Preparation method of modified polymer insulator material

A polymer and insulator technology, which is applied in the field of preparation of modified polymer insulator materials, can solve problems such as smoke pollution, high price, and susceptibility to pollution, and achieve the effect of meeting life requirements and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

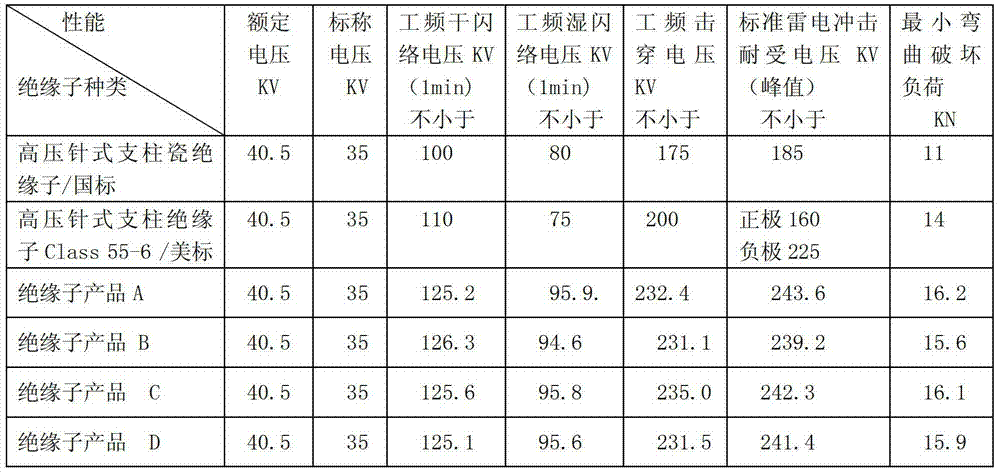

Examples

Embodiment 1

[0014] Preheat the internal mixer to 150°C, add 6.765Kg (according to density conversion, the volume is 0.0075m 3 ) polypropylene with a molecular weight of 100,000, lower the top bolt, banbury at 0.6MPa and 150°C for 115s, and then add 40.545Kg (converted by density, the volume is 0.0425m 3 ) Polyethylene with a molecular weight of 100,000 was banburyed at 0.6MPa and 150°C for 115s, raised the top bolt, banburyed at 150°C for 115s, and finally discharged, cooled and granulated to obtain insulator material A.

Embodiment 2

[0016] Preheat the internal mixer to 170°C, add 11.275Kg (according to density conversion, the volume is 0.0125m 3 ) After polypropylene with a molecular weight of 150,000, lower the top bolt, banbury at 0.6MPa and 170°C for 115s, and then add 35.775Kg (converted by density, the volume is 0.0375m 3 ) The polyethylene with a molecular weight of 150,000 was banburyed at 0.6MPa and 150°C for 115s, raised the top bolt, banburyed at 170°C for 115s, and finally discharged, cooled and granulated to obtain insulator material B.

Embodiment 3

[0018] Preheat the internal mixer to 150°C, add 9.02Kg (converted by density, the volume is 0.01m 3 ) polypropylene with a molecular weight of 200,000, lower the top bolt, banbury at 0.5MPa and 150°C for 120s, and then add 38.16Kg (converted by density, the volume is 0.04m 3 ) The polyethylene with a molecular weight of 200,000 was banburyed at 0.5MPa and 150°C for 120s, raised the top bolt, banburyed at 150°C for 120s, and finally discharged, cooled and granulated to obtain insulator material C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com