Cementing type double-umbrella-shaped and three-umbrella-shaped disk-shaped suspension type polymer composite string insulator unit

A composite insulator, polymer technology, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of complex operating conditions, reduced creepage distance utilization, affecting the safe operation of polymer insulators, etc., to improve pollution. The effect of lightning voltage, excellent hydrophobicity, fast and convenient maintenance and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

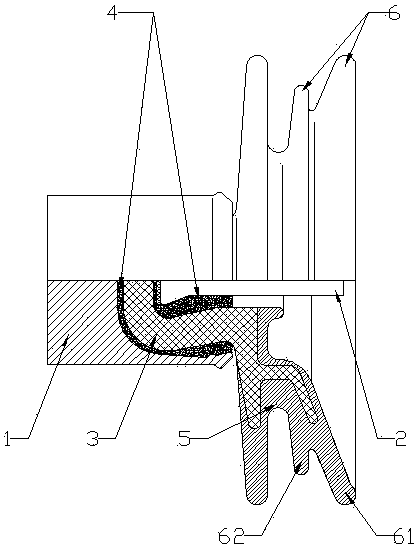

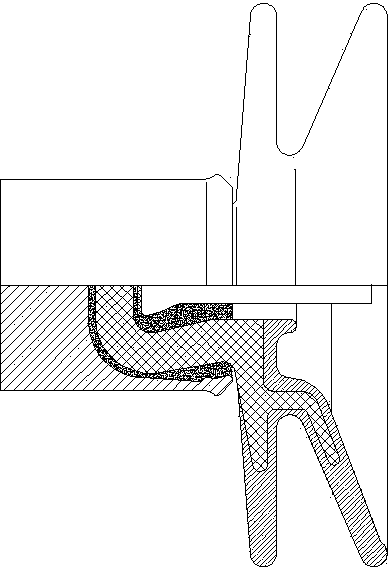

[0022] In order to better understand the purpose, structure and function of the present invention, the glue-mounted double-umbrella and triple-umbrella disk-shaped suspension polymer composite insulator string components proposed in the embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings .

[0023] Such as figure 1 As shown, the glue-mounted double-umbrella-shaped and three-umbrella-shaped disc-shaped suspension polymer composite insulator string elements proposed in the first embodiment of the present invention include: steel cap fittings 1, steel foot fittings 2, insulating core parts 3, polymer Sheath 5, polymer umbrella skirt 6; wherein said steel cap fitting 1 is provided with a cavity with a U-shaped section inside, and said steel foot fitting 2 is provided with a conical head matching said cavity position; the cone head part of the steel foot fitting 2 is set in the cavity of the steel cap fitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com