Polymer insulator

A technology of insulators and polymers, applied in the direction of insulators, suspension/strain insulators, electrical components, etc., can solve problems such as electrical breakdown and cracks in the umbrella part 54, and achieve the effect of reducing the amount of rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

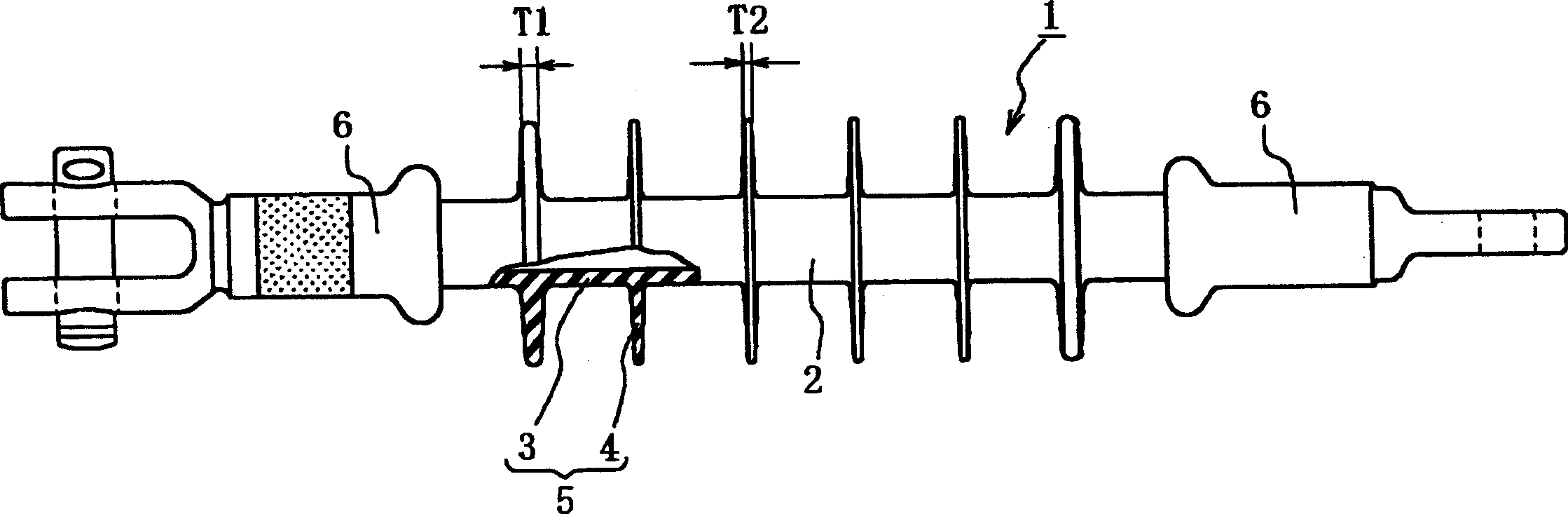

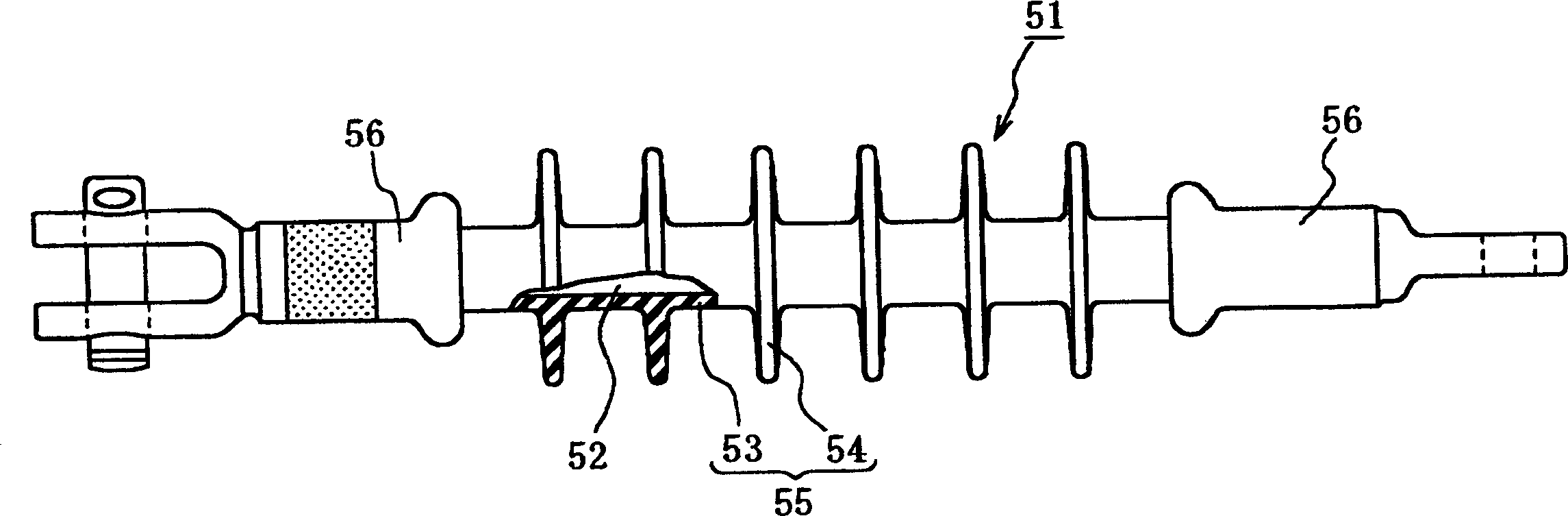

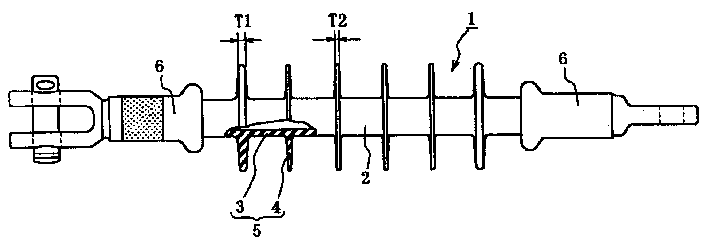

[0011] figure 1 It is a partial sectional view showing the structure of an example of the polymer insulator of the present invention. exist figure 1 In the example shown, the polymer insulator 1 is composed of an FRP core 2 as a core member, a casing 5 formed of a cylindrical portion 3 and an umbrella portion 4 disposed on the outer periphery of the FRP core 2, and grips disposed at both ends of the FRP core. Accessories 6 constitute. The above structure is the same as the prior art polymer insulator. The present invention is characterized by, as figure 1 As shown, among the plurality of umbrellas 4 , the thickness of the umbrellas 4 at both ends is thicker than the thickness of the umbrellas 4 other than the two ends.

[0012] That is, in figure 1 In the example shown, the thickness ( T1 ) of the canopy 4 at both ends is thicker than the thickness ( T2 ) of the canopy 4 other than both ends. In addition, for the thickness (T1) of the umbrella portion 4 at both ends,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com