Method for improving flashover performance of vacuum edge surface of polymer insulator

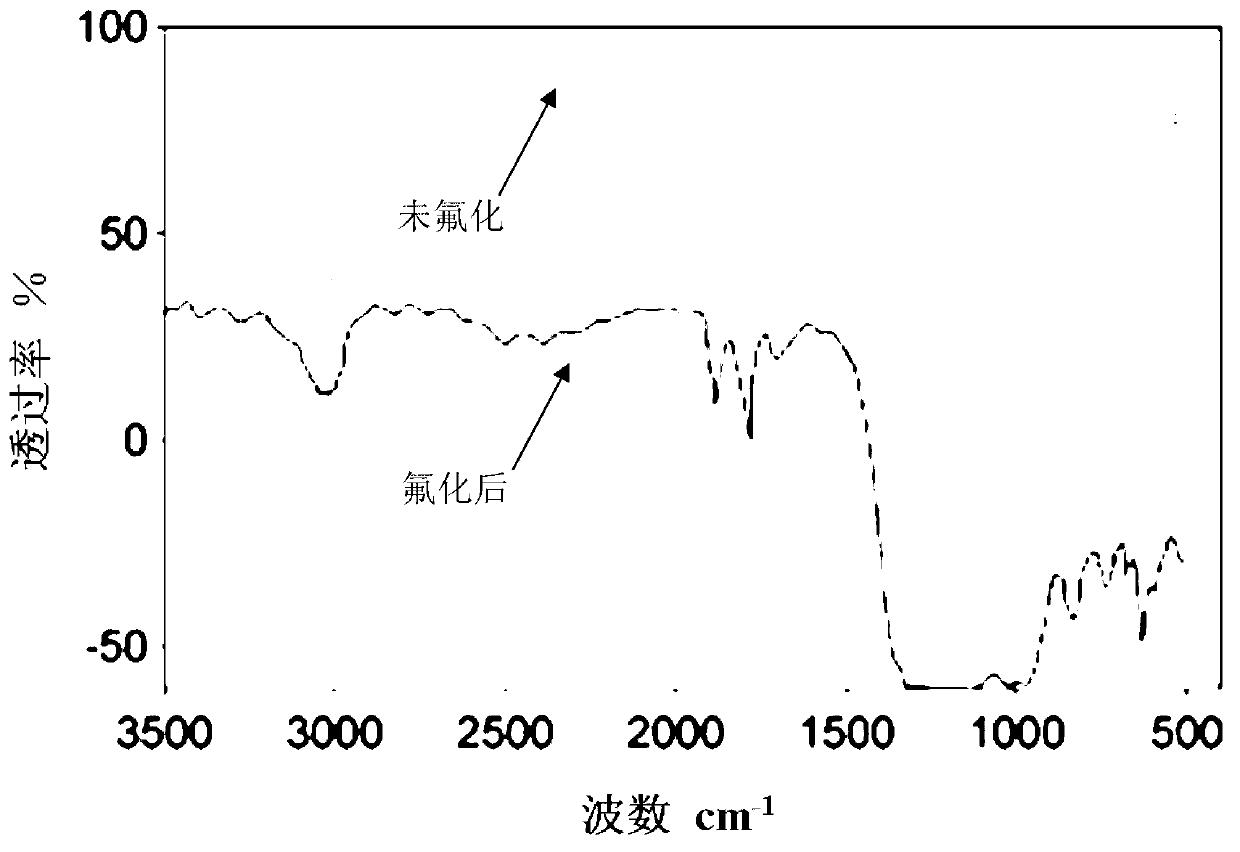

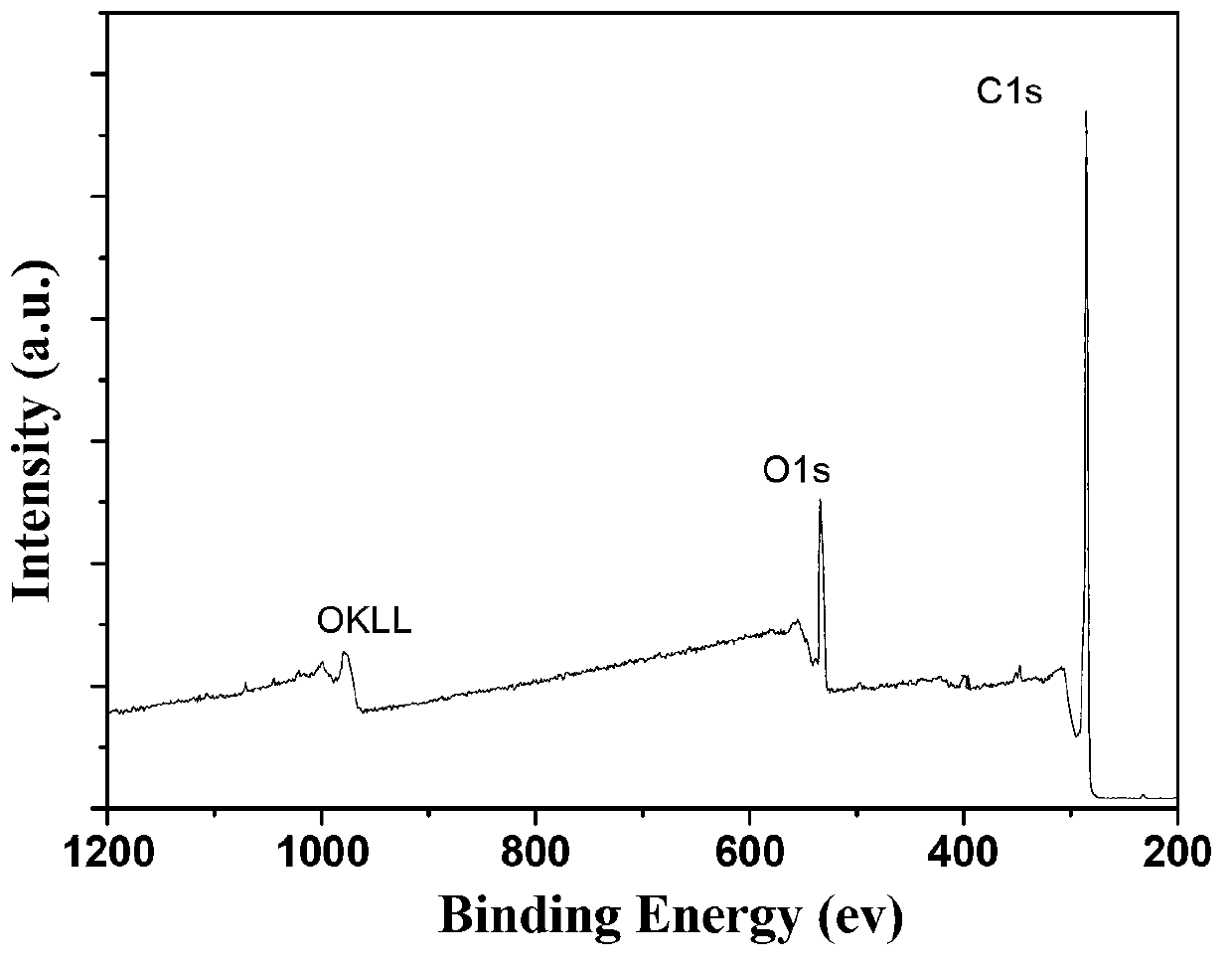

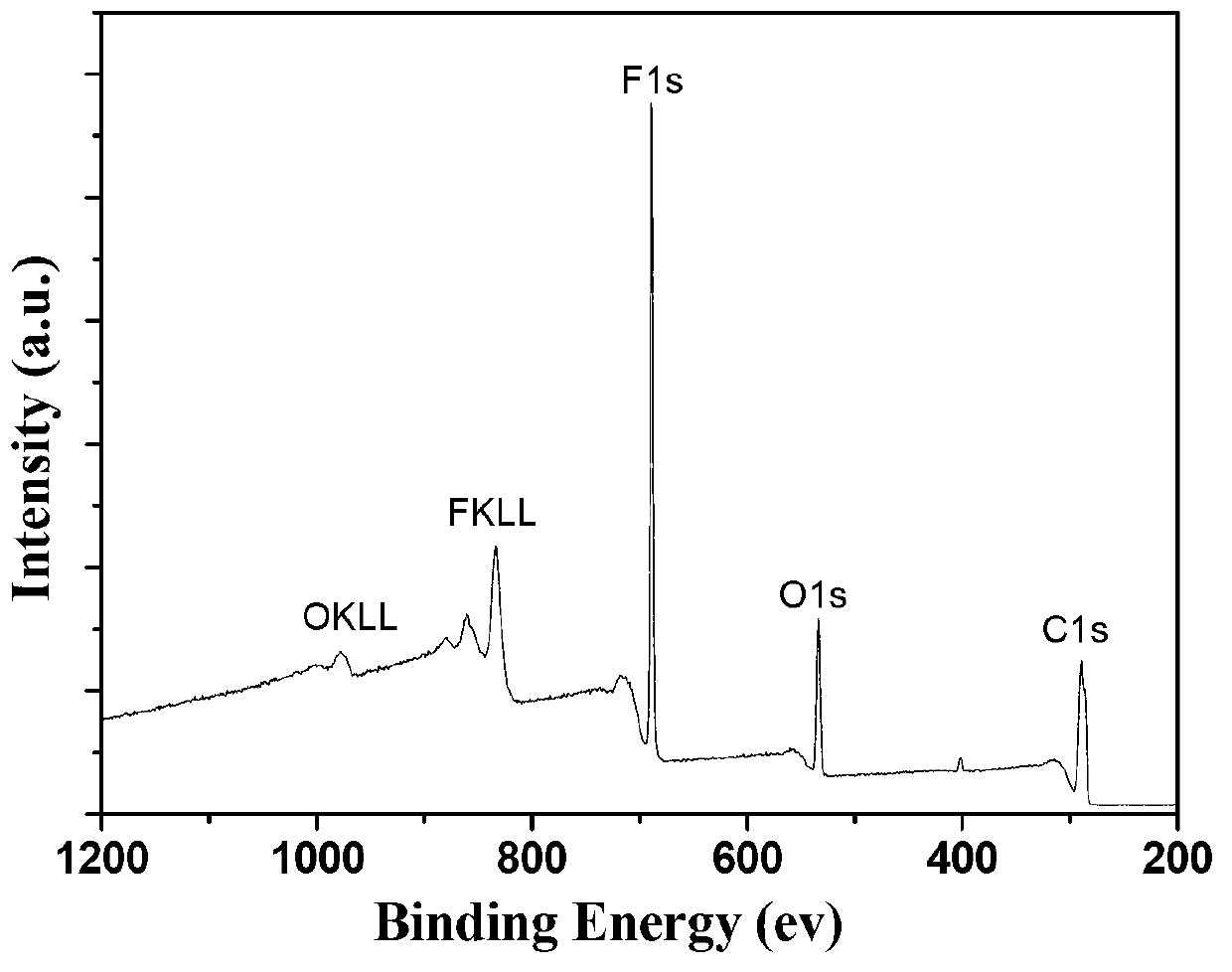

A technology of surface flashover and insulator, applied in insulators, electrical components, circuits, etc., can solve the problem of no one involved, and achieve the effect of less influencing factors, high reliability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) At room temperature 25°C, put polystyrene insulators into a closed reactor, and then evacuate the reactor to a pressure of less than 10 -2 Pa;

[0024] 2) Fill the reactor with 1.0 atm of fluorine / nitrogen mixed gas, in which the volume concentration of fluorine is 20%;

[0025] 3) Control the temperature of the reactor to 50°C, and the reaction time is 2h;

[0026] 4) After the reaction, use nitrogen to purge the fluorine-containing mixed gas in the reaction chamber into the lye absorption tower for tail gas treatment;

[0027] 5) Take out the polystyrene insulator after cooling the reactor to room temperature.

Embodiment 2

[0029] 1) At room temperature, put the high-density polyethylene insulator into a closed reactor, and then vacuumize the reactor to a pressure of less than 10 -2 Pa;

[0030] 2) Fill the reactor with 2 atm chlorine trifluoride / nitrogen mixed gas, wherein the volume concentration of chlorine trifluoride gas is 5%;

[0031] 3) Carry out the reaction at room temperature (18°C), and the reaction time is 24h;

[0032] 4) After the reaction, use nitrogen to purge the fluorine-containing mixed gas in the reaction chamber into the lye absorption tower for tail gas treatment;

[0033] 5) Open the reactor and take out the polyethylene insulator.

Embodiment 3

[0035] 1) At room temperature, put polyamide (nylon) insulators into a closed reactor, and then vacuumize the reactor to a pressure of less than 10 -2 Pa;

[0036] 2) Fill the reactor with 0.1atm xenon difluoride gas;

[0037] 3) The reaction is carried out at 100°C, and the reaction time is 0.5h;

[0038] 4) After the reaction, use nitrogen to purge the xenon difluoride gas in the reaction chamber into the lye absorption tower for tail gas treatment;

[0039] 5) Open the reactor and take out the nylon insulator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com