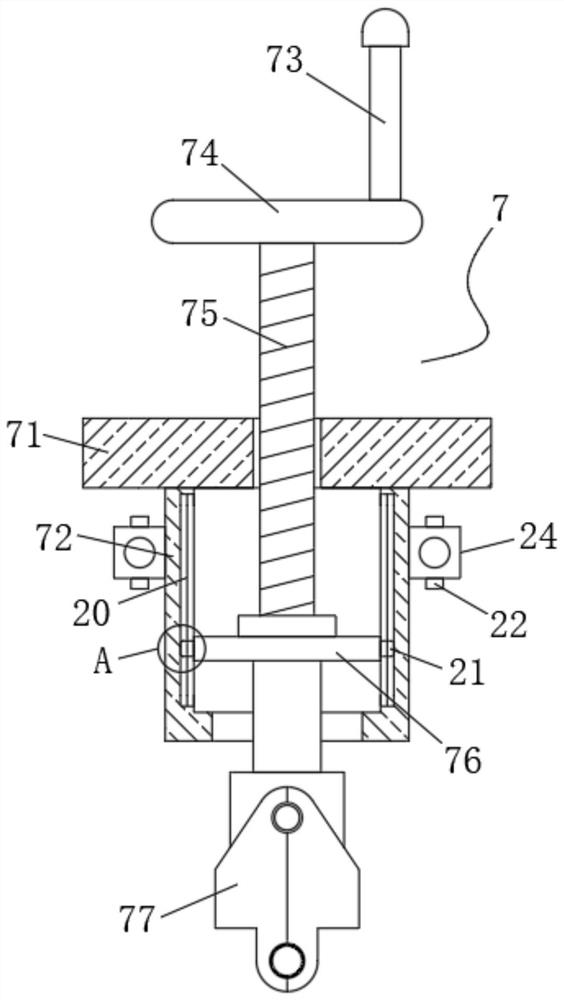

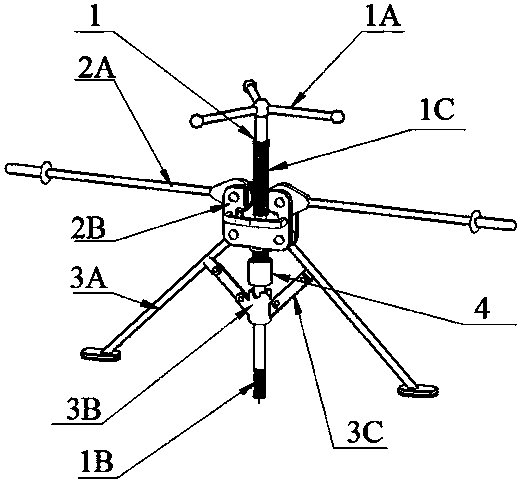

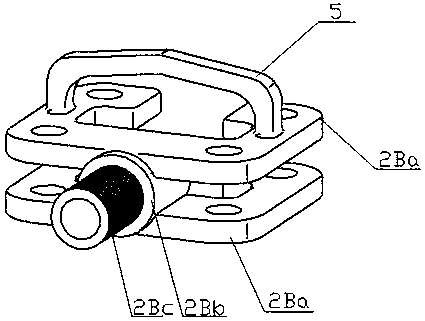

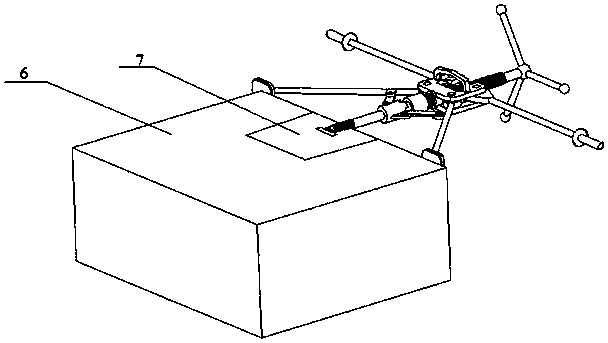

Large die mold active material withdrawing device

The invention discloses a large die mold active material withdrawing device. The large die mold active material withdrawing device comprises a locating mechanism, a withdrawing mechanism, a supportingmechanism and a limiting part, wherein the locating mechanism is of a rod-shaped structure with a first operating handle. The withdrawing mechanism comprises a second operating handle and an operation structure, the second operating handle is connected with the operation structure through a rotating shaft, and the locating mechanism is sleeved with the withdrawing mechanism in a penetrating mode.The supporting mechanism comprises supporting legs and supporting leg tensile degree control parts, one ends of the supporting legs are connected with operation structure through the rotating shaft,the other ends of the supporting legs can be erected on the die mold in a padding mode, and the locating mechanism is sleeved with the supporting leg tensile degree control parts in a penetrating mode. The locating mechanism is sleeved with the limiting part in a penetrating mode, and the limiting part is connected with the operation mechanism to control the size of the tensile degree of the supporting legs. The large die mold active material withdrawing device realizes the non-knocking withdrawing of large active materials, and the problems of poor surface quality of sand mold caused by knocking and easy damage and low service life of the withdrawing device are solved.

Owner:KOCEL EQUIP

Bearing dismounting tool and bearing dismounting method

PendingCN112720345AEasy to take outImprove disassembly efficiencyMetal-working hand toolsPull forceScrew thread

The invention discloses a bearing dismounting tool and a bearing dismounting method. The bearing dismounting tool comprises a pin screw rod, a threaded push rod and a pin used for hooking an inner ring of a bearing. A push rod through hole is formed in the threaded push rod, the pin screw rod is in threaded connection with the push rod through hole, a pin hole penetrating through the push rod through hole is formed in one end of the threaded push rod, the pin is slidably connected with the pin hole, one end of the pin is provided with a pin slope, and one end of the pin screw rod is provided with a push rod tip used for extruding the pin slope so as to push the pin to stretch out of the threaded push rod. The pin is pushed out in the spiral downward movement process of the pin screw rod relative to the threaded push rod, then the inner ring of the bearing is hooked to apply pulling force to the bearing, and therefore the bearing can be taken out conveniently, and the bearing dismounting efficiency is improved; and parts cannot be damaged in the taking-out process, and the bearing taking-out reliability is improved.

Owner:湖南麦谷科技有限公司

Partial discharge two-in-one intelligent sensor

PendingCN111579952ATake out stableGuaranteed stabilityTesting using acoustic measurementsMeasurement instrument housingStructural engineeringControl theory

The invention relates to the field of sensors, and particularly discloses a partial discharge two-in-one intelligent sensor, which comprises a protective shell and a two-in-one detection mechanism installed in the protective shell. A sealing cover is arranged at the top end of the protective shell. The two-in-one detection mechanism is sleeved with an integrated positioning installation box with an upward opening, and the two-in-one detection mechanism is poured in the positioning installation box through an insulating material. Positioning sliding rods are arranged at the corners of the periphery of the lower surface of the positioning installation box, the bottoms of the positioning sliding rods are fixedly connected with the bottom of the protective shell, and the bottoms of the positioning sliding rods are sleeved with damping springs. A first sliding groove allowing the positioning sliding rod to slide up and down is formed in the position, corresponding to the positioning slidingrod, of the positioning installation box. Sliding blocks of a T-shaped structure are installed on the side walls of the periphery of the positioning installation box. When the intelligent sensor is overhauled, the intelligent sensor can be stably taken out by hand only by reversely rotating the screw rod by hand.

Owner:上海贤业电气科技有限公司

Nasopharynx cancer circulating tumor cell detection kit

ActiveCN113976201ARealize storageAchieve airtight storageSupporting apparatusMedical equipmentNasopharyngeal cancer

The invention provides a nasopharynx cancer circulating tumor cell detection kit, and relates to the technical field of medical equipment. Thenasopharynx cancer circulating tumor cell detection kit comprises a box body device, wherein a bearing device is arranged at the top of the box body device, a control structure is arranged at the outer end of the bearing device, the bearing device comprises bearing frames, bearing barrels are fixed on the bearing frames, and are arranged on the bearing frames in an array mode, the bearing device can be installed at the top position of the box body device in a sliding mode, the bearing frames are installed on the bearing device in a swinging mode, the adjacent bearing frames are of a staggered structure so as to improve the effect of temporarily placing reagents, a sealing plate is mounted at the top of a partition assembly mounted in the box body device, and the sealing plate on a partition box can be closed through a transmission assembly, so that the effect of sealing stored reagents is achieved, and the problems that the reagents are inconvenient to place and take out in the sample collection process, the sealing performance of a kit is poor when the reagents are stored, and the conveying process is not stable enough are solved.

Owner:广州市红十字会医院

A seamless building curtain wall structure and its disassembly method

ActiveCN110777990BQuick releaseQuick installationWallsArchitectural engineeringMechanical engineering

Owner:江苏锦上装饰设计工程有限公司

Wine bottle cork puller and use method

ActiveCN110407144ASolve the situation of fragile bottle stoppersThe removal process is smoothStopper removalPlastic recyclingWine bottleEngineering

The invention provides a wine bottle cork puller and a use method. The wine bottle cork puller comprises an insertion pin used for penetrating a bottle cork and provided with an axial through hole, aprobe arranged in the through hole in a sliding manner, and a sliding part connected to the probe and stretching out of the through hole from the upper portion. The upper portion of the insertion pinis fixedly connected with a supporting plate used for supporting the insertion pin. The sliding part penetrates the supporting plate. The probe slides out of the through hole, gets rid of elastic deformation and is expanded towards the outer side. By means of the wine bottle cork puller, the supporting plate is used for driving the insertion pin to descend so that the insertion pin can penetrate the bottle cork; then the sliding part is used for sliding the probe in the insertion pin out of an opening in the sharp end of the insertion pin, the probe gets rid of the elastic deformation state and abuts against the bottom of the bottle cork, the sliding part and the supporting plate are upwards pulled, and therefore the bottle cork is pulled out. Compared with the prior art, the wine bottle cork puller linearly penetrates the bottle cork, force is exerted to the bottom of the bottle cork for pulling out the bottle cork, the problem of bottle cork damage can be effectively solved, and stability of the cork pulling process is improved.

Owner:CHINA GREAT WALL WINE CO LTD

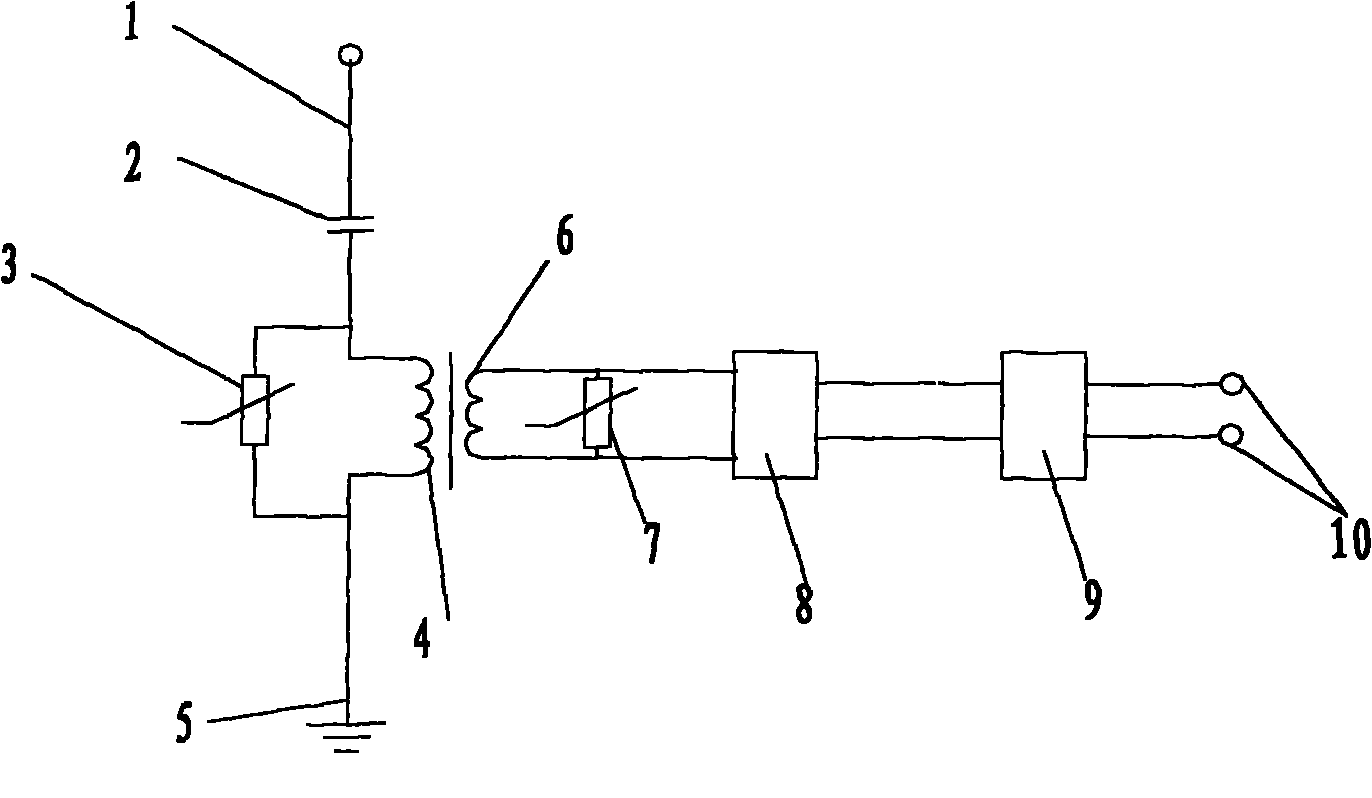

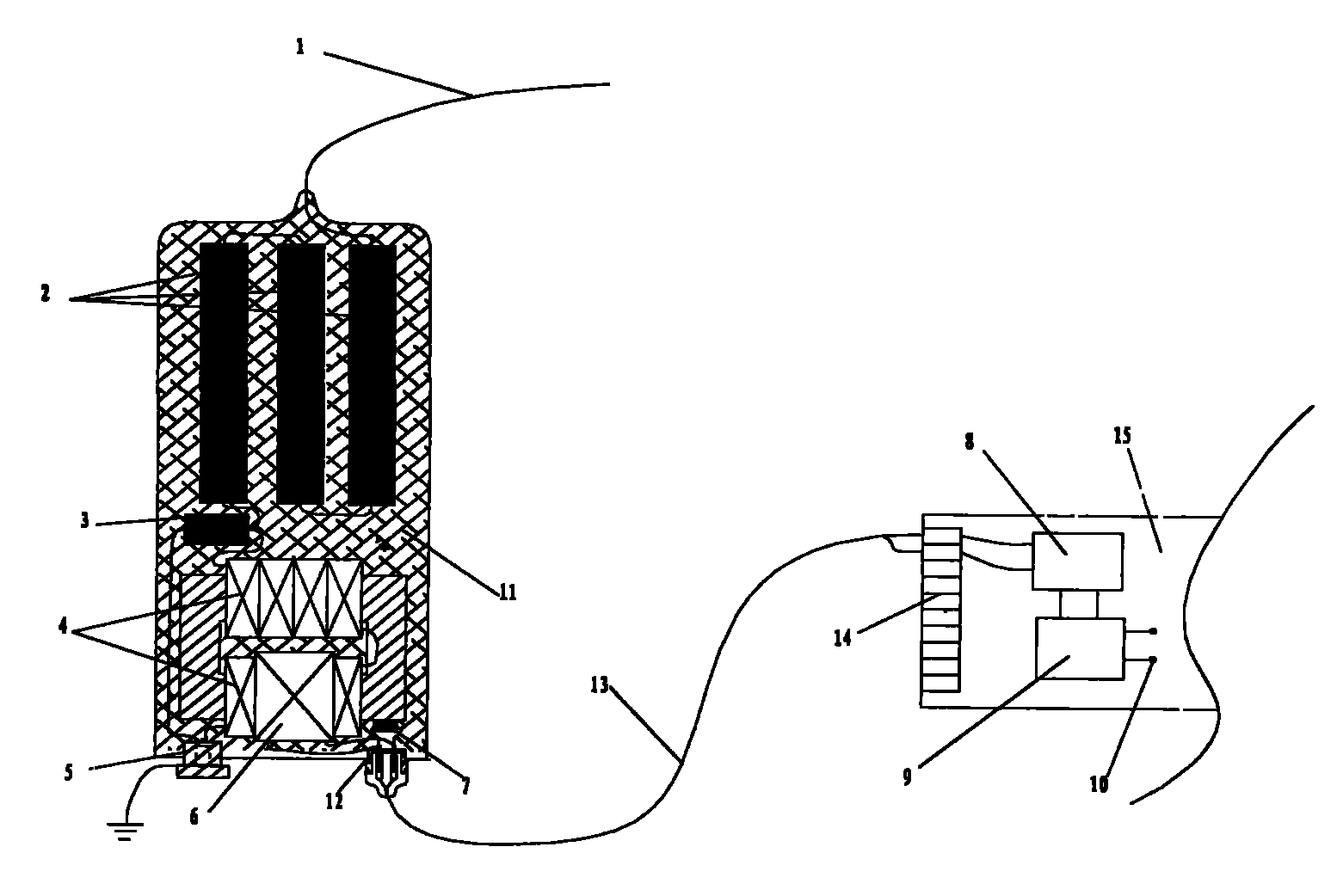

Power supply technology of 10KV electronic measuring system

InactiveCN101902132ASafe removalTake out stableAc-dc conversion without reversalDc-dc conversionHigh voltage capacitorsLow voltage

The invention provides a power supply technology of a 10KV electronic measuring system in an occasion without a conventional power supply. In a cast insulating material, a 10KV high-voltage insulating wire, a dry high-voltage capacitor and a primary measuring coil of a transformer are sequentially connected in series, the other end of the high-voltage wire is connected with high voltage of a 10KV electric power system, the other end of the primary measuring coil of the transformer is connected with the ground, a secondary measuring coil of the transformer is sequentially connected with an AC filtering rectifier unit and a switch type DC voltage stabilizing module, both ends of the primary measuring coil and the secondary measuring coil of the transformer are respectively bridged with a high-voltage piezoresistor and a low-voltage piezoresistor, and a DC working power supply which can safely, stably and reliably satisfy electric power requirement and has good electromagnetic compatibility can be obtained at the output end of the DC voltage stabilizing module in order to lead an electronic type mutual inductor and an electronic type electric energy measuring circuit board to work.

Owner:LANGFANG GAOSHAN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com