Method for using hot isostatic pressing to produce double-alloy blisk

A hot isostatic pressure diffusion, integral blisk technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as difficulty, many influencing factors, and complex processes, and achieve the effect of reducing difficulty and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

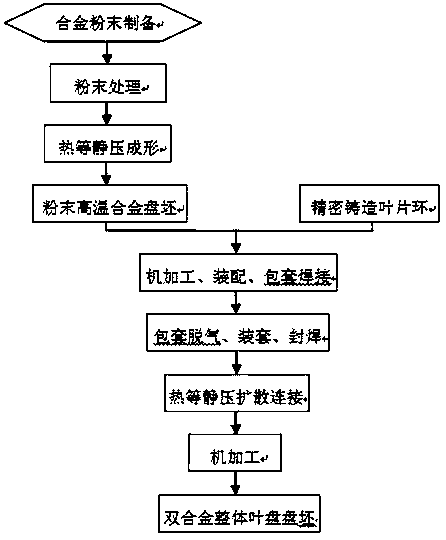

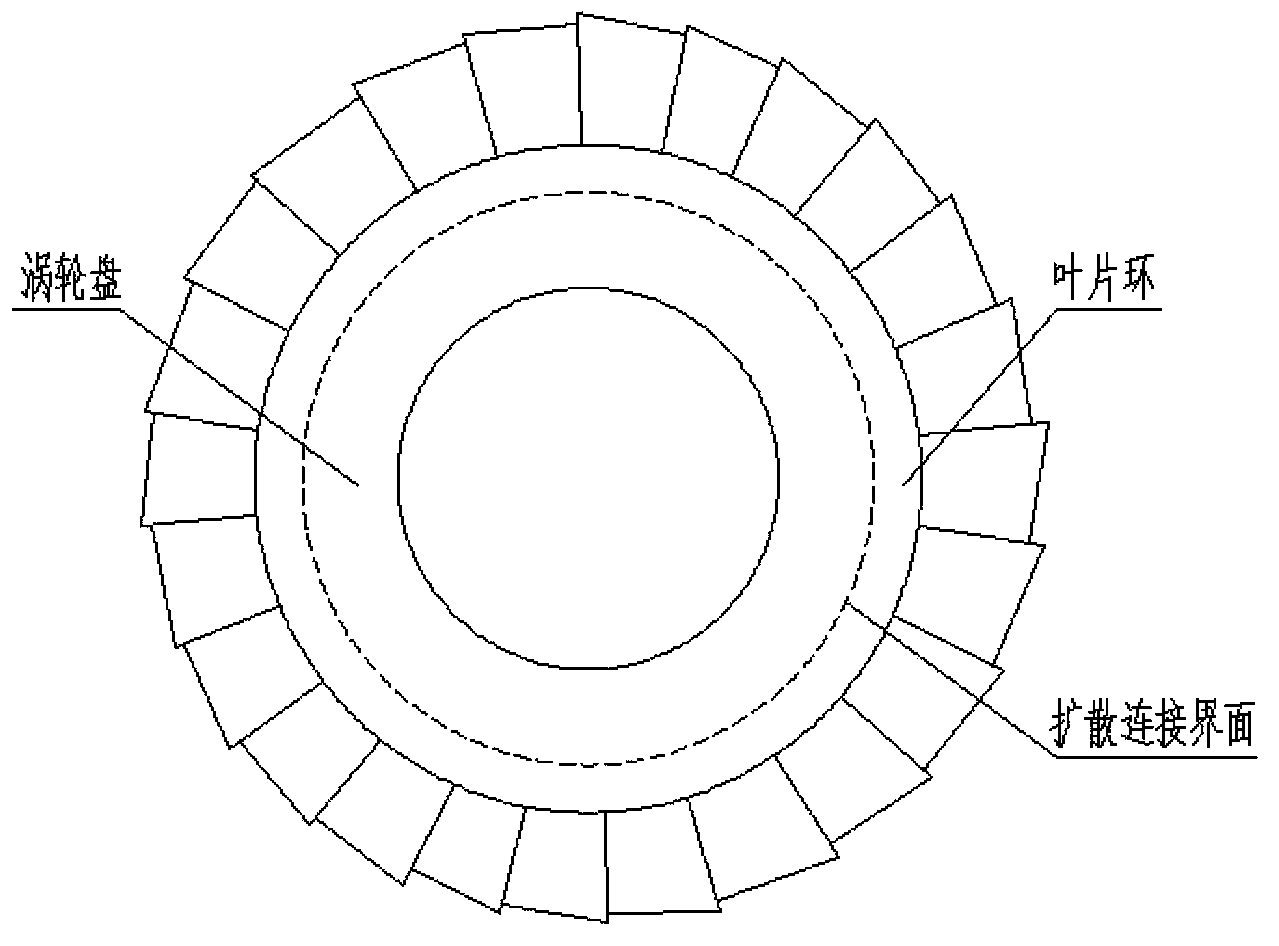

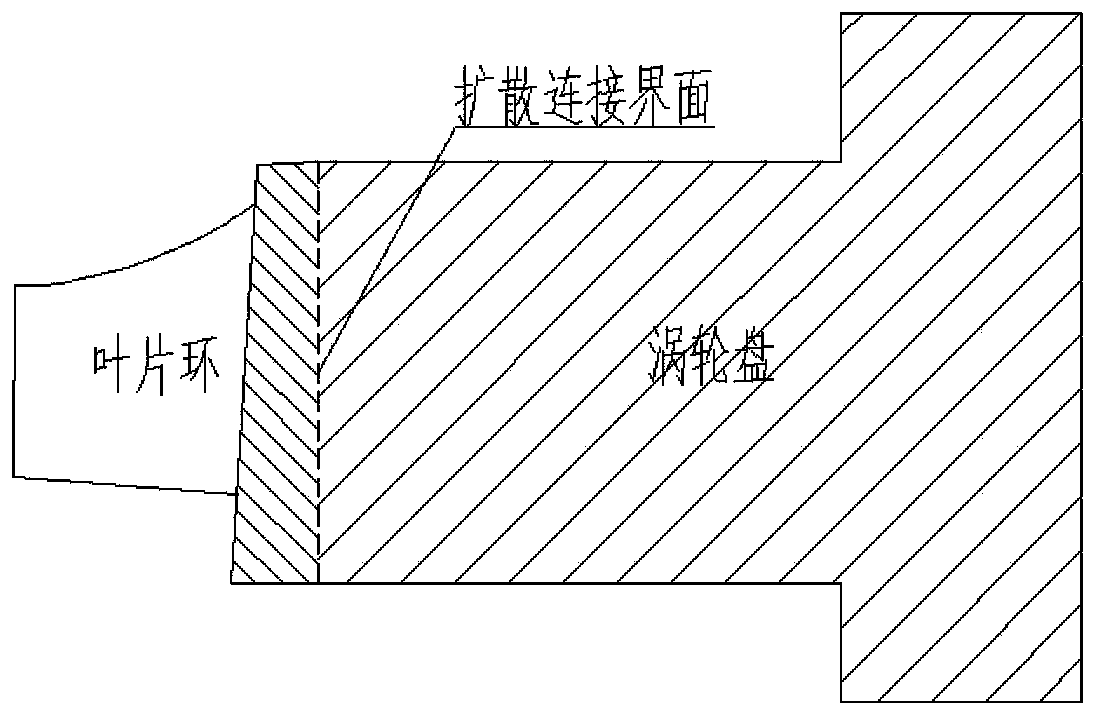

[0021] combined with figure 1 Further explain the method of the present invention to prepare a double-alloy blisk by using superalloy powder as the intermediate layer hot isostatic pressure diffusion connection. The body of the double-alloy blisk is a powder superalloy FGH91, and the blade ring is a cast superalloy K418B.

[0022] (1) Prepare FGH91 superalloy powder by plasma rotating electrode method, powder sieving, electrostatic de-inclusion treatment, and then undergo hot isostatic pressing (1180~1200℃ / 4h / 130MPa) to make dense powder superalloy disk blank;

[0023] (2) The K418B blade ring formed by precision casting and the FGH91 disk blank are machined, gap assembled and welded, and the gap size between the inner diameter of the blade ring and the outer diameter of the disk is 1~2mm to make a double alloy integral blade disk jacket;

[0024] (3) Select FGH91 alloy powder with the same chemical composition, particle size composition, and purity as the disc body, and use i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com