Glass cement applying device for high-place glass window frame

A glass glue and glass window technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of low safety factor, broken glue, uneven application of glass glue, etc., so as to reduce the workload and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

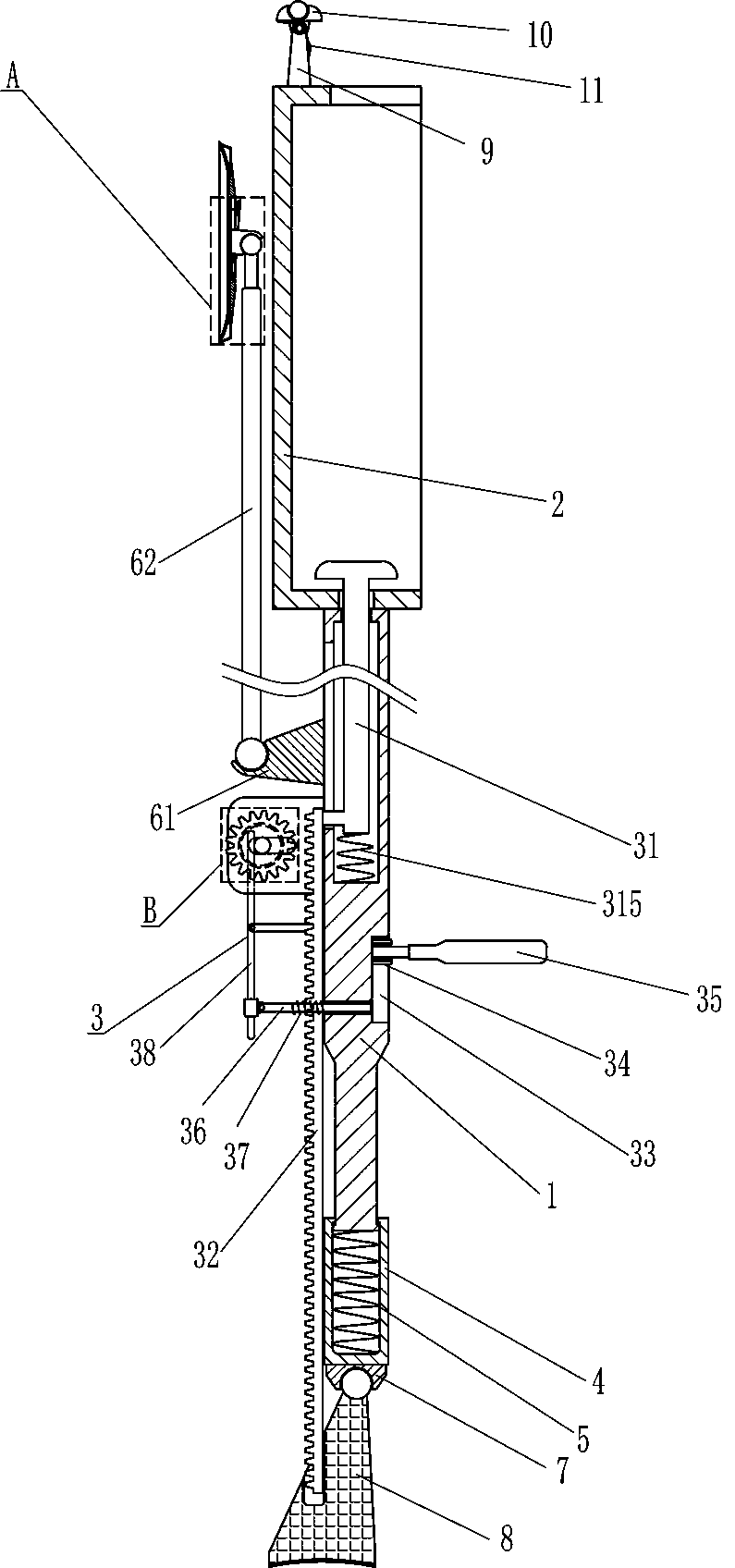

[0019] A device for applying glass glue to the frame of a glass window at a high place, such as figure 1 , figure 2 and Figure 4 As shown, it includes a hollow branch pipe 1, a placement frame 2, a pushing device 3, a guide sleeve 4 and a second spring 5, a placement frame 2 is installed on the top of the hollow branch pipe 1, and a pushing device 3 is installed in the hollow branch pipe 1, wherein the pushing The device 3 is used to push out the glass glue. The bottom end of the hollow branch pipe 1 is slidingly provided with a guide sleeve 4 , and a second spring 5 is connected between the bottom end of the hollow branch pipe 1 and the guide sleeve 4 .

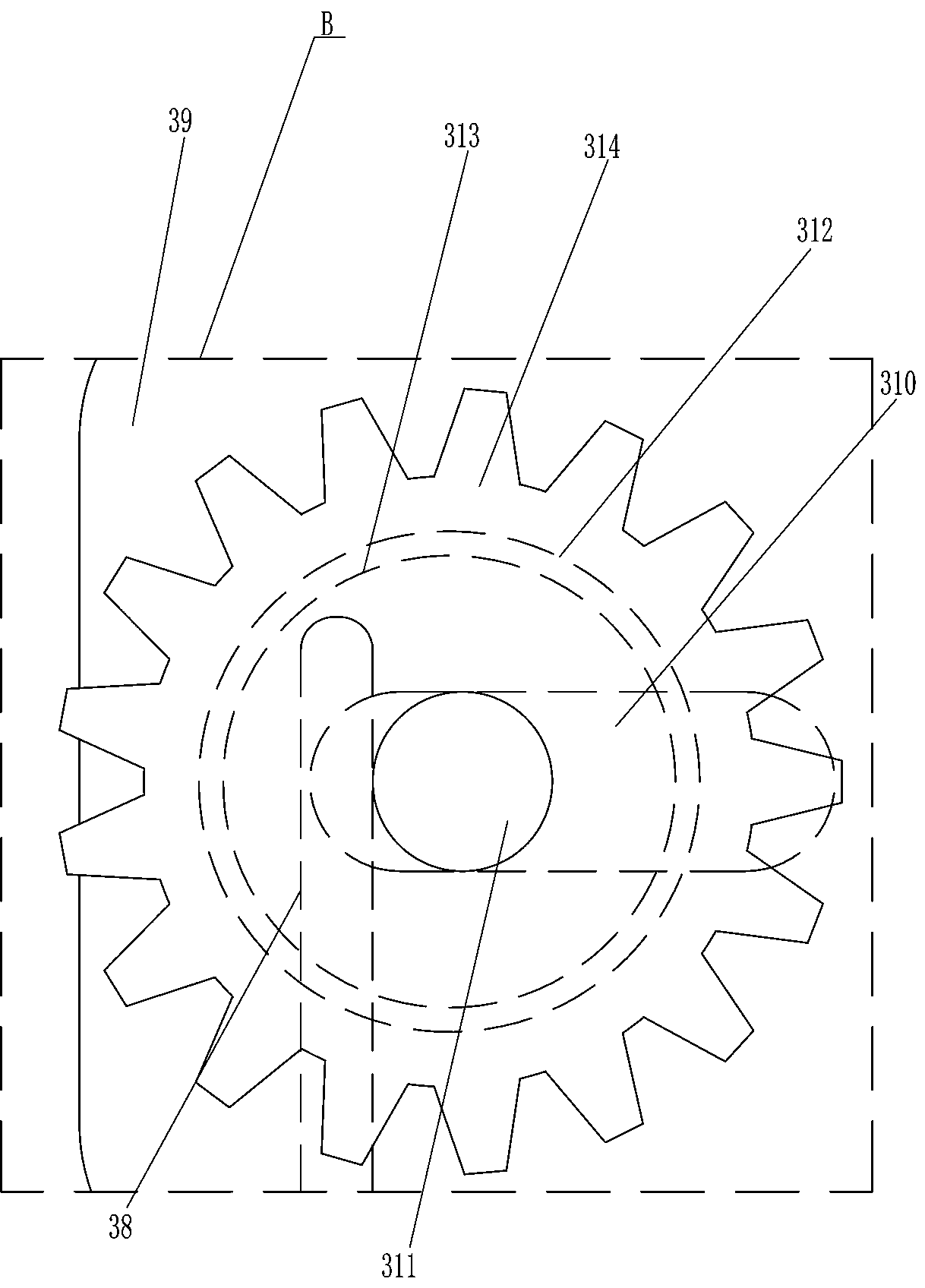

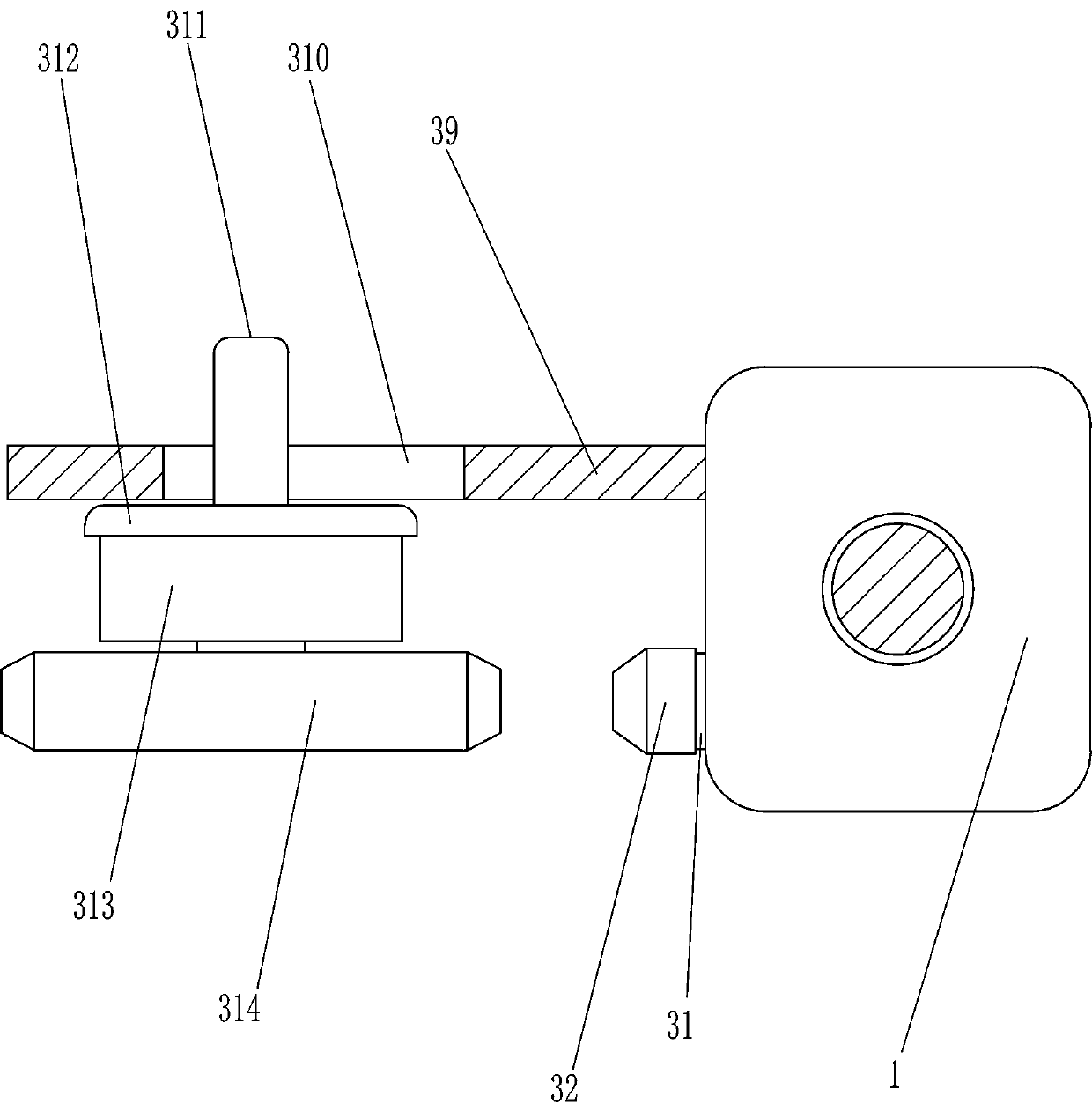

[0020] Propelling device 3 comprises T-shaped push rod 31, tooth bar 32, slide block 34, clamp bar 35, slide bar 36, first spring 37, vertical swing bar 38, mounting plate 39, slide bar 311, mounting plate 312, Geared motor 313, gear 314 and tension spring 315, the sliding type in the hollow branch pipe 1 is provided wit...

Embodiment 2

[0023] On the basis of Example 1, such as figure 1 and image 3As shown, a fixing device 6 is also included, and the fixing device 6 includes a first universal ball joint seat 61, a telescopic rod 62, a riser 63, a second universal ball joint seat 64, an N-shaped handle 65, a first torsion spring 66, double-groove fixed pulley 68, first backguy 69, L-shaped swing bar 610, third spring 611, second backguy 612 and suction cup 613, the first universal ball joint seat 61 is installed on the rear side of the left part of hollow branch pipe 1, The first universal ball joint seat 61 is equipped with a telescopic rod 62 through a universal ball, the other end of the telescopic rod 62 is provided with a second universal ball joint seat 64, and a vertical plate 63 is installed on the left side of the second universal ball joint seat 64, The middle part on the right side of the riser 63 is hingedly connected with an N-type handle 65, and the hinge between the N-type handle 65 and the ri...

Embodiment 3

[0026] On the basis of Example 2, such as figure 1 As shown, it also includes a third universal ball joint seat 7 and a supporting plate 8, a third universal ball joint seat 7 is installed at the bottom of the guide sleeve 4, and a support for supporting stability is installed at the bottom of the third universal ball joint seat 7 plate 8.

[0027] It also includes a mounting rod 9, a rolling block 10 and a second torsion spring 11. The mounting rod 9 is installed on the top of the placement frame 2, and the rolling block 10 is installed on the top of the mounting rod 9 through a hinge connection, and the mounting rod 9 is connected to the rolling block 10. A second torsion spring 11 is provided.

[0028] When the operator is using the glass glue to smear the glass window frame, the operator can support the shoulder with the supporting plate 8, which can make the operator more stable and labor-saving when smearing the glass glue.

[0029] Because the rolling block 10 is in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com