3D printing-based manufacturing method for conductivity gradient polymer insulator

A gradient polymer and 3D printing technology, applied in the direction of insulators, circuits, electrical components, etc., can solve the problems of rare applications, achieve the effect of flexible regulation and increase the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

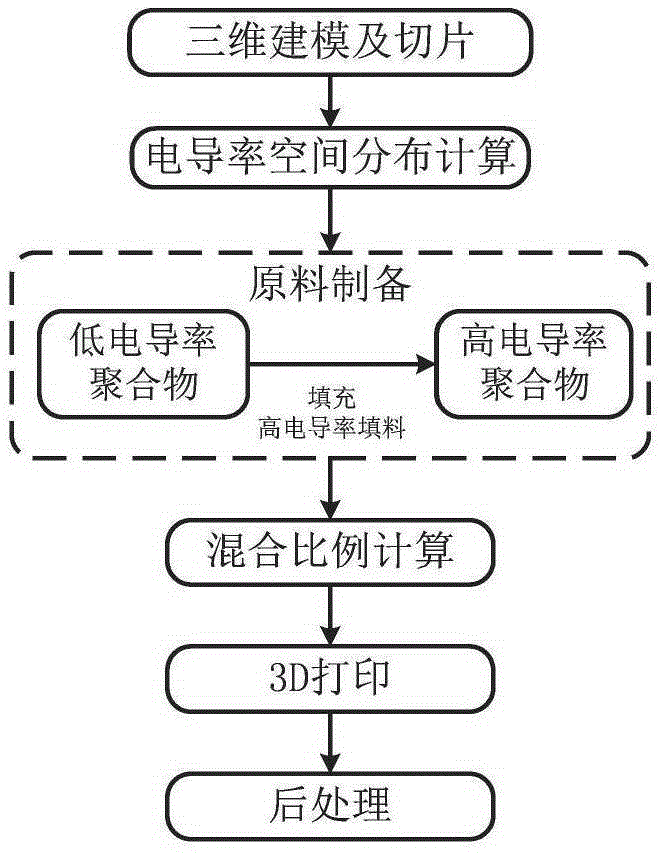

[0031] see figure 1 As shown, the present invention is based on the 3D printing conductivity gradient polymer insulator manufacturing method, which specifically includes the following steps:

[0032] Step 1: Construct a 3D CAD model of the insulator geometry and conductivity spatial distribution, divide the model into multiple geometric units and generate the STL file of the model, use the slicing software to simulate the 3D CAD model defined by the STL file according to the preset layer thickness Divide it into different layers, calculate the printing trajectory of each layer, and finally get the G-code control file required by the 3D printing device.

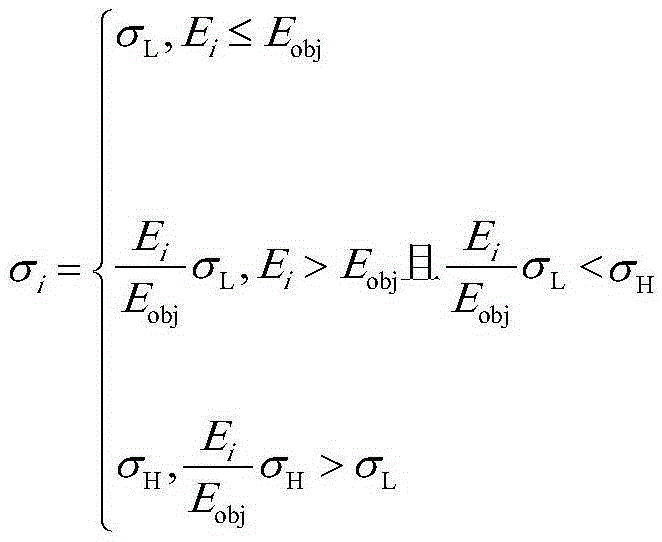

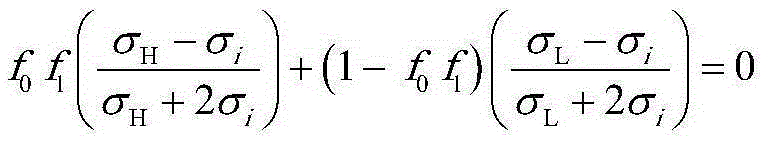

[0033]Step 2: Use the three-dimensional finite element method to calculate the electric field distribution inside and on the surface of the insulator, and obtain the spatial distribution of the conductivity of the insulator according to the actual electrical characteristic requirements of the insulator. Specifically, the insi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com