Patents

Literature

53 results about "Polymer insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer insulators were first developed in the 1950s to replace conventional ceramic insulators. They were not, however, available until the 1960s because of initial design flaws. These insulators are generally constructed of fiberglass reinforced polymer rods and a polymer housing.

Lightning arrester

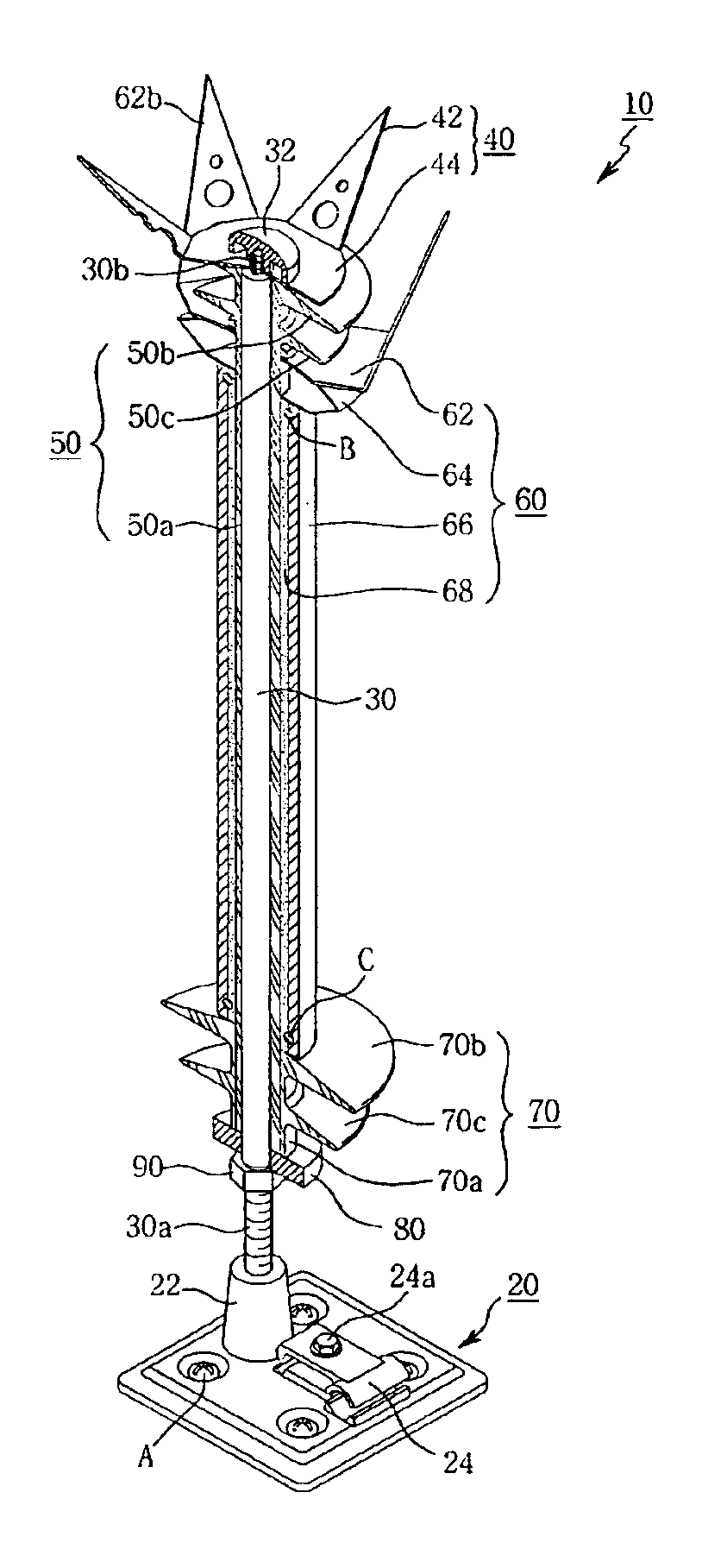

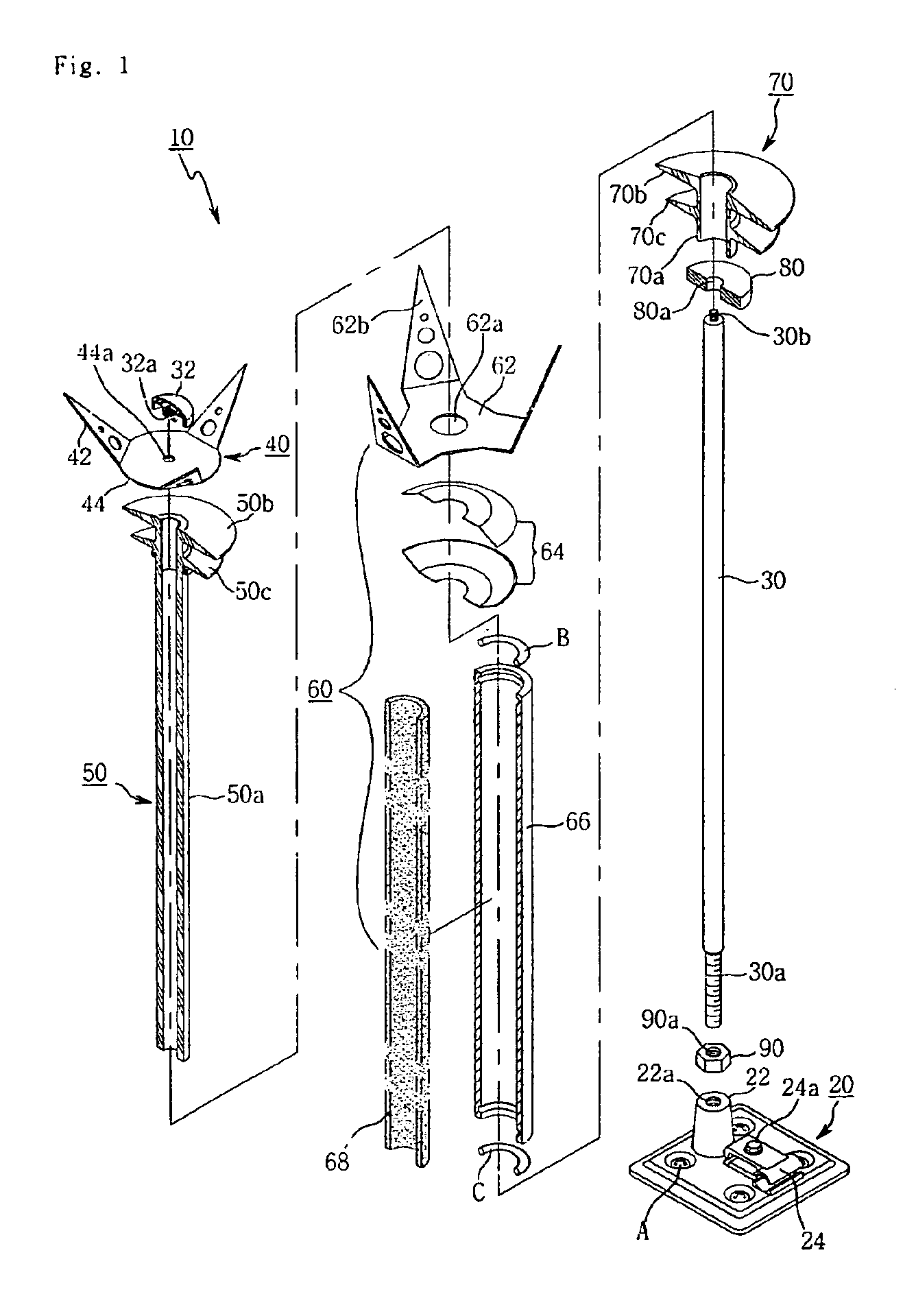

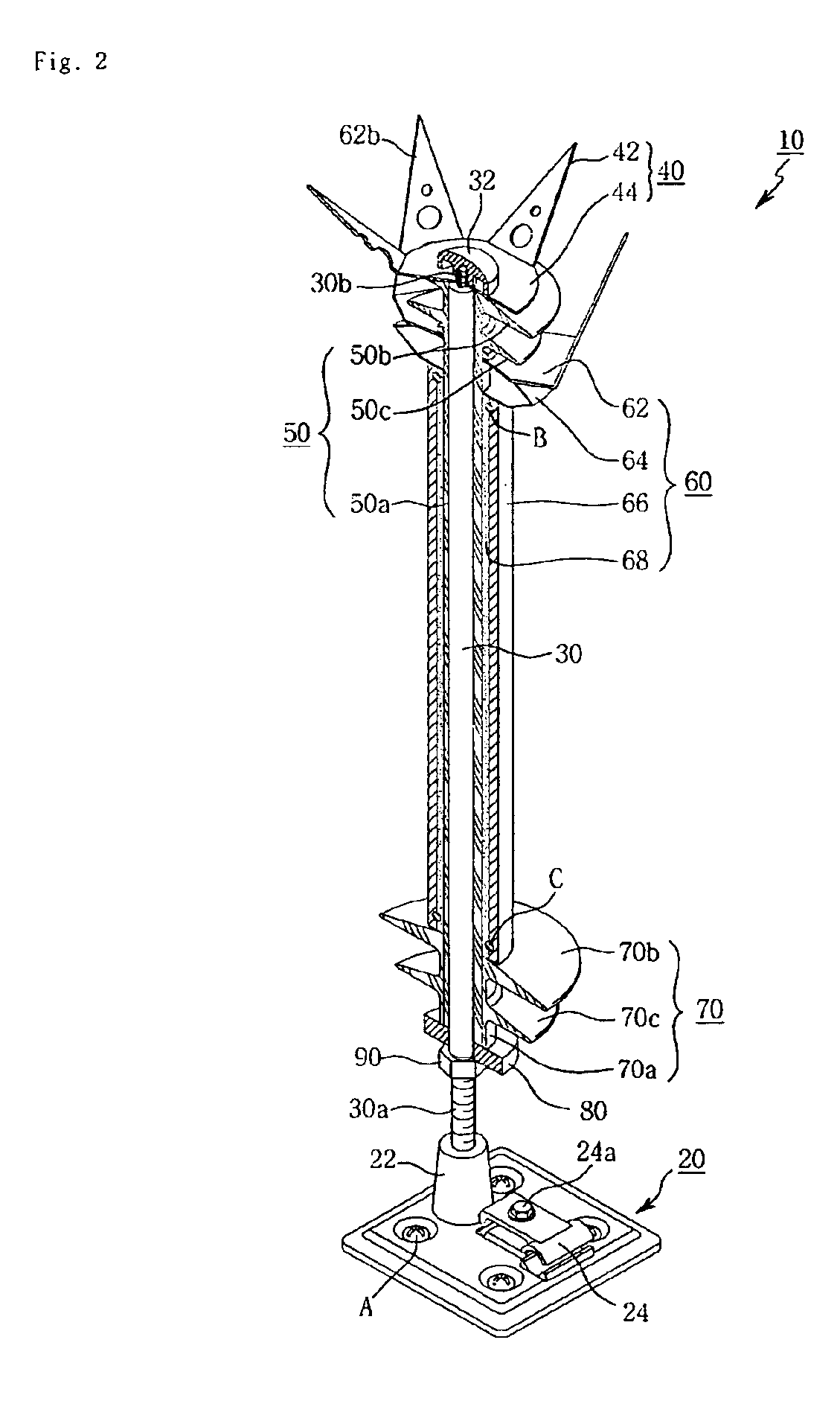

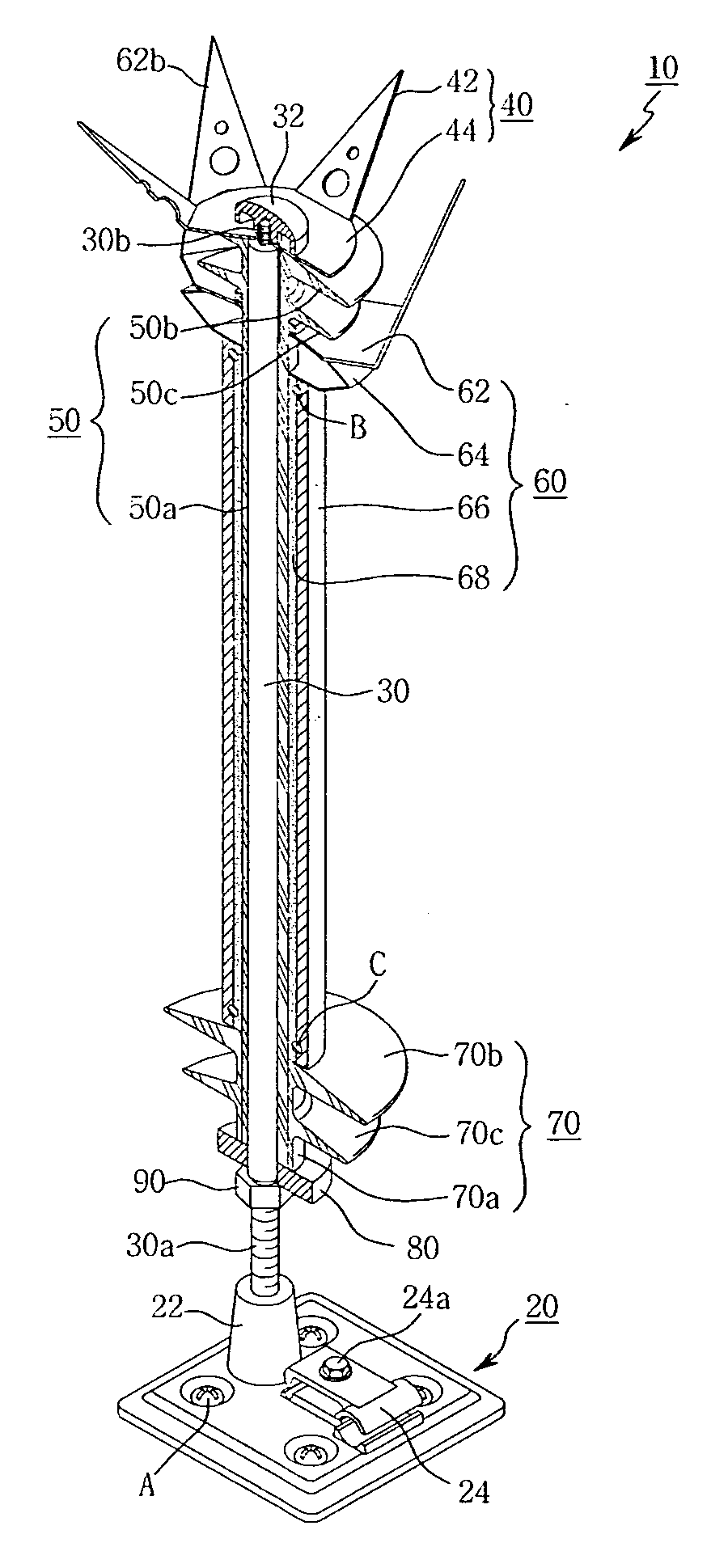

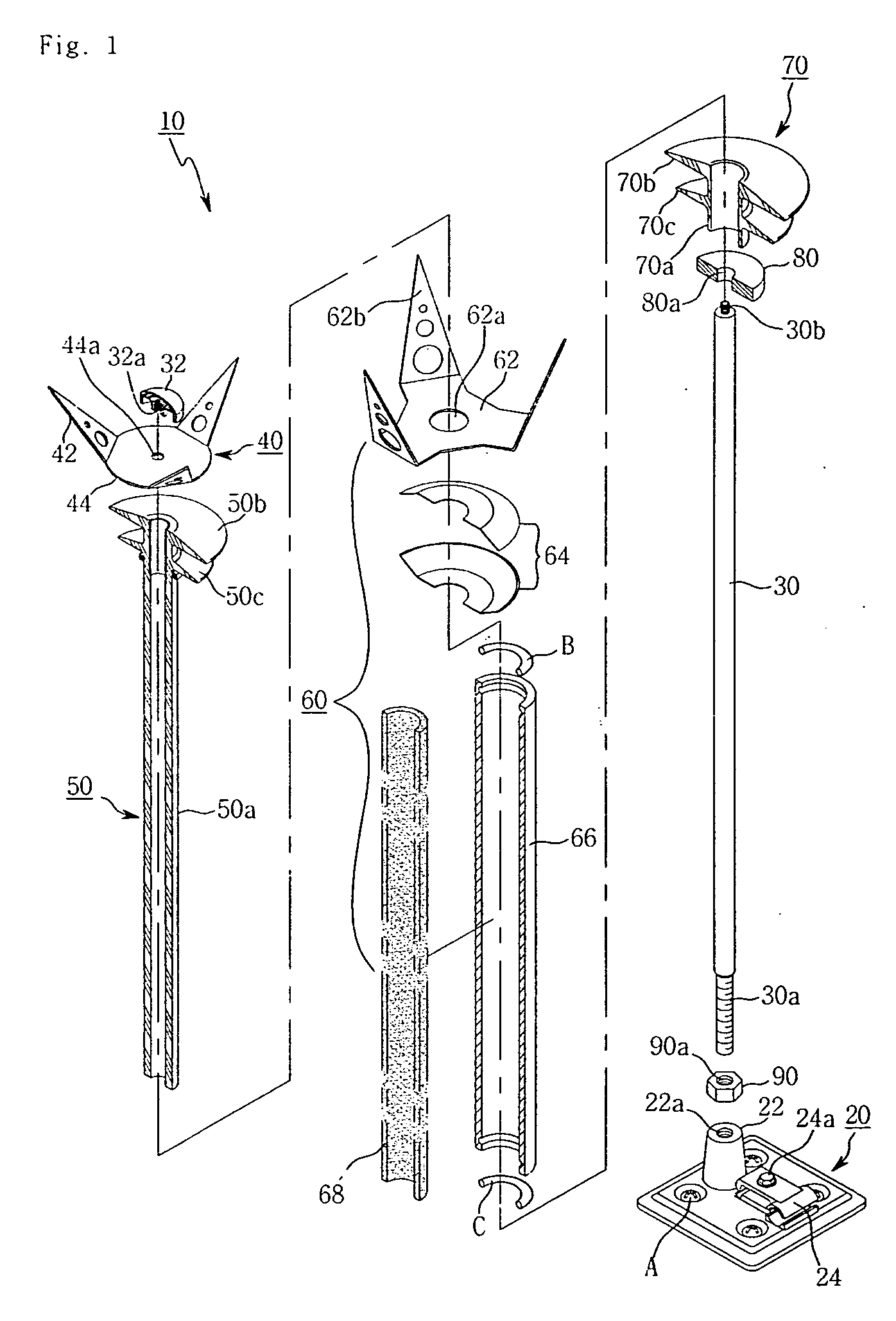

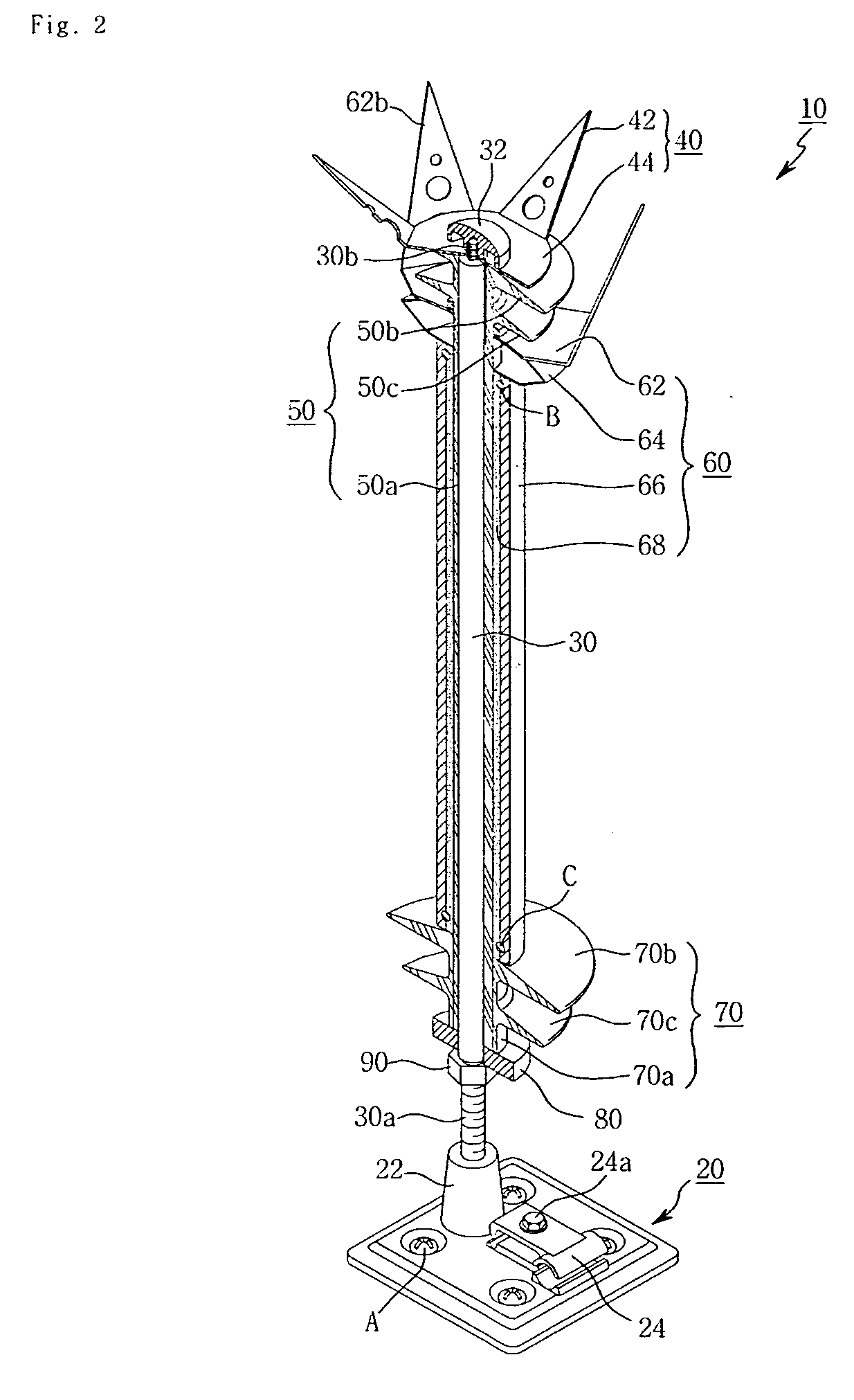

InactiveUS6875915B1Improve reliabilityDischarge safetyTents/canopiesConnection to earthPolymer insulationEngineering

Disclosed is a lightning arrester. The lightning arrester safely discharges earth charge of a main electrode section and an auxiliary electrode section regardless of a variation of charge contained in air, so charge charged in a thundercloud is safely discharged into the earth even if the thundercloud is located far-remote from the earth. The lightning arrester has a fixing base fixedly installed on an object to be protected by grounding a lightning circuit connected to a ground electrode grounded to an earth, a fixing bar vertically installed at one side of an upper surface of the fixing base and made of conductive material, a main electrode section making contact with an upper portion of the fixing bar and made of conductive material, an upper polymer insulator including an elongated column member formed at a center thereof with a hollow section for receiving the fixing bar therein, and upper and lower disc-shaped plates integrally formed at an upper end of the elongated column member for ensuring an insulation distance, and an auxiliary electrode section aligned below the main electrode section without making contact with the main electrode section and made of conductive material. The elongated column member of the upper polymer insulator passes through a center of the auxiliary electrode section in order to fill space charge in the auxiliary electrode section.

Owner:LEE TECH KOREA CO LTD

Silicone rubber compositions for high-voltage electrical insulators and polymer insulators

InactiveUS6063487AReduce moisture absorption performanceImprove electrical performancePlastic/resin/waxes insulatorsFibre treatmentIon contentPolymer science

A silicone rubber composition comprising (A) 100 parts by weight of an organopolysiloxane composition of the organic peroxide or addition curing type, (B) 1-100 parts by weight of finely divided silica, and (C) 30-500 parts by weight of aluminum hydroxide is suitable for use as a high-voltage electrical insulator. The aluminum hydroxide (C) has a water-soluble sodium ion content of up to 0.01% by weight and exhibits pH 6.5-8.0 and an electrical conductivity of up to 50 mu s / cm when measured as a 30 wt % water slurry and preferably has been treated to be hydrophobic. The composition cures into a silicone rubber having improved high-voltage electrical insulating properties even under rigorous conditions.

Owner:SHIN ETSU CHEM IND CO LTD

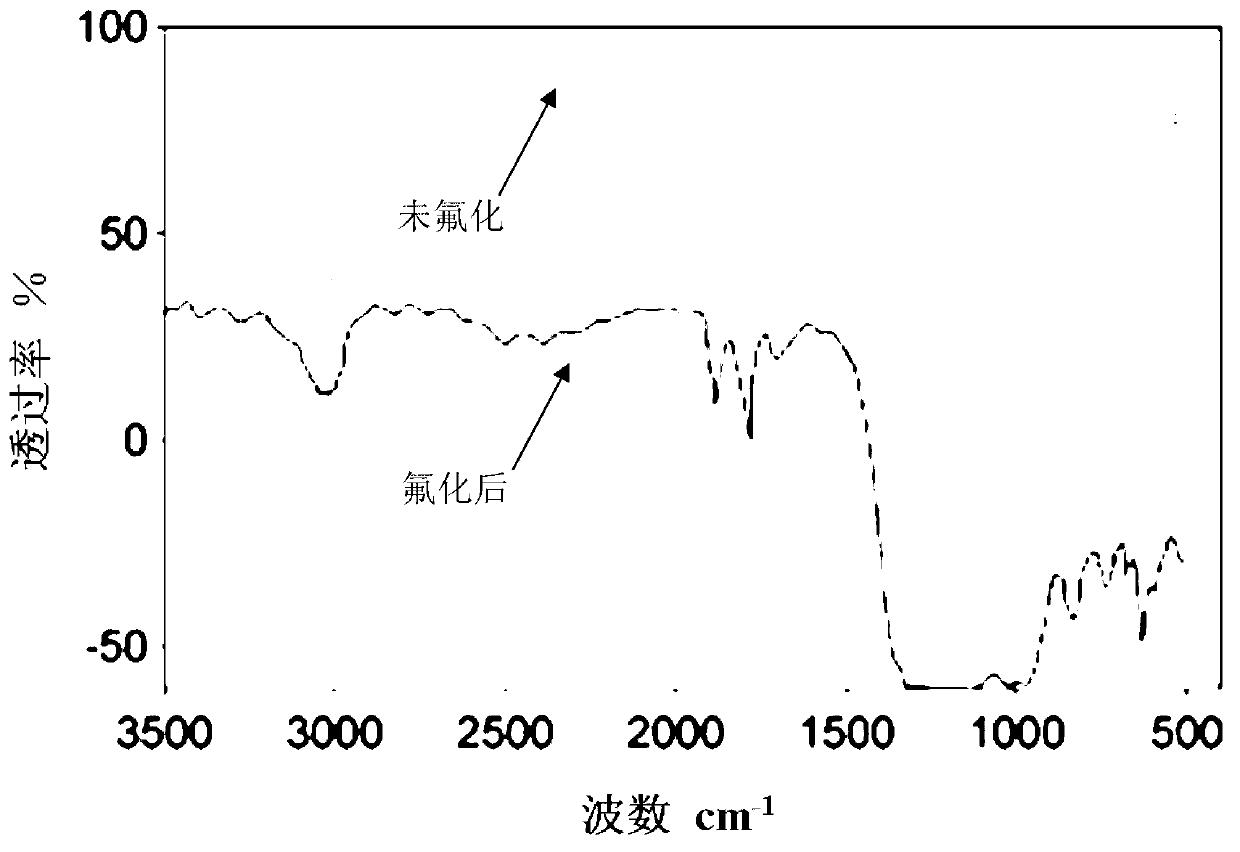

Method for improving flashover performance of vacuum edge surface of polymer insulator

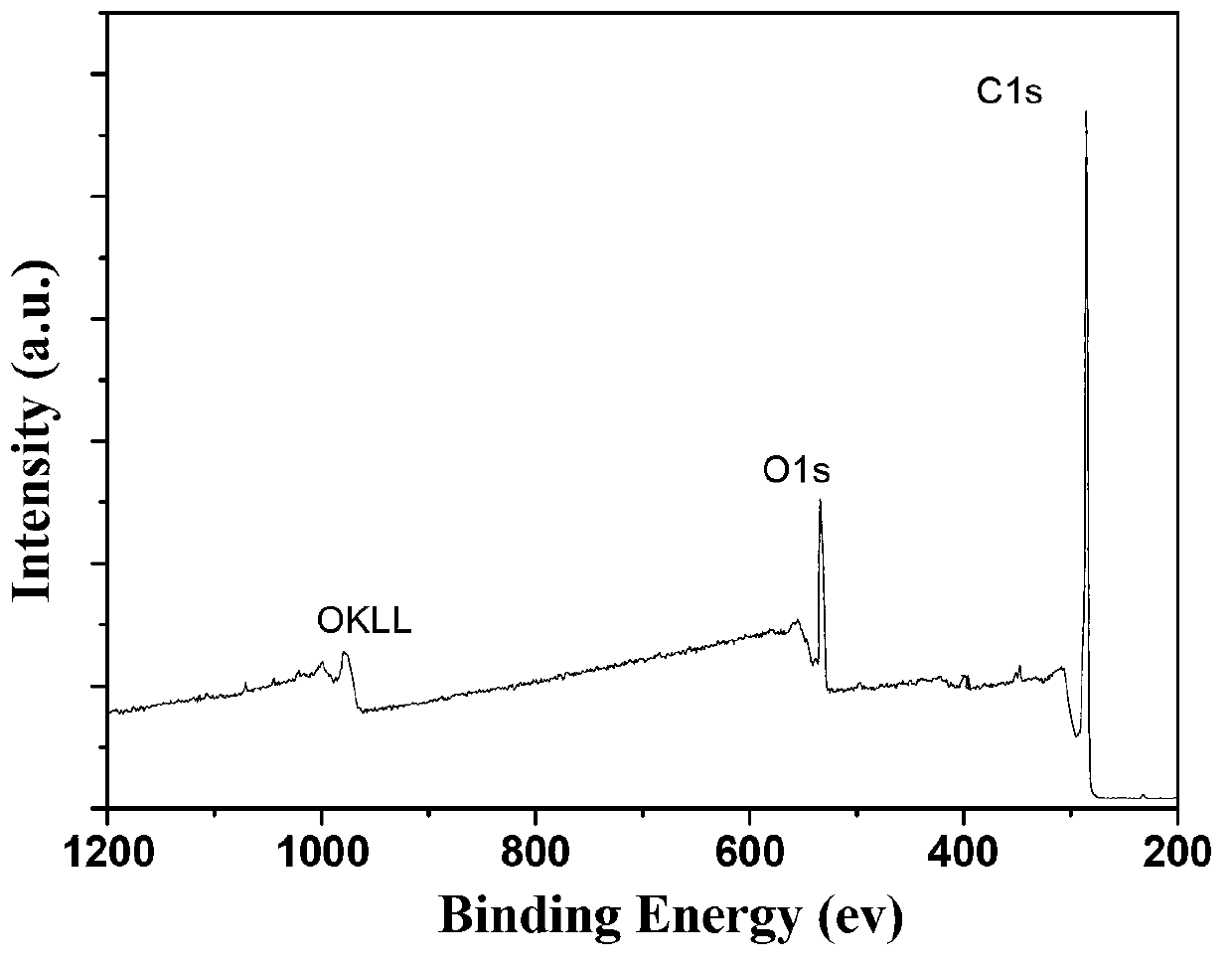

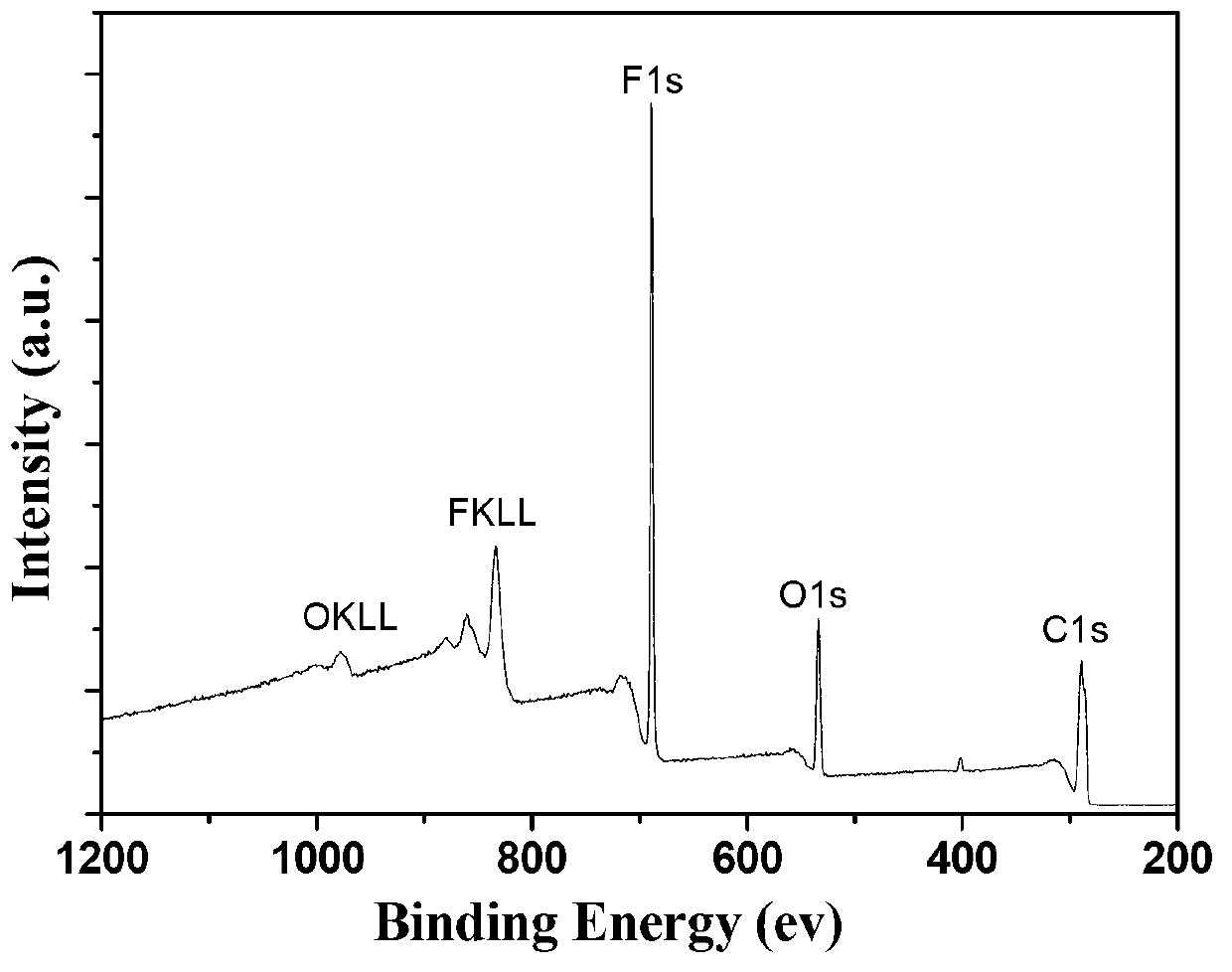

The invention belongs to the technical field of high-voltage electrical insulating material, and particularly relates to an effective method for improving the flashover performance of a vacuum edge surface of a polymer insulator. The method comprises the step of enabling the polymer insulator to be contacted with fluorine-containing gas with a certain proportion at a certain temperature for generating fluoridation to form a fluoride layer with a certain thickness on the surface of the polymer. The method has the characteristics that the fluoride layer is formed on the surface of the polymer such as polyethylene, polypropylene, nylon and the like by the fluoridation of the gas, so that the flashover performance of the vacuum edge surface of the insulator can be improved, the surface breakdown voltage of the insulator is increased, and the insulating strength of the surface of the fluorizated insulator is 1.2-1.6 times higher than that of the non-fluorizated insulator.

Owner:NORTHWEST INST OF NUCLEAR TECH

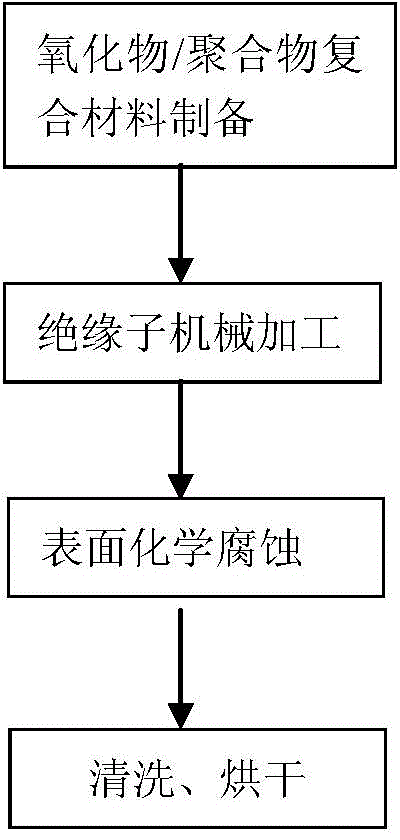

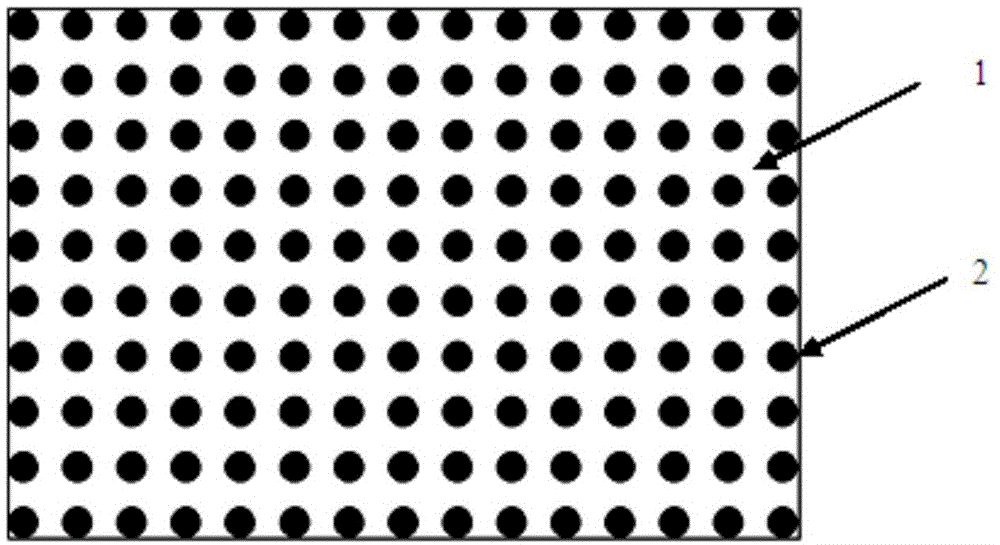

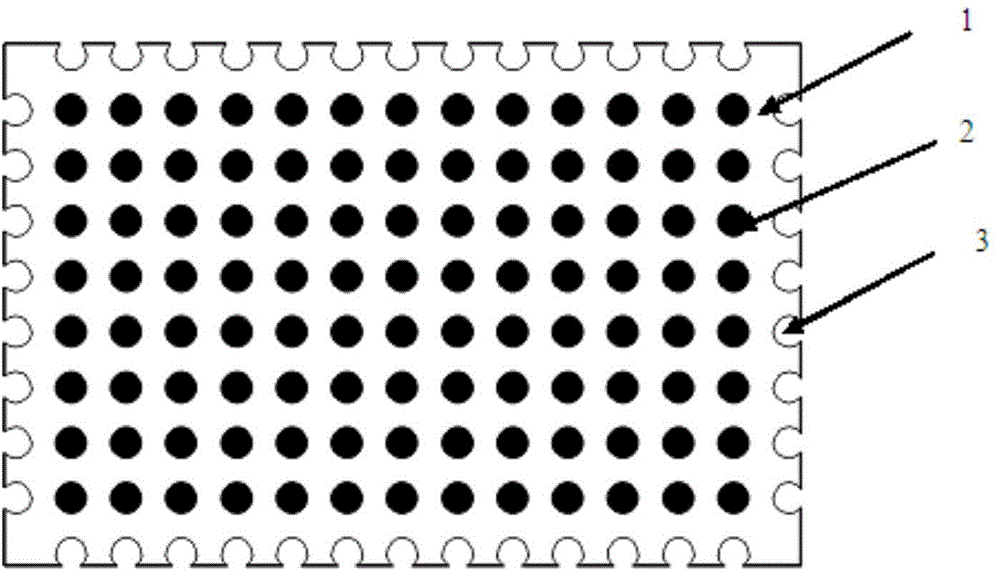

Polymer insulator with uniform hole distribution on surface and preparation method thereof

ActiveCN104900299AImprove mechanical propertiesUniform distribution of holesPlastic/resin/waxes insulatorsQuartz/glass/vitreous enamelsPolymer scienceGas phase

The invention relates to a polymer insulator with uniform hole distribution on the surface and a preparation method thereof. The method mainly includes the following steps: a composite material with uniform oxide particle distribution is obtained through a polymerization reaction by taking fumed silica as a thixotropic agent and oxide particles ranging from tens of nanometers to several microns as a surface pore-forming agent in polymer monomer solution; and after the composite material is machined into a polymer insulator, the oxide particles on the surface are etched and removed by a chemical etching method to obtain a polymer insulator with uniform hole distribution on the surface. By adjusting the size and mass ratio of the oxide particles, control on the hole size and hole density distribution on the surface of the polymer insulation material is realized, the vacuum surface flashover characteristic of the insulator is improved, and the surface breakdown voltage of the insulator is improved. The vacuum surface flashover field strength of an insulator with a special surface structure is improved by 20-50% compared with a pure polymer insulator.

Owner:NORTHWEST INST OF NUCLEAR TECH

Preparation method of modified polymer insulator material

ActiveCN103194015AMeet the electrical characteristicsMeet life requirementsInsulatorsPolymer scienceLife time

The invention relates to a preparation method of a modified polymer insulator material. The preparation method of the modified polymer insulator material comprises the following steps of: pre-heating an internal mixer to 150 DEG C to 160 DEG C; dropping an upper top bolt after adding polypropylene, banburying for 115 seconds to 125 seconds under the pressure of 0.5MPa-0.6MPa and temperature of 150 DEG C to 170 DEG C; then adding polythene and banburying for 115 seconds to 125 seconds under the pressure of 0.5MPa-0.6MPa and temperature of 150 DEG C to 170 DEG C; raising the upper top bolt, banburying for 115 seconds to 125 seconds under the temperature of 150 DEG C to 170 DEG C; and finally discharging, cooling and pelletizing, wherein the molecular weight of each of polypropylene and polyethylene is 10 thousand to 20 thousand. The modified polymer insulator material prepared by the preparation method not only can satisfy the electrical characteristics and mechanical performance requirements of the insulator, but also can satisfy the service life requirement. Besides, the preparation method has an antifouling self-cleaning function and has the advantages of high cost performance, energy conservation and environment protection and no pollution, so that the product can be recycled after reaching the service life.

Owner:JIANGSU JINSANLI POWER EQUIP

Lightning arrester

InactiveUS20050061525A1Improve reliabilityDischarge safetyTents/canopiesConnection to earthPolymer insulationEngineering

Disclosed is a lightning arrester. The lightning arrester safely discharges earth charge of a main electrode section and an auxiliary electrode section regardless of a variation of charge contained in air, so charge charged in a thundercloud is safely discharged into the earth even if the thundercloud is located far-remote from the earth. The lightning arrester has a fixing base fixedly installed on an object to be protected by grounding a lightning circuit connected to a ground electrode grounded to an earth, a fixing bar vertically installed at one side of an upper surface of the fixing base and made of conductive material, a main electrode section making contact with an upper portion of the fixing bar and made of conductive material, an upper polymer insulator including an elongated column member formed at a center thereof with a hollow section for receiving the fixing bar therein, and upper and lower disc-shaped plates integrally formed at an upper end of the elongated column member for ensuring an insulation distance, and an auxiliary electrode section aligned below the main electrode section without making contact with the main electrode section and made of conductive material. The elongated column member of the upper polymer insulator passes through a center of the auxiliary electrode section in order to fill space charge in the auxiliary electrode section.

Owner:LEE TECH KOREA CO LTD

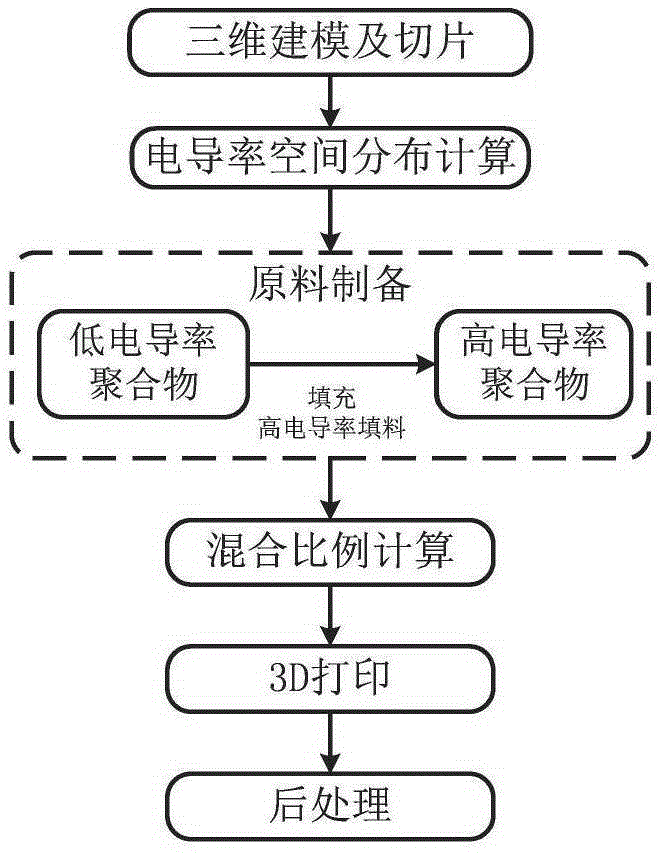

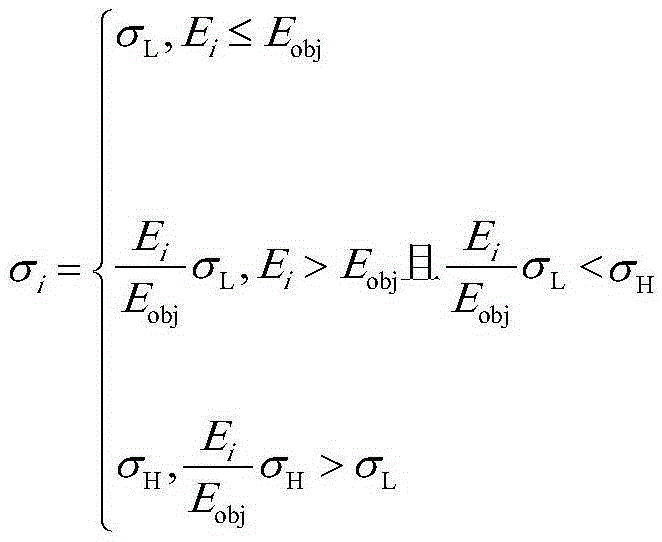

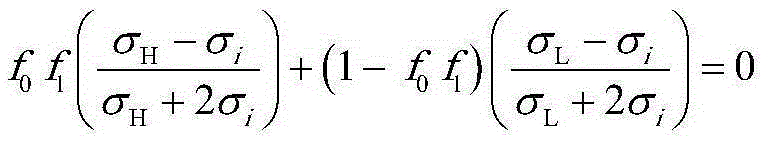

3D printing-based manufacturing method for conductivity gradient polymer insulator

ActiveCN105321635AImprove breakdown voltageAchieving spatial distribution of conductivityInsulatorsManufacturing technologyMulti dimensional

The invention belongs to the field of manufacturing of high-voltage equipment, and discloses a 3D printing-based manufacturing method for a conductivity gradient polymer insulator. The method comprises the following steps: (1) three-dimensional modeling for the insulator and model slicing; (2) conductivity space distribution calculation; (3) raw material preparation; (4) mixing ratio calculation; (5) 3D printing of the insulator; and (6) post-treatment. Compared with a centrifugal manufacturing technology, according to the 3D printing-based manufacturing method for the conductivity gradient polymer insulator disclosed by the invention, the conductivity space distribution of a multi-dimensional insulator material can be achieved; and the targets of flexibly regulating and controlling internal and superficial electric field intensities of the insulator under direct-current voltage and improving the breakdown voltage of the insulator are reached.

Owner:XI AN JIAOTONG UNIV

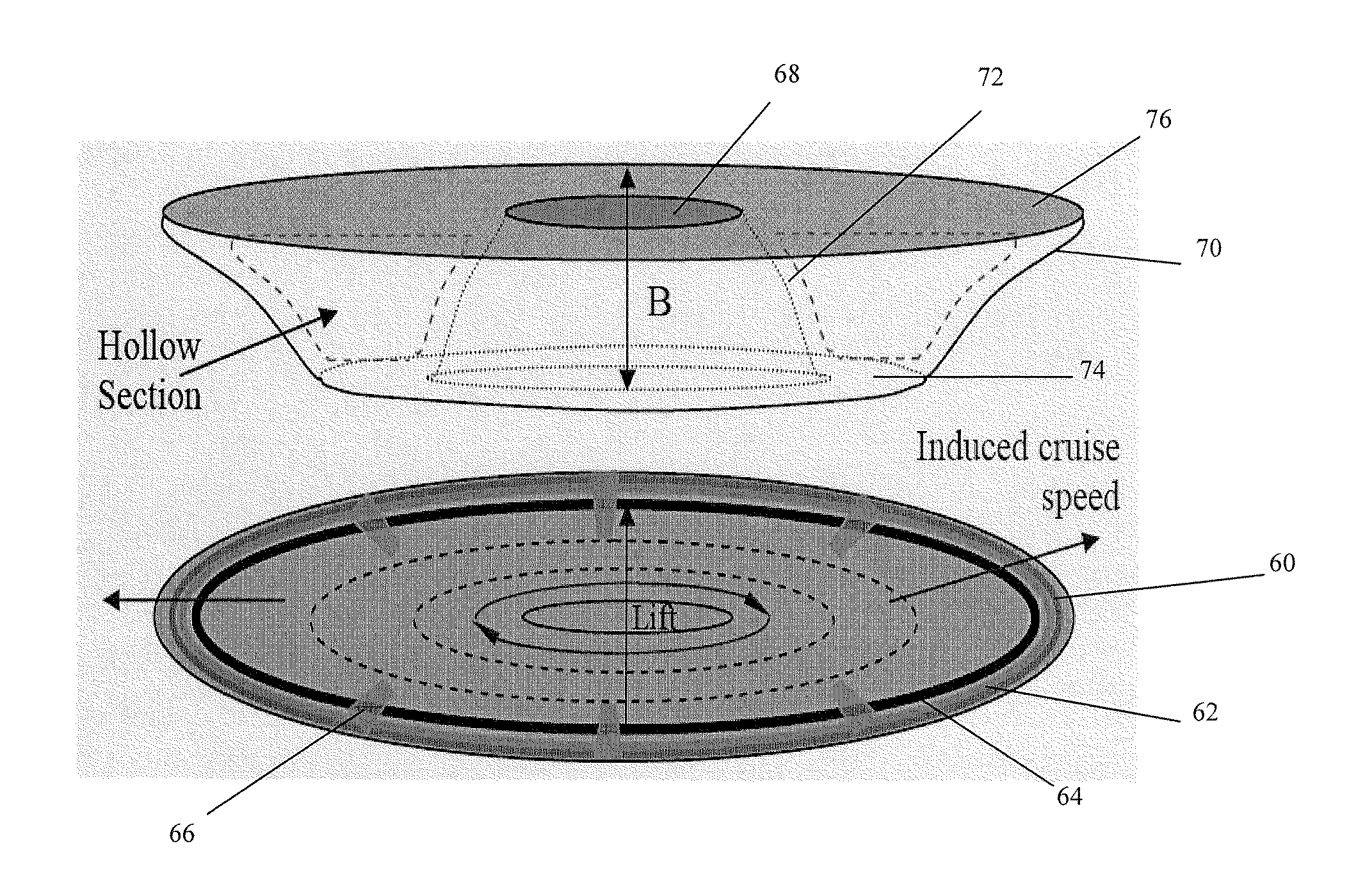

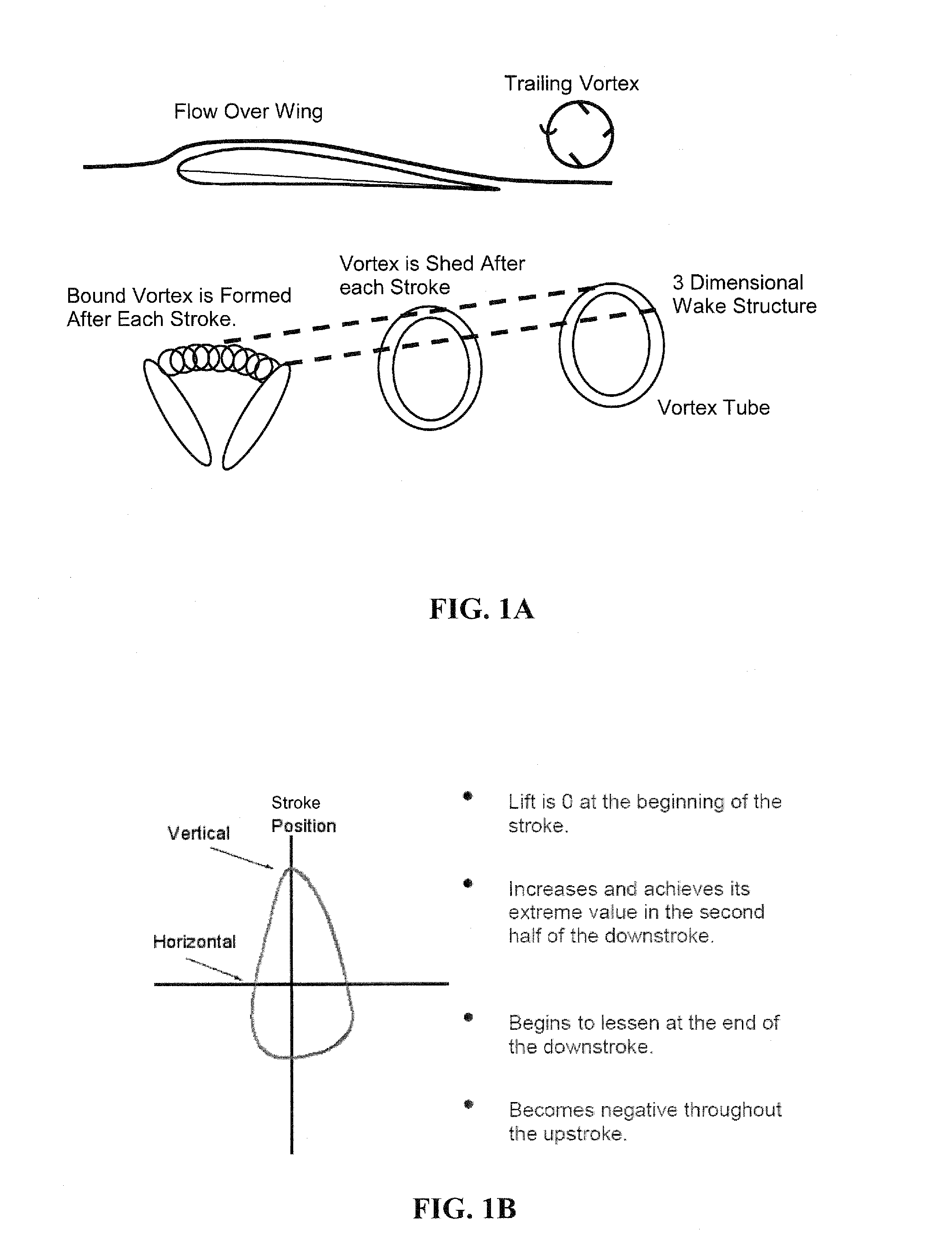

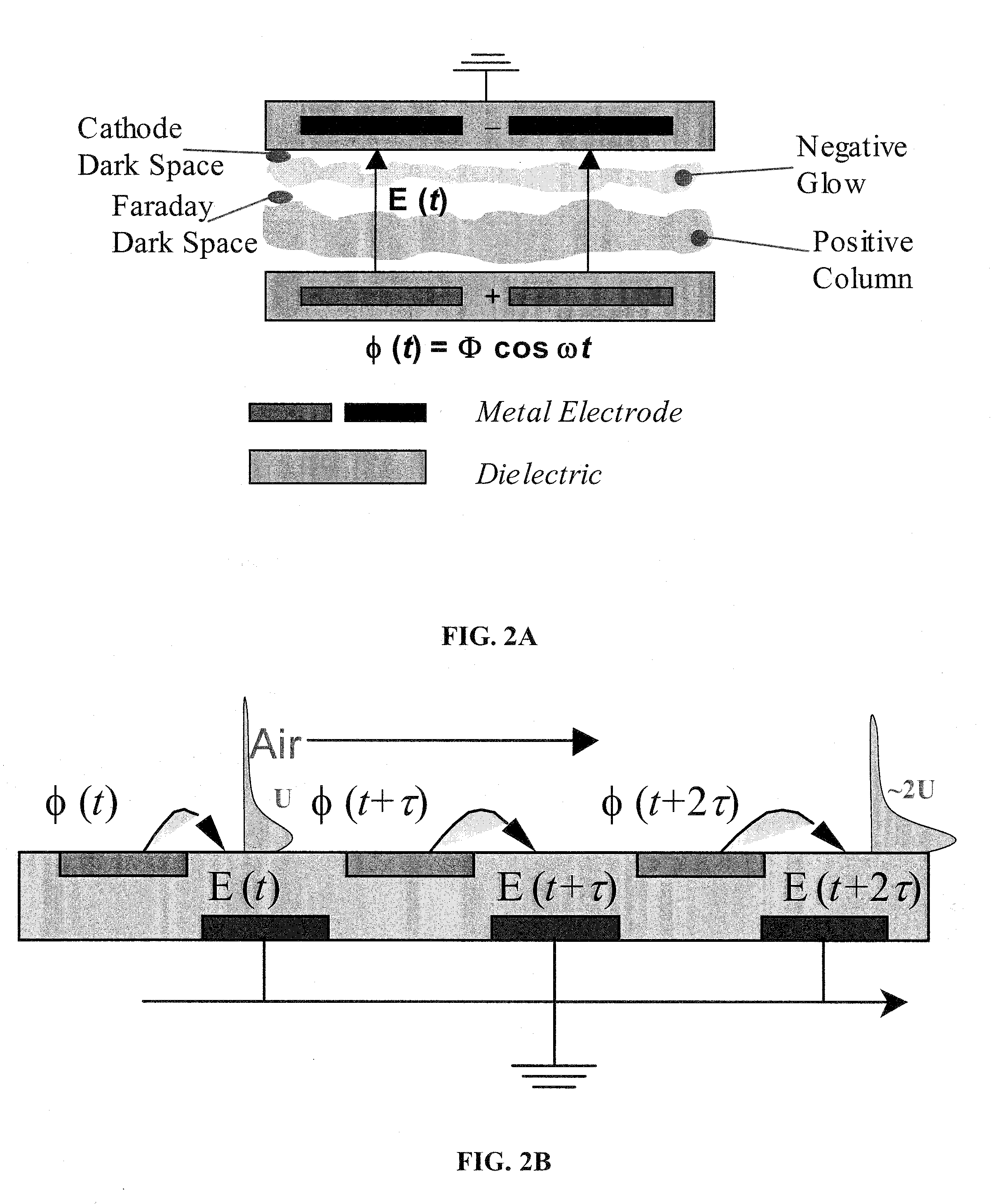

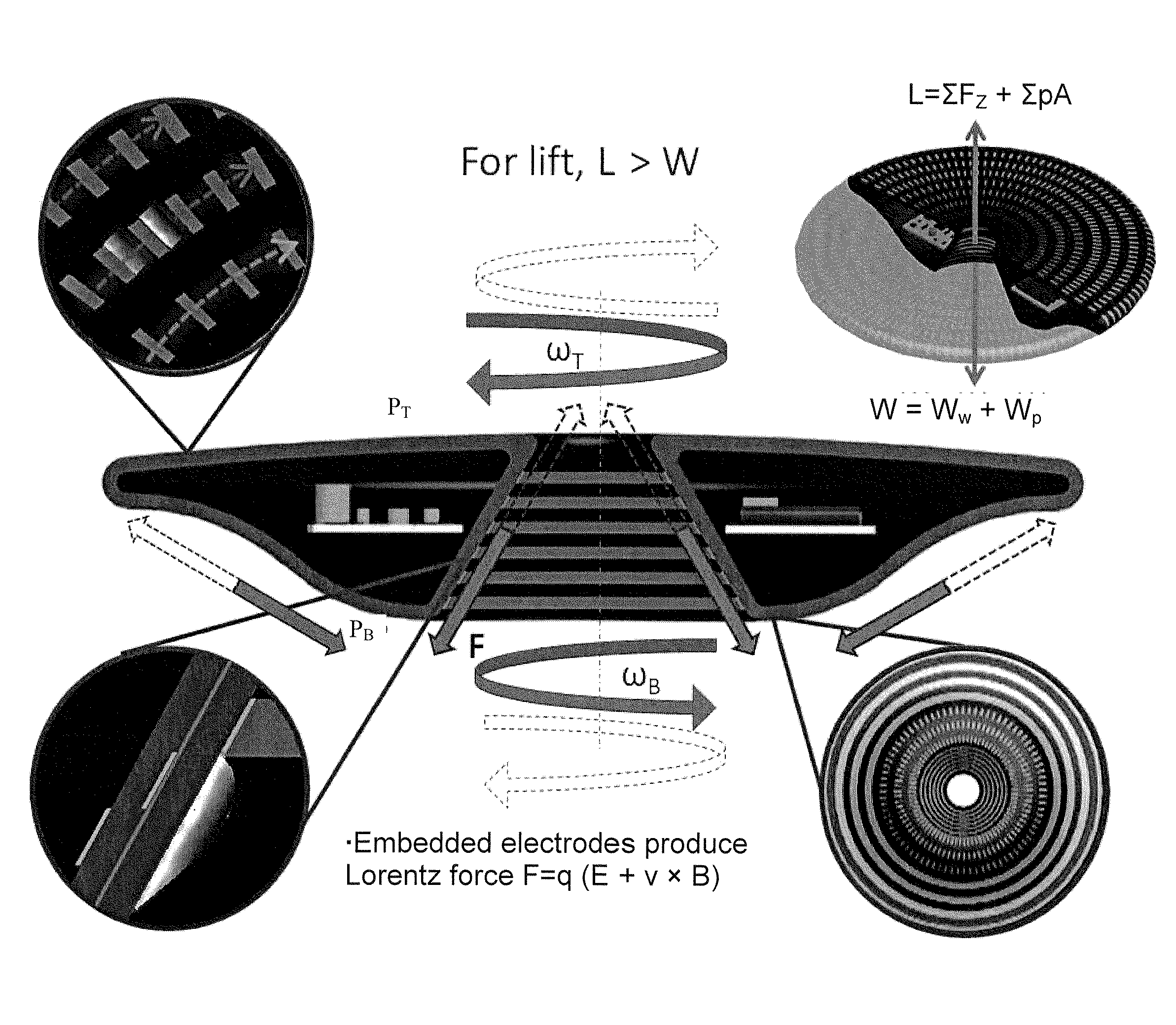

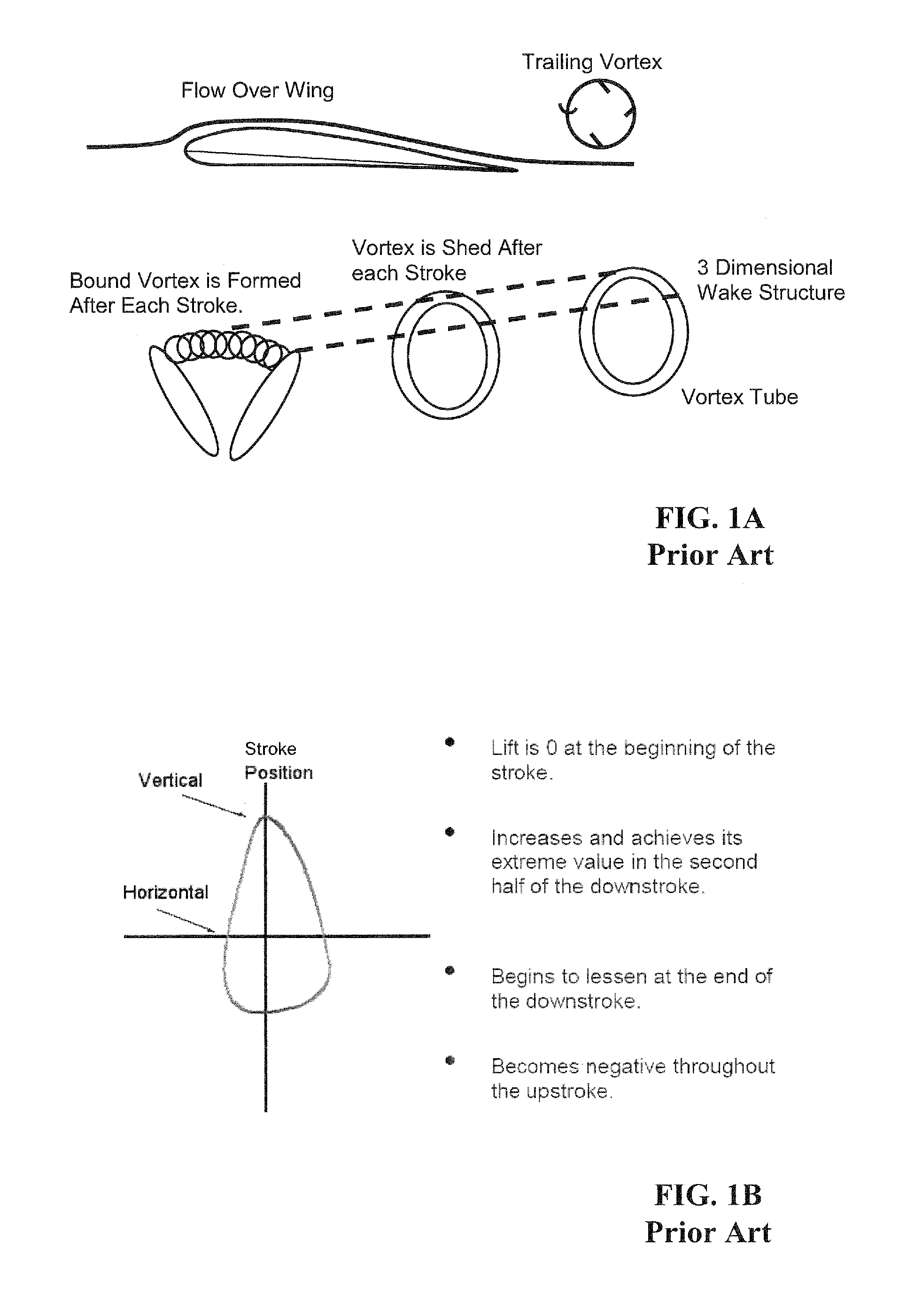

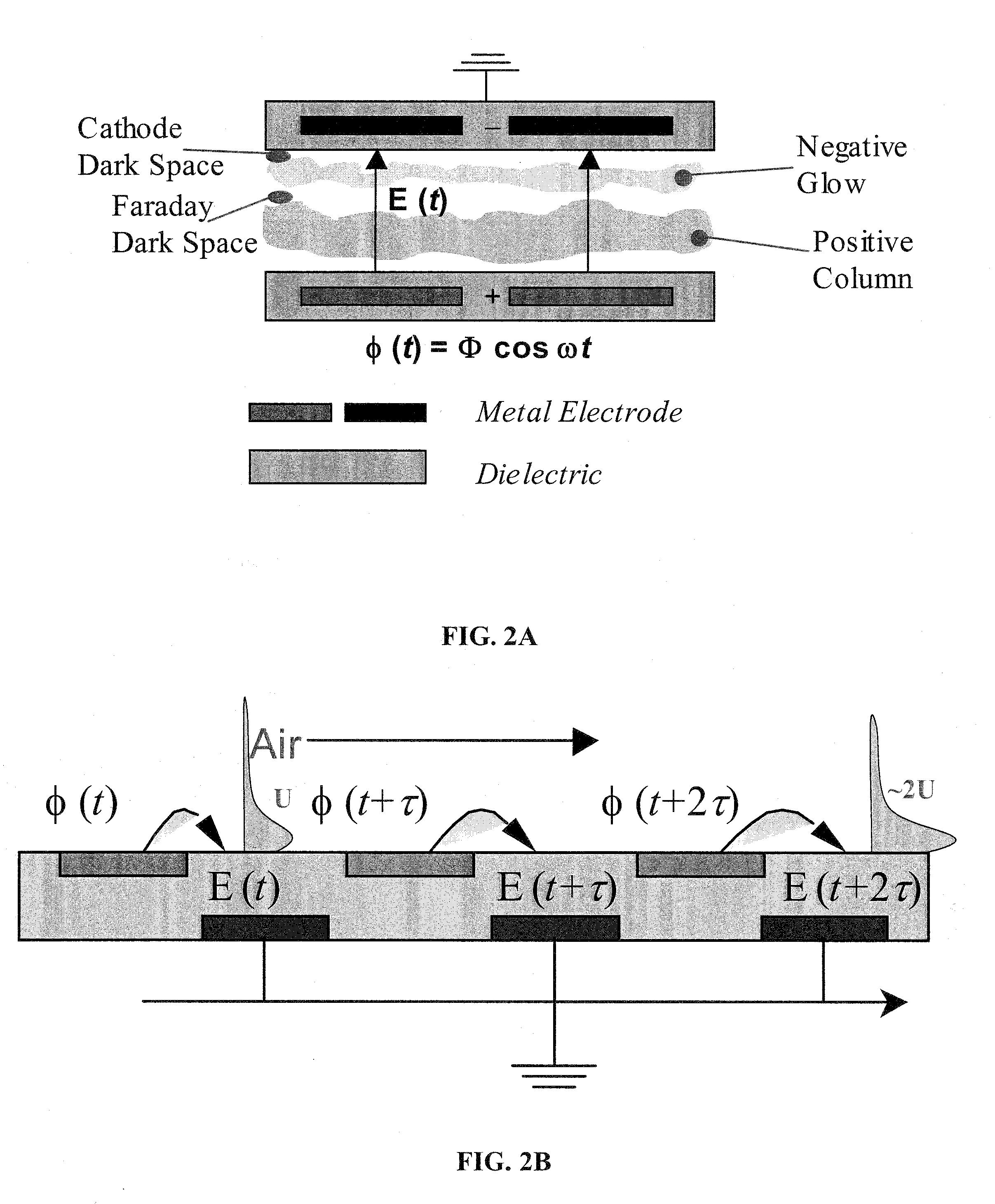

Wingless Hovering Of Micro Air Vehicle

ActiveUS20100102174A1Low lift to drag ratioEfficient degradationFlying saucersWingsElectricityDielectric

Embodiments of the subject invention relate to a Wingless Hovering Micro Air Vehicle (WHOMAV) and its Power Source Unit (PSU). Embodiments can operate at reasonable power levels for hovering and withstanding expected wind gusts. Embodiments of the subject invention can have a diameter less than 15 cm. Embodiments can have one or more smooth (continuous curvature) surface and can be operated using electromagnetic and electrohydrodynamic principles. The wingless design of specific embodiments can allow operation with no rotating or moving components. Additional embodiments can allow active response to the surrounding flow conditions. The issue of low lift to drag ratio and degradation of airfoil efficiency due to the inability of laminar boundary layers attachment can also be significantly reduced, or eliminated. The electromagnetic force can be generated by applying a pulsed (alternating / rf) voltage between a set of grounded and powered electrodes separated by a polymer insulator, dielectric, or other material with insulating properties.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Wingless hovering of micro air vehicle

ActiveUS8382029B2Lower ratioEfficient degradationFlying saucersUnmanned aerial vehiclesDielectricElectricity

Embodiments relate to a Wingless Hovering Micro Air Vehicle and its Power Source Unit. Embodiments can operate at reasonable power levels for hovering and withstanding expected wind gusts. Embodiments can have a diameter less than 15 cm. Embodiments can have one or more smooth (continuous curvature) surface and can be operated using electromagnetic and electrohydrodynamic principles. The wingless design of specific embodiments can allow operation with no rotating or moving components. Additional embodiments can allow active response to the surrounding flow conditions. The issue of low lift to drag ratio and degradation of airfoil efficiency due to the inability of laminar boundary layers attachment can also be significantly reduced, or eliminated. The electromagnetic force can be generated by applying a pulsed (alternating / rf) voltage between a set of grounded and powered electrodes separated by a polymer insulator, dielectric, or other material with insulating properties.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

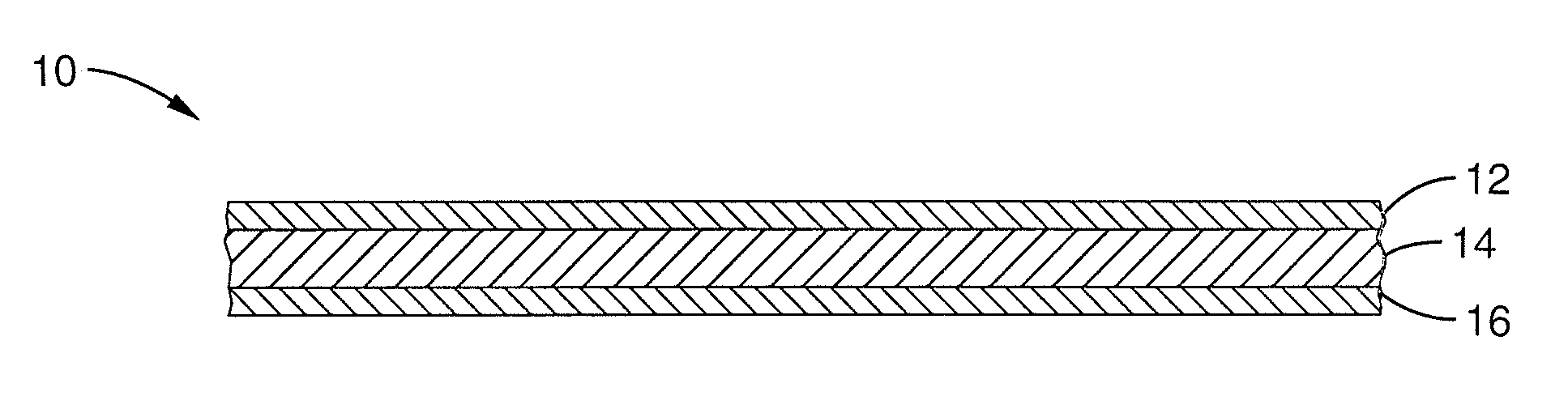

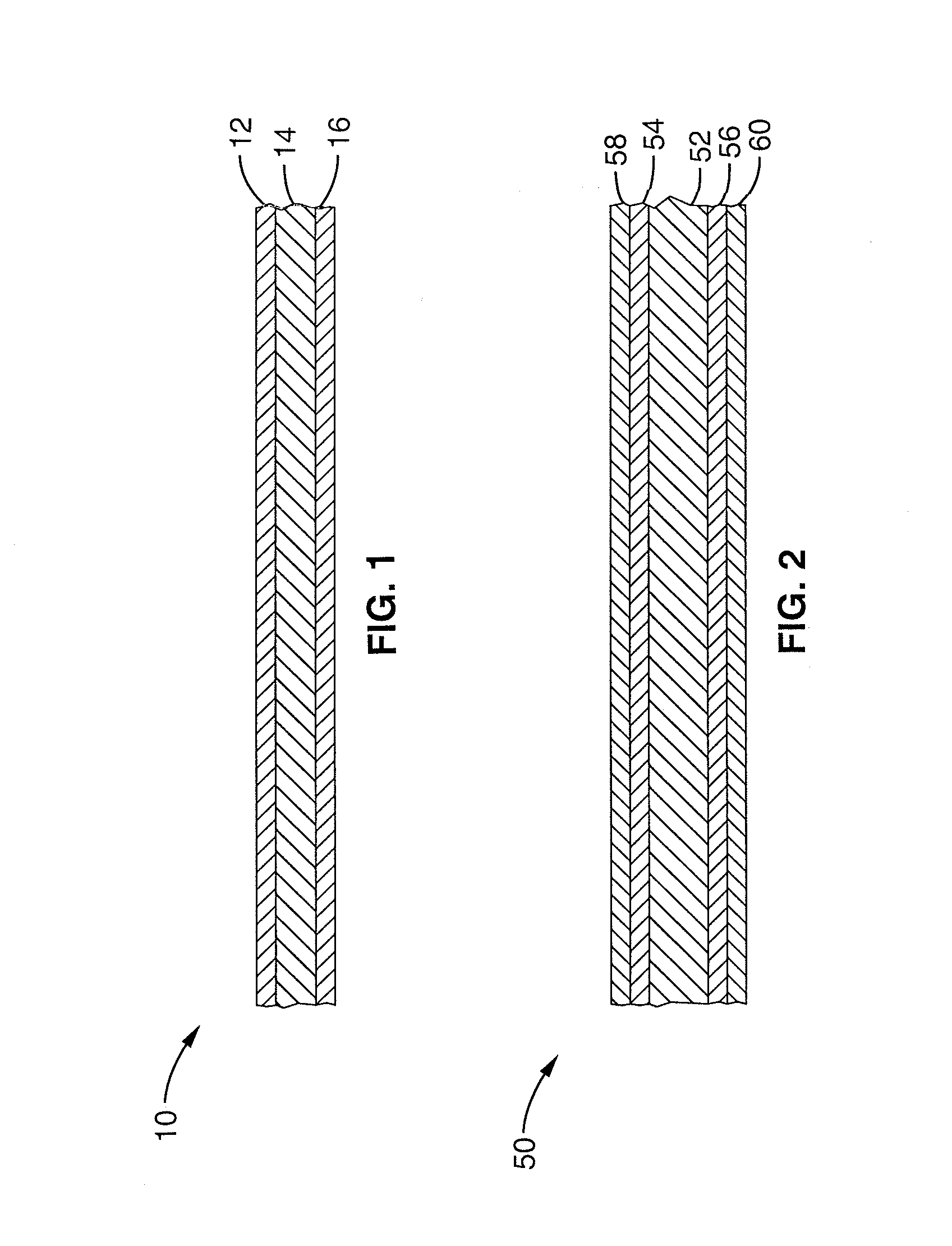

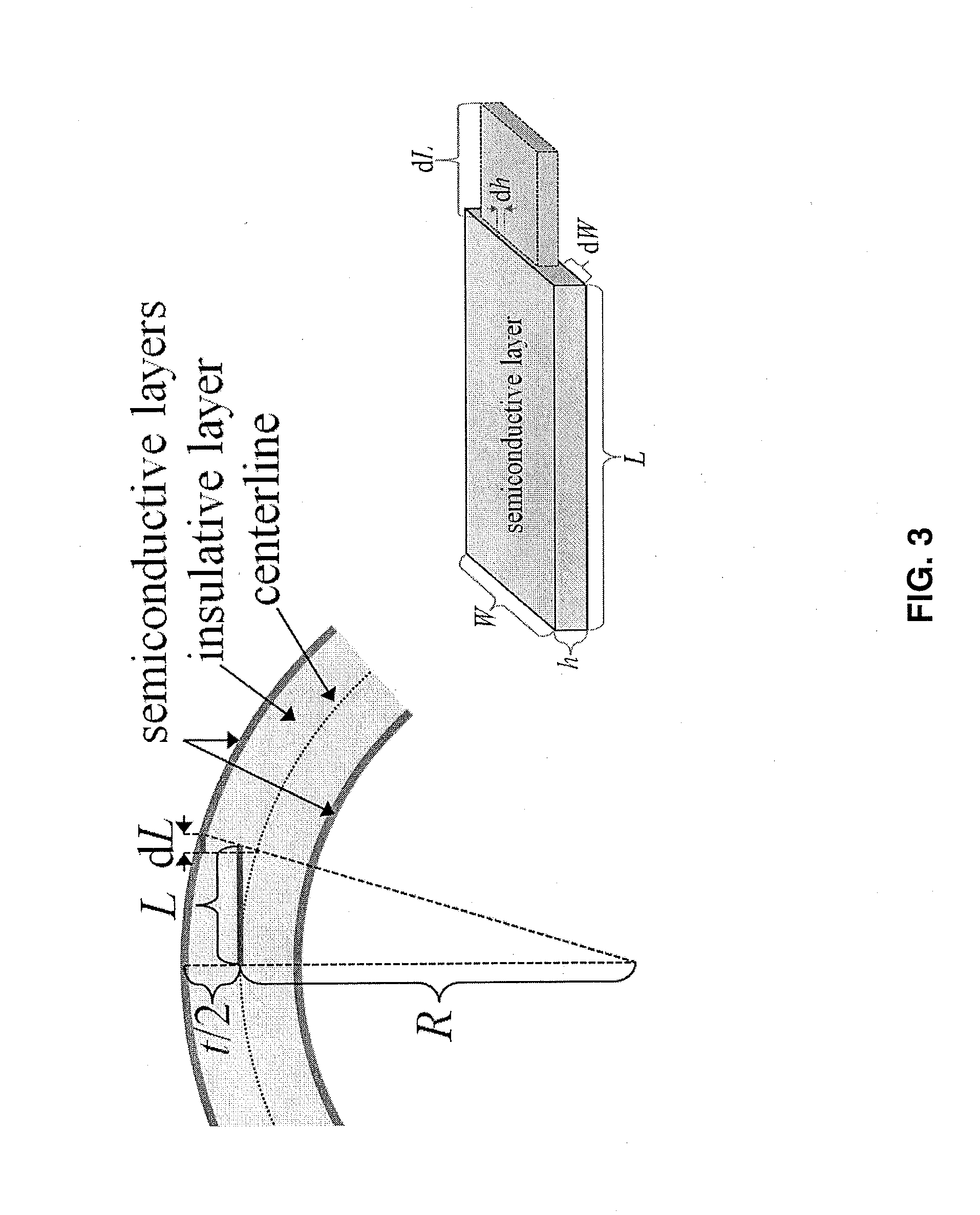

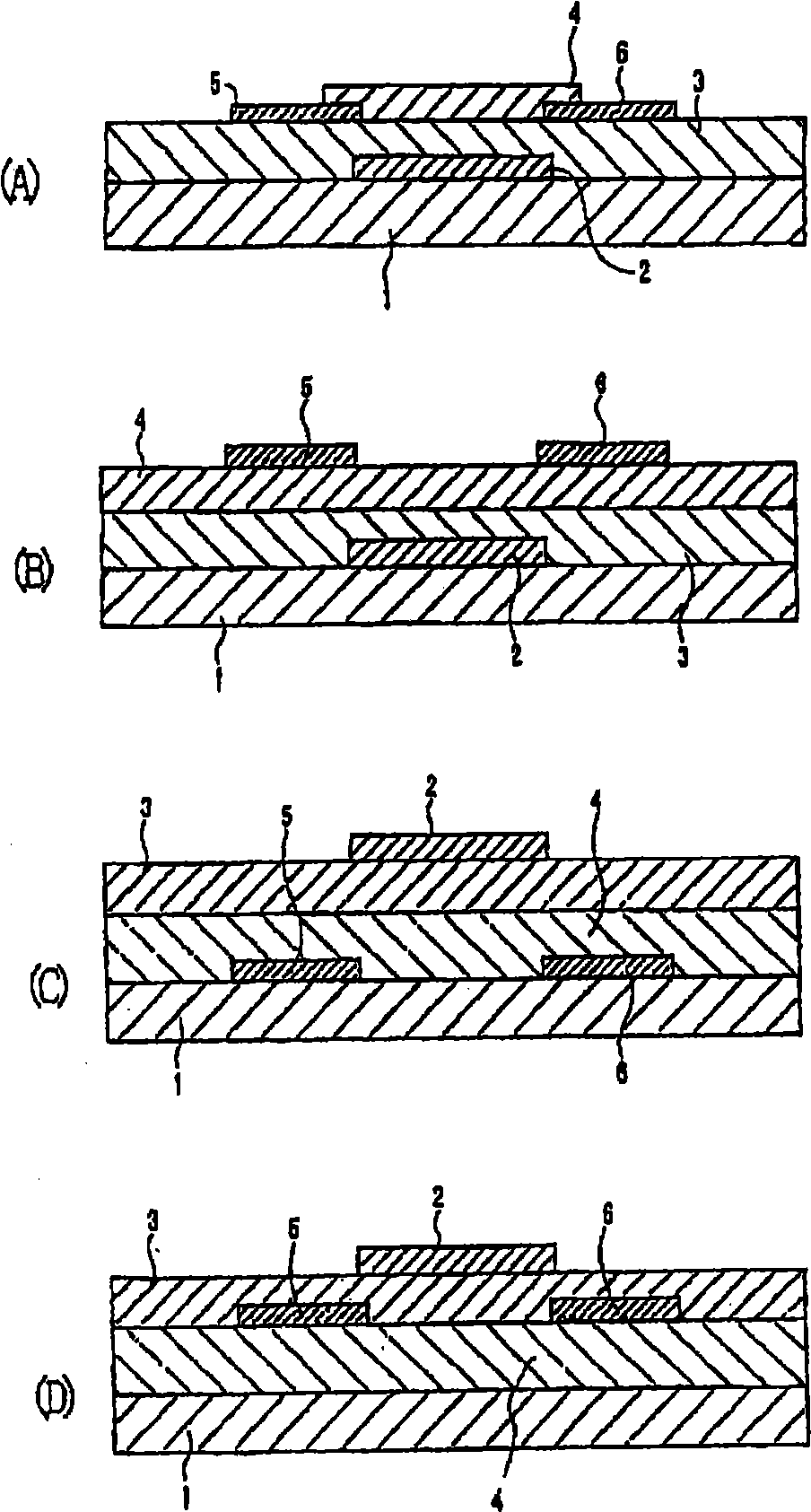

Flexible and moldable materials with bi-conductive surfaces

InactiveUS20130105193A1Simple and and scalable processIncreased durabilitySynthetic resin layered productsConstructions elementsPolymer insulationDeposition process

A flexible, moldable material is provided with bi-conductive surfaces that can be fabricated using simple, cost-effective, and scalable deposition processes. The material is a composite structure composed of two conductive or semi-conductive sheets sandwiching a thin polymer insulator, all bonded together at their interfaces. The two functionalized sheets are made of conductive or semi-conductive particles dispersed through a flexible polymer. In one embodiment, a protective coating over the outer conductive sheets is applied to improve the durability of the composite structure. The material can be patterned into custom shapes and patterns with sizes ranging from meso-scale (millimeters) to macro-scale (meters) dimensions. The thicknesses of the components can also be tailored to be thin, such as a few hundred microns, yet the material maintains very good durability.

Owner:RGT UNIV OF CALIFORNIA

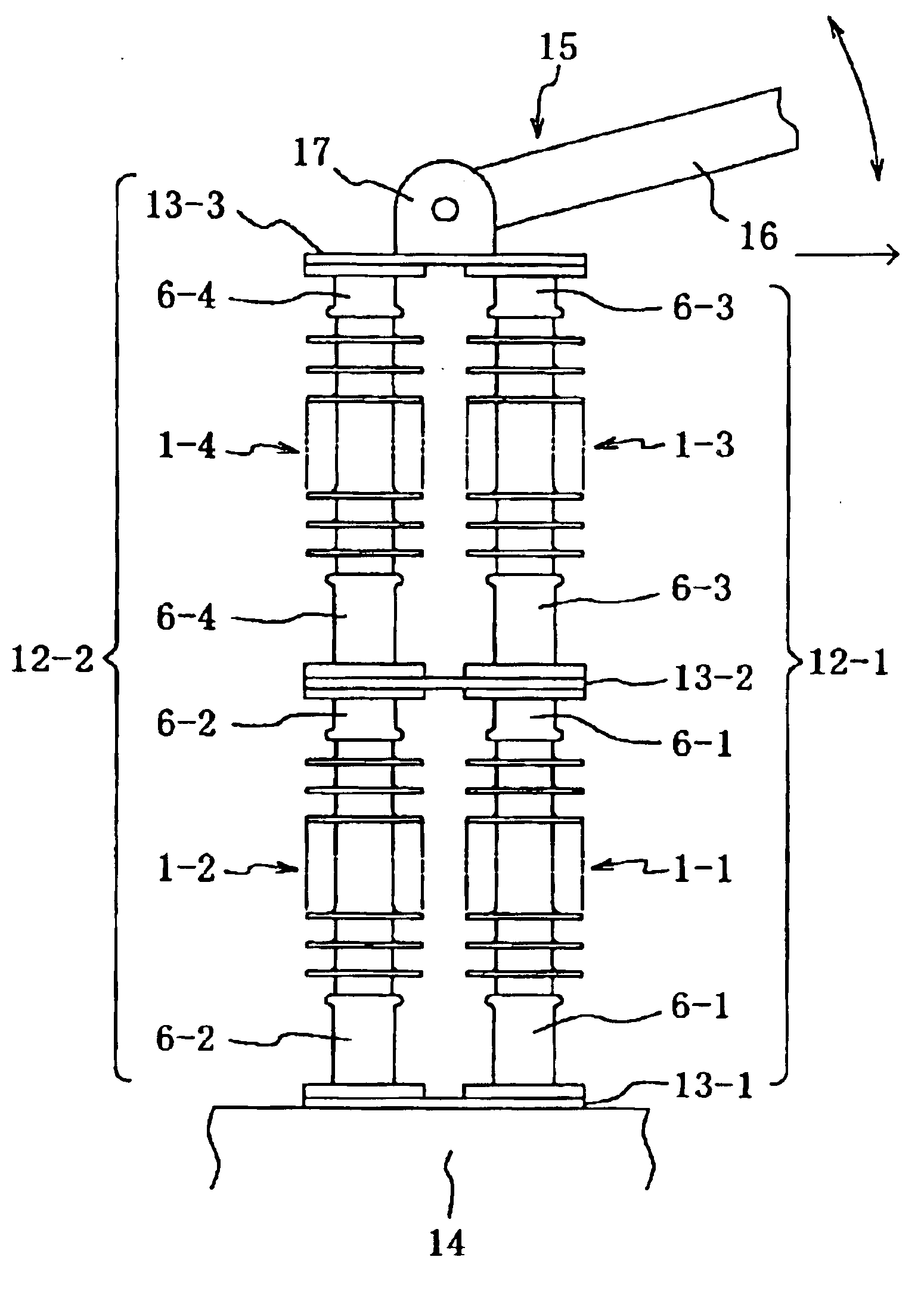

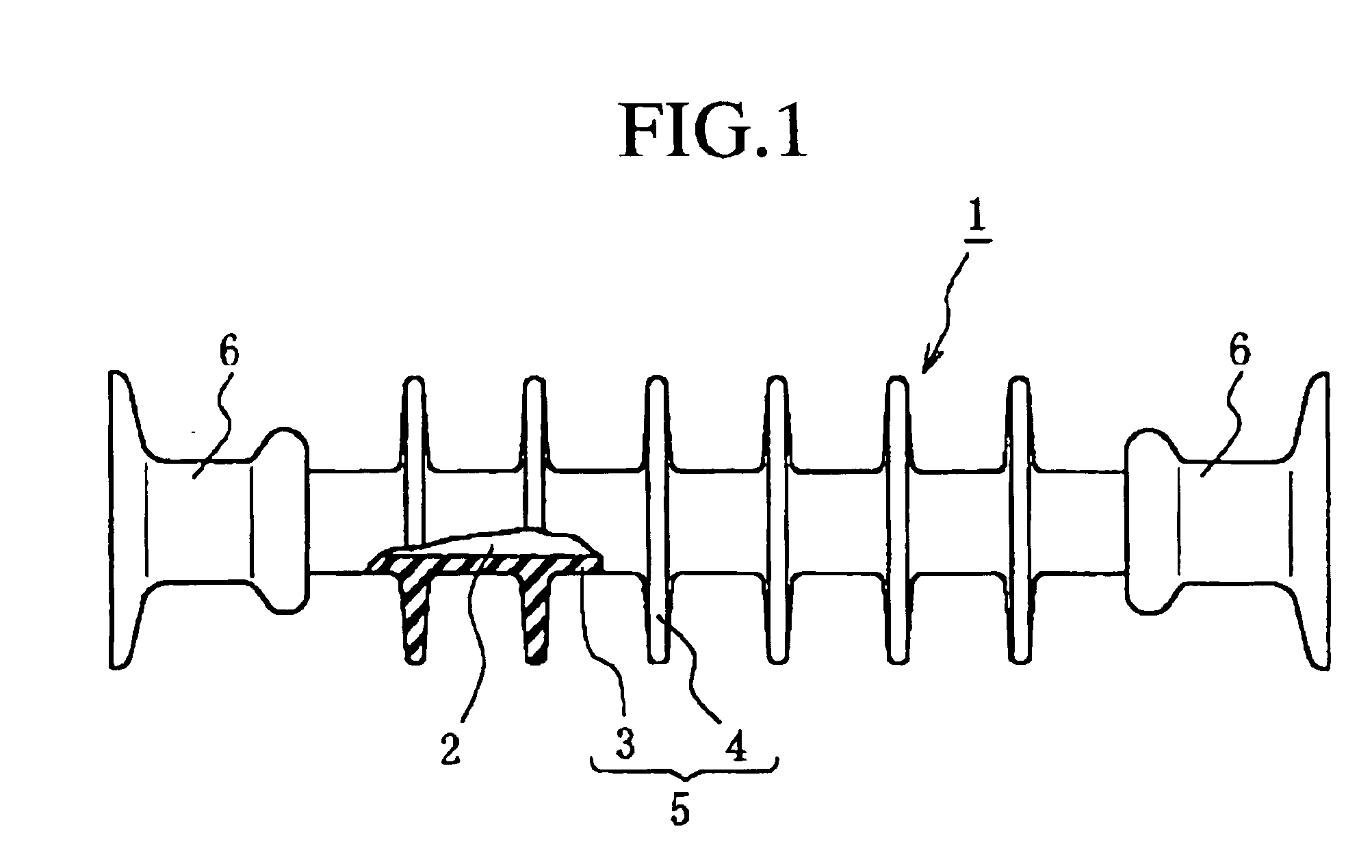

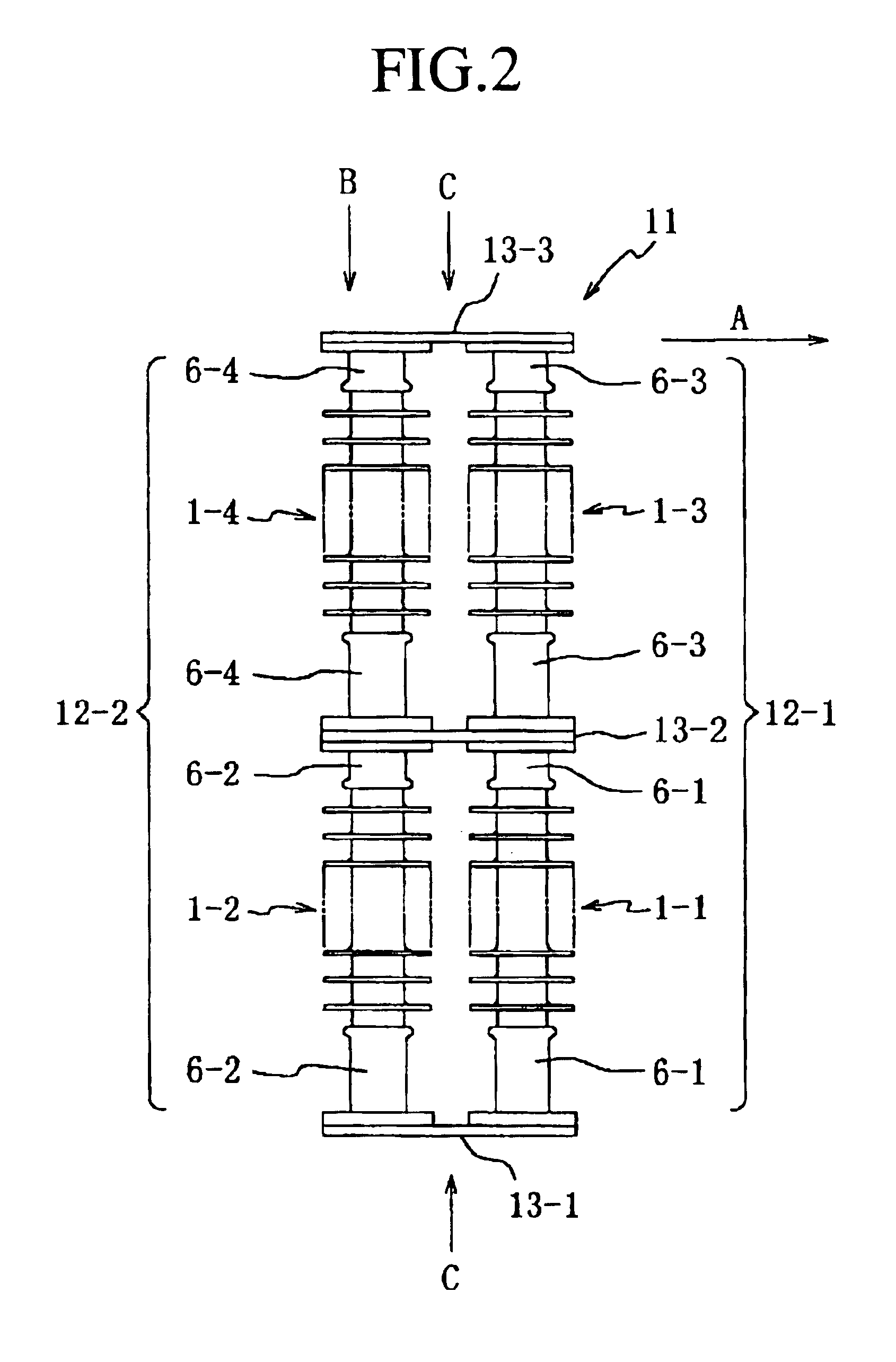

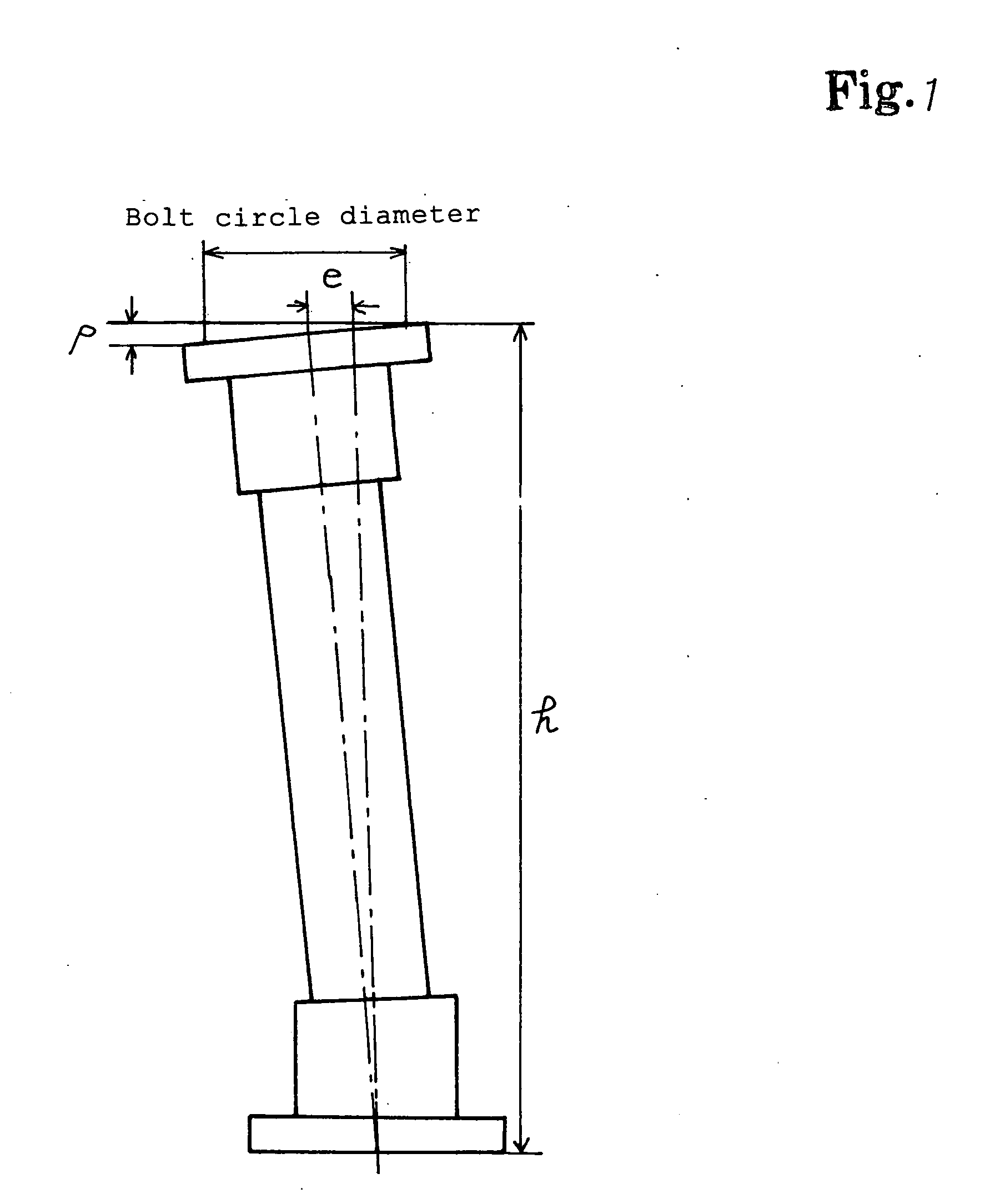

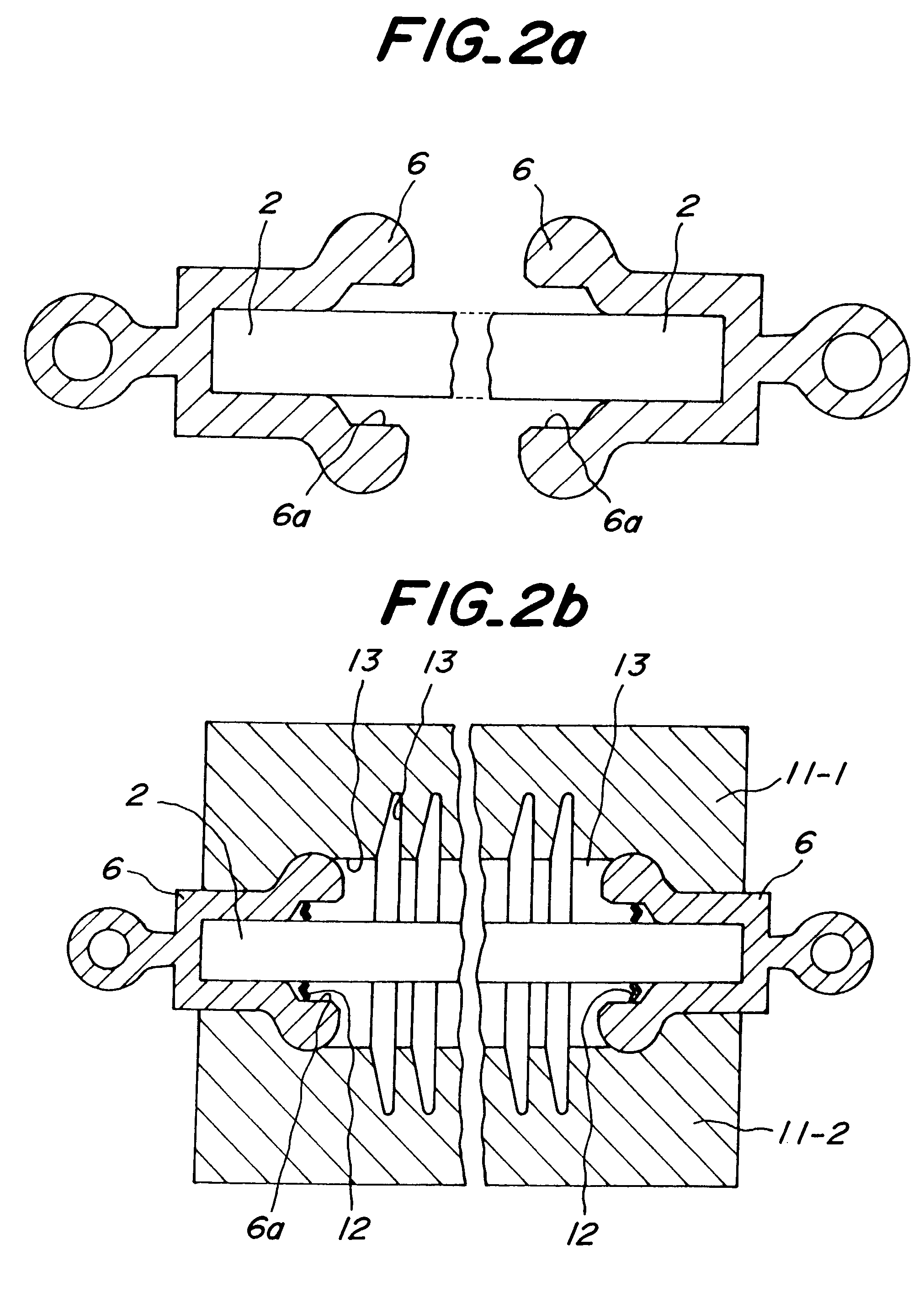

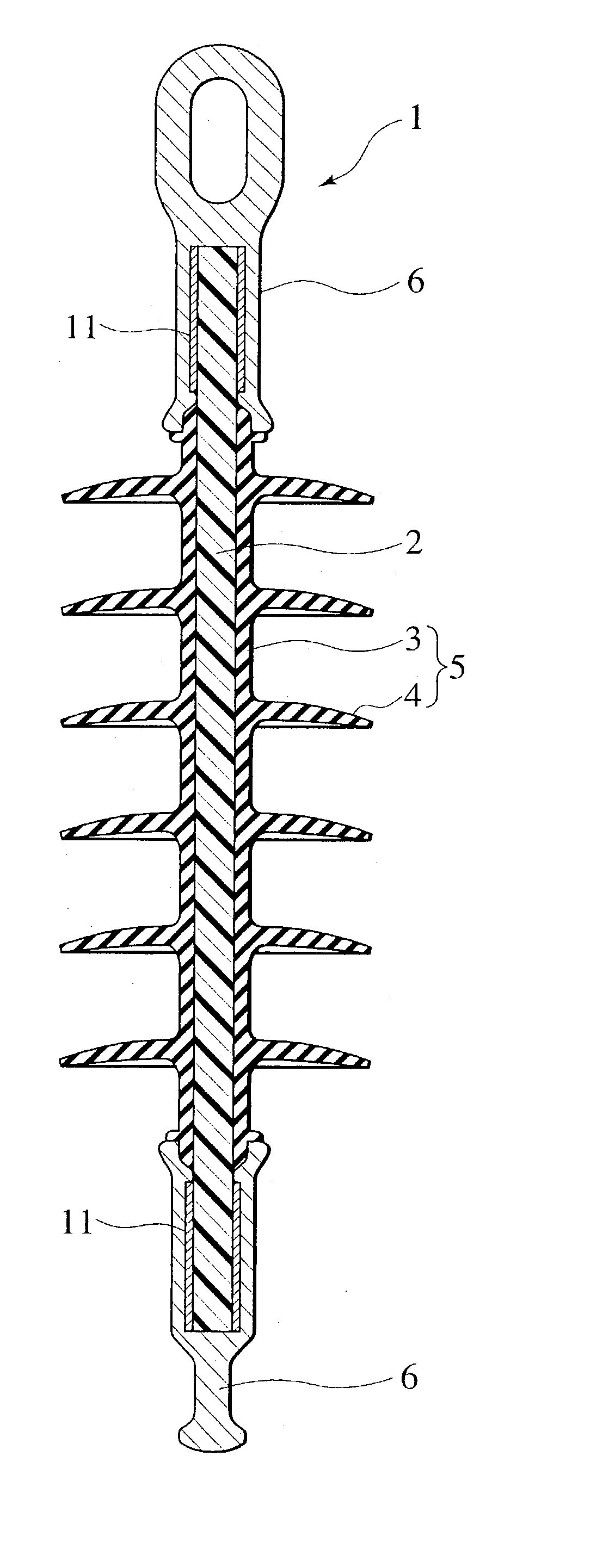

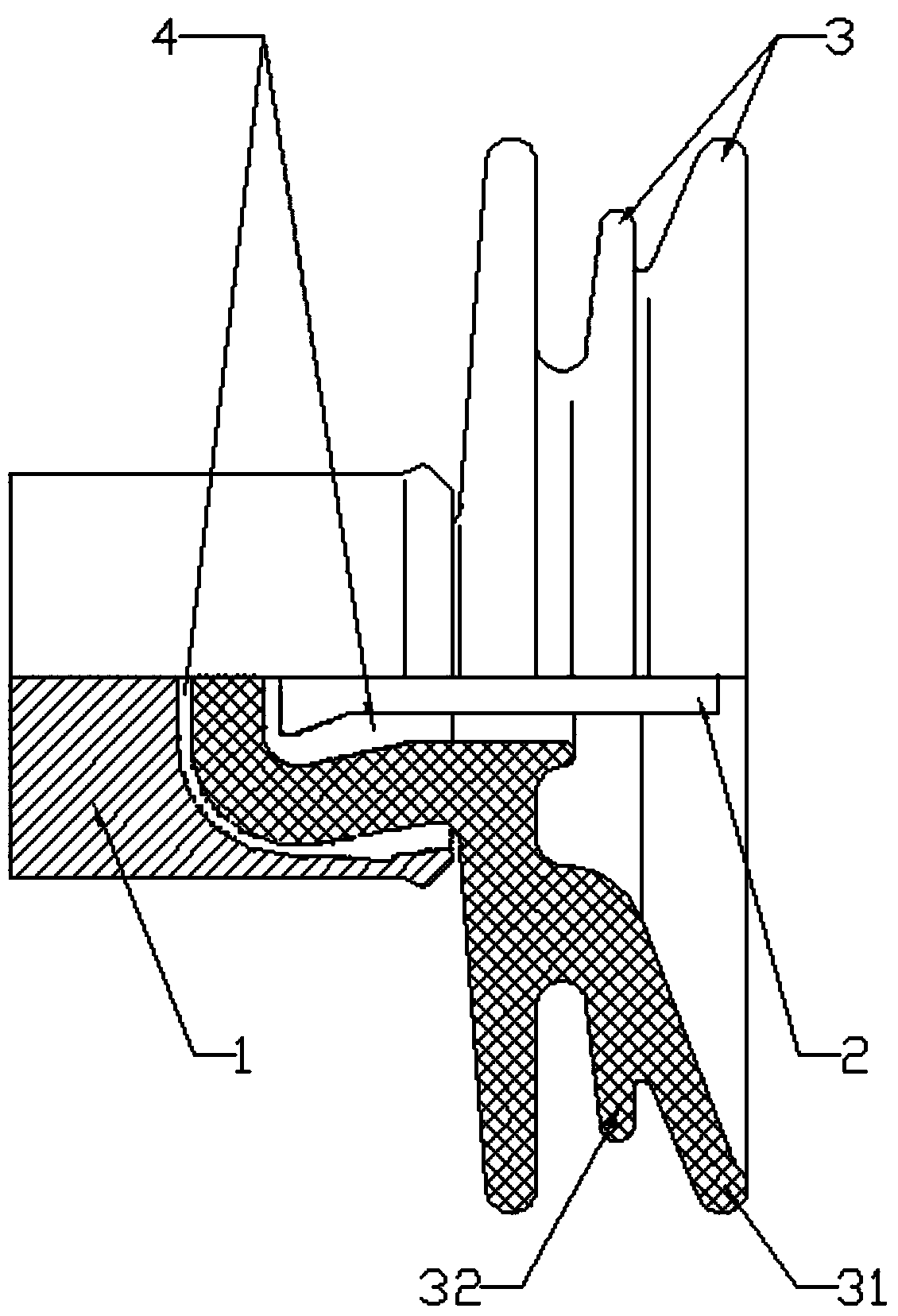

Polymer insulator apparatus and method of mounting same

InactiveUS6897384B2High strengthEasy to getPasturing equipmentSuspension/strain insulatorsPolymer insulationEngineering

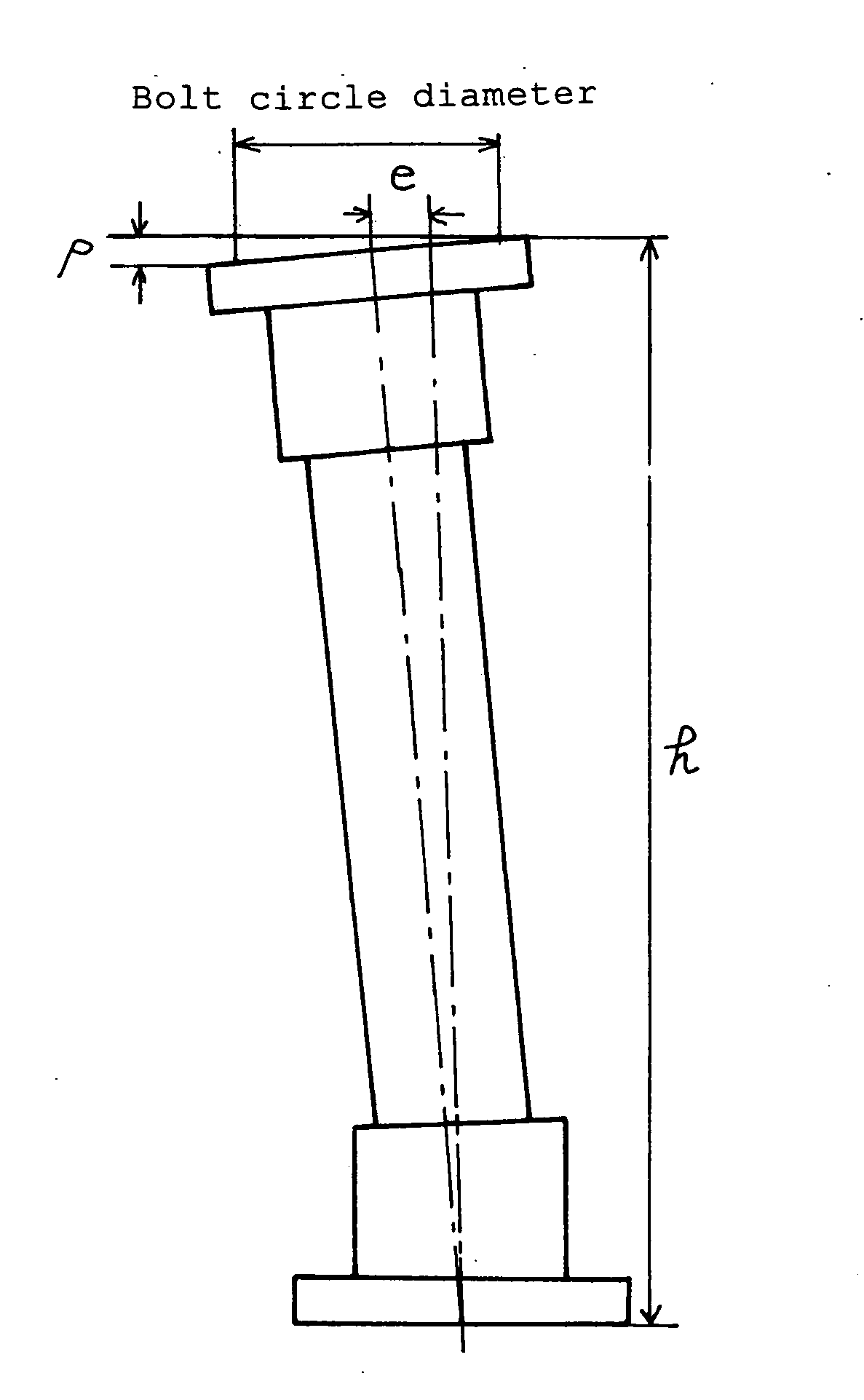

The cantilever and compression strength of a polymer post insulator decreases according to lengthening of lever length of the polymer post insulator. By combining polymer post insulators to construct a structure having an increased strength in an arbitrary direction, a polymer insulator apparatus and a method for mounting the same can provide a sufficient strength and rigidity even as a long insulator for high voltage that requires a long insulation distance. Polymer post insulator columns 12-1, 12-2, in which plural polymer post insulators 1-1 to 1-4 are stacked, are arranged in parallel. The polymer post insulator columns 12-1, 12-2 arranged in parallel are connected with each other via connecting plates 13-1 to 13-3 at each connection site of the polymer post insulators 1-1 to 1-4 constituting the polymer post insulator columns 12-1, 12-2 as well as at the top and bottom of the polymer post insulator columns 12-1, 12-2. Thus, the cantilever strength in a direction of arranging the polymer post insulator columns 12-1, 12-2 in parallel is increased, and also the compression strength in a direction of stacking the polymer post insulators 1-1 to 1-4 is increased.

Owner:NGK INSULATORS LTD

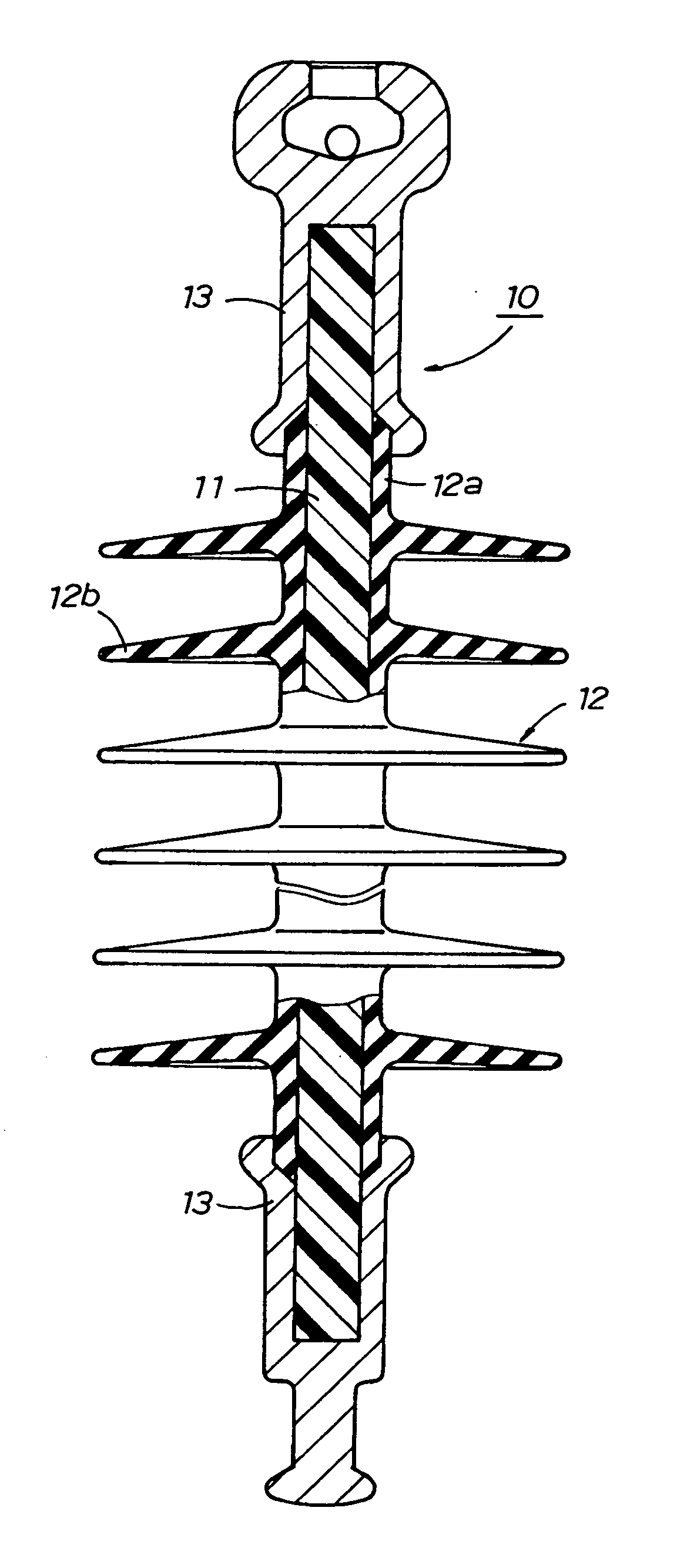

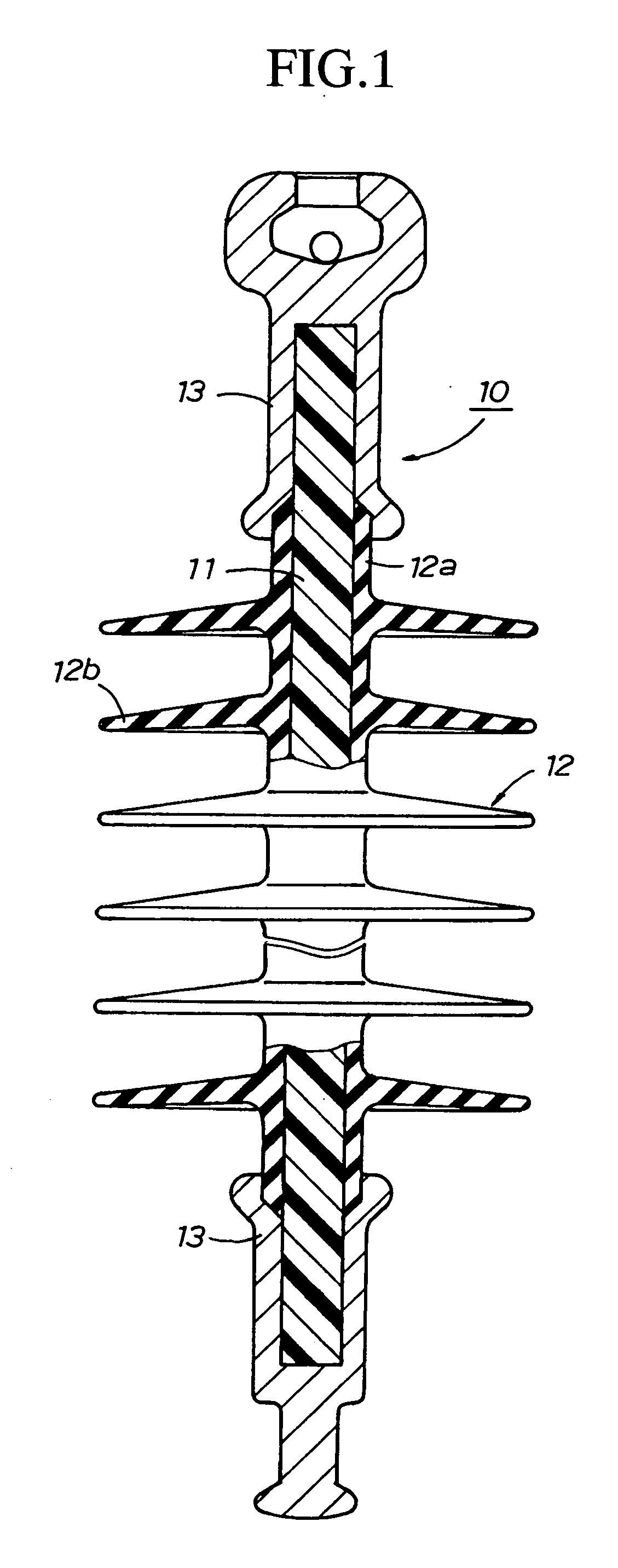

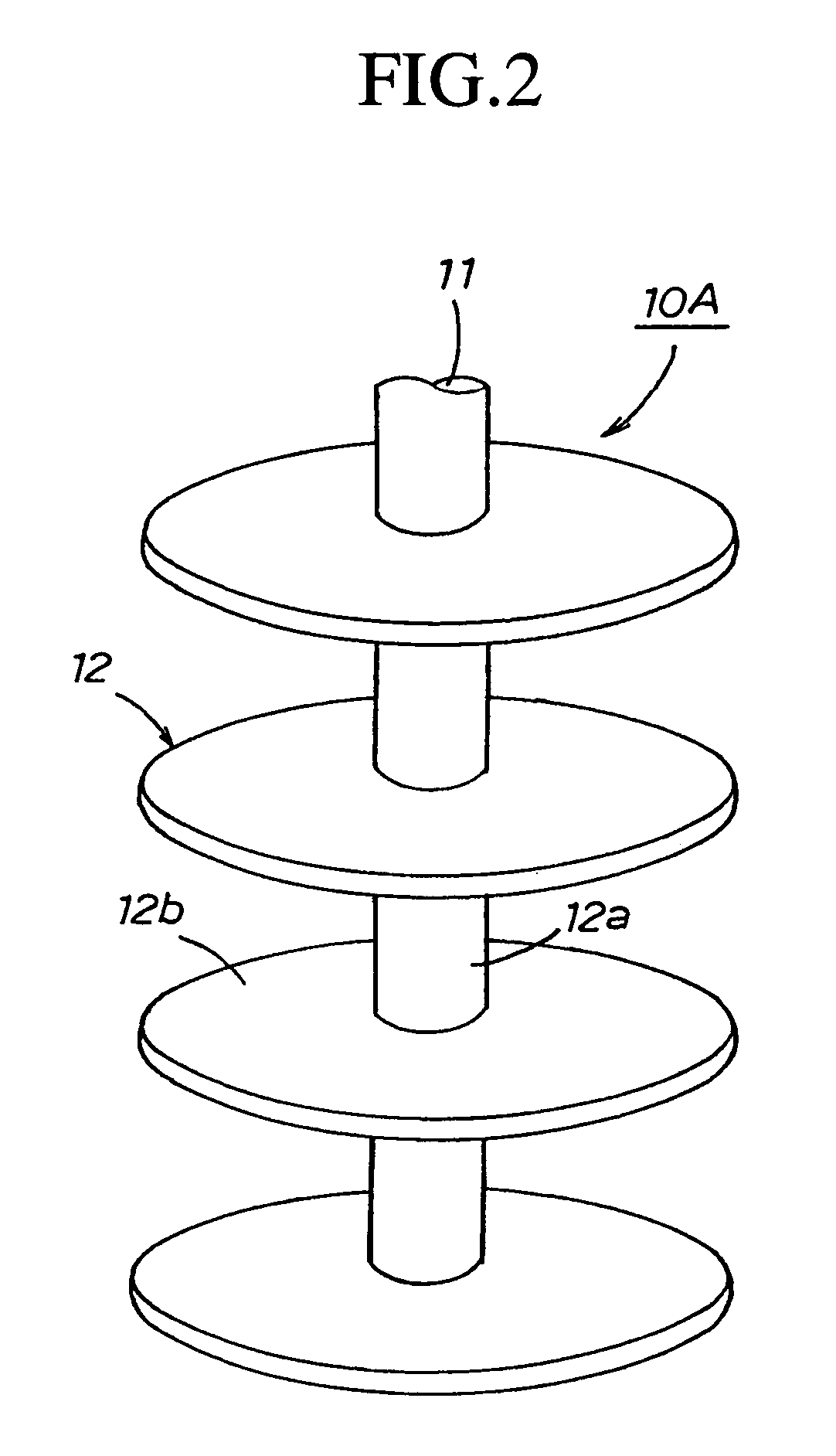

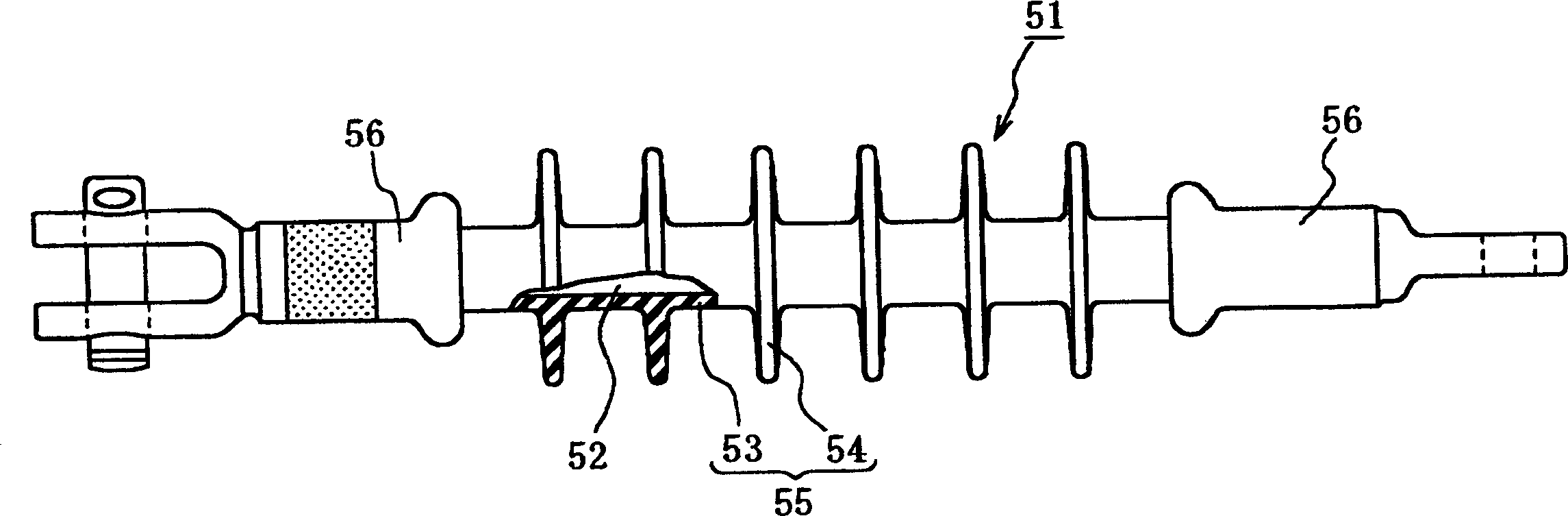

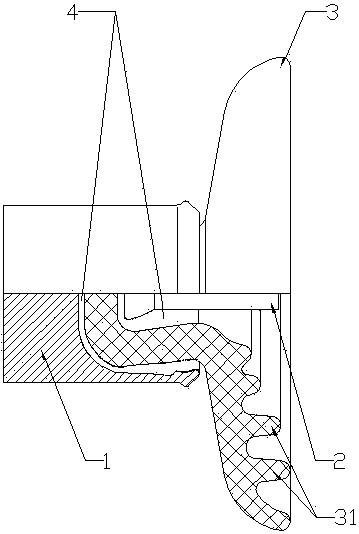

Bird-pecking-preventive polymer insulator

InactiveUS20050120975A1Avoid breakingAvoid peckingOverhead installationBiocideRubber materialPlastic materials

An object of the present invention is to prevent breakage of a cover member of a polymer insulator caused by pecking by a bird, through use of an avian repellent which is carried by the polymer insulator and an avian repellency maintained at least during construction of power transmission equipment, thereby inhibiting pecking of the polymer insulator by birds. The bird-pecking-preventive polymer insulator according to the present invention includes an insulator body, and a holding metal piece 13 fitted on each end of the insulator body, the insulator body being composed of a core member 11 formed of a reinforced plastic material and a cover member 12 formed of a rubber material and covering the periphery of the core member, wherein the cover member 12 carries an avian repellent such as capsaicin.

Owner:NGK INSULATORS LTD

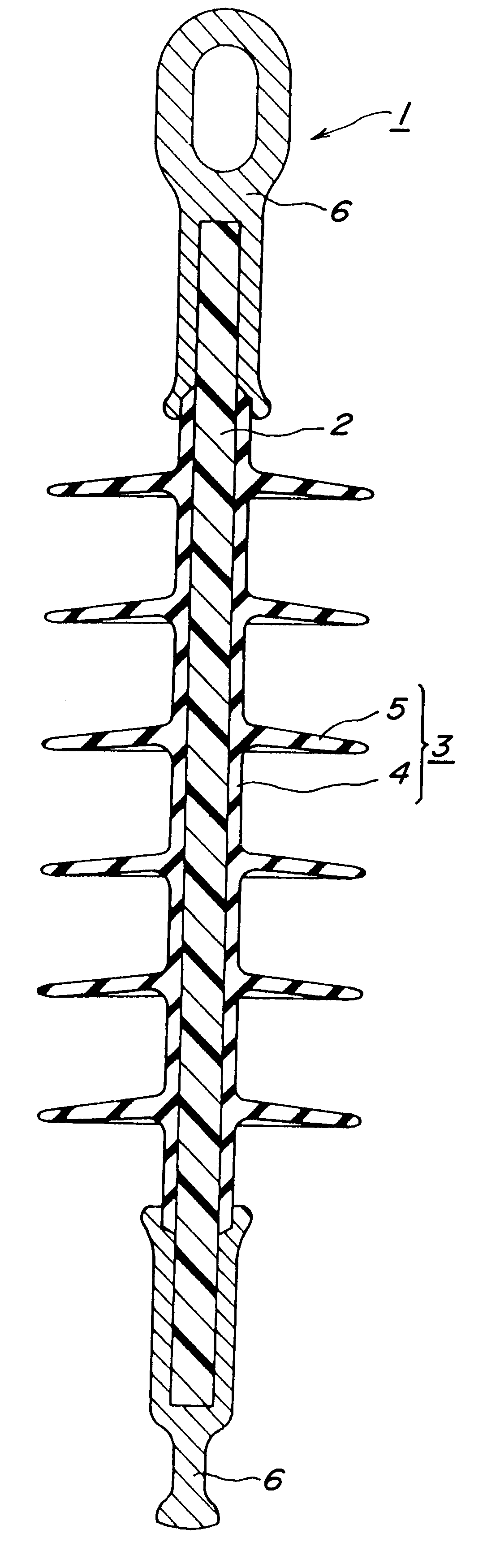

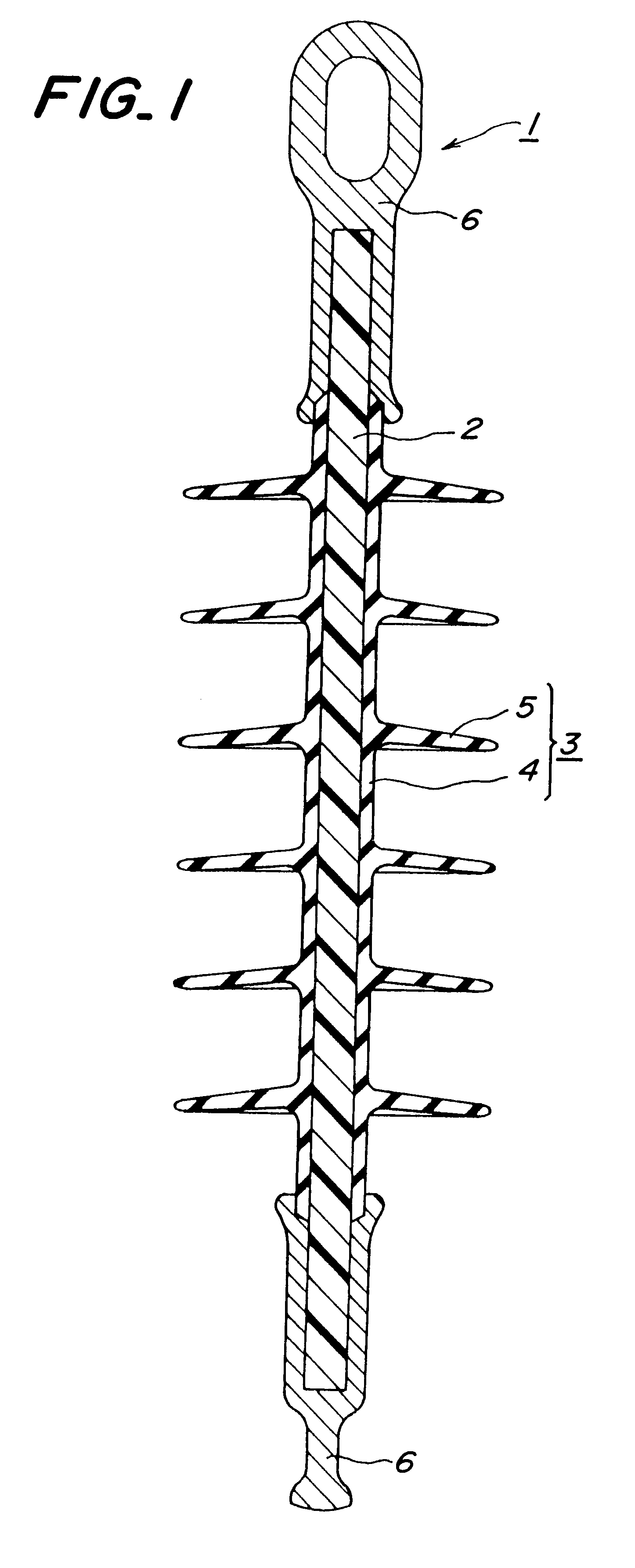

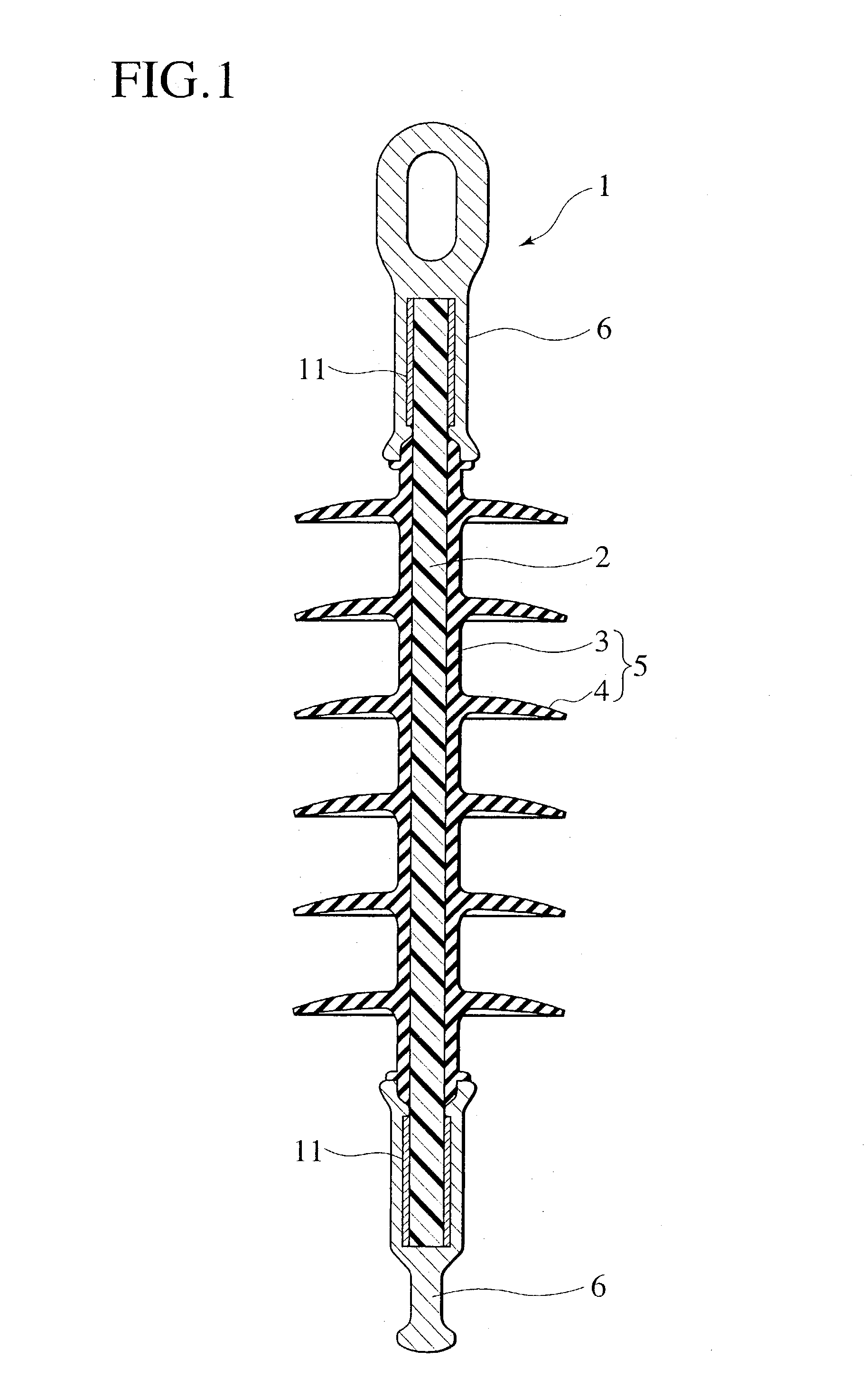

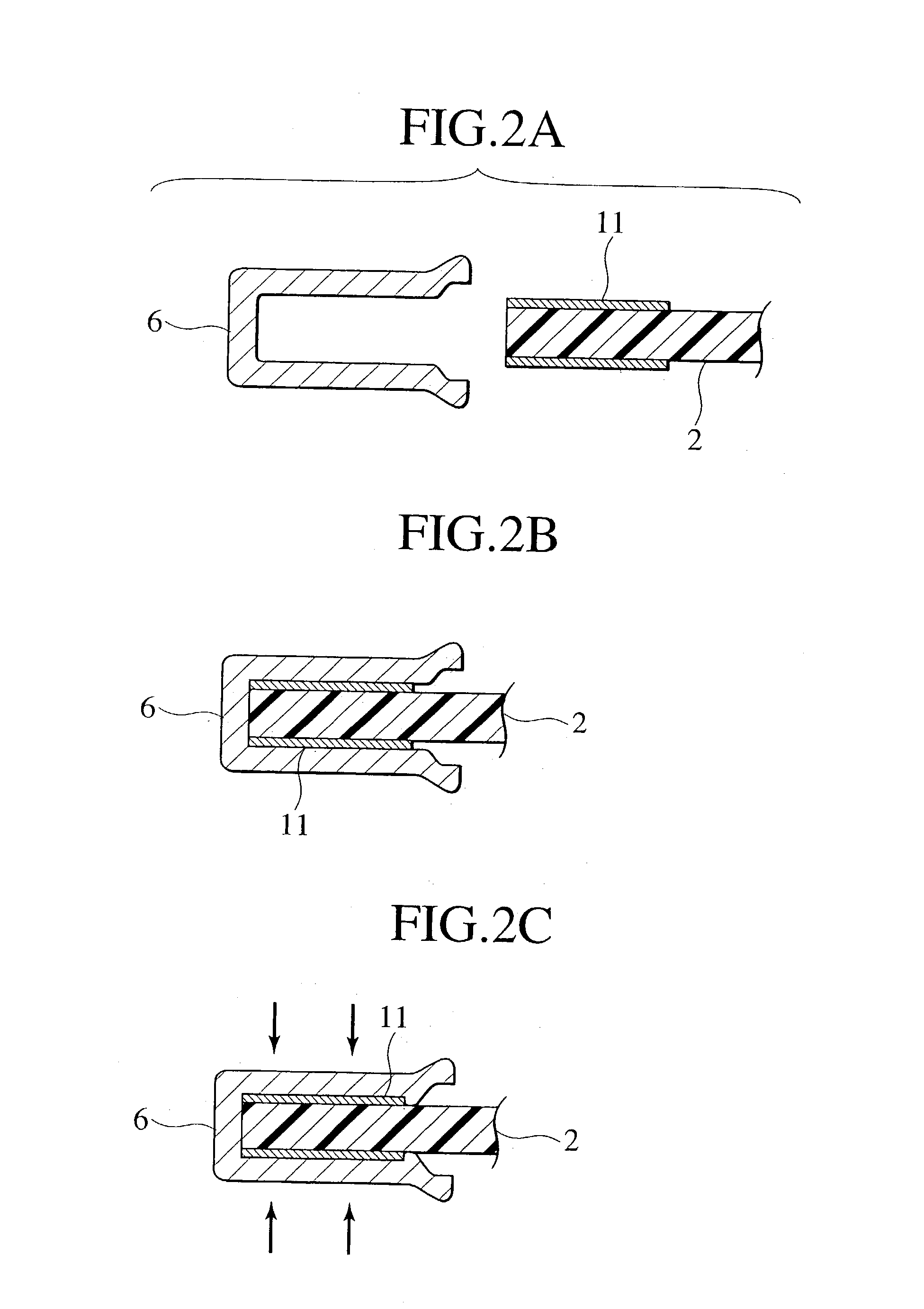

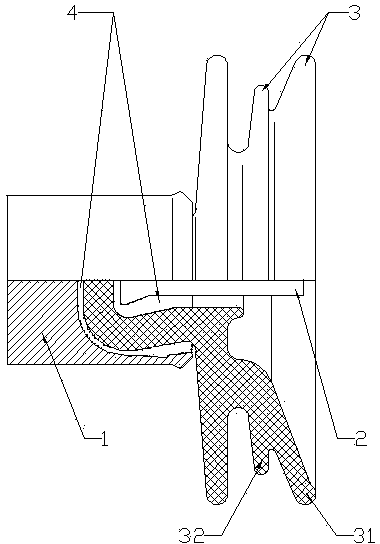

Polymer SP insulator

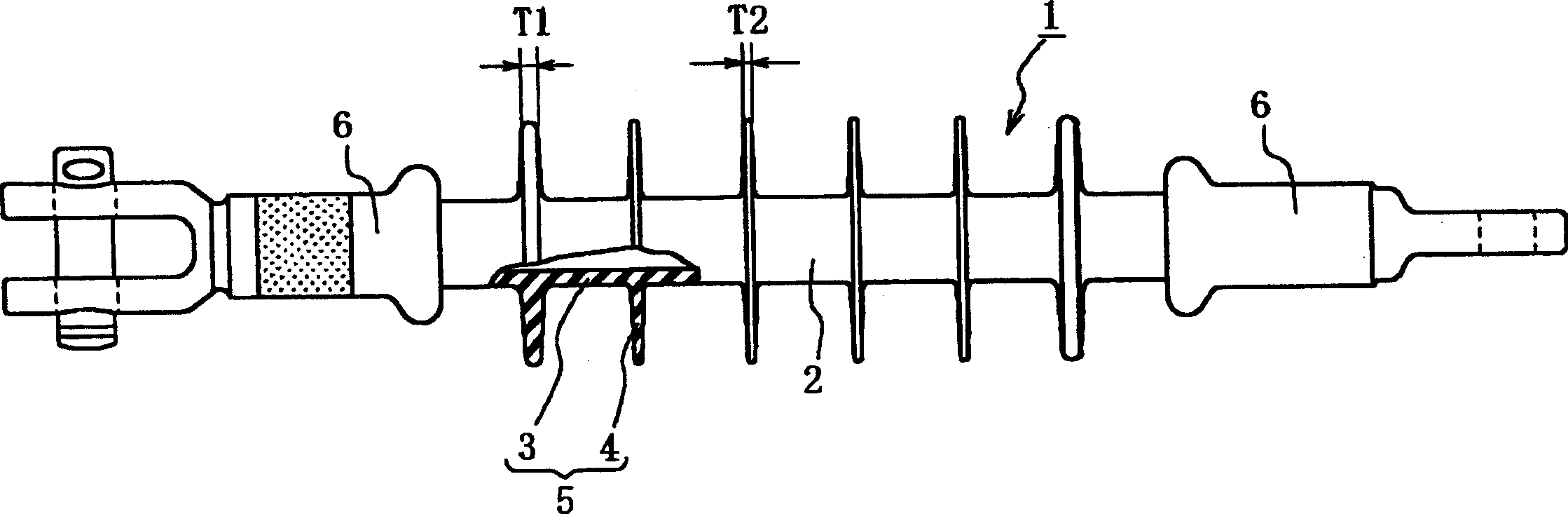

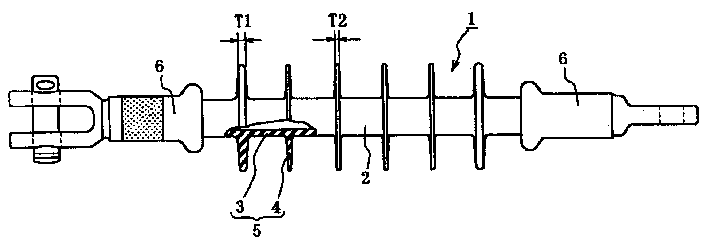

ActiveUS20060131063A1Length tolerance can be controlledIncrease of parallelismSupporting insulatorsInsulating bodiesStress concentrationPolymer insulation

A polymer SP insulator comprising an FRP core 1, a sheath 2 having a plurality of sheds 6 provided on outer periphery of FRP core 1, and metal-end-fittings 3, 4 crimped to upper and lower ends of FRP core 1, in which a flat plate 11 for adjusting the overall length dimension after crimping the metal-end-fitting 4 is assembled in the inner bottom of the metal-end-fitting 4, and the overall length dimension is uniformly adjusted by the thickness of the flat plate 11. Further, a stress concentration portion such as cross groove is provided in the outer bottom of the lower Metal-end-fitting 4, and prevents instability by deformation of flange 8 when crimping the Metal-end-fitting 4. In this configuration, in spite of the structure of crimping metal-end-fittings at upper and lower ends of the FRP core, the overall length tolerance, parallelism and eccentricity can be suppressed. In order to assure the flashover distance economically, preferably, the diameter of sheds of at least highest position and lowest position is larger than the diameter of intermediate shed.

Owner:NGK INSULATORS LTD

Method of detecting overcoating rubber flowed in space between core member and securing metal fitting of polymer insulator

InactiveUS6189387B1Accurate measurementWork measurementMaterial strength using steady torsional forcesCoated surfacePolymer insulation

A method of detecting an overcoating rubber flowed in a space between a core member and a securing metal fitting of a polymer insulator having the core member, the overcoating arranged around the core member and the securing metal fitting fixed to at least one end of the core member, is disclosed. The method includes the steps of: applying a torque in a circumferential direction to the securing metal fitting, after forming the overcoating rubber but before fixing the securing metal fitting to the core member; deforming an index provided on a surface of the overcoating; and detecting whether the overcoating rubber is existent or not in the space between the securing metal member and the core member in response to a deforming extent indicated by the index.

Owner:NGK INSULATORS LTD

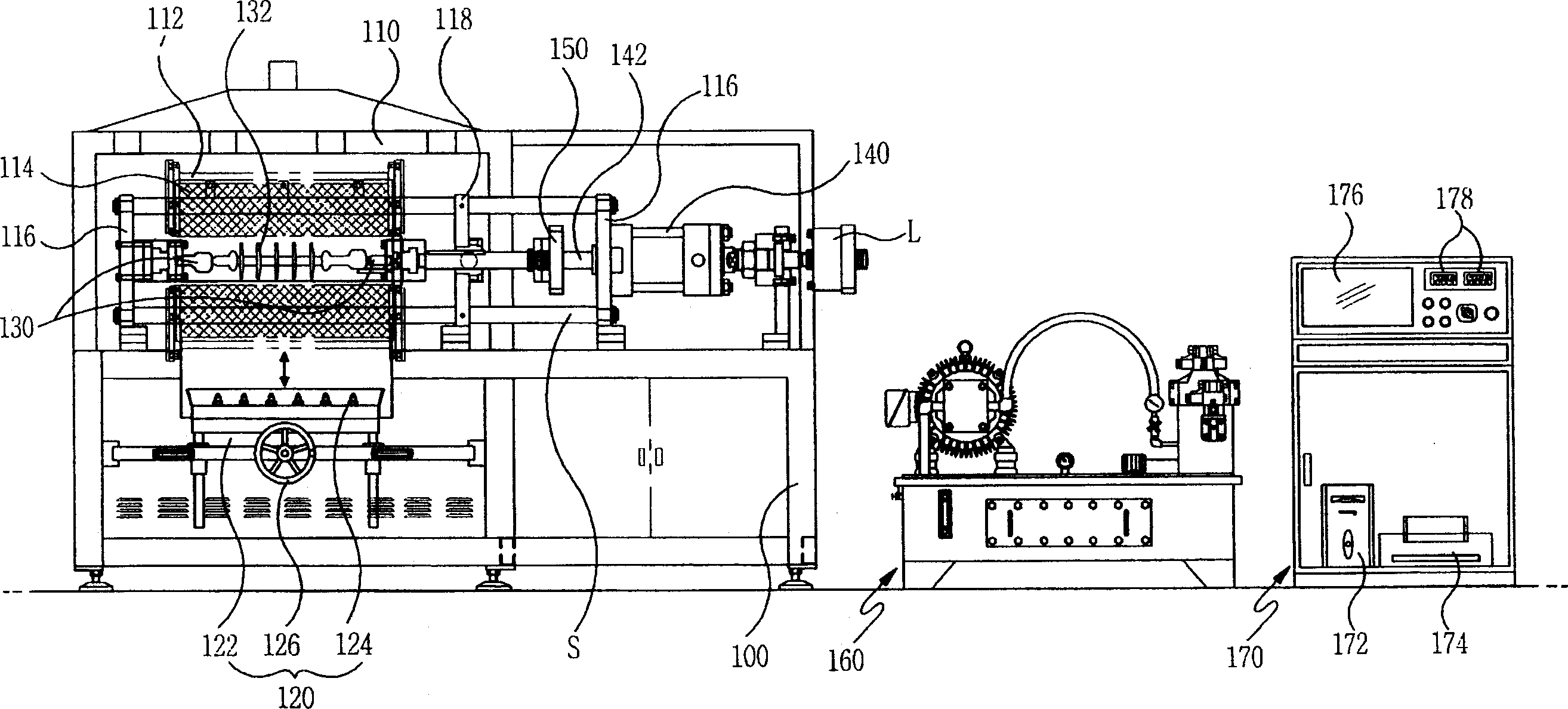

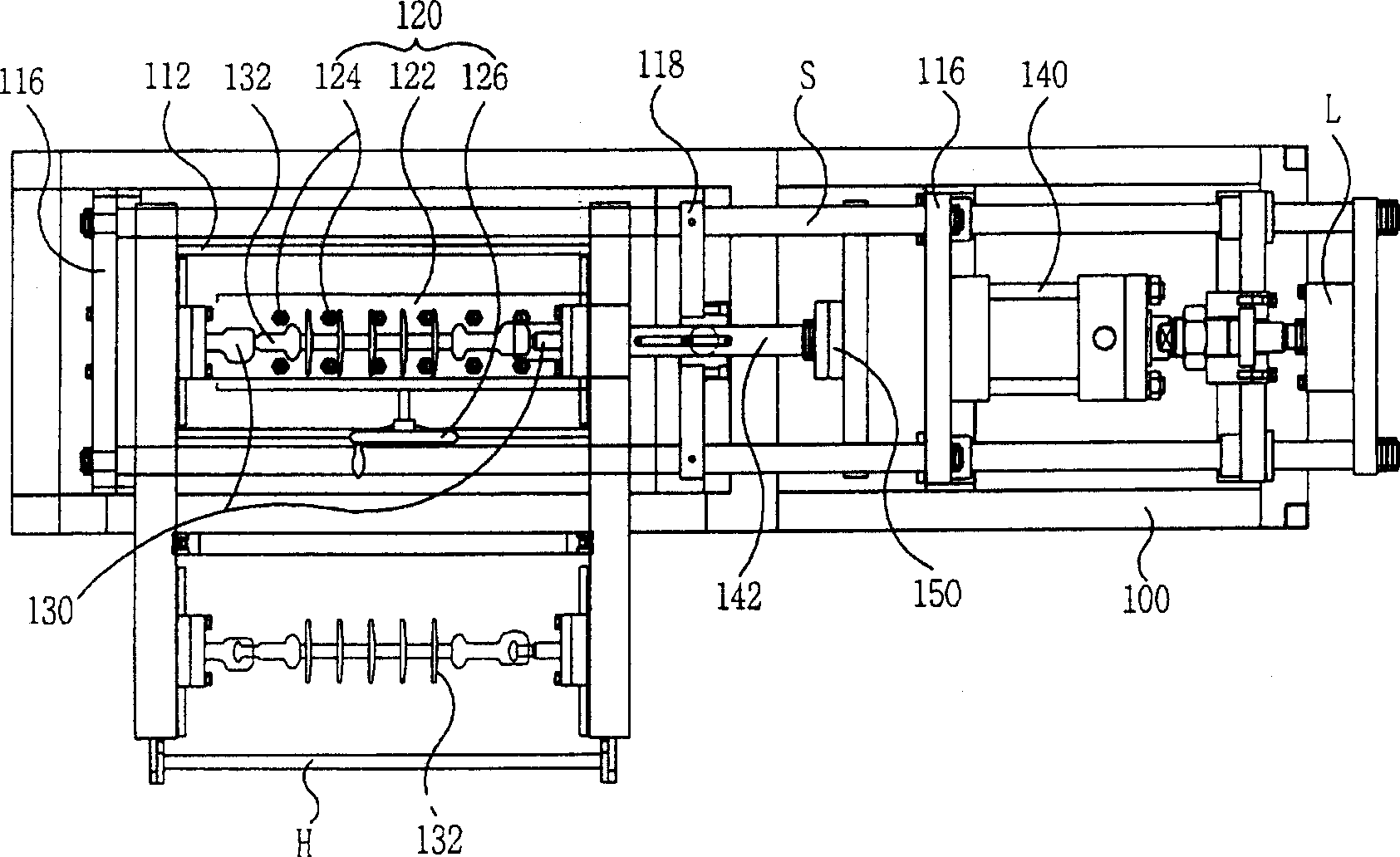

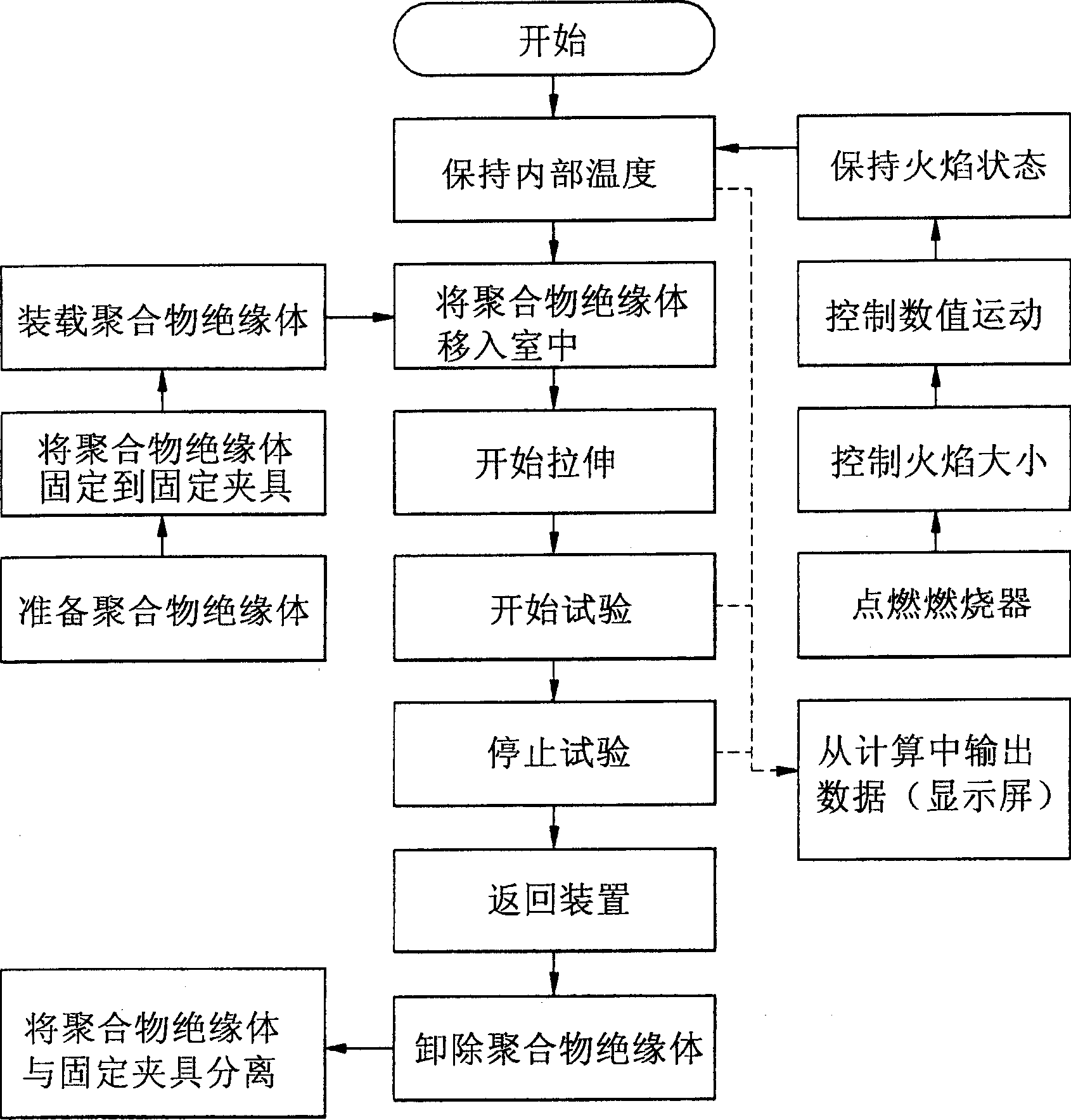

Forest fire simulated test equipment for polymer insulator

InactiveCN1737529AAvoid accidentsMaterial strength using tensile/compressive forcesInvestigating material ductilityElectrical resistance and conductancePolymer insulation

A device for forest fire simulation test of a polymer insulator is provided, which comprises a heating unit arranged below the polymer insulator that is positioned inside a heating furnace to supply a heating source; a stretching force supply unit arranged collinearly to the polymer insulator and used to supply the polymer insulator with a stretching force when the corresponding end of the polymer insulator is fixed to a fixation clamp; a stretching force measuring unit for measuring the stretching force applied to the polymer insulator, the stretching force measuring unit comprising a dynamometer that is used to convert a dependent variable of the polymer insulator produced by the stretching force supply unit to a resistance to measure loads, and is arranged in the same line as the stretching force supply unit and positioned behind thereof, and a data storage / output unit for storing and output temperature values of the heating unit and data values measured by the stretching force measuring unit.

Owner:KOREA ELECTRIC POWER CORP

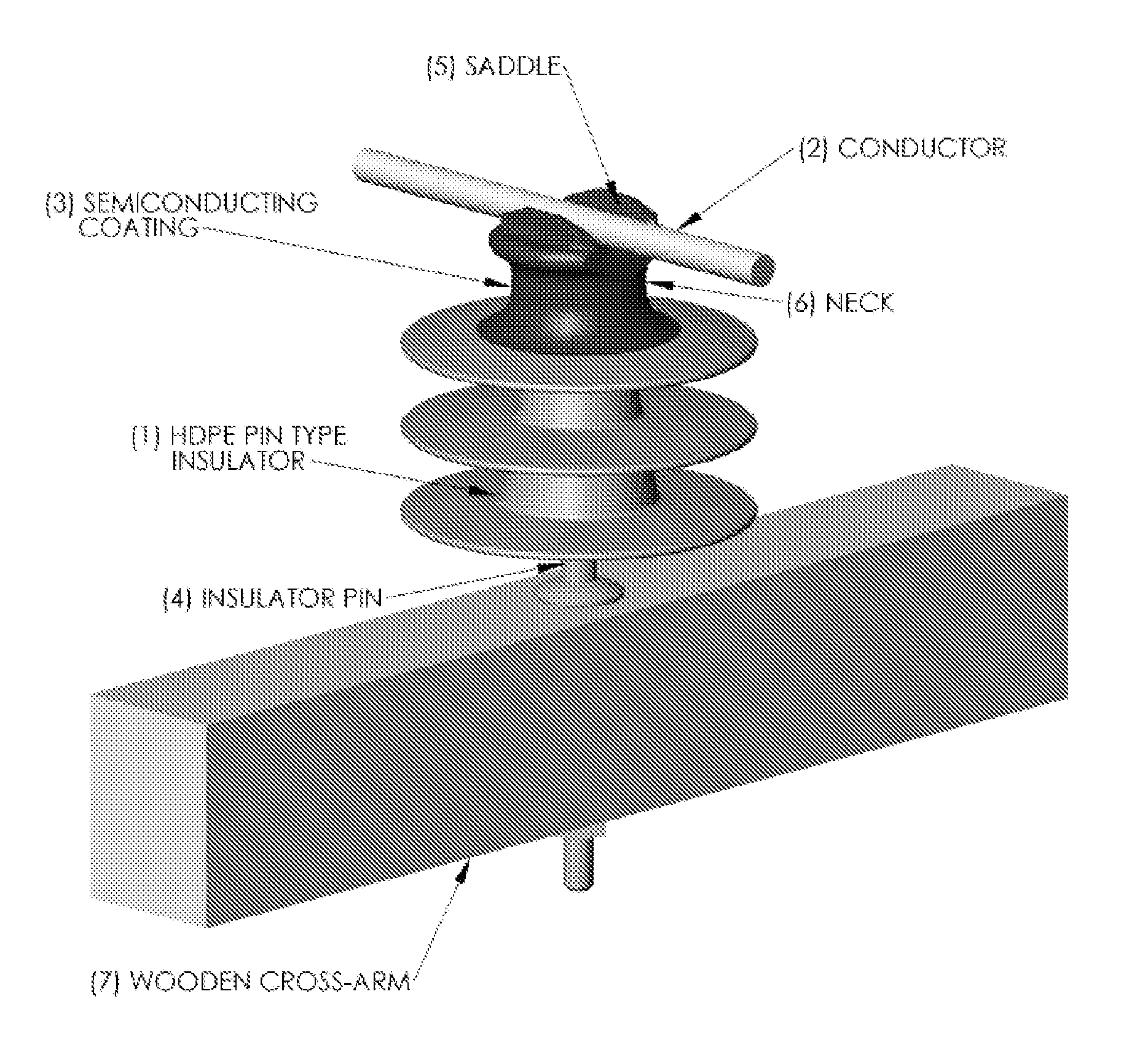

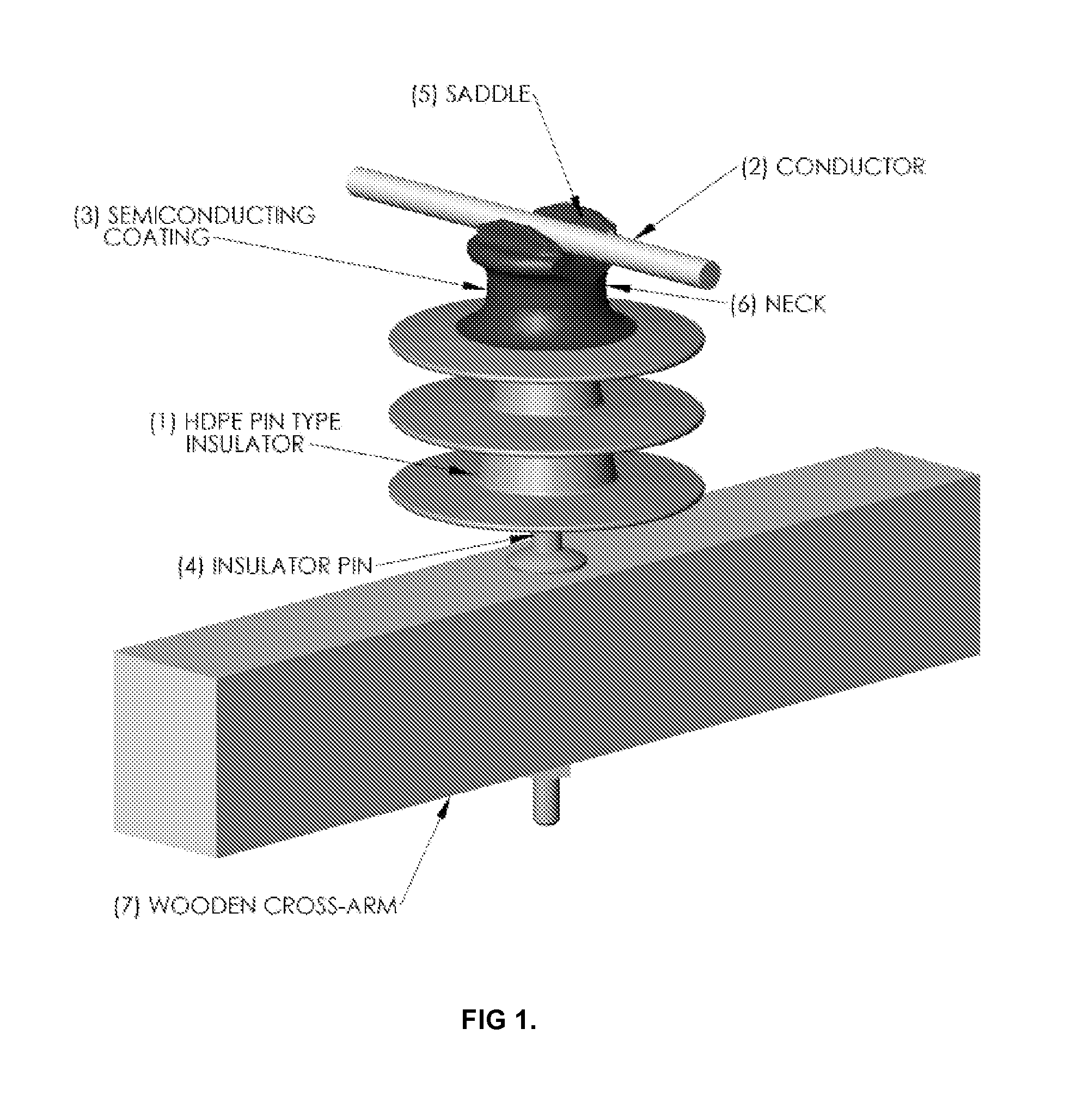

Method of increasing puncture strength and high voltage corona erosion resistance of medium voltage polymer insulators

InactiveUS20080057215A1Reduces or eliminates corona erosion (corona cutting) of the polymer materialElectric shock equipmentsPretreated surfacesPolymer sciencePolymer insulation

Medium voltage polymer insulators coated with semi-conducting refractory paint exhibit higher puncture strength and better corona erosion (corona cutting) resistance than a typical non-coated polymer insulator. The refractory semi-conducting paint is surface bonded to the ends of the polymer chains via electron beam reactive processing methods resulting in a mechanical bond on a molecular level to the polymer chain.

Owner:HENDRIX WIRE & CABLE

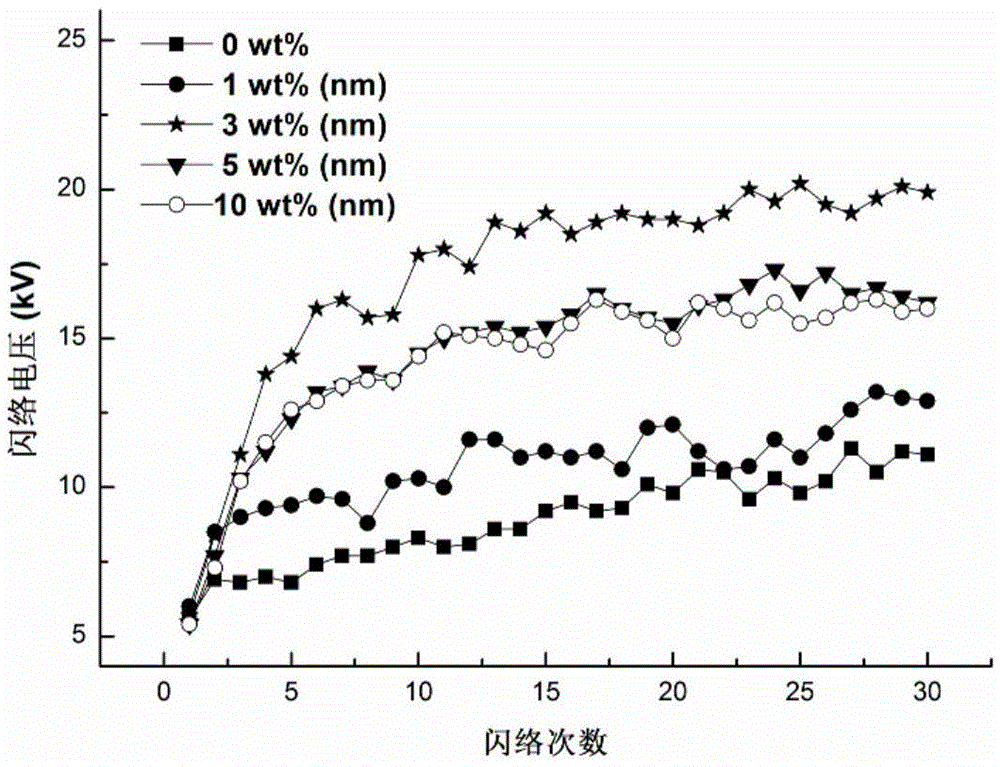

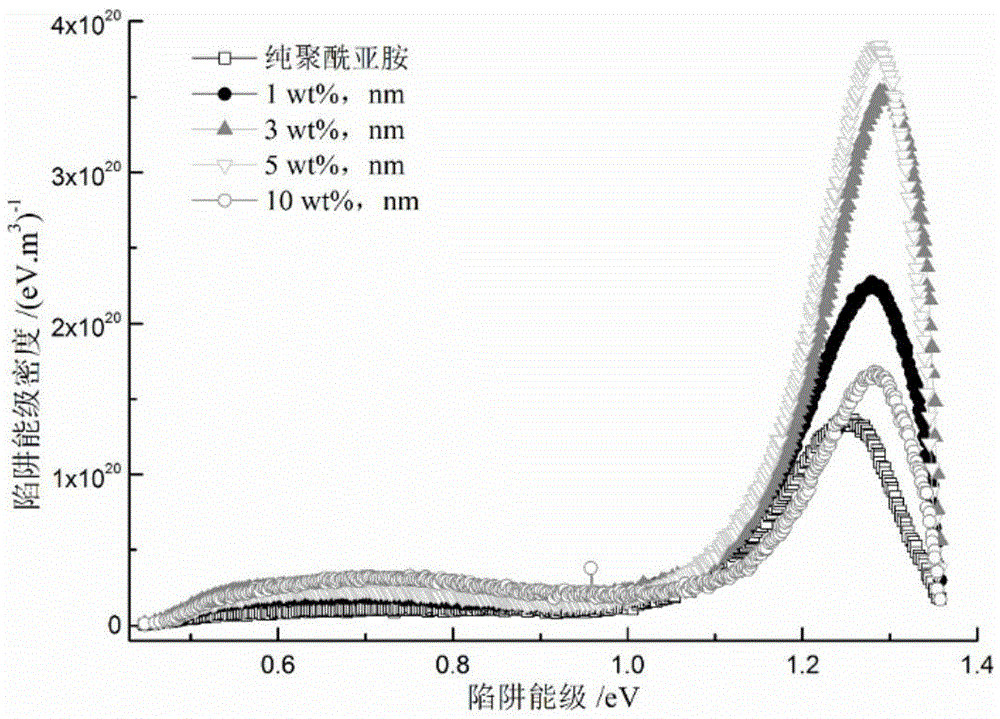

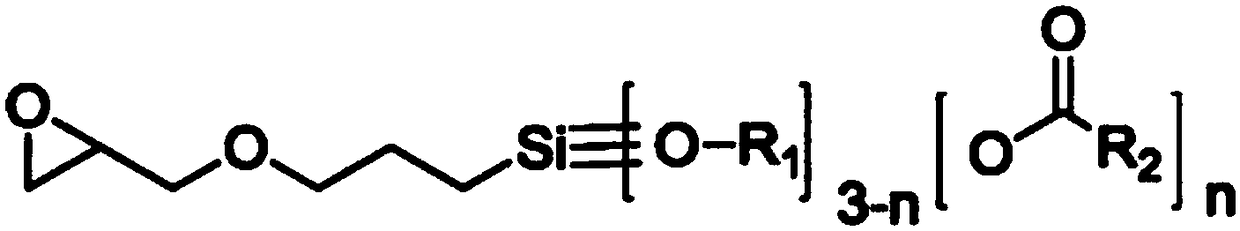

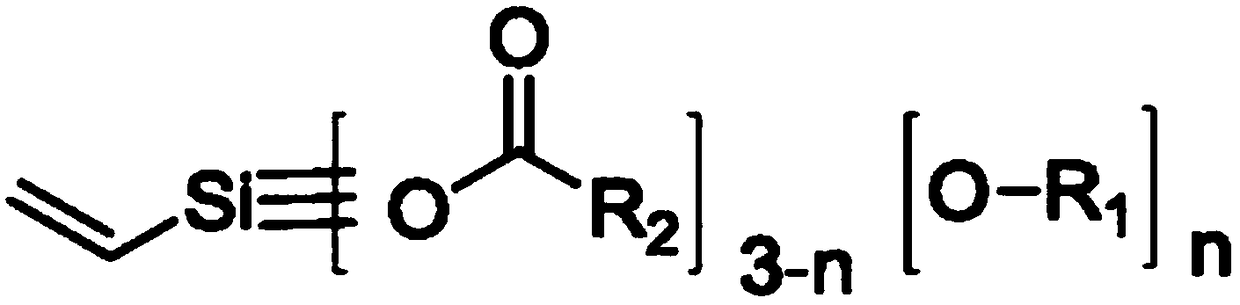

Polymer insulator material and preparation method thereof

InactiveCN105602248AReduce surface activityImprove interface compatibilityPlastic/resin/waxes insulatorsPolymer scienceAlcohol

The invention discloses a polymer insulator material which is prepared from, by mass, 90-99% of polyimide and 1-10% of zinc oxide powder. A preparation method includes the following steps of firstly, adding nanometer zinc oxide powder to a mixed alcohol-water solution containing a coupling agent, dispersing the mixed solution through the ultrasonic oscillation and high-speed stirring combined mode, and conducting grinding after vacuum drying to obtain modified nanometer zinc oxide micro powder; secondly, dispersing the modified nanometer zinc oxide micro powder in the first step in ethyl alcohol, adding polyimide to be evenly stirred and dried to obtain the polymer insulator material powder, and pressing and forming the prepared polymer insulator material powder. The compound sample is prepared through a blending compound mode, operation is easy, conditions are easy to control, the environment is not polluted, and the material can be applied to preparation of polymer insulators of various powder materials. Therefore, the material has the advantages of being wide in application range, high in reliability, simple in process, high in operability and the like.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

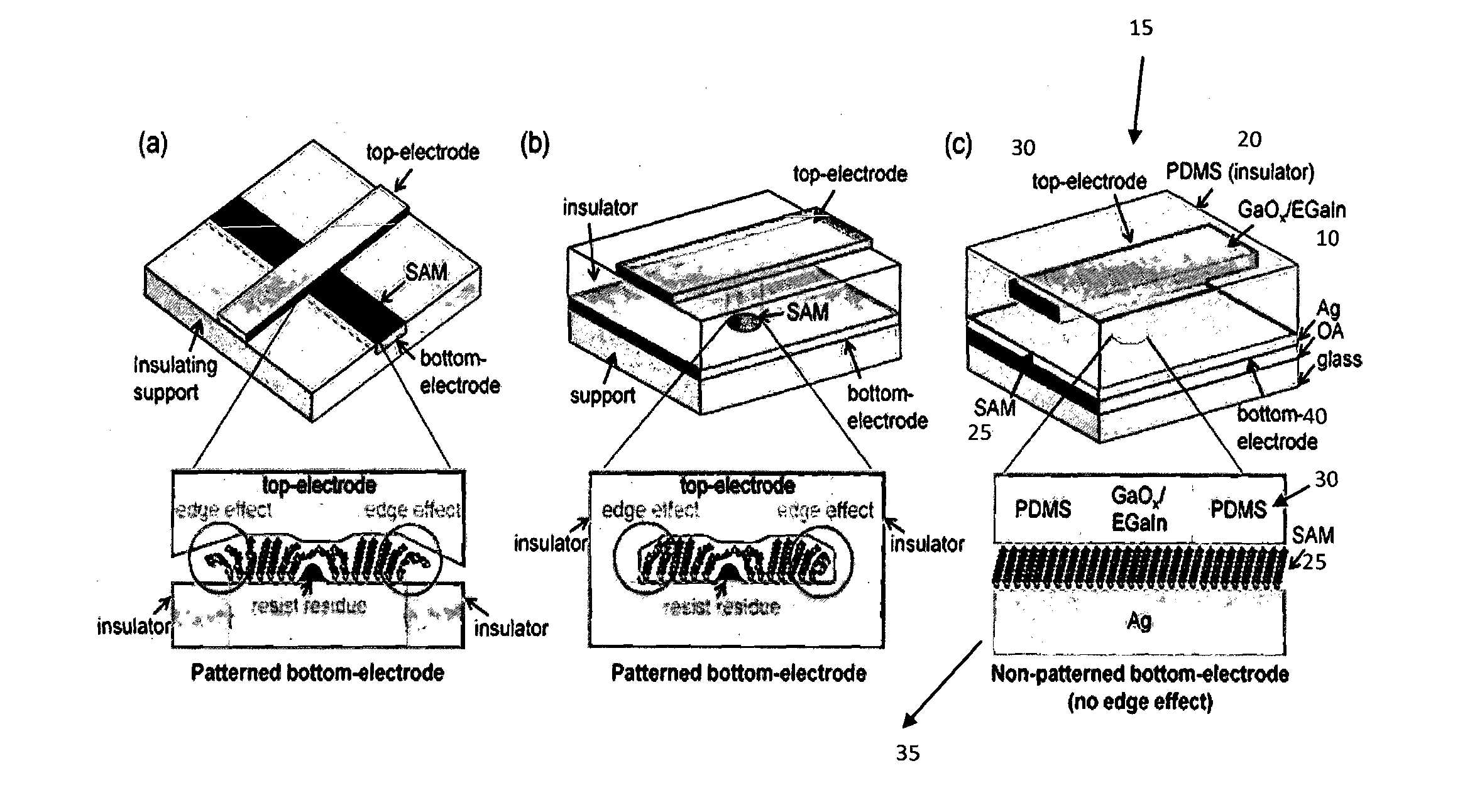

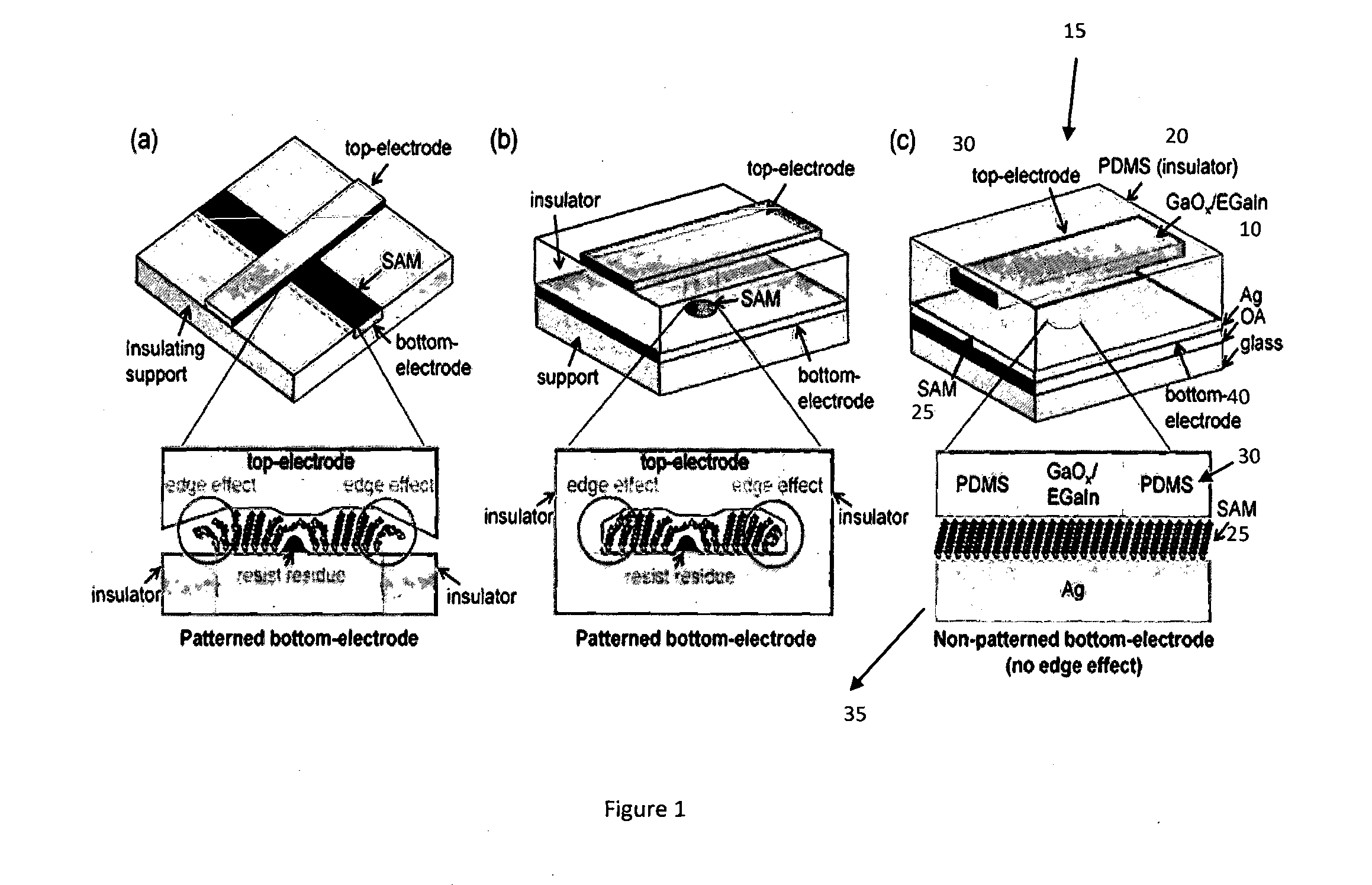

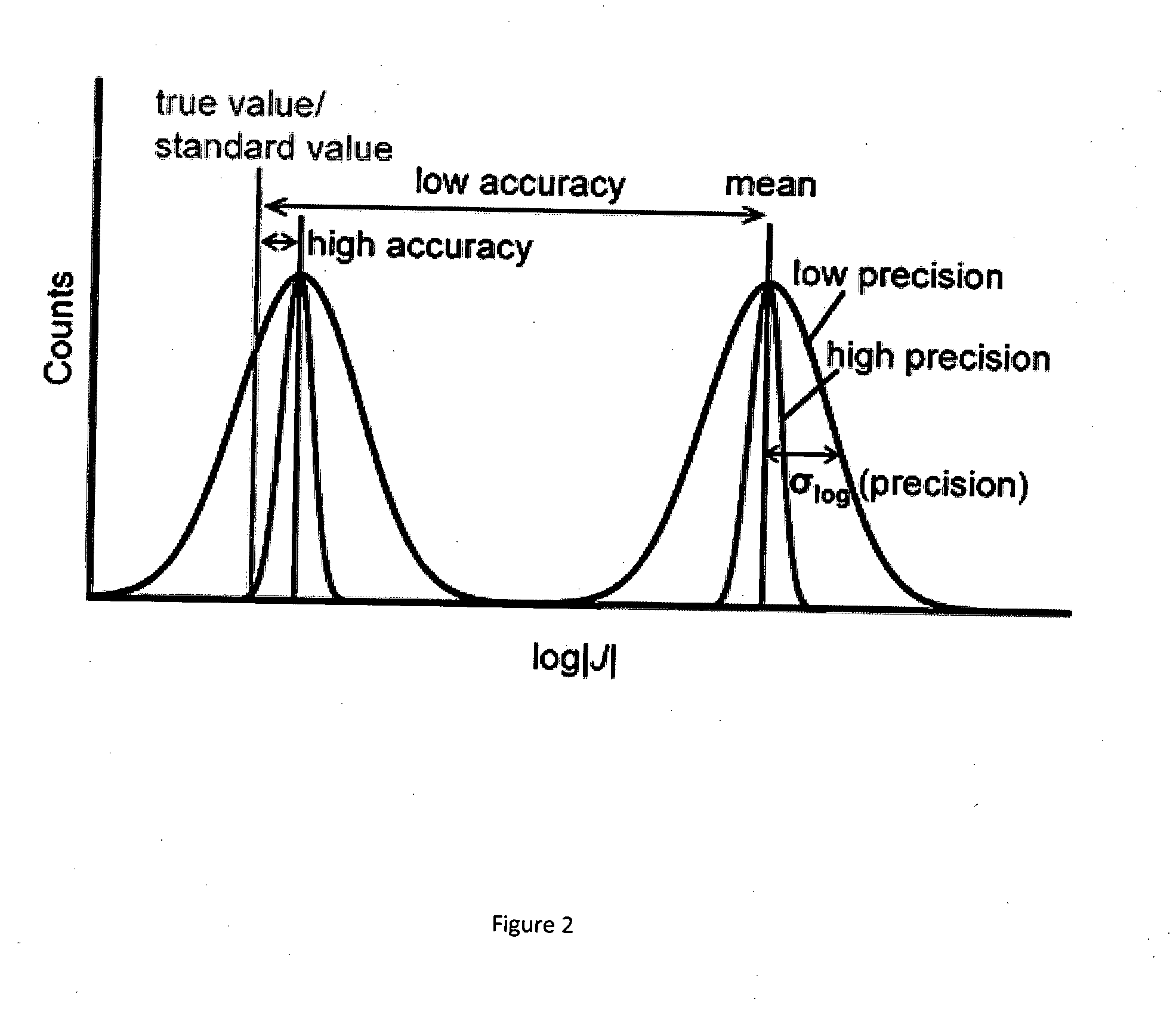

Electrical contact

ActiveUS20160293722A1Surface free energy is not minimizedLow viscositySolid-state devicesMaterial analysis by electric/magnetic meansPolymer insulationLiquid metal

The present invention relates to an electrical contact. In particular, it relates to an electrical contact capable of establishing an electrical contact with a soft material. More particular, the electrical contact comprises (a) a non-Newtonian liquid metal alloy, the non-Newtonian liquid metal alloy is formed in a polymer insulator, wherein the contact surface of the electrical contact that contacts the soft material is a smooth flat non-patterned surface, the surface comprising the non-Newtonian liquid metal alloy sandwiched between the polymer insulator. The microfluidic device comprising the electrical contact and a method for forming the electrical contact are also disclosed.

Owner:NAT UNIV OF SINGAPORE

Method in connection with a radiosonde and system

ActiveUS20180180769A1Improve consistencyHigh measurement accuracyTransmission systemsMaterial analysis by electric/magnetic meansPressure decreaseRadiosonde

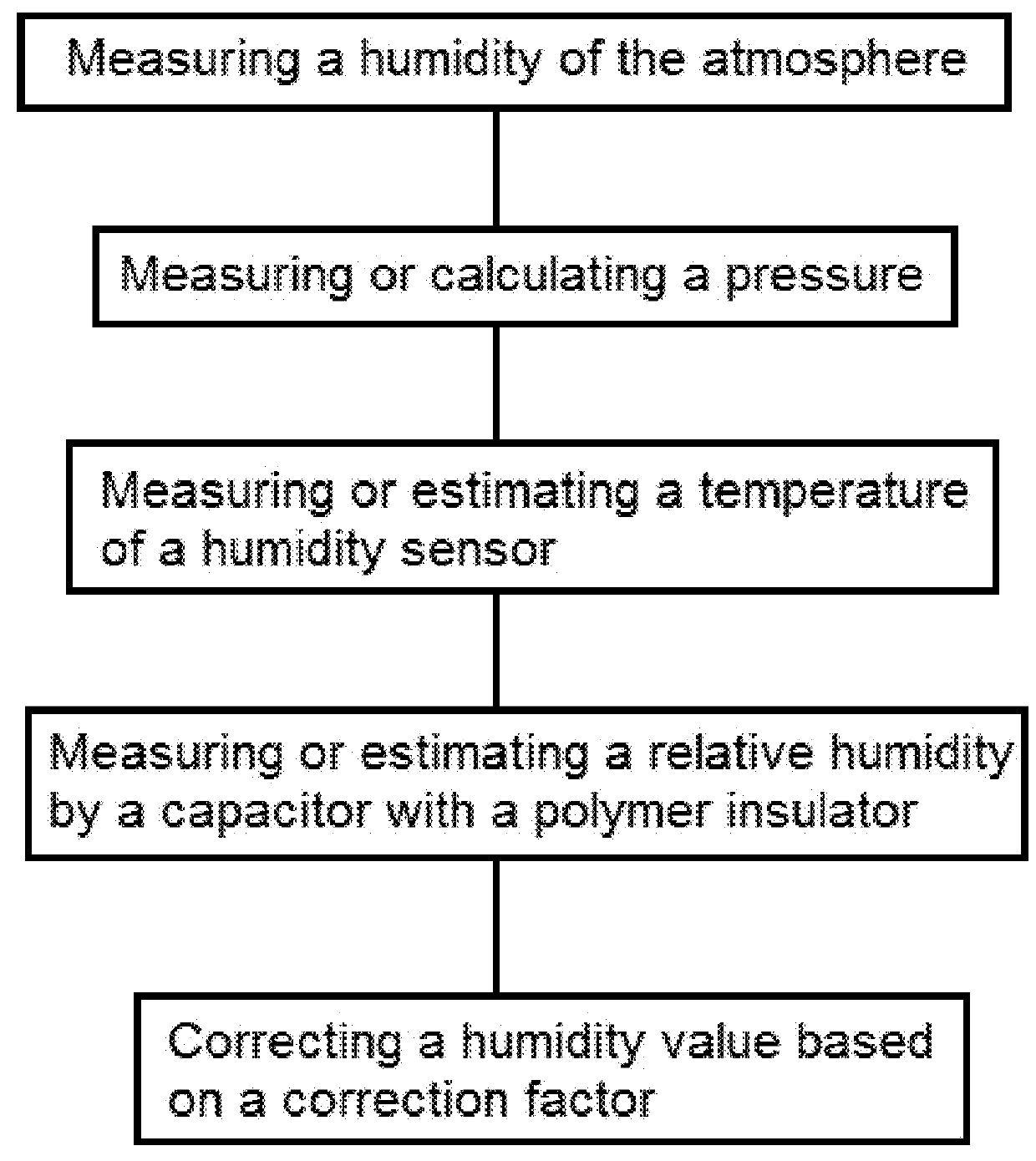

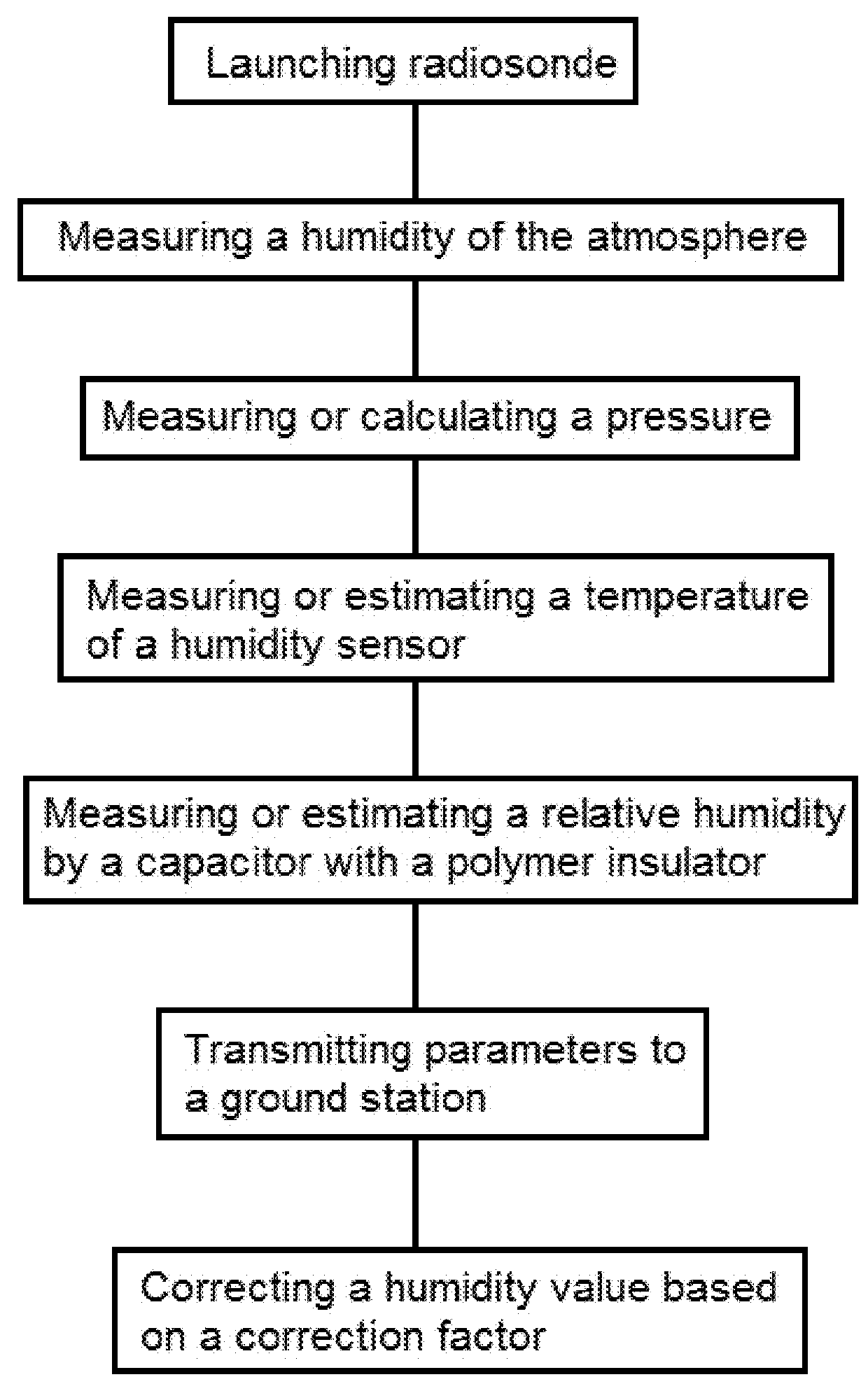

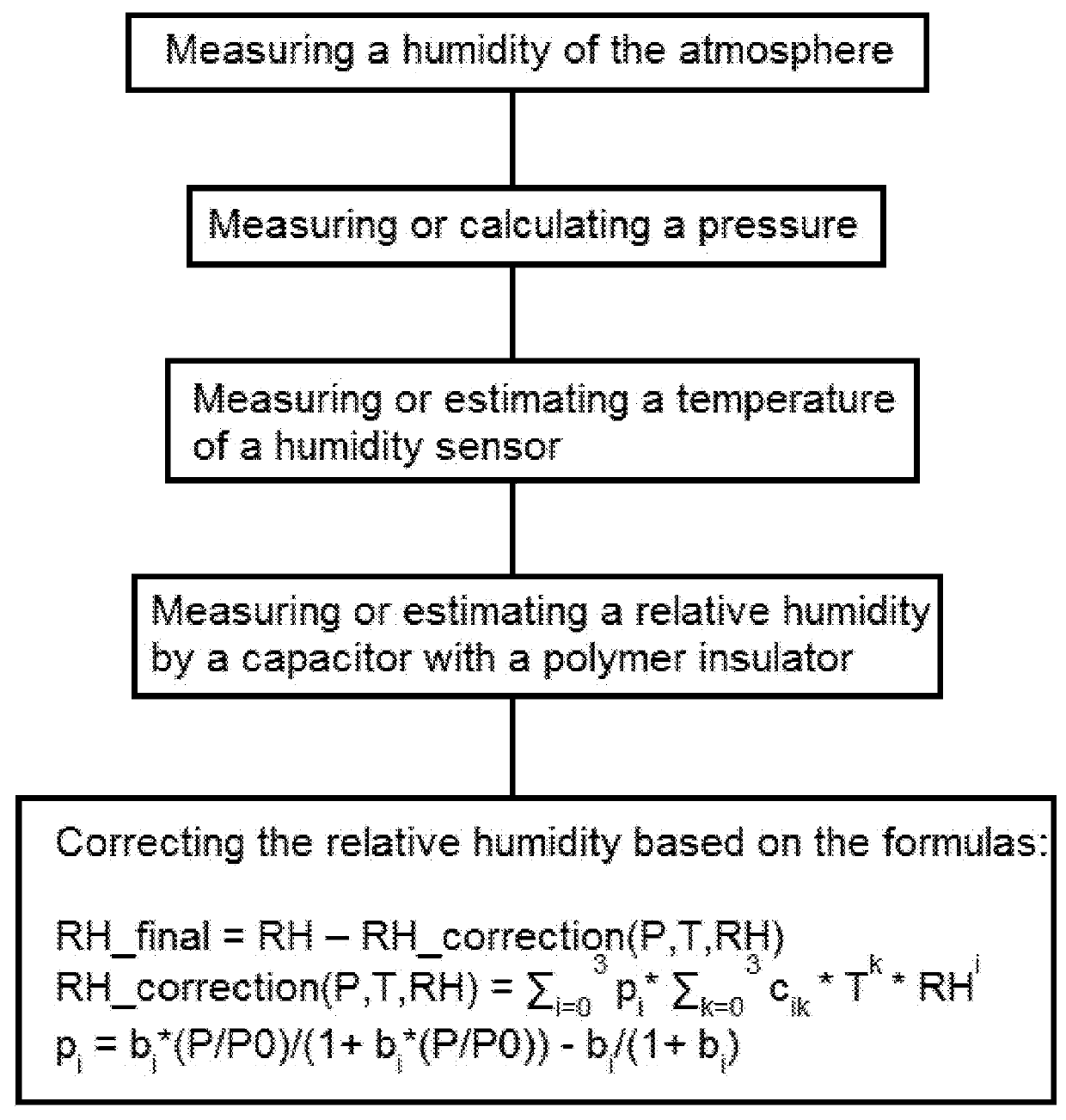

According to an example aspect of the present invention, there is provided a method in connection with a radiosonde, the method comprising measuring a humidity of the atmosphere at several different altitudes in the atmosphere, measuring a pressure at several different altitudes in the atmosphere or calculating the pressure from an altitude of the radiosonde obtained from GPS or other satellite navigation system, measuring or estimating a temperature of a humidity sensor, and measuring a relative humidity by a capacitor with a polymer insulator, wherein the relative humidity value is corrected based on a correction factor, which is a function of pressure, humidity sensor temperature, and relative humidity, such that the humidity value decreases when pressure decreases.

Owner:VAISALA

Preparation method of modified polymer insulator material

ActiveCN103194015BMeet the electrical characteristicsMeet life requirementsInsulatorsPolymer scienceLife time

The invention relates to a preparation method of a modified polymer insulator material. The preparation method of the modified polymer insulator material comprises the following steps of: pre-heating an internal mixer to 150 DEG C to 160 DEG C; dropping an upper top bolt after adding polypropylene, banburying for 115 seconds to 125 seconds under the pressure of 0.5MPa-0.6MPa and temperature of 150 DEG C to 170 DEG C; then adding polythene and banburying for 115 seconds to 125 seconds under the pressure of 0.5MPa-0.6MPa and temperature of 150 DEG C to 170 DEG C; raising the upper top bolt, banburying for 115 seconds to 125 seconds under the temperature of 150 DEG C to 170 DEG C; and finally discharging, cooling and pelletizing, wherein the molecular weight of each of polypropylene and polyethylene is 10 thousand to 20 thousand. The modified polymer insulator material prepared by the preparation method not only can satisfy the electrical characteristics and mechanical performance requirements of the insulator, but also can satisfy the service life requirement. Besides, the preparation method has an antifouling self-cleaning function and has the advantages of high cost performance, energy conservation and environment protection and no pollution, so that the product can be recycled after reaching the service life.

Owner:JIANGSU JINSANLI POWER EQUIP

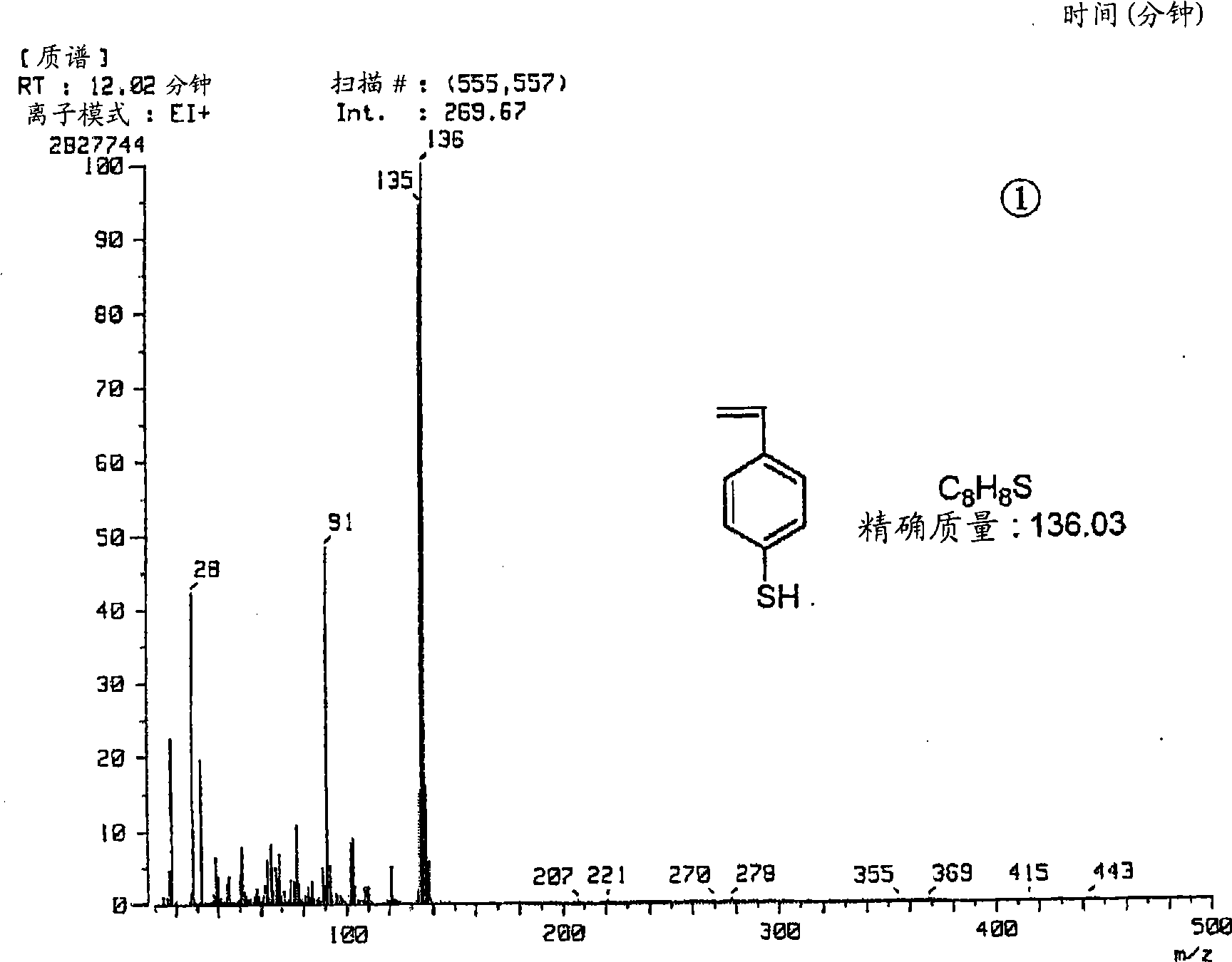

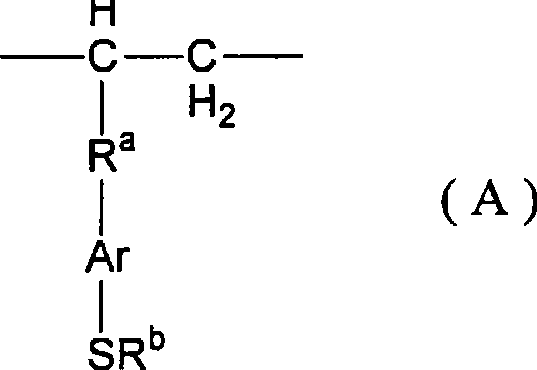

Insulating layer, electronic device, field effect transistor, and polyvinylthiophenol

ActiveCN101501080AGood component propertiesImprove featuresTransistorSolid-state devicesHydrogen atomOrganic group

For the purpose of providing an insulting layer which enables to improve device characteristics when used in an electronic device, a polymer insulator containing a repeating unit represented by the formula below is contained in the insulating layer. In the formula, R represents a direct bond or an arbitrary linking group; Ar represents an optionally substituted divalent aromatic group; and R represents a hydrogen atom, a fluorine atom or a monovalent organic group.

Owner:MITSUBISHI RAYON CO LTD

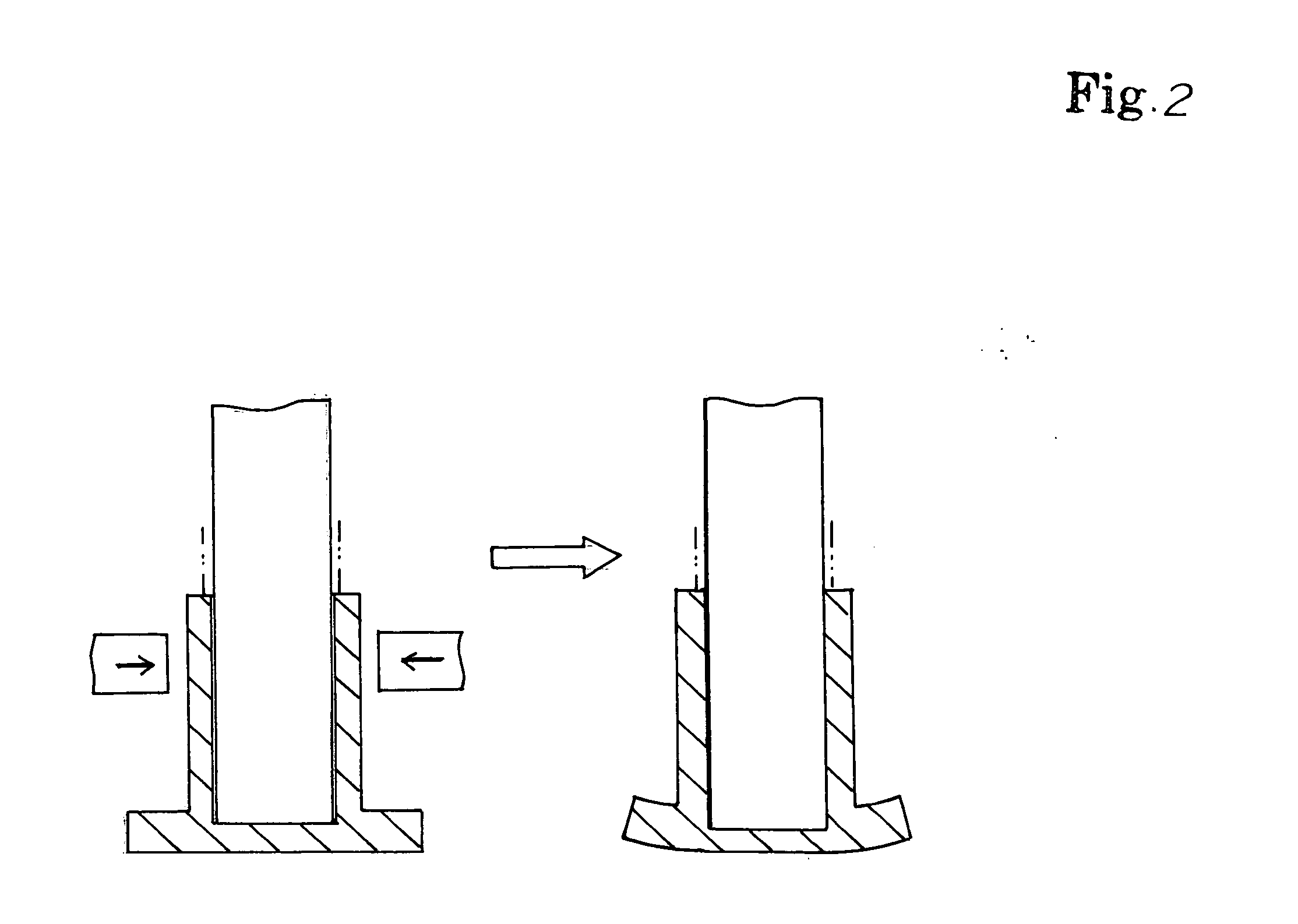

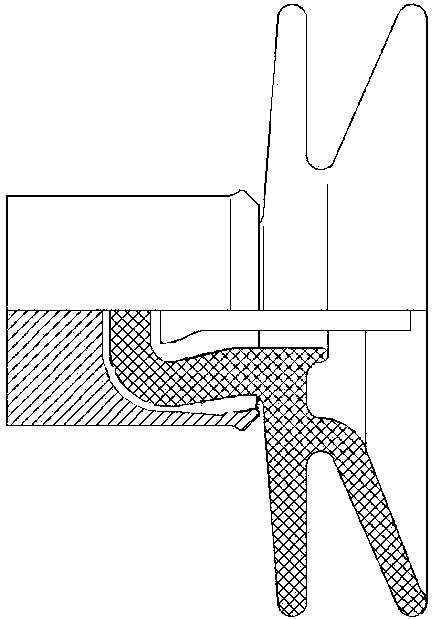

Method for joining core member and gripper in polymer insulator, and polymer insulator

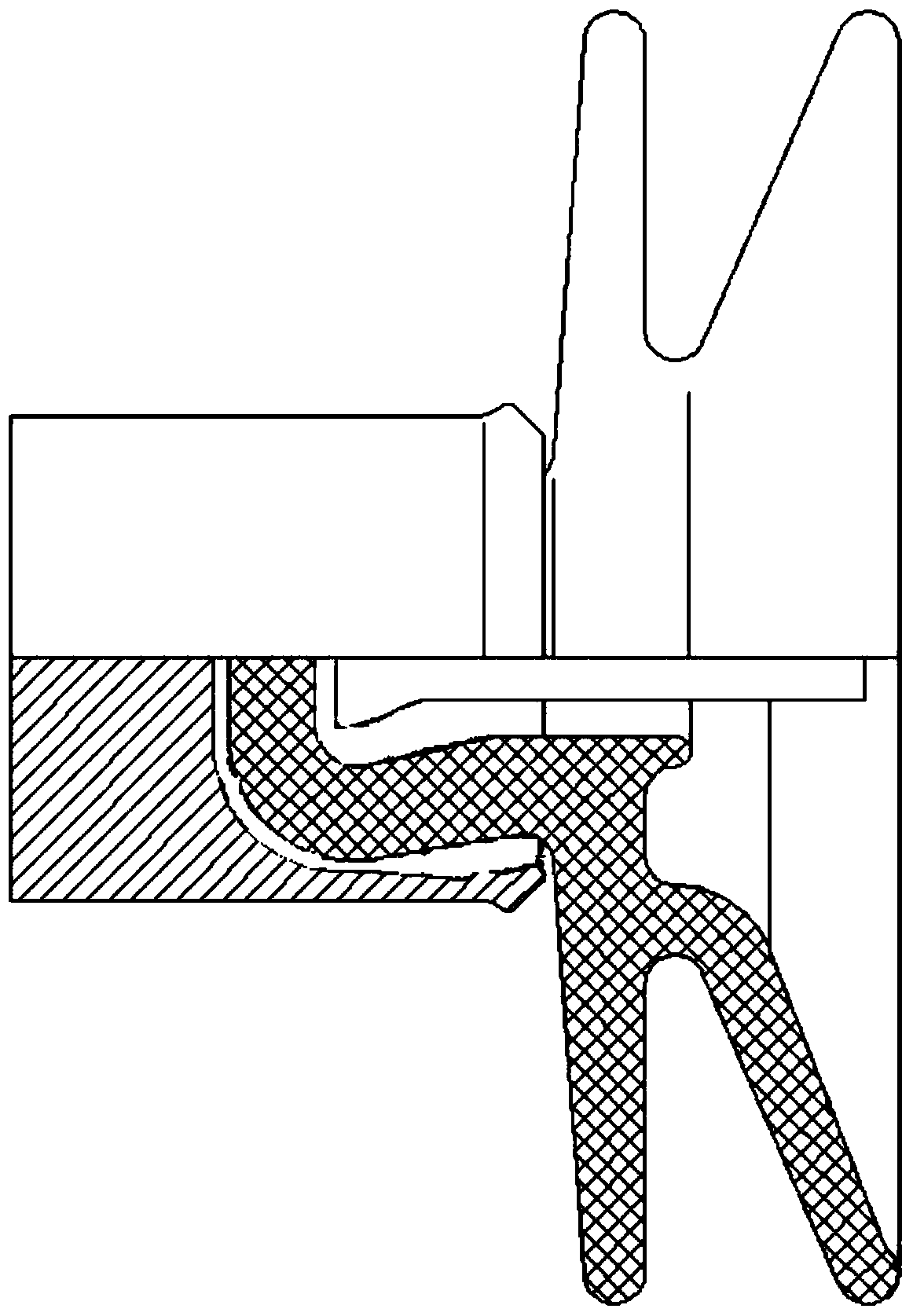

InactiveUS20030178225A1High tensile strengthShortening of clinch and lengthLaminationLamination apparatusPolymer insulationEngineering

A method for joining a core member and grippers in a polymer insulator including a core member, an outer sheath comprised of a body and caps, which are provided around the core member, and the grippers provided on both ends of the core member, comprising (a) providing the core member with a filler on the outer circumferential surface thereof or the grippers with a filler on the inner circumferential surface thereof, (b) inserting the core member into the grippers, and (c) clinching the grippers to fasten the grippers and the core member.

Owner:NGK INSULATORS LTD

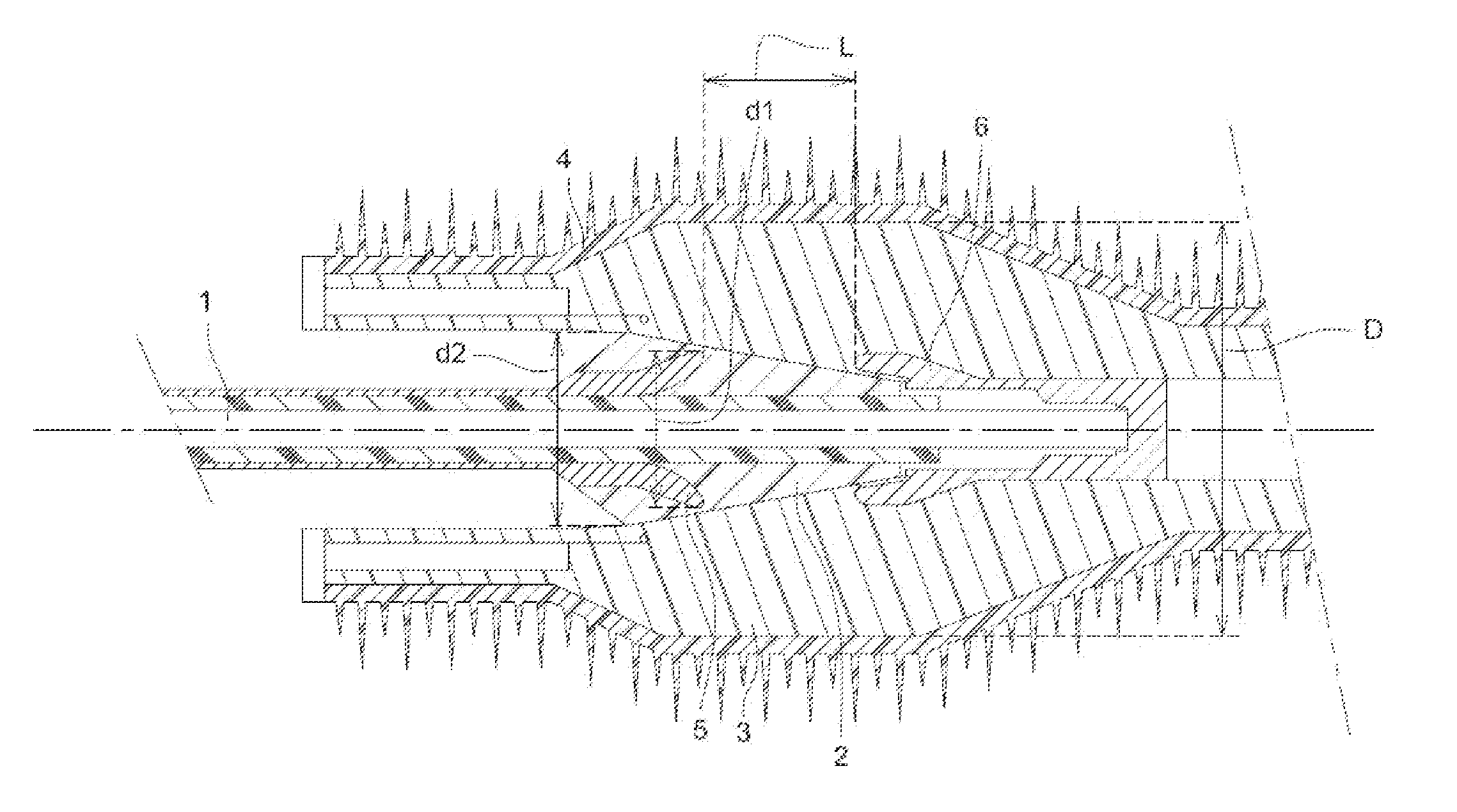

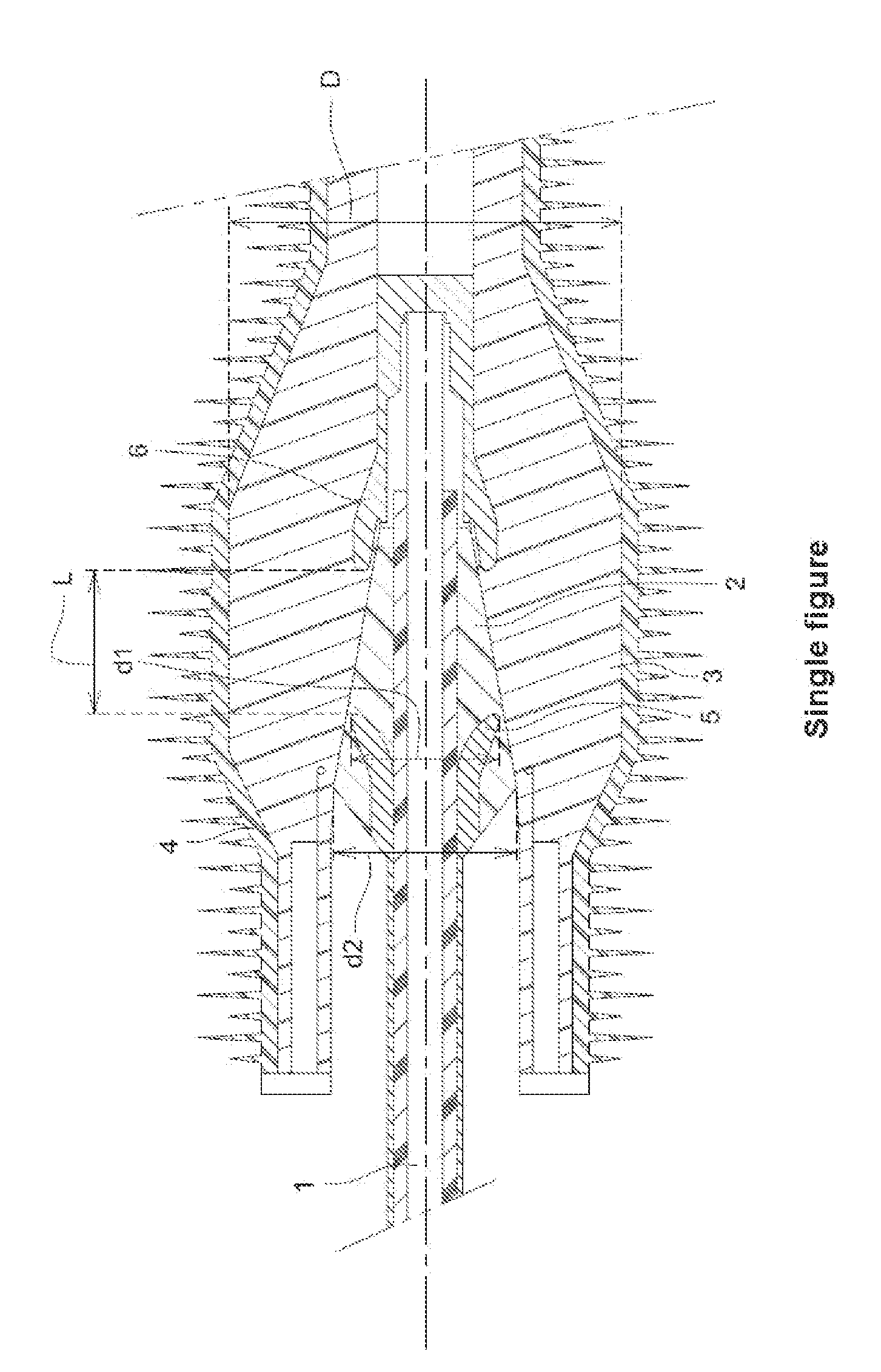

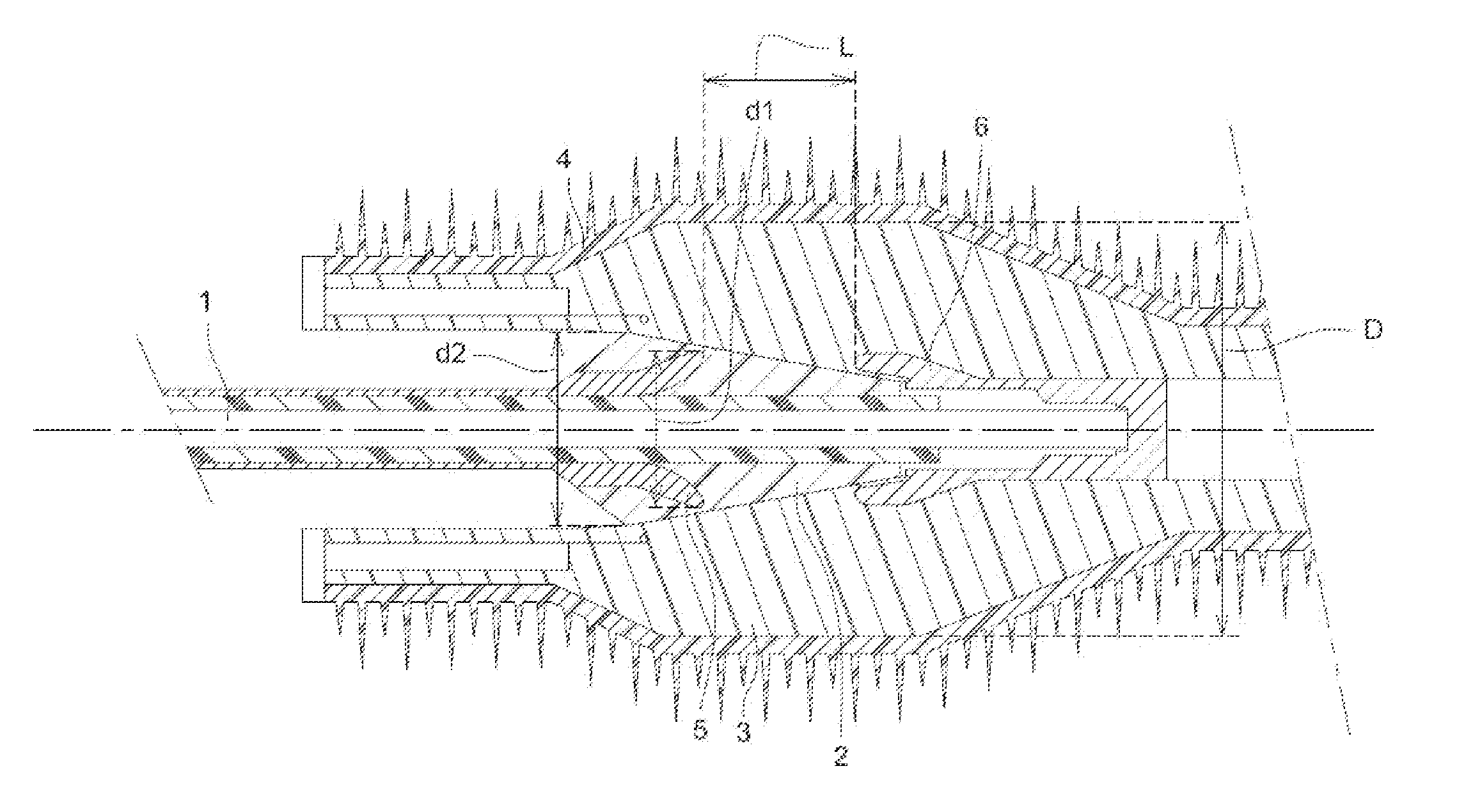

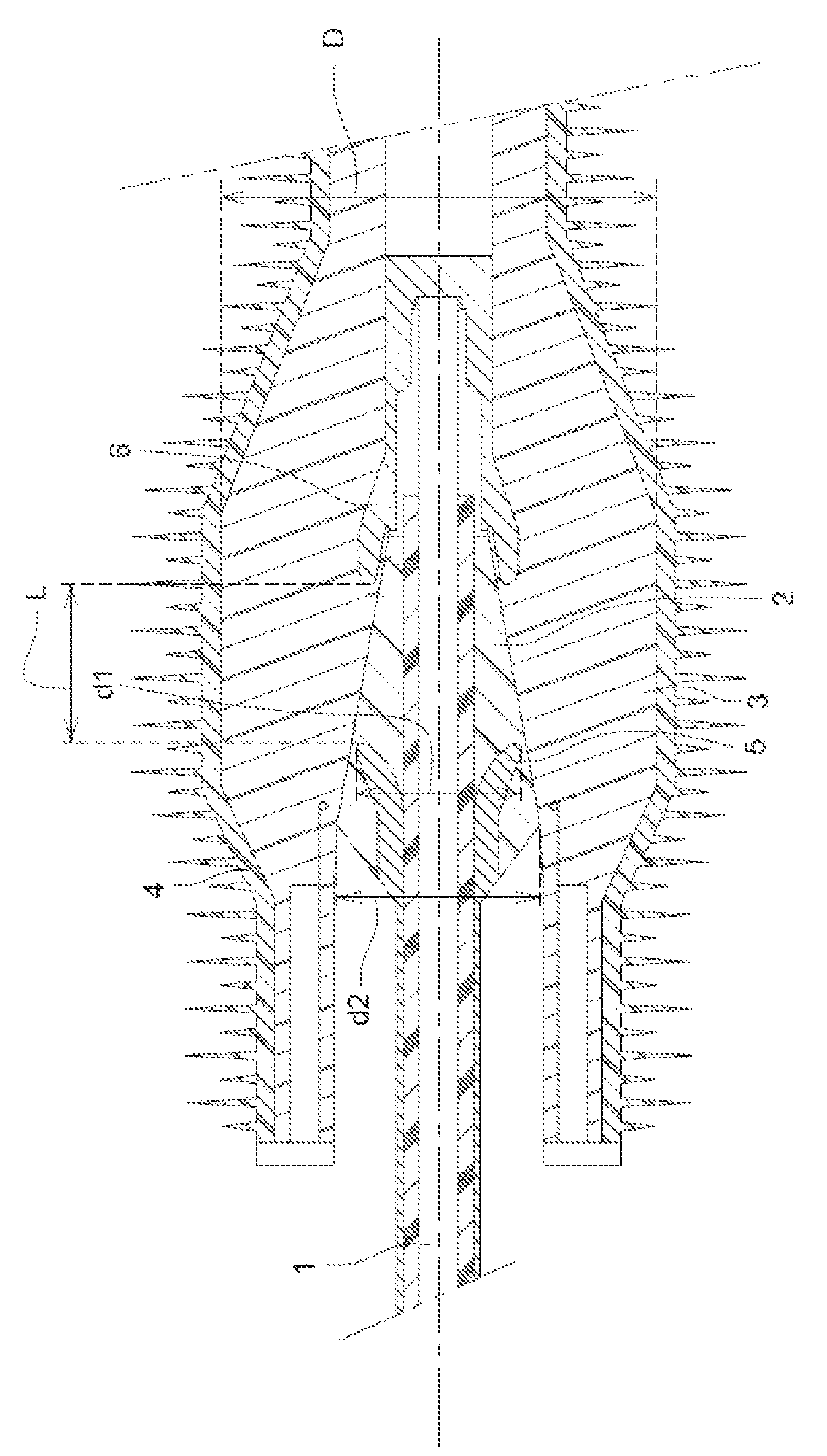

Electrical termination for extra high voltage

ActiveUS20120138360A1Improve electrical performanceCable terminationsMaximum diameterUltra high voltage

A termination for extra high voltage includes, around a central conductor (1), a deflector cone (2) made of flexible material covered by a polymer insulator having a first internal insulating element (3) and containing a conducting deflector (5), the conductor (1) is connected to an output terminal (6). The maximum diameter (D) of the first insulating element (3) at right angles to the length (L) of the deflector cone (2) included between the conducting deflector (5) and the adjacent end of the output terminal (6) is greater than or equal to double the maximum diameter (d1) of the conducting deflector (5).

Owner:NEXANS

Method for preparing cable trench cover plate by adopting retired insulator rubber and core rod powder

ActiveCN108429218AGood performance parametersEnable recyclingCable installations on groundGlass fiberEpoxy

The invention discloses a cable trench cover plate prepared by doping retired polymer insulator rubber and core rod powder and a preparation method thereof. The retired insulator rubber and core rod are pulverized, and the pulverized retired insulator rubber and core rod serve as fillers and respectively added to silicone rubber and glass fiber reinforced epoxy resin and prepare a composite resincapable trench cover plate through high-temperature moulding and solidification. The method realizes recycling and reusing of the retired insulator material in the field of cable trench cover plate preparation for the first time. The test shows that the cable trench cover plate prepared according to the preparation method is excellent in various performance parameters and that mechanical propertyand thermal property test data results of the cable trench cover plate are higher than that of an ordinary concrete cover plate and steel fiber reinforced cover plate. The method achieves a technicaleffect of recycling a lot of retired insulator materials under the condition of not influencing the performance of the composite resin cover plate in all aspects for the first time, and has importantsignificance and application values on the aspects of waste macromolecular material recycling, energy conversation and sustainable development of materials.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

Silicone rubber composition for use as high-voltage insulator and polymer insulator

ActiveUS20130266799A1Improve acid resistanceLong life-timeRubber insulatorsPlastic/resin/waxes insulatorsPolymer scienceAluminium hydroxide

A silicone rubber composition comprising (A) an organopolysiloxane composition of the organic peroxide cure or addition reaction cure type, (B) a normally solid organic compound having at least two ester bonds per molecule, and (C) particulate aluminum hydroxide having an average particle size of up to 20 μm is suited for use as high-voltage electric insulator since it maintains insulating properties for a long term in outdoor service and has acid resistance and a long lifetime even in polluted areas.

Owner:SHIN ETSU CHEM IND CO LTD +1

Adhesive binding and suspended type polymer insulator chain element with double-umbrella or triple-umbrella disc-shaped umbrella shirt

InactiveCN103824662ASimple structureImprove hydrophobicitySuspension/strain insulatorsAdhesivePolymer insulation

The invention discloses an adhesive binding and suspended type polymer insulator chain element with a double-umbrella or triple-umbrella disc-shaped umbrella shirt. The adhesive binding and suspended type polymer insulator chain element comprises a steel cap and a steel leg. A cavity with the U-shaped cross section is formed inside the steel cap. A conical head portion matched with the cavity is arranged on the steel leg. The conical head portion of the steel leg is arranged in the cavity of the steel cap. A polymer insulating piece is arranged between the conical head portion and the cavity. The polymer insulating piece comprises the double-umbrella or triple-umbrella umbrella shirt. The surface of the umbrella shirt is coated with an RTV stain-proofing coating. An adhesive binding portion is arranged at the center of the umbrella skirt. The adhesive binding portion is an inverted conical cavity. The conical head portion of the steel leg and the adhesive binding portion are connected into a whole in an adhesive binding mode through adhesives. The cavity of the steel cap and the adhesive binding portion are connected into a whole in an adhesive binding mode through adhesives. The adhesive binding and suspended type polymer insulator chain element can resist bird trouble, sand wind and external damage and can assist in climbing.

Owner:HEBEI XINHUA HIGH VOLTAGE ELECTRICAL EQUIP

Polymer insulator

InactiveCN1447348AReduce thicknessReduce quality problemsSuspension/strain insulatorsEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

Cementing type bell-shaped disk-shaped suspension type polymer string insulator unit

InactiveCN103456425AIncrease pollution flashover voltageImprove hydrophobicitySuspension/strain insulatorsAdhesivePolymer insulation

The invention discloses a cementing type bell-shaped disk-shaped suspension type polymer string insulator unit. The polymer string insulator unit comprises a steel cap metal element and a steel foot metal element, wherein a cavity with a U-shaped section is formed in the steel cap metal element, the steel foot metal element is provided with a cone head portion matched with the cavity, the cone head portion of the steel foot metal element is arranged in the cavity of the steel cap metal element, a polymer insulating element is arranged between the cone head portion and the cavity, the polymer insulating element comprises a bell-shaped skirt, the center of the skirt is provided with a cementing portion which is a cavity of an inverted cone shape, the inner wall of a bell-shaped body is provided with a plurality of prismatic protrusions coaxial with the polymer insulating element, the cone head portion of the steel foot metal element is integrated with the cementing portion through an adhesive in a cementing mode, and the cavity of the steel cap metal element is integrated with the cementing portion through an adhesive in a cementing mode. The polymer string insulator unit has the advantages of preventing bird damages, and being resistant to wind and sand, resistant to damages caused by external force and capable of assisting climbing.

Owner:HEBEI XINHUA HIGH VOLTAGE ELECTRICAL EQUIP

Cementing type double-umbrella-shaped and three-umbrella-shaped disk-shaped suspension type polymer string insulator unit

InactiveCN103456433AGood pollution flashover characteristicsIncrease pollution flashover voltageSuspension/strain insulatorsAdhesivePolymer insulation

The invention discloses a cementing type double-umbrella-shaped and three-umbrella-shaped suspension type polymer string insulator unit. The polymer string insulator unit is characterized by comprising a steel cap metal element and a steel foot metal element, wherein a cavity with a U-shaped section is formed in the steel cap metal element, the steel foot metal element is provided with a cone head portion matched with the cavity, the cone head portion of the steel foot metal element is arranged in the cavity of the steel cap metal element, a polymer insulating element is arranged between the cone head portion and the cavity, the polymer insulating element comprises a skirt of a double-umbrella-shaped or three-umbrella-shaped structure, the center of the skirt is provided with a cementing portion which is a cavity of an inverted cone shape, the cone head portion of the steel foot metal element is integrated with the cementing portion in a cementing mode through an adhesive, and the cavity of the steel cap metal element is integrated with the cementing portion in a cementing mode through an adhesive. The polymer string insulator unit has the advantages of preventing bird damages, and being resistant to wind and sand, resistant to damages caused by external force and capable of assisting climbing.

Owner:HEBEI XINHUA HIGH VOLTAGE ELECTRICAL EQUIP

Electrical termination for extra high voltage

ActiveUS8785780B2Electrically conductive connectionsCable inlet sealing meansMaximum diameterUltra high voltage

A termination for extra high voltage includes, around a central conductor (1), a deflector cone (2) made of flexible material covered by a polymer insulator having a first internal insulating element (3) and containing a conducting deflector (5), the conductor (1) is connected to an output terminal (6). The maximum diameter (D) of the first insulating element (3) at right angles to the length (L) of the deflector cone (2) included between the conducting deflector (5) and the adjacent end of the output terminal (6) is greater than or equal to double the maximum diameter (d1) of the conducting deflector (5).

Owner:NEXANS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com