Rubber belt track iron tooth with trapezoidal guide rail surfaces

A rubber track and guide rail surface technology, applied in the field of track iron teeth, can solve the problems of affecting the service life of the track, falling into the gap, noise, etc., and achieve the effect of reducing track derailment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

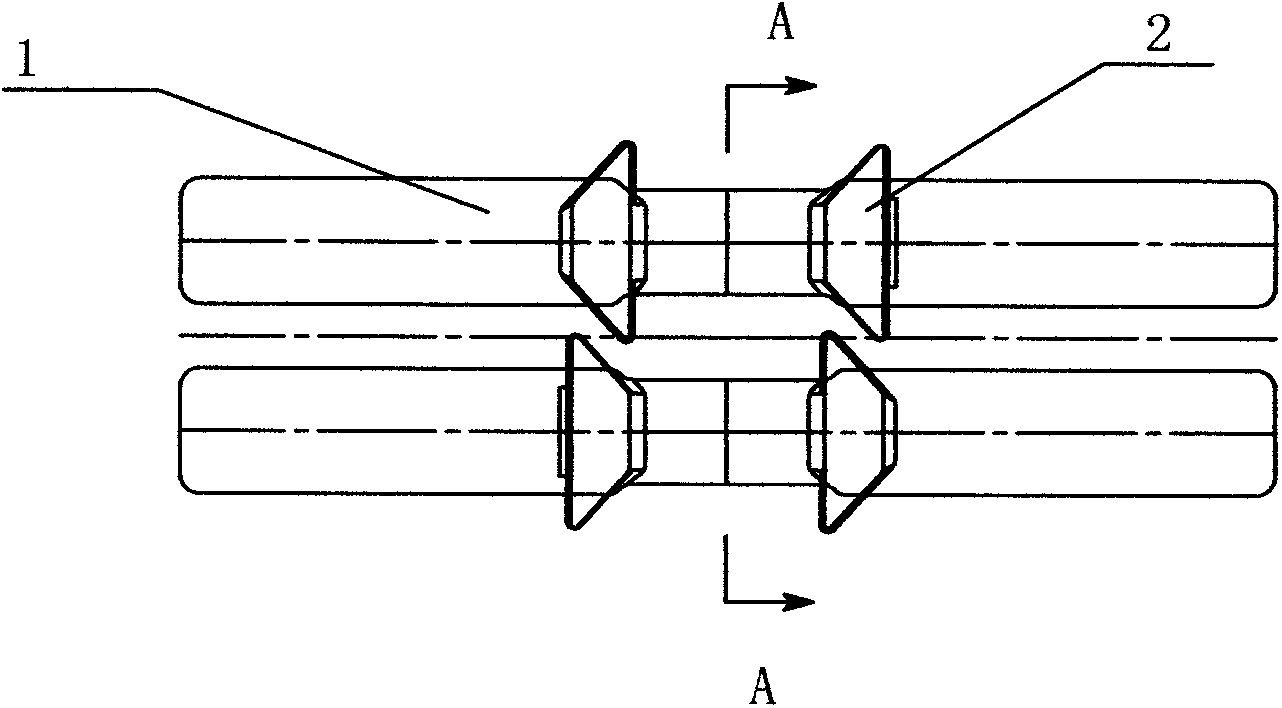

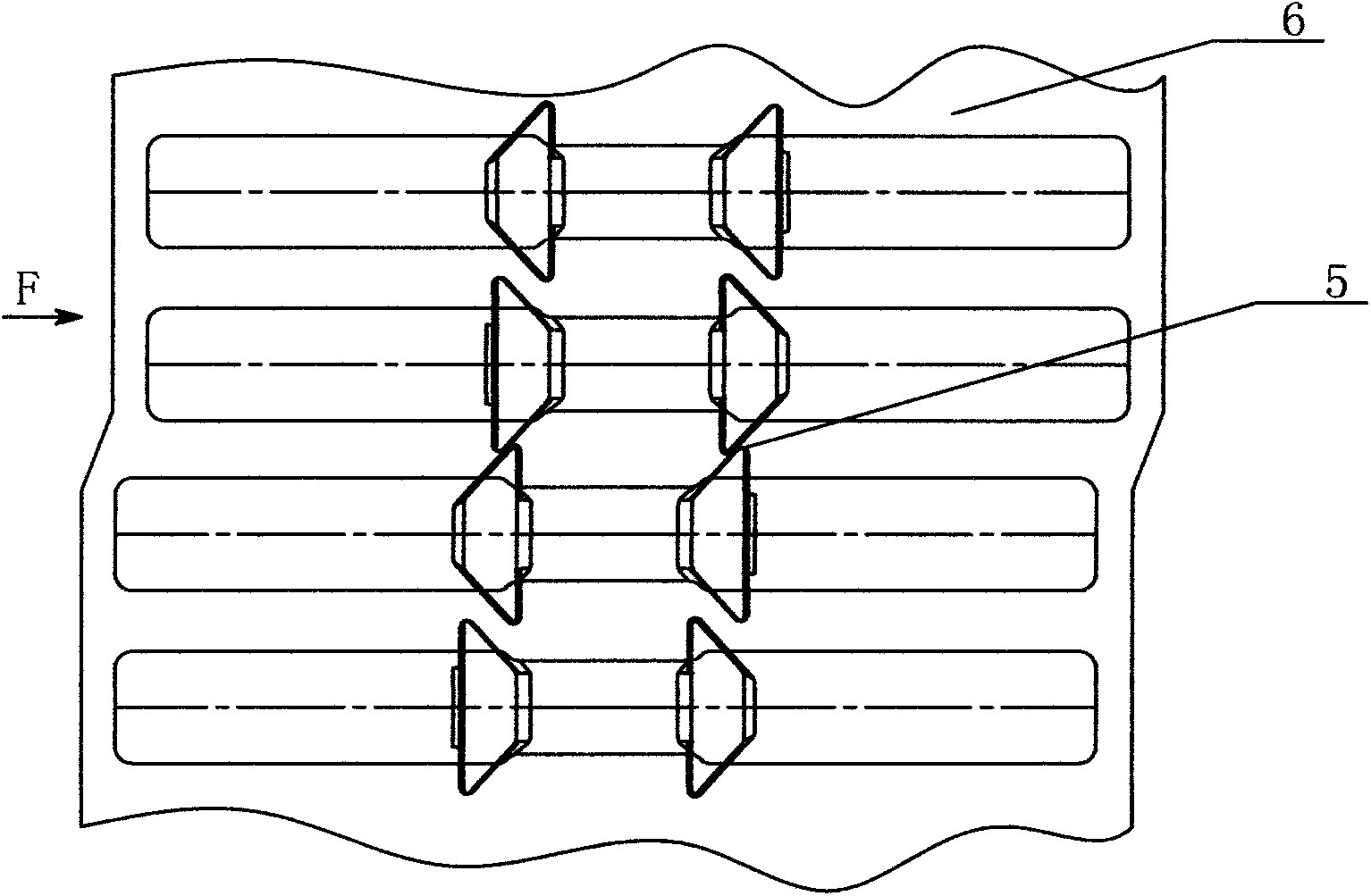

[0016] A rubber crawler iron tooth with a trapezoidal guide rail surface, including an iron tooth body 1, trapezoidal guide rail surfaces 2 in the same direction are arranged on the left and right sides of the iron tooth body 1, and the trapezoidal track surfaces 2 on the upper and lower adjacent sides are in different directions.

[0017] In this embodiment, the horizontal projections of the trapezoidal track surfaces 2 adjacent to the upper and lower sides have overlapped parts.

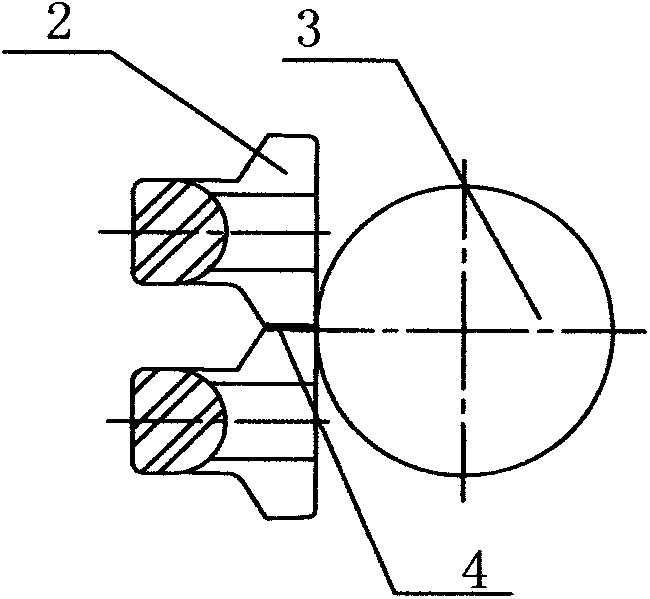

[0018] as attached figure 1 , 2 As shown, trapezoidal guide rail surfaces 2 on the left and right sides are formed on the iron tooth body part 1 of the rubber crawler, and the left and right sides are arranged in the same direction, and the upper and lower adjacent trapezoidal guide rail surfaces 2 are arranged in opposite directions, which are laid in the mold in turn and vulcanized with rubber. , the track roller 3 walks on the trapezoidal guide rail surface 2, and the upper and lower adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com