Rotary actuated high lift gapped aileron

A technology of rotary actuation and rotary actuator, which is applied in the directions of wing adjustment, fuselage bulkhead, transportation and packaging, etc., and can solve problems such as heavy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following detailed description is exemplary in nature and is not intended to limit the application and uses of the disclosure or embodiments of the disclosure. Descriptions of specific devices, techniques, and applications are provided as examples only. Modifications to the examples described herein will be readily apparent to those skilled in the art, and the general principles defined herein may be applied to other examples and applications without departing from the spirit and scope of the present disclosure. The present disclosure should be accorded scope consistent with the claims, and not limited to the examples described and shown herein.

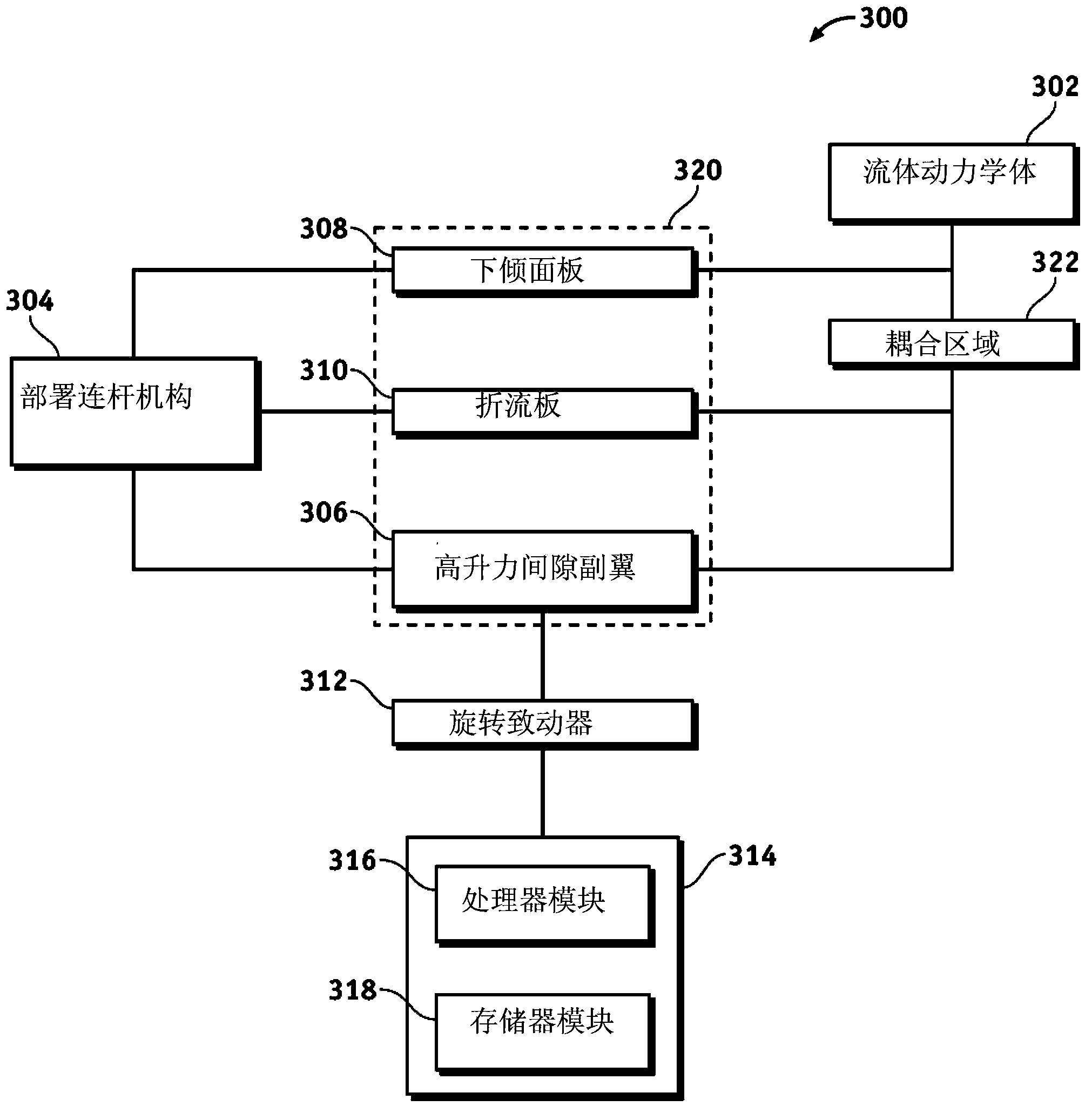

[0020] Embodiments of the present disclosure may be described herein in terms of functional and / or logical block components and various procedural steps. It should be appreciated that such structural components may be realized by a number of hardware, software and / or firmware components configured to perform the specified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com