Automatic disassembly connection structure and touch all-in-one machine

A connection structure and automatic disassembly technology, applied in the field of TV, can solve the problems of easily damaged product appearance, cumbersome disassembly process, low production delivery rate, etc., and achieve the effect of reducing the difficulty of installation and disassembly, and reducing the difficulty of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

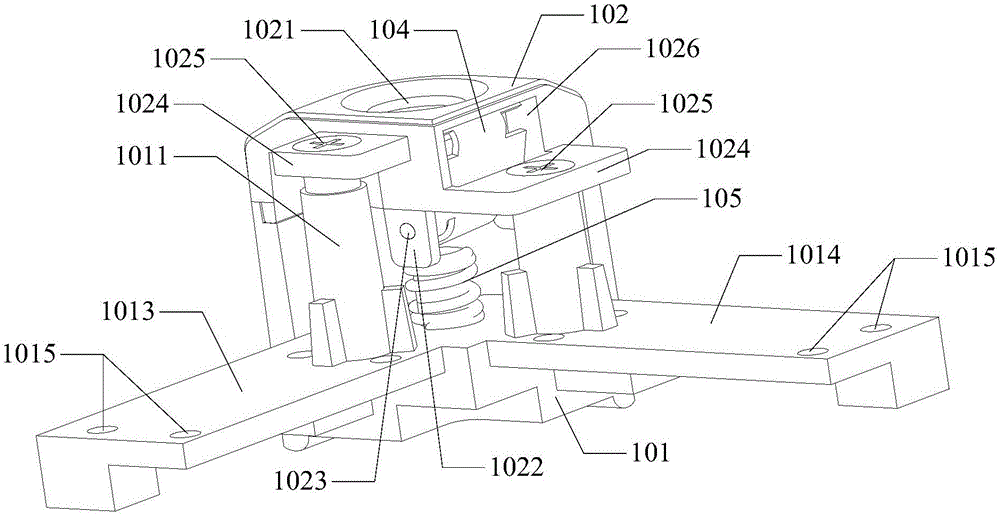

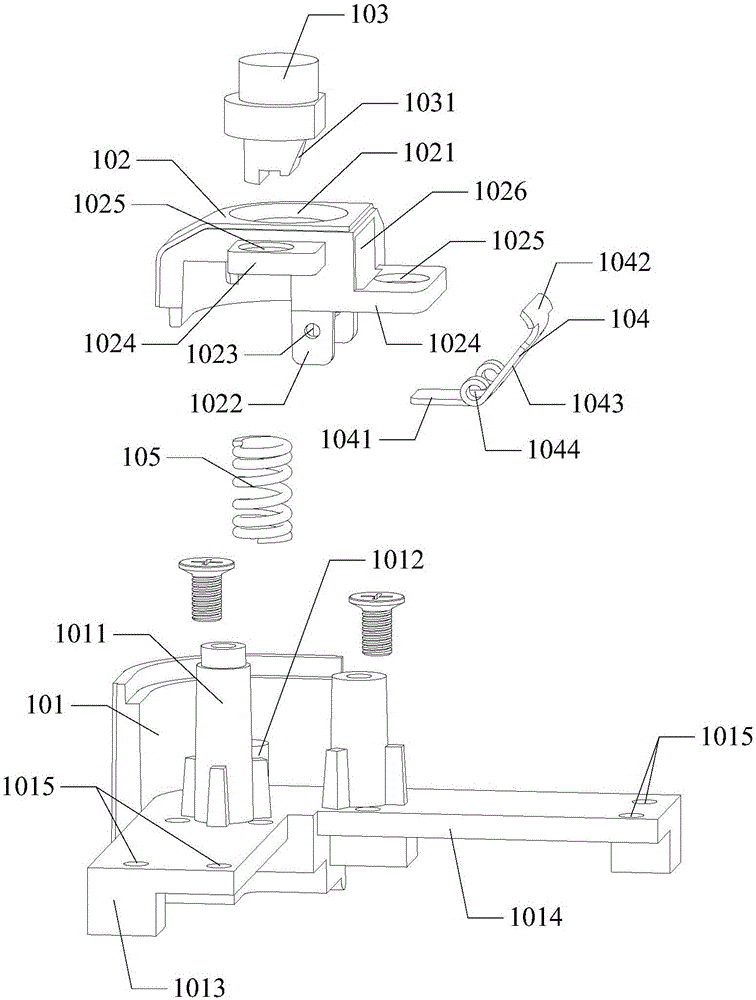

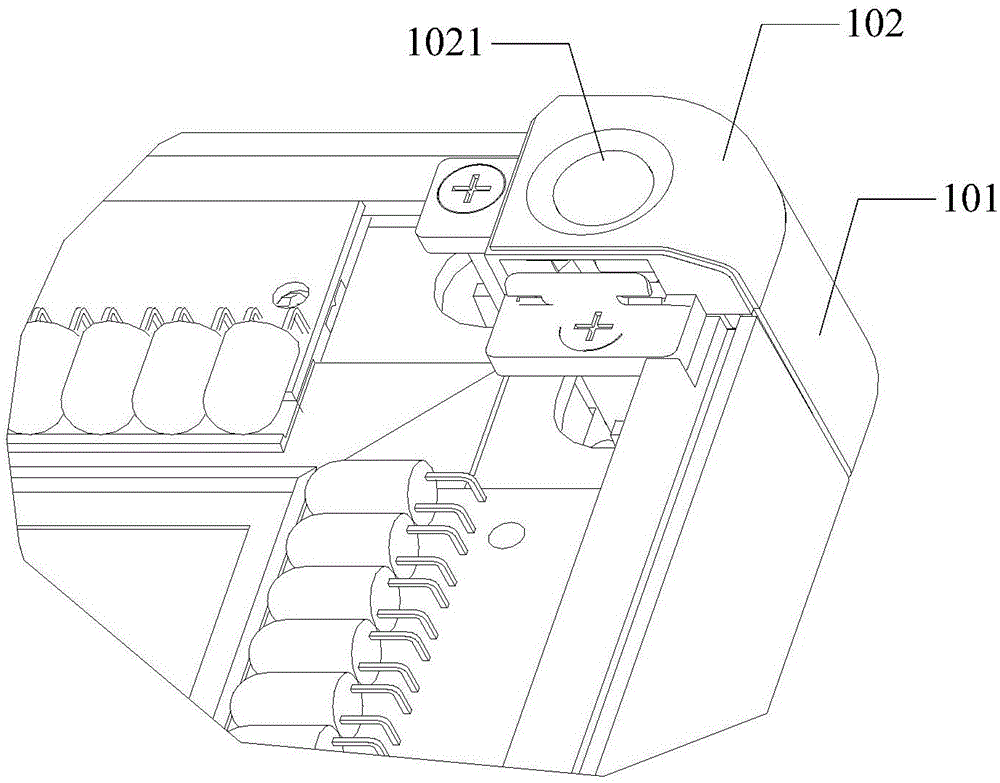

[0024] refer to Figure 1 to Figure 5 , figure 1 It is a structural schematic diagram of an embodiment of the automatic disassembly and assembly connection structure of the present invention; figure 2 It is an exploded schematic diagram of the automatic disassembly and assembly connection structure of the present invention; image 3 It is a structural schematic diagram of the connection between the automatic detachable connection structure of the present invention and the first fixing member; Figure 4 It is a structural schematic diagram of the engagement and fixing of the spring piece and the second fixing member of the automatic disassembly and assembly connection structure of the present invention; Figure 5 It is a structural schematic diagram of the automatic detachable connection structure of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com