Hub shot blasting machine

A technology of shot blasting machine and wheel hub, which is applied in the direction of abrasive jetting machine tools, abrasive materials, metal processing equipment, etc. It can solve problems such as damage to hooks and rollers, limited angle range of shot blasting machine, unreasonable design of shot blasting angle, etc., and achieve reduction Roller table damage, good shot blasting effect, and reasonable installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

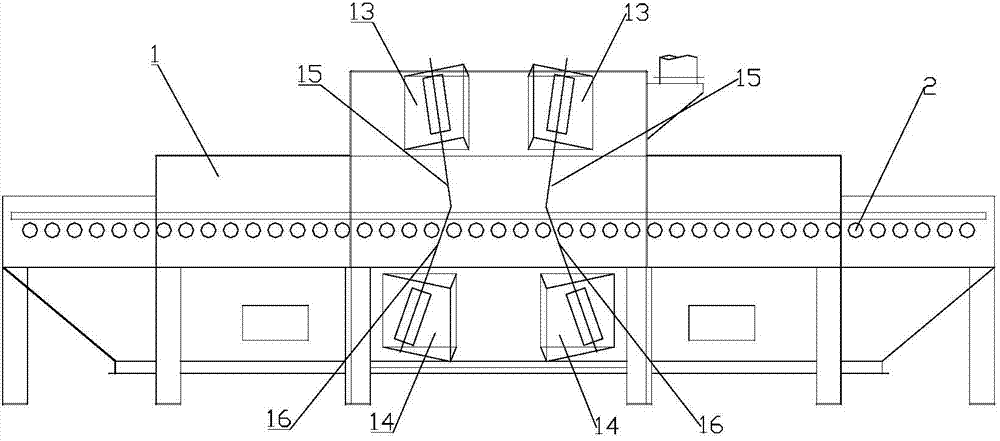

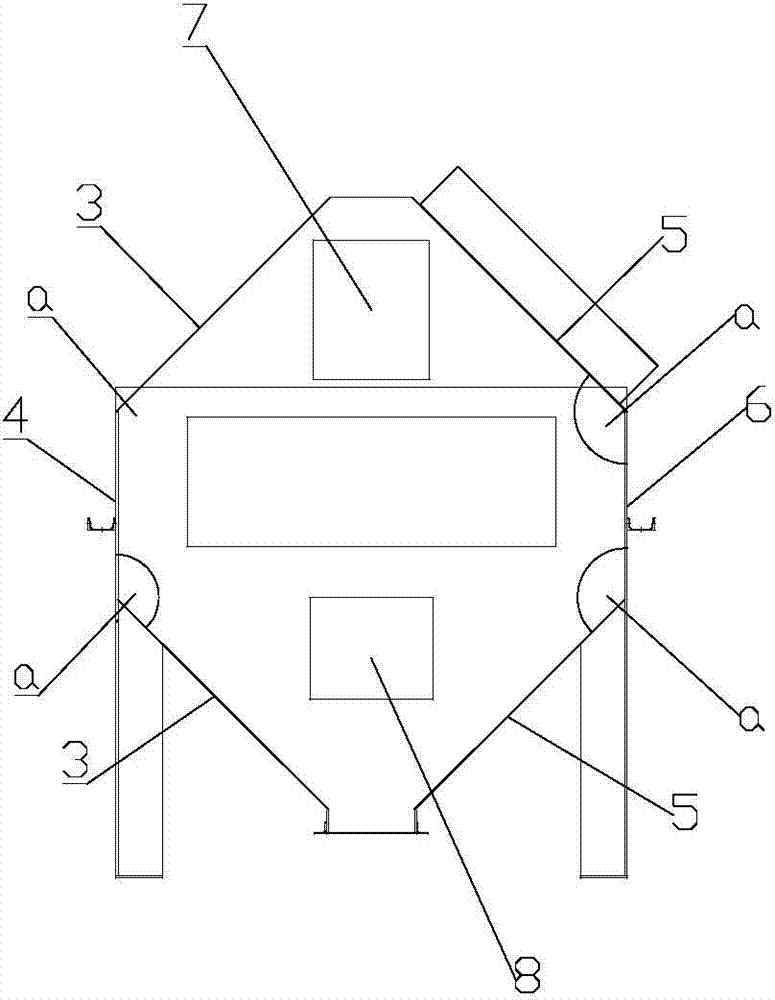

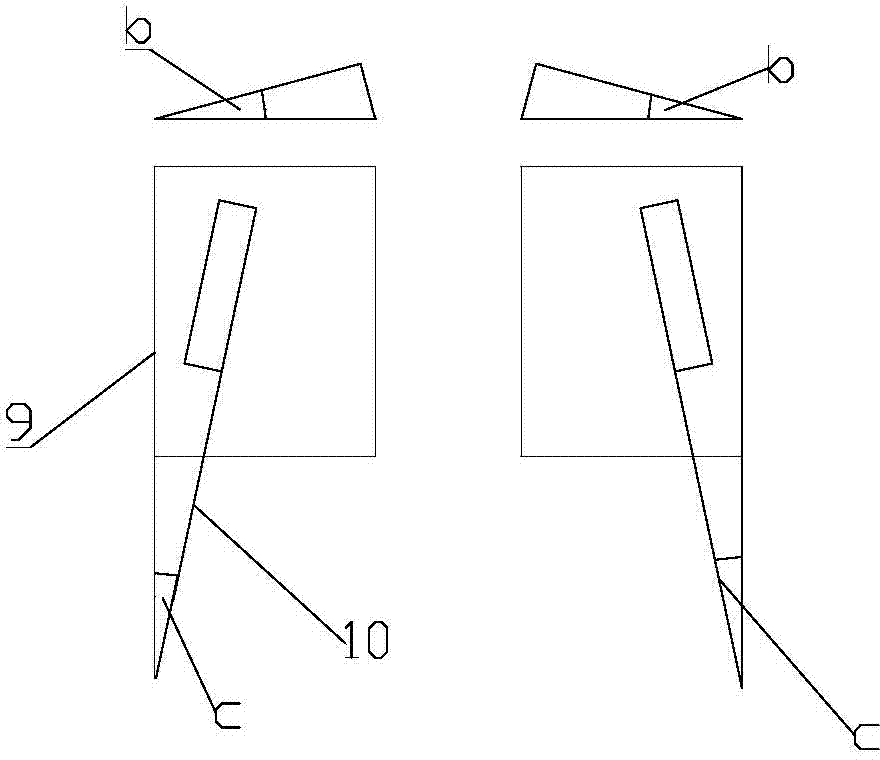

[0016] Such as Figure 1 to Figure 4 as shown, figure 1 It is a schematic diagram of the main structure of the present invention, and at the same time, it also shows the direction angle of the projectile thrown by the shot blaster.

[0017] The hub shot blasting machine includes a frame 1. A cleaning room and a conveying roller table 2 are arranged on the frame 1. The conveying roller table 2 passes through the cleaning room. The conveying roller table 2 is composed of a plurality of conveying rollers. Two adjacent conveying rollers The distance between them is l, and the range of the distance l is 170mm; the cleaning chamber is divided into upper cleaning chamber 7 and lower cleaning chamber 8 by the conveying roller table. 8 The left and right side walls are composed of two parts, the left vertical wall 4 and the left inclined wall 3, the right vertical wall 6 and the right inclined wall 5; the left vertical wall 4 and the left inclined wall 3 form an angle a, and the angle...

Embodiment 2

[0021] The hub shot blasting machine includes a frame 1. A cleaning room and a conveying roller table 2 are arranged on the frame 1. The conveying roller table 2 passes through the cleaning room. The conveying roller table 2 is composed of a plurality of conveying rollers. Two adjacent conveying rollers The distance between them is 1, and the range of the distance 1 is 175mm; the cleaning chamber is divided into upper cleaning chamber 7 and lower cleaning chamber 8 by the conveying roller table. 8 The left and right side walls are composed of two parts, the left vertical wall 4 and the left inclined wall 3, the right vertical wall 6 and the right inclined wall 5; the left vertical wall 4 and the left inclined wall 3 form an angle a, and the angle a is 130 degree angle, the right vertical wall 6 and the right inclined wall 5 form an included angle and also form an angle a, and the angle a is an angle of 130 degrees.

[0022] The cleaning room is provided with a shot blasting ma...

Embodiment 3

[0025] The hub shot blasting machine includes a frame 1. A cleaning room and a conveying roller table 2 are arranged on the frame 1. The conveying roller table 2 passes through the cleaning room. The conveying roller table 2 is composed of a plurality of conveying rollers. Two adjacent conveying rollers The distance between them is l, and the range of distance l is 180mm; the cleaning room is divided into upper cleaning room 7 and lower cleaning room 8 by the conveying roller table. 8 The left and right side walls are composed of two parts, the left vertical wall 4 and the left inclined wall 3, the right vertical wall 6 and the right inclined wall 5; the left vertical wall 4 and the left inclined wall 3 form an angle a, and the angle a is 133 degree angle, the right vertical wall 6 and the right inclined wall 5 form an included angle and also form an angle a, and the angle a is an angle of 133 degrees.

[0026] The cleaning room is provided with a shot blasting machine seat, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com