Building beam column reinforcement cage main reinforcement positioning frame

A technology for steel cages and buildings, applied to online networks, other household appliances, household appliances, etc., can solve the problems of affecting the construction period, long time for making steel cages, and complicated position calibration, so as to achieve reliable and accurate arrangement positions and facilitate popularization and use , Take out the effect of simple and labor-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

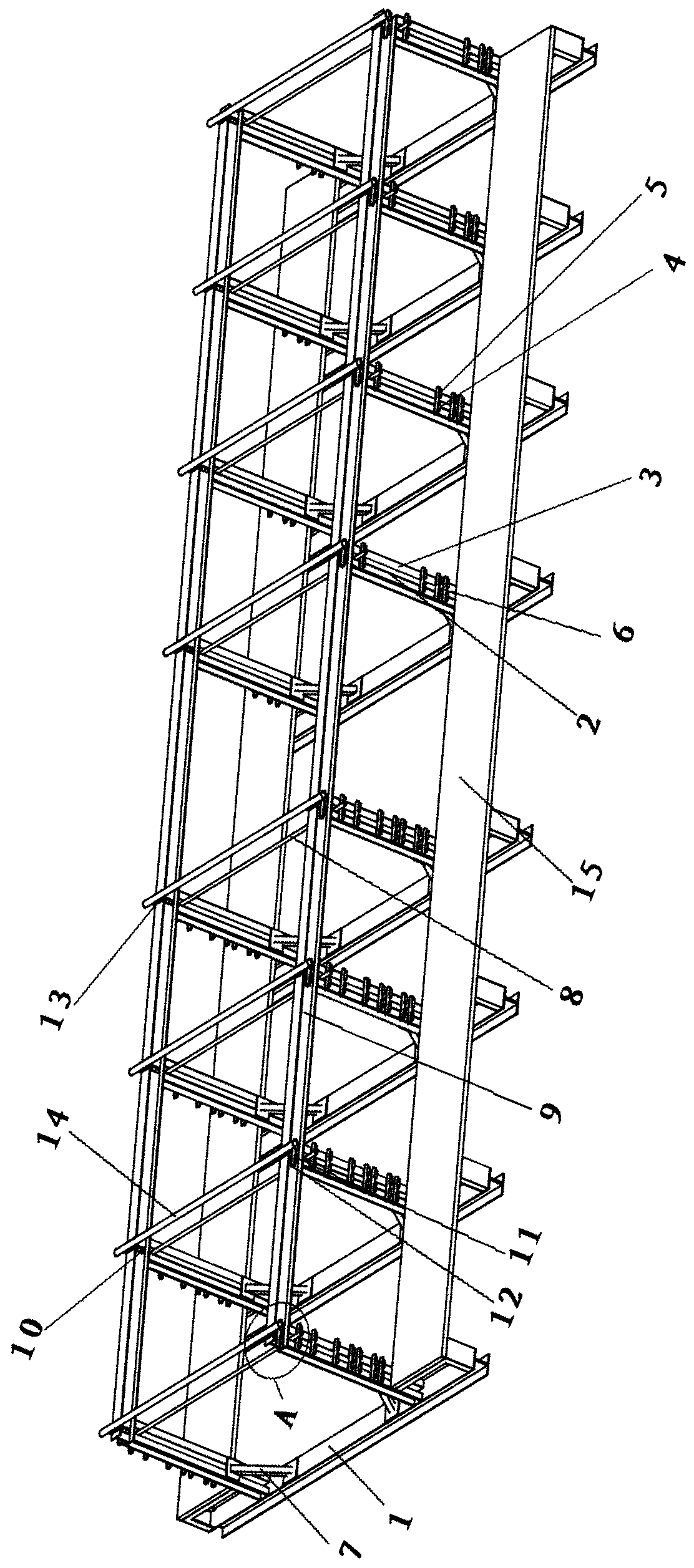

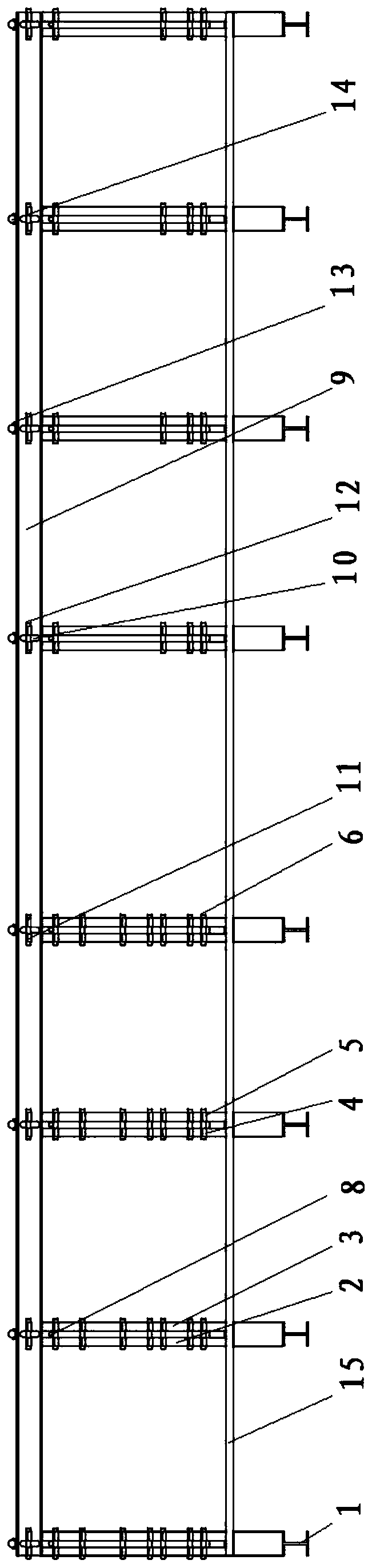

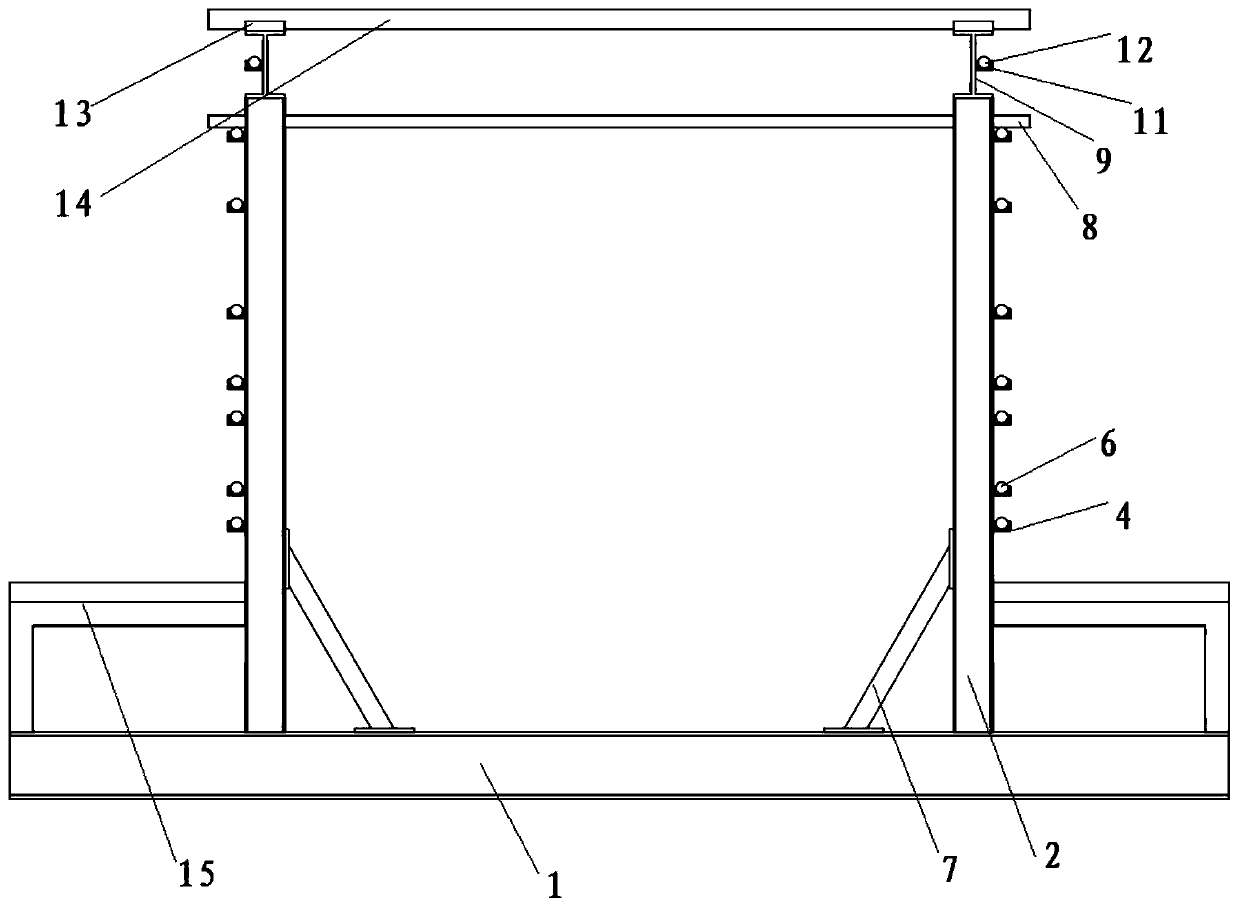

[0030] Such as Figure 1 to Figure 5 Shown, the present invention comprises two top support steel beams 9 that are arranged in parallel, a plurality of reinforcement cage load-bearing rods 14 that are arranged on top of the two top support steel beams 9 in parallel along the length direction of the top support steel beams 9 and a plurality of The length direction of the top supporting steel beams 9 is parallel to the supporting positioning mechanism arranged at the bottom of the two top supporting steel beams 9. The number of the supporting positioning mechanisms is equal to the number of the steel cage load-bearing bars 14 and corresponds one by one. The main reinforcement 17 is built on the steel cage load-bearing rod 14, the stirrup 16 is sleeved outside the main reinforcement 17, and the side wall of the top supporting steel beam 9 is provided with a plurality of limiting through holes 10 for the positioning rod 8 to pass through, each top The quantity of the limit through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com