Egg fetching plug strip and comb matching structure

A technology of matching structure and nest spleen, which is applied in the field of matching structure of egg retrieval plug and nest spleen, can solve the problems of disapproval, contrary to the nesting habit of bees, affecting the output of royal jelly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

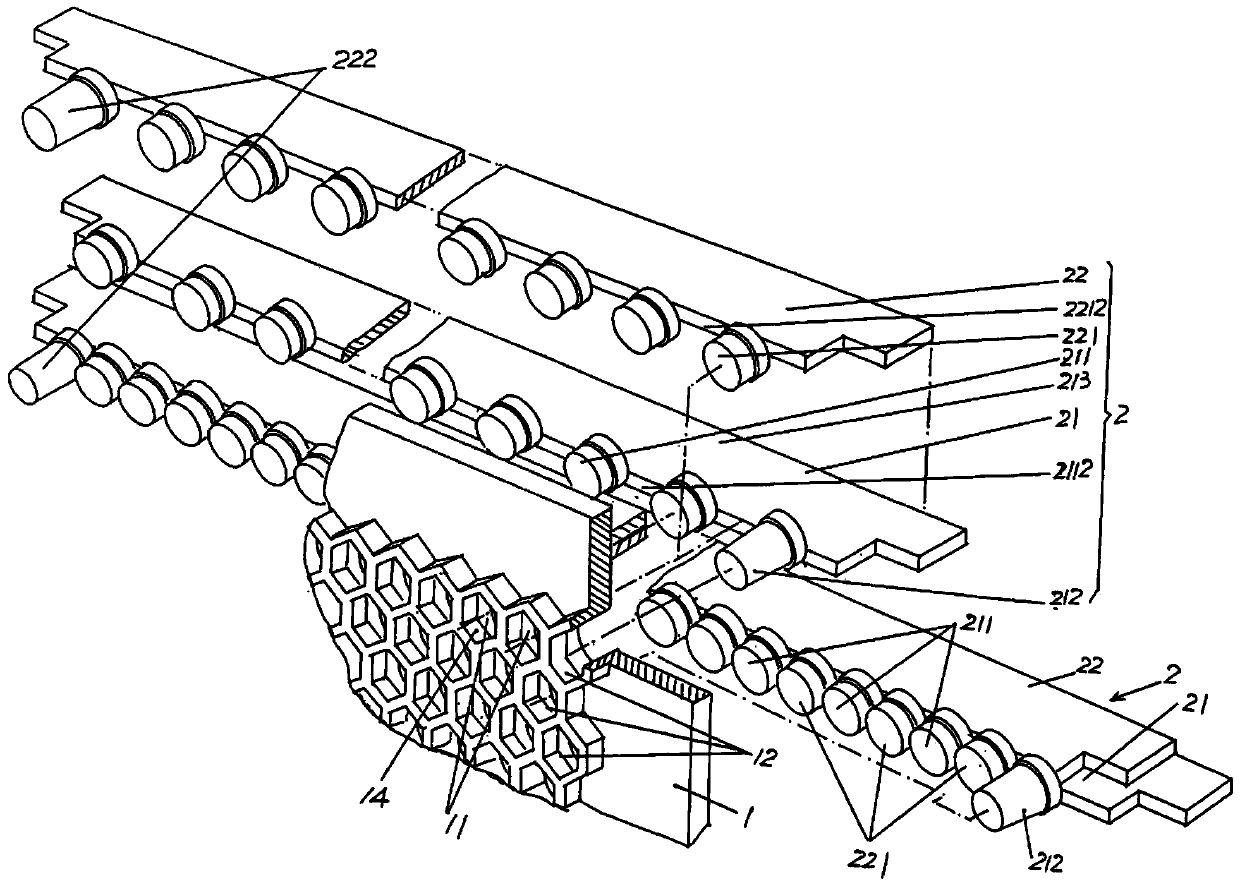

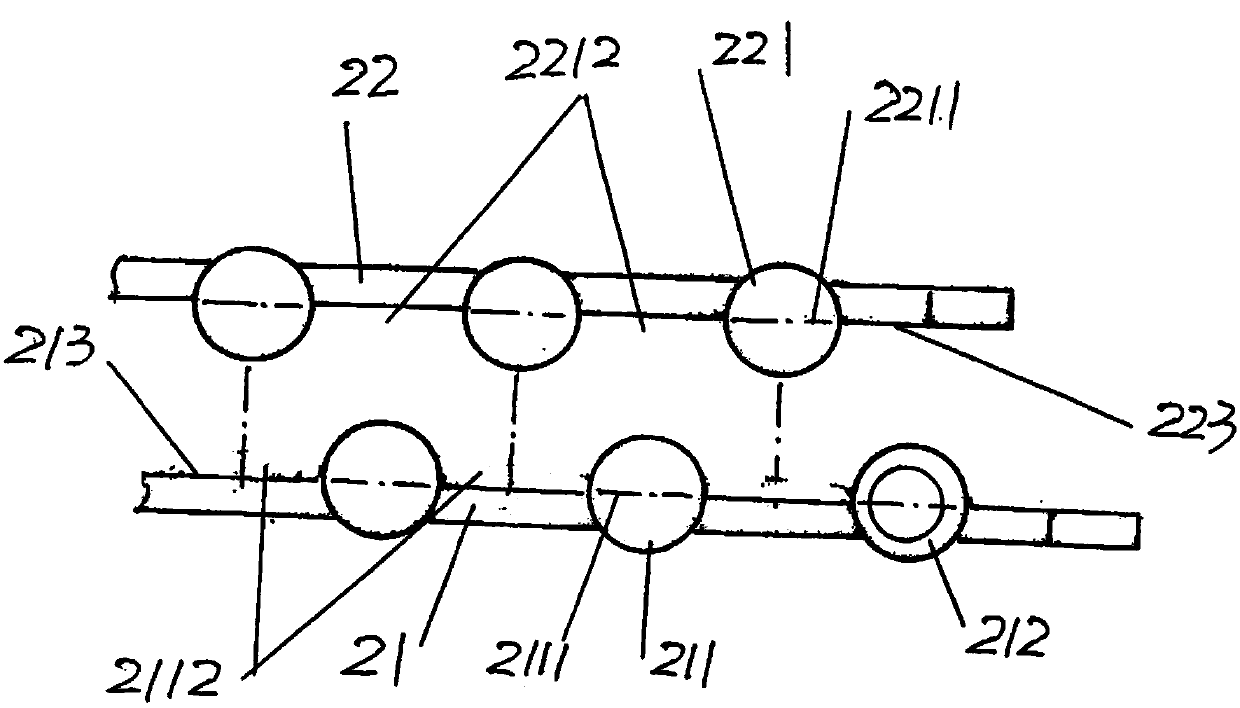

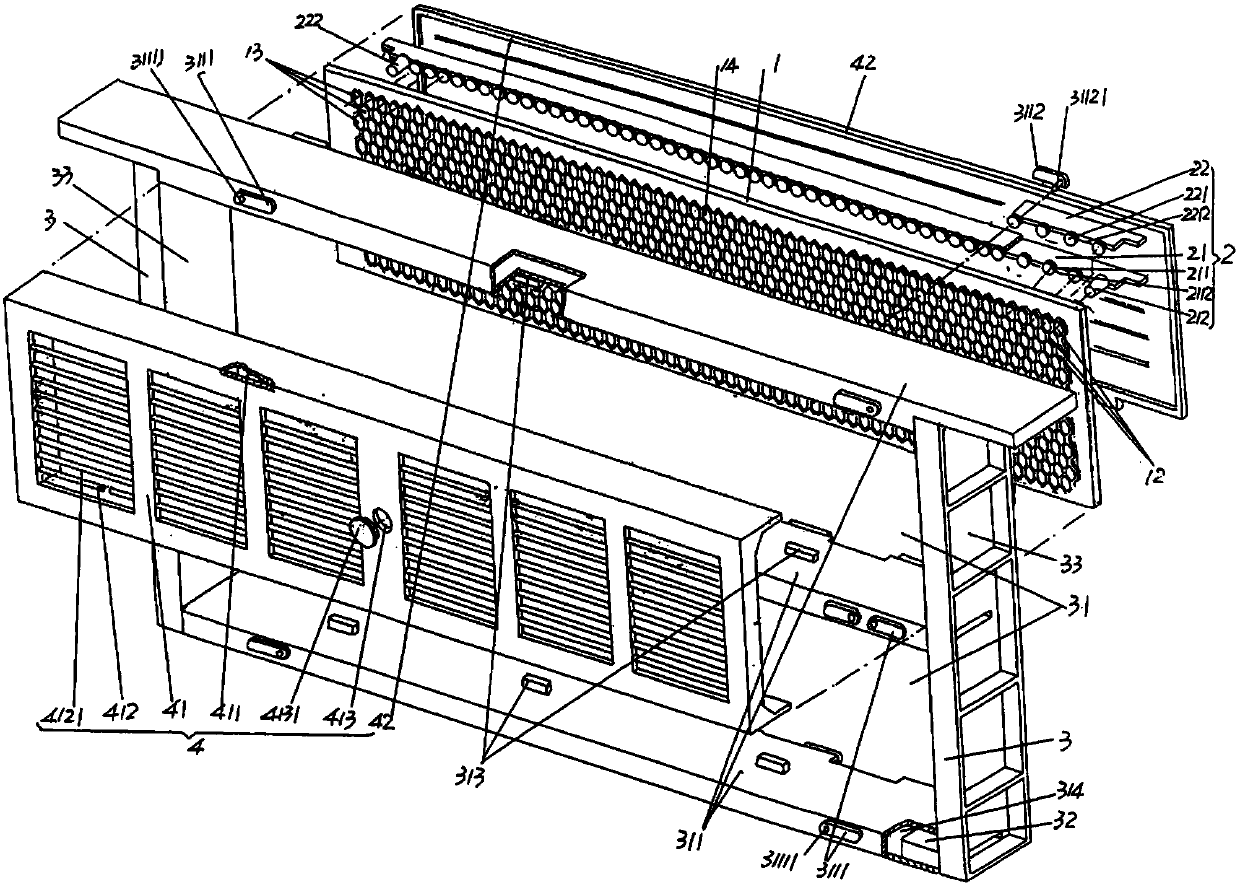

[0029] See figure 1 and figure 2 , a honeycomb body 1 is given, on which the honeycomb body 1 is formed in a dense state, that is, there are holes that are independent of each other and adjacent to each other and penetrate from one side of the thickness direction of the honeycomb body 1 to the other side. The nest hole 11, that is to say the nest hole 11 is a through hole, and a group of egg retrieval mechanisms 2 is provided, the number of the group of egg retrieval mechanisms 2 is the same as that of the spleen nest opened on the spleen body 1. The number of rows of holes 11 is equal and is plug-fitted with the nests of the honeycomb. The number of rows mentioned here refers to the number of rows arranged horizontally on the spleen body 1 of the honeycomb cells. For example, when the number of rows arranged horizontally is sixteen rows, the number of rows is sixteen rows (that is, ten Six rows), and for example, when there are sixty spleen nest holes 11 on each row, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com