Multi-station numerical control machining tool

A CNC machining machine tool and multi-station technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the accuracy of recycling processing, increasing processing procedures, and reducing work efficiency, so as to achieve easy sorting, The effect of improving work efficiency and saving processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

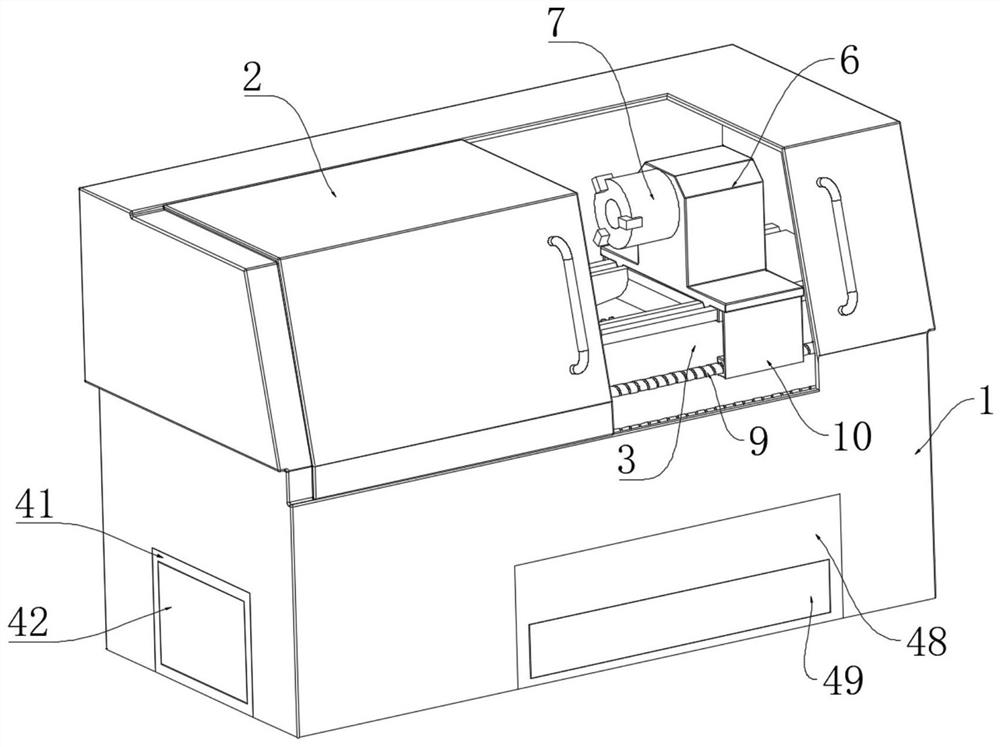

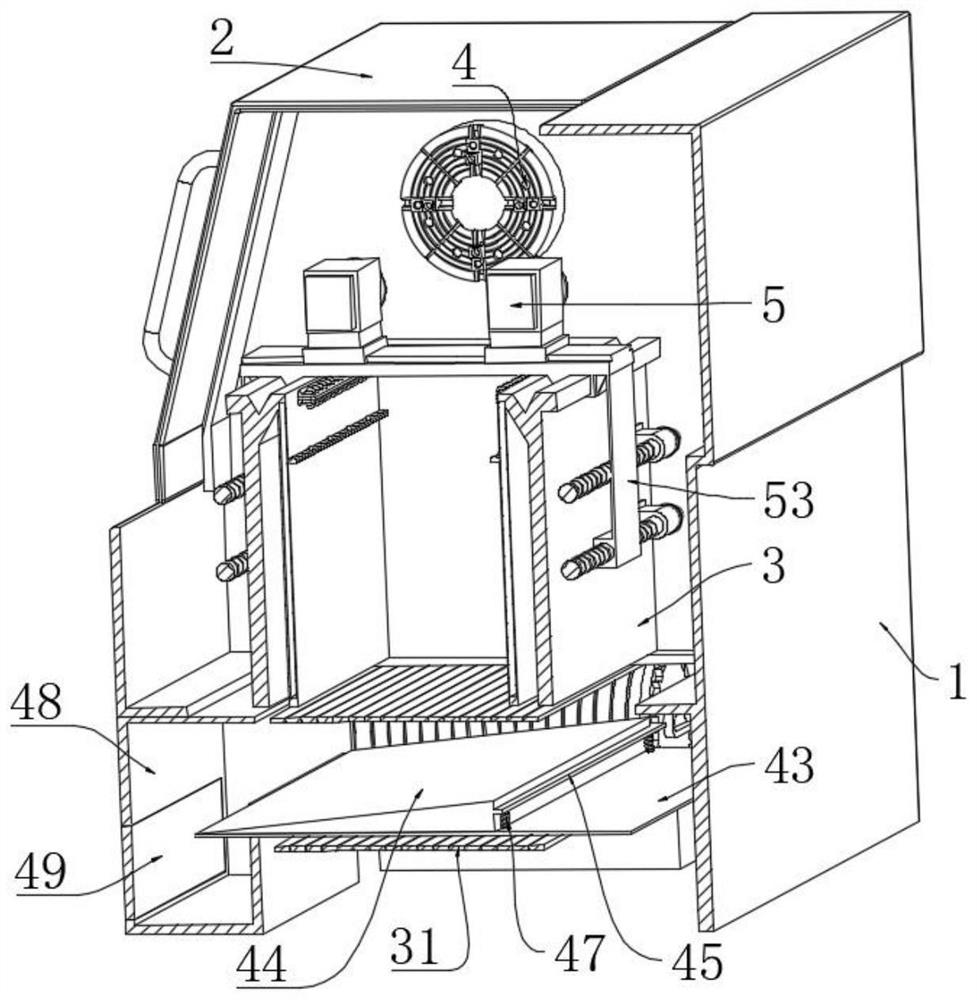

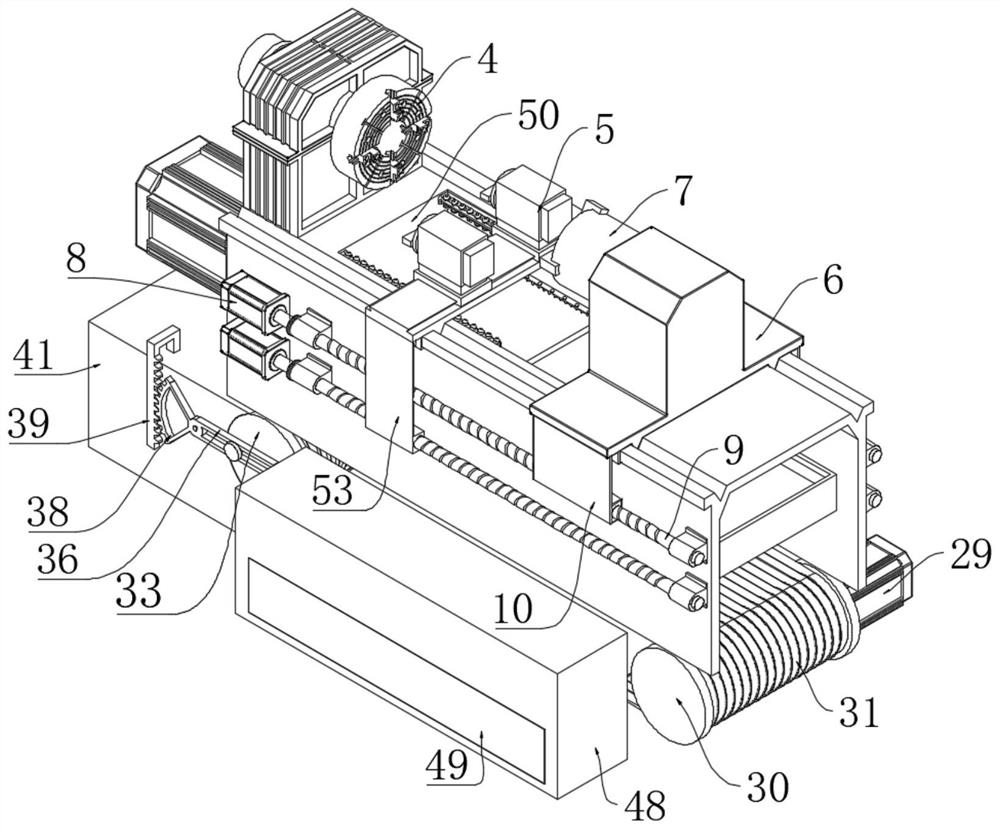

[0032] Such as Figure 1-11 The shown multi-station numerical control processing machine tool includes a box body 1, a movable door 2 is slidably installed on one side of the box body 1, a workbench 3 is fixedly installed inside the box body 1, and a The material receiving port 50, the four-jaw chuck 4 is fixedly installed on the workbench 3 by bolts, the top of the workbench 3 is slidably installed with a mobile frame 53 and a mobile table 6, and the mobile frame 53 is located between the mobile table 6 and the four-jaw chuck 4 In between, the top of the mobile frame 53 is slidably connected with a variety of cutting tools 5 with adjustable positions, and the mobile frame 53, the mobile platform 6 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com