Full-automatic seal ring edge repairing machine

A sealing ring and trimming machine technology, which is applied in the field of grinding and polishing equipment, can solve the problems of wasting labor costs, poor product consistency, and low labor efficiency, so as to save labor costs, save tool setting time, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

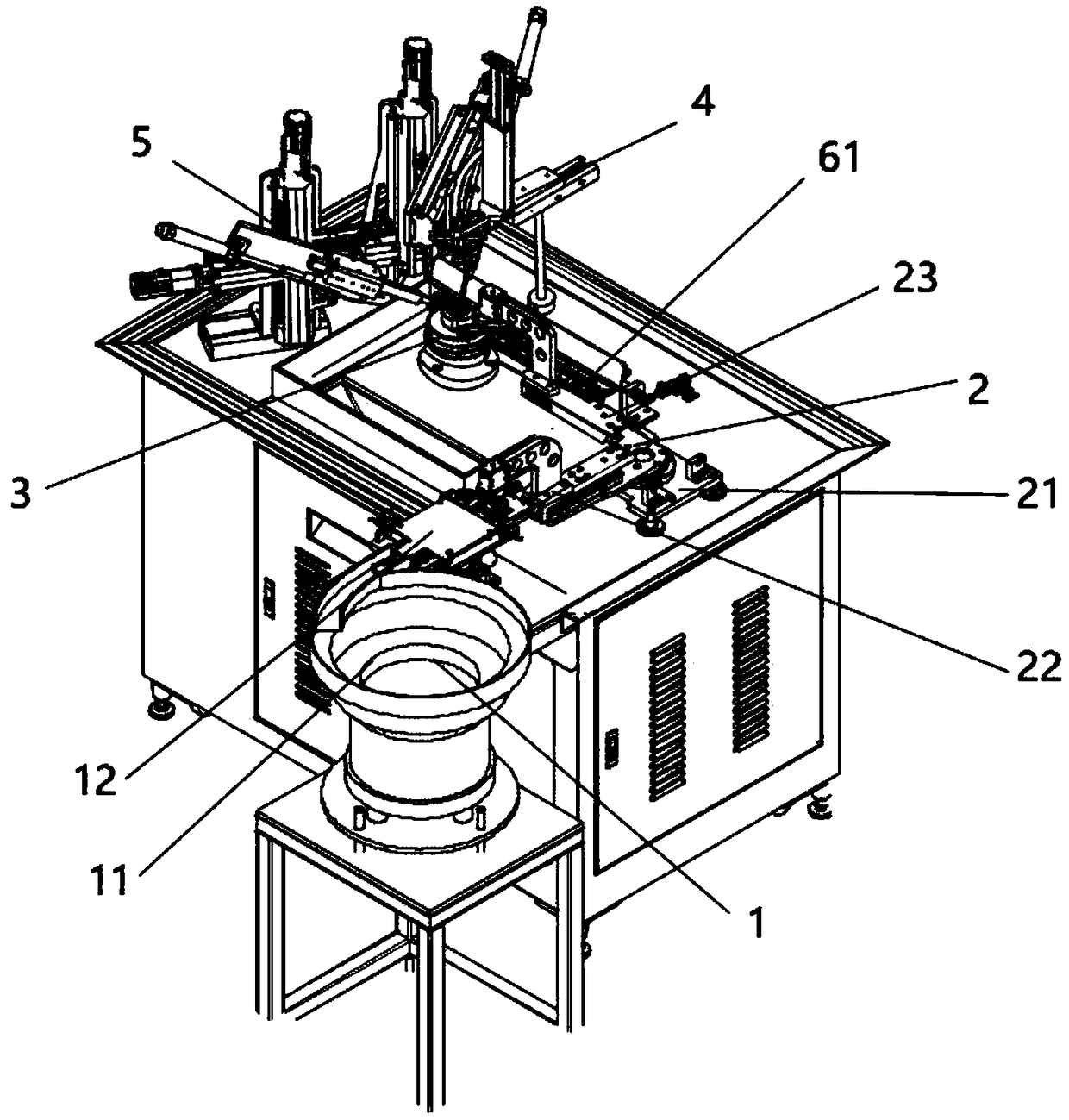

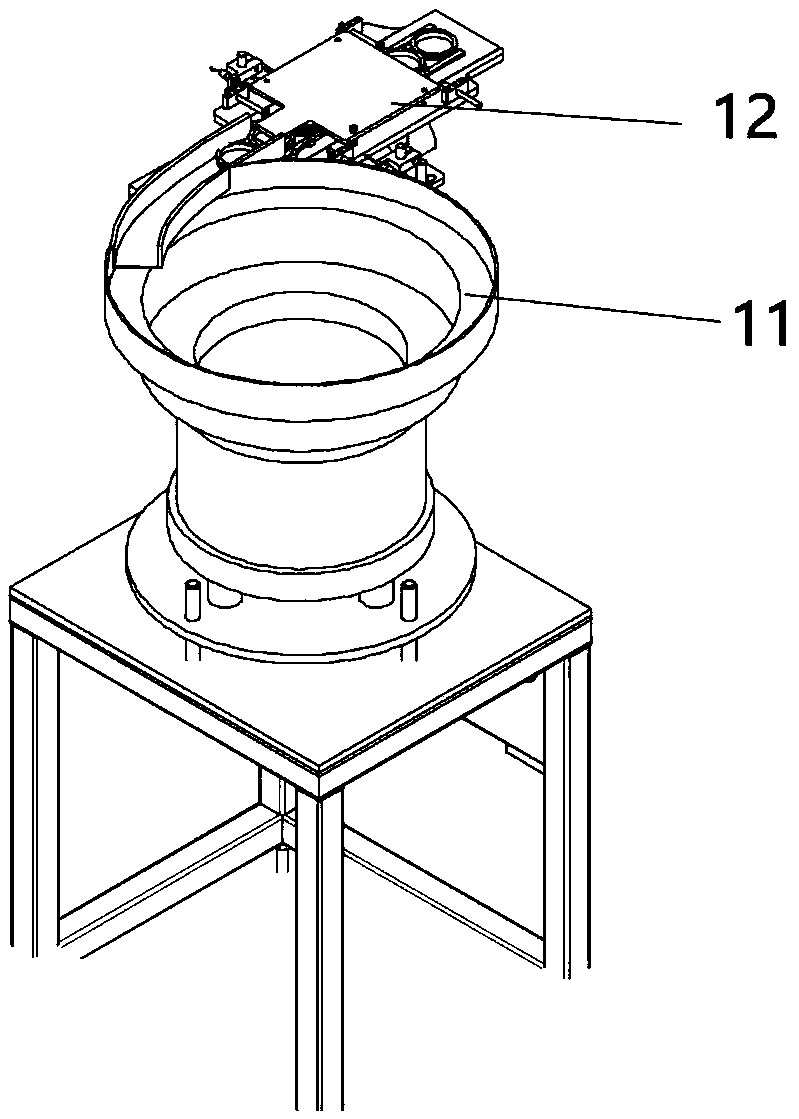

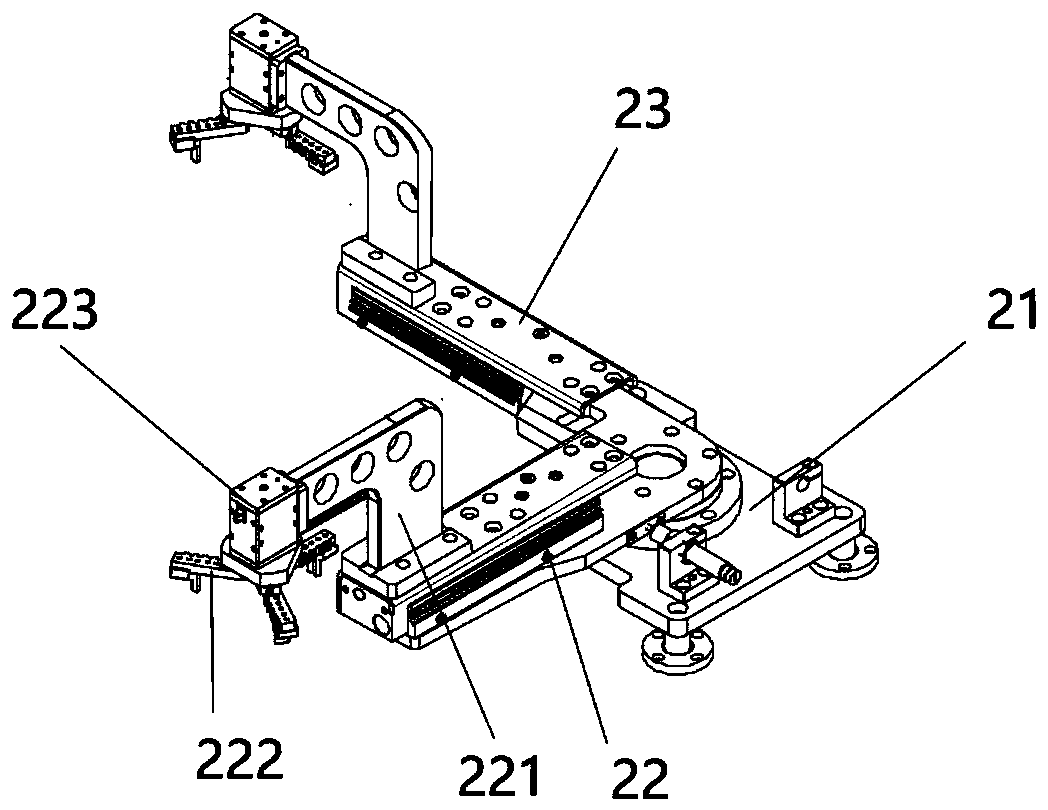

[0042] Such as figure 1 As shown, the present invention discloses a fully automatic sealing ring trimming machine, comprising a feeding device 1, a clamping device 2, a mold 3, a pressing wheel device 4, a trimming device 5 and a waste collection device 6; The device 1 comprises a vibrating plate 11 and a direct shock 12, such as figure 2, the inside of the vibrating plate 11 is a spiral structure, the outlet of the vibrating plate 11 is connected to the feed port of the straight vibrator 12, and the vibrating plate 11 is used to ensure that the step surface of the material faces upward; the straight vibrator 12 Infrared sensors 121 are arranged on both sides to detect whether the material is in place; the clamping device 2 includes a feeding jaw 22 and a lowering jaw 23, and the loading jaw 22 is used to clamp the material into the mold 3 Middle; the blanking jaw 23 is used to clamp the trimmed material in the mold 3 .

[0043] Such as Figure 5 As shown, the mold 3 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com