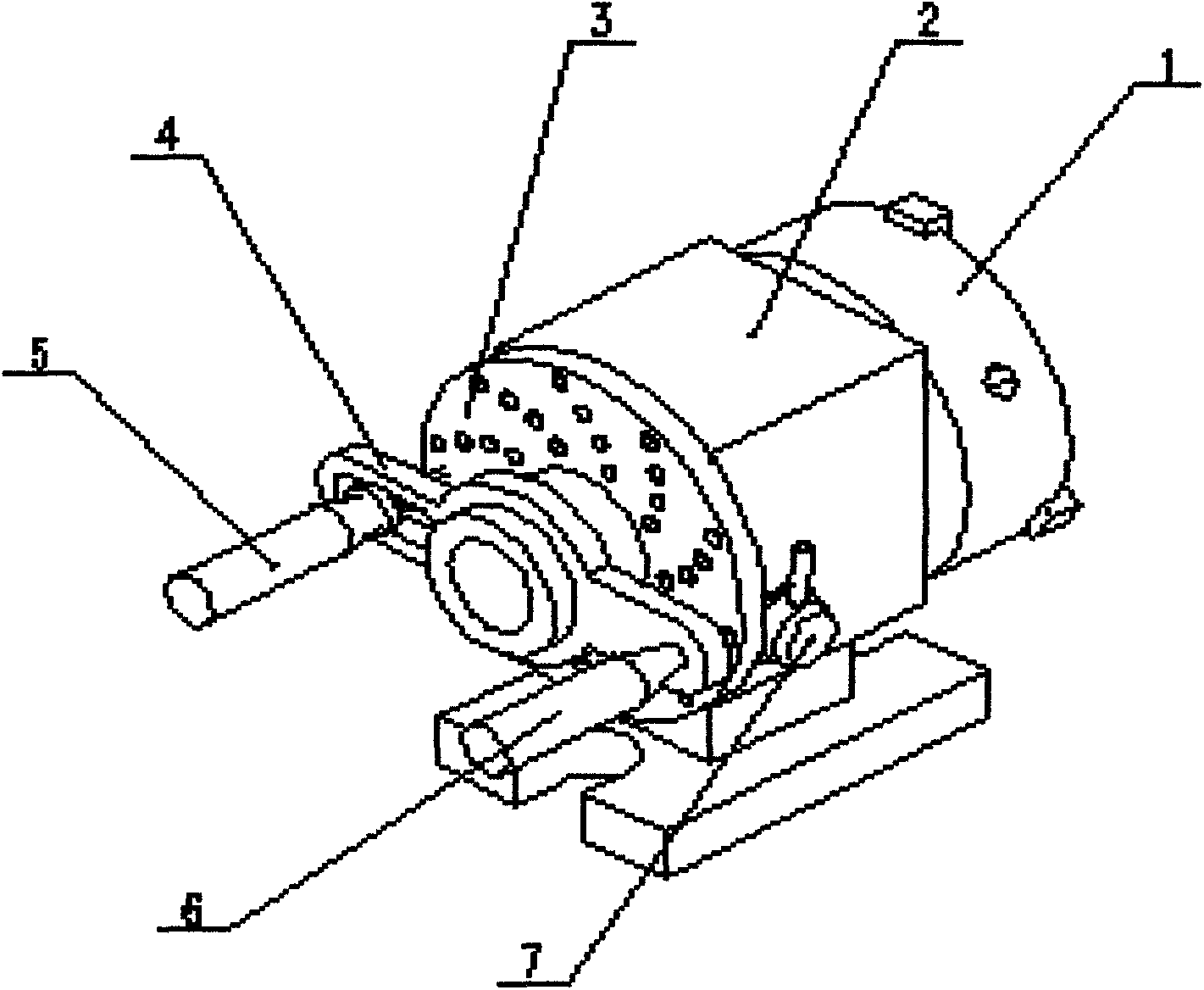

Simple indexing head

A dividing head, simple technology, applied in the direction of metal processing machinery parts, precision positioning equipment, metal processing equipment, etc., can solve the problems of bulky, bulky dividing head, inconvenient use, etc., to achieve small size and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] When manufacturing, the shape of the bracket is produced first, and cast iron material is used for pouring. The inner holes at both ends of the bracket are equipped with bearings, and the chuck shaft passes through the bearings and is connected with the fixed sleeve by threads. When assembling, pay attention to the bearing clearance. It is not easy to be large enough. If the clearance is too large, it will cause indexing errors. There is a locking handle in front of the stand. This locking handle is used to lock the chuck shaft. The purpose is to fix the chuck shaft without being affected by external forces when marking the line, and to operate normally. The scale line from 1 to 360° is engraved on the chuck for easy degree adjustment. The disk is fixed on the side of the stand with threads, and there are indexing holes on the disk, which are used to fix the degree. When in use, shake the rocker, after adjusting the degree, insert the fixed rod into the indexing hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com