Welding device for keyboard circuit board

A keyboard circuit board, welding device technology, applied in auxiliary devices, printed circuits, welding equipment and other directions, can solve problems such as large factory space occupation, insufficient automation, and waste easily polluting the factory environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

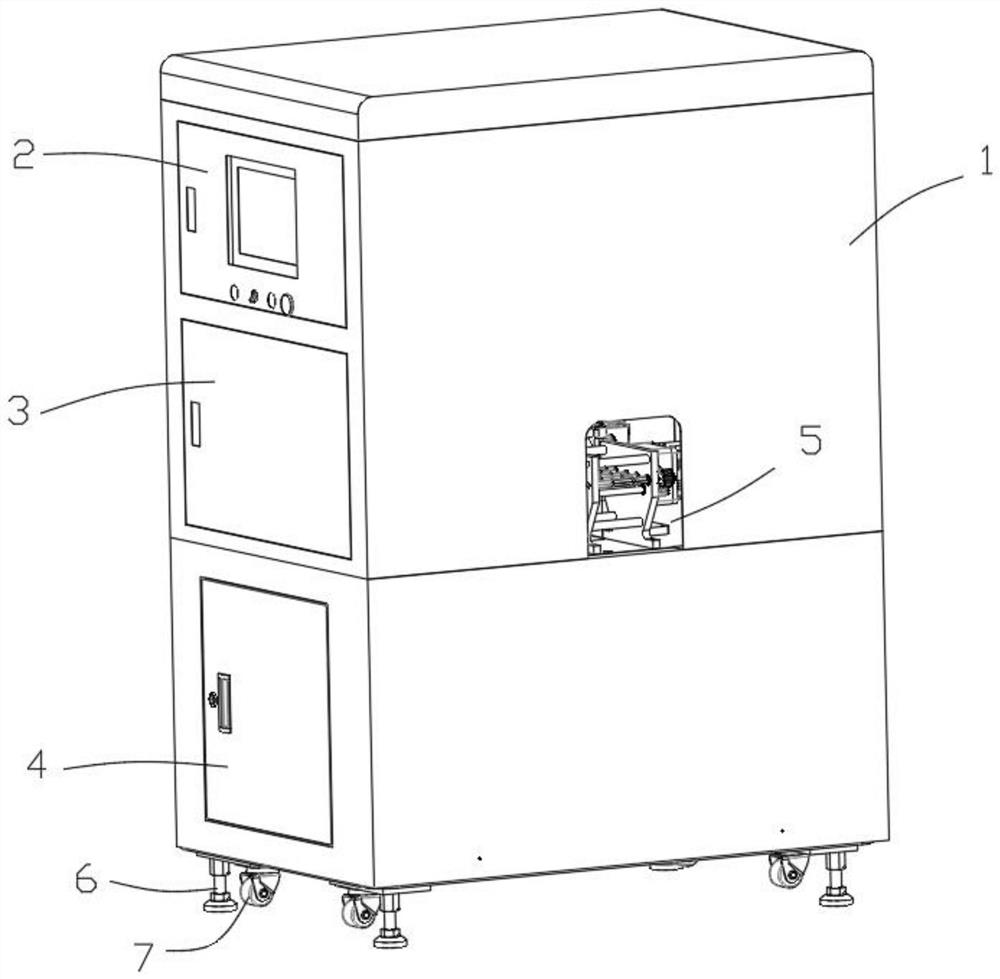

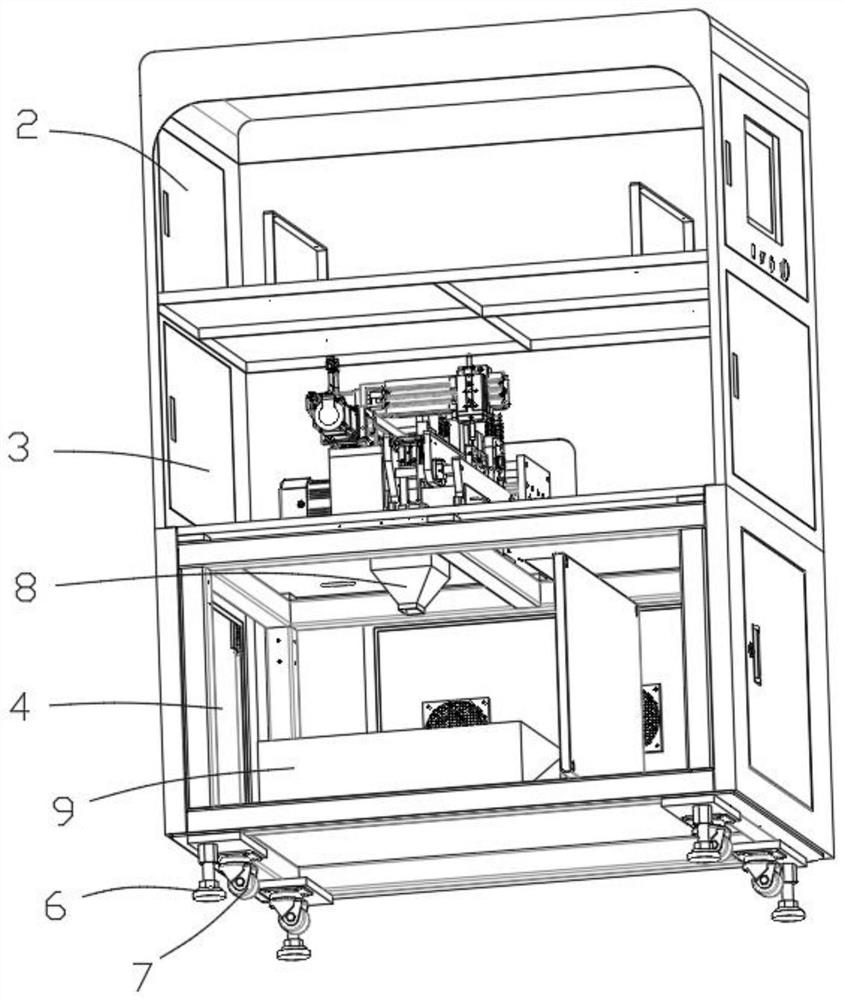

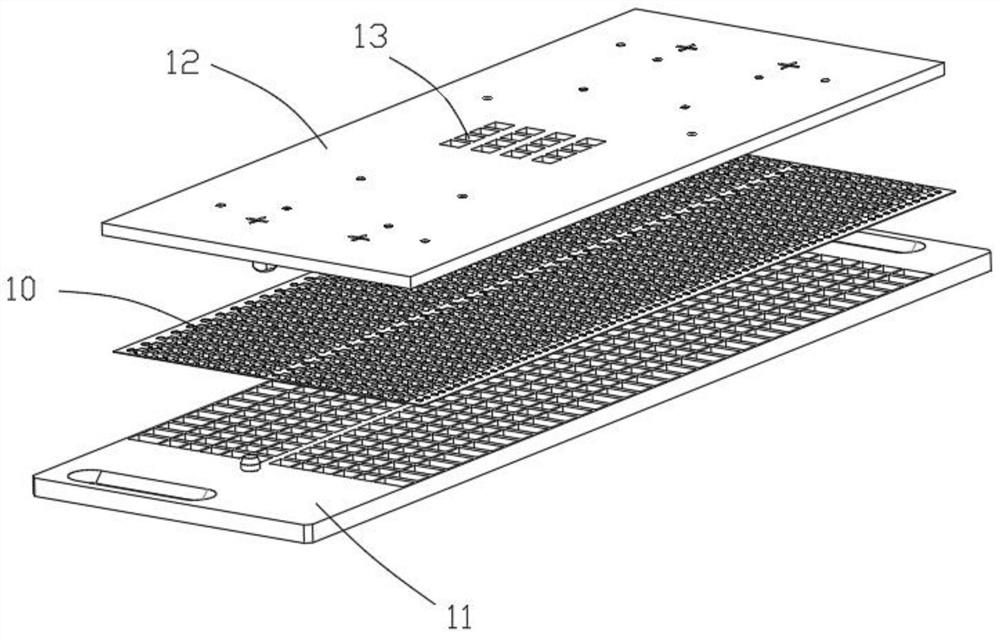

[0060] Such as Figure 1-Figure 11 As shown, the present embodiment provides a welding device for the keyboard circuit board 10 (hereinafter referred to as the welding device), which is applicable to automatic welding of the keyboard circuit board 10 installed in the jig 169, further, it can also be Automatic cleanup, automatic detection, etc. Specifically, it includes a cabinet body 1, and the inside of the cabinet body 1 is divided into an upper space 2, a middle space 3 and a lower space 4 by partitions. The middle space 3 is provided with a feeding assembly 14 and a welding delivery platform 15 . The feed assembly 14 is used to receive the jig 169 with the keyboard circuit board 10 installed from the outside of the cabinet 1, the welding delivery platform 15 is used to receive the jig 169 delivered by the feed assembly 14, and the multi-axis welding mechanism 16 is used to align the jig Multiple positions of the keyboard circuit board 10 on the 169 are welded. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com