Sheet type oxygen sensor and mounting and working modes thereof

A technology of oxygen sensor and working method, which is applied in the direction of instruments, measuring devices, noise reduction devices, etc., can solve the problems of reducing the degree of contact between hot air and the probe, cost, volume design layout restrictions, shortening the ignition time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

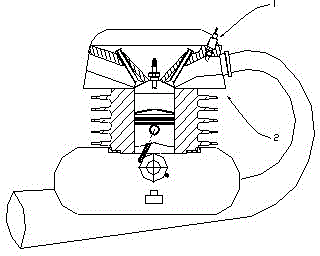

[0021] Such as figure 1 As shown, the chip oxygen sensor 1 is installed on the opposite side of the engine cylinder head 2 and the engine exhaust chain, about 70 mm away from the exhaust valve 3a, and can be used to quickly and effectively detect the oxygen content in the exhaust gas.

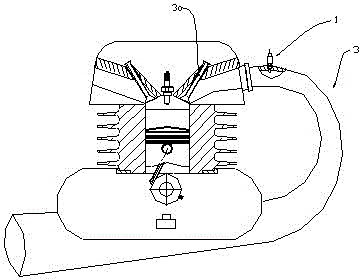

[0022] figure 2 It is a schematic diagram of the second installation structure of the chip oxygen sensor and its installation and working method provided by the present invention. The chip oxygen sensor 1 is installed at a position within about 300mm from the engine exhaust valve 3a.

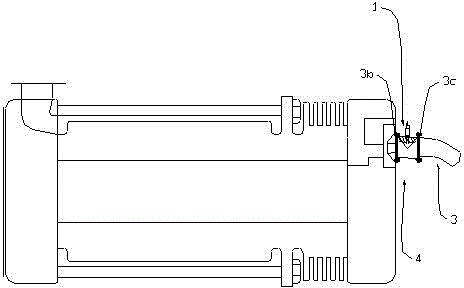

[0023] image 3 Shown is a schematic diagram of the third installation structure of the chip oxygen sensor provided by the present invention and its installation and working method, which includes an exhaust extension channel 4 connected between an engine exhaust port 3b and an exhaust pipe flange 3c, The oxygen sensor 1 is installed on the exhaust extension duct 4 . In addition, the exhaust channel 4 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com