A constant liquid level control device for granulating tower slag-water mixture

A technology of control device and granulation tower, which is applied in the field of constant and stable liquid level control device of slag-water mixture in the slag washing granulation tower, which can solve the problems of blast furnace conditions being greatly affected, overflow of slag-water mixture, unusable granulation tower, etc. problems, to achieve the effects of accurate measurement, saving electricity costs, and easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

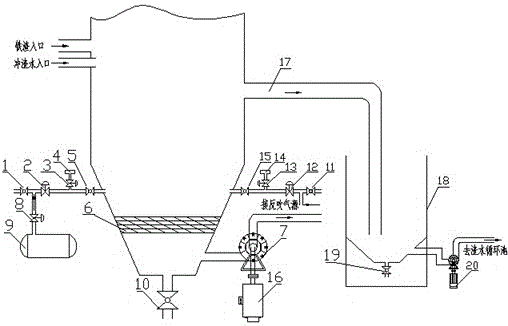

[0019] A device for controlling the constant liquid level of a granulated tower slag-water mixture according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] A granulation tower slag-water mixture constant liquid level control device, comprising a granulation tower, a liquid level measurement pipeline is arranged on the granulation tower, the inlet of the liquid level measurement pipeline is located 60 cm above the grid grid 6, and the A slag water overflow pipe 17 is provided between the inlet of the liquid level measurement pipeline and the iron slag inlet, and the other end of the slag water overflow pipe 17 is placed in the overflow tank 18, and the slag water is connected to the bottom of the overflow tank through a pipeline. In the water circulation pool, an overflow tank water pump motor 20 is provided on the pipeline between the overflow tank and the slag water circulation pool, and a sewage discharge pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com