Sampling device of smoke and dust with automatically positioning detecting point

A sampling device and automatic positioning technology, applied in the direction of sampling devices, etc., can solve the problems of harsh environmental conditions, scalding of sampling pipes and sampling holes, large manual positioning errors, etc., and achieve the effects of reducing labor intensity, rapid removal, and high positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

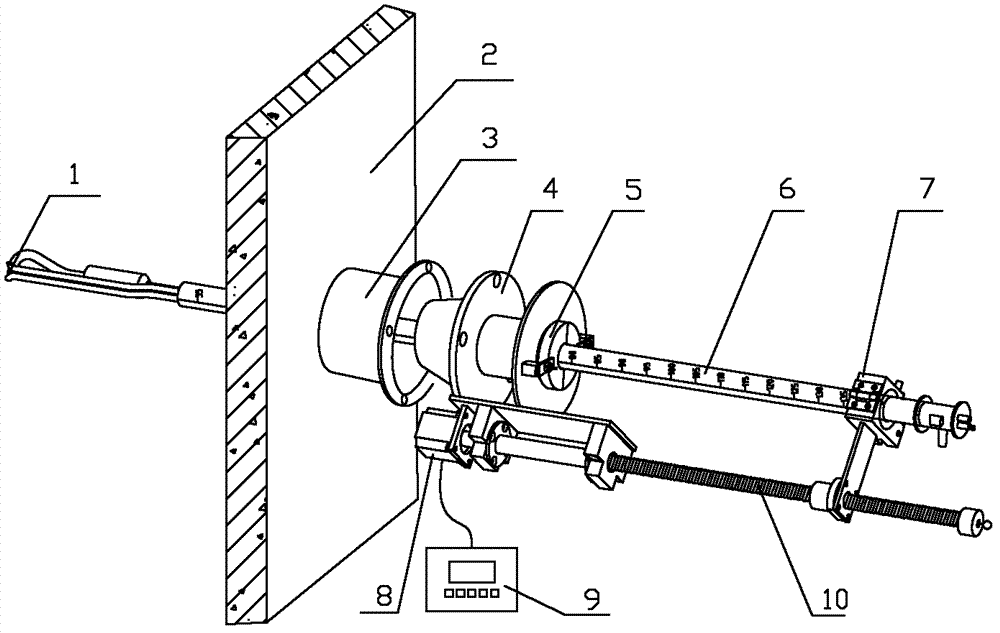

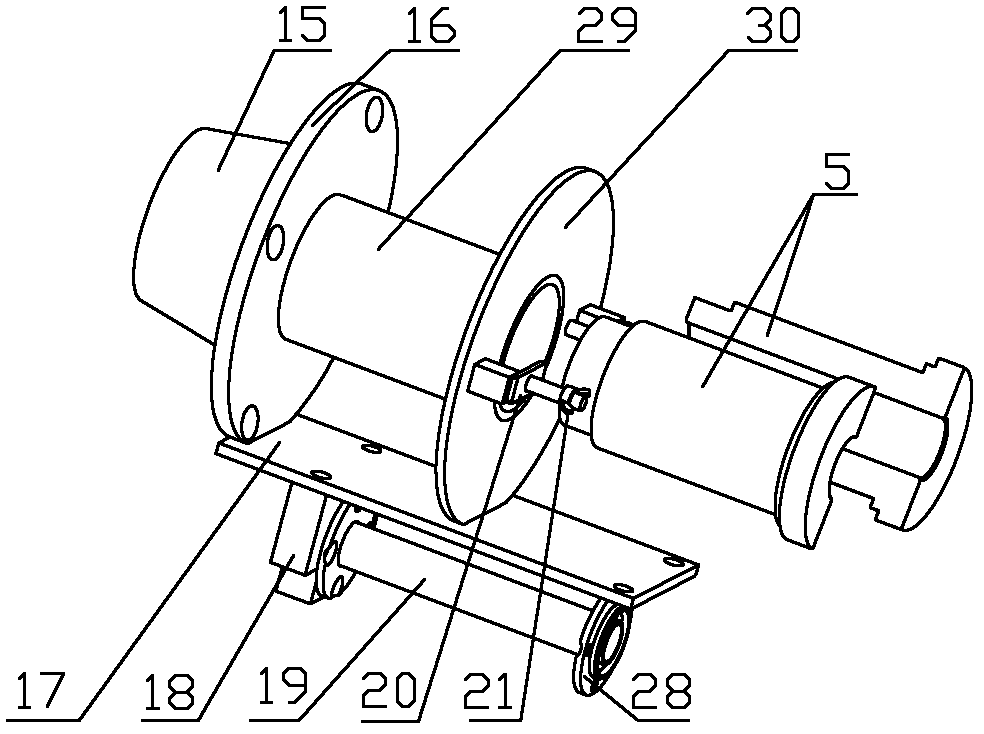

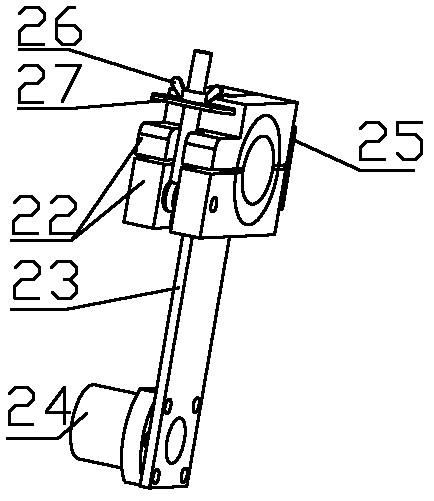

[0030] Such as figure 1 , figure 2 , image 3 As shown, a soot sampling device for automatically positioning and measuring points, including a sampling nozzle 1, a fixing device 4, a PTFE shaft sleeve 5, a soot sampling tube 6, a sampling tube connector 7, a stepping motor 8, and a soot sampler The main engine 9, the screw rod 10, the fixed bearing part, the fixing device 4 includes a flange 16 connected with the sampling hole 3 arranged on the outer wall of the flue 2, and the middle of the fixing device 4 is embedded with a cylinder consisting of two semi-circular cylinders. The PTFE shaft sleeve 5, the dust sampling tube 6 is slidingly arranged in the polytetrafluoro shaft sleeve 5, the smoke sampling tube 6 is provided with a sampling nozzle 1 at one end, and a sampling tube connector 7 is fixed at the other end, and the sampling tube connector 7 includes a screw drive seat 24 with an internal thread, one end of the screw rod 10 is set in the screw drive seat 24, and th...

Embodiment 2

[0039] Such as Figure 4 As shown, the present embodiment also includes a flue hanging ring 11, a screw hanging ring 31 and a soft rope 12, the flue hanging ring 11 is arranged on the outer wall 2 of the flue, and the screw hanging ring 31 is arranged on the side of the screw mandrel 10 away from the stepping motor 8. At one end, the flue suspension ring 11 and the screw rod suspension ring 31 are connected by a soft rope 12 .

[0040] When using an extended or overweight smoke sampling pipe 6, if it is fixed only by the flange 16 of the fixing device 4 and the flange connection of the sampling hole 3, there is a possibility that the smoke sampling pipe 6 is not fixed firmly, the tail shakes or the tail droops. The fixing method of auxiliary hanging on the basis of flange fixing can be adopted, and the screw hanging ring 31 at the end of the screw rod 10 is connected with the flue hanging ring 11 on the outer wall 2 of the flue with a soft rope 12, and the pulling forc...

Embodiment 3

[0042] Such as Figure 5 As shown, this embodiment also includes a support frame 14 and a screw roller 32 , the bottom of the support frame 14 is set on the ground 13 , and the top is connected to the end of the screw 10 away from the stepper motor 8 through the screw roller 32 .

[0043] When using an extended or overweight sampling pipe, if it is only fixed by the flange connection between the fixture flange 16 and the sampling hole 3, there is a possibility that the smoke sampling pipe 6 may not be fixed firmly, the tail may shake or the tail may droop. The fixing method of auxiliary ground support on the basis of flange fixing, the upper end of the support frame 14 is connected and fixed on the end of the screw rod 10 away from the stepping motor 8 through the screw roller 32, so that the screw rod 10 is kept balanced, and the bottom of the support frame 14 is stable Fixed on the ground 13. Others are the same as in Example 1 and will not be described again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com