Rotation type demolding mechanism for J-shaped drain trap

The technology of a demoulding mechanism and water trap, which is applied in the field of J-shaped water trap rotary demoulding mechanism, can solve the problems of high labor intensity, low production efficiency and high labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

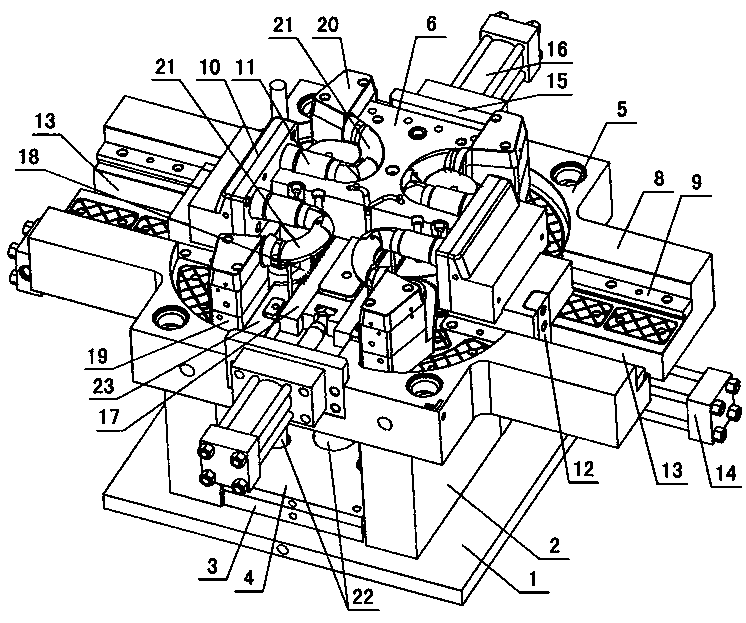

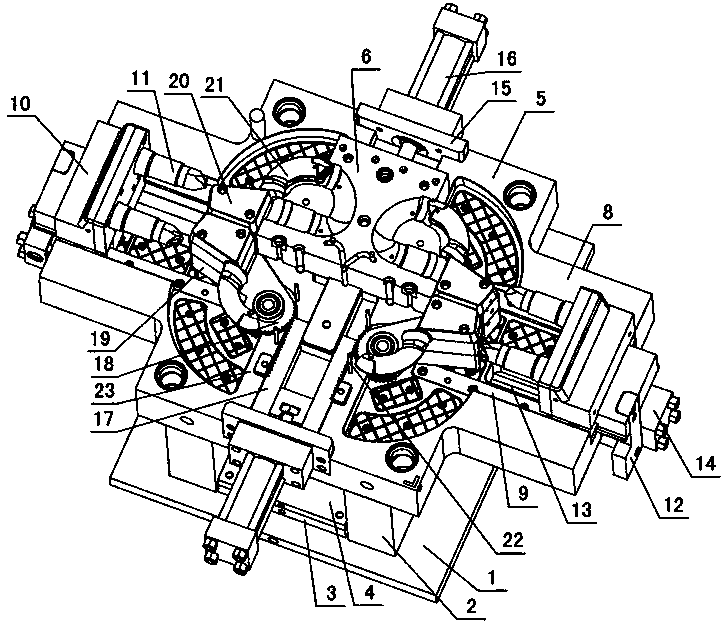

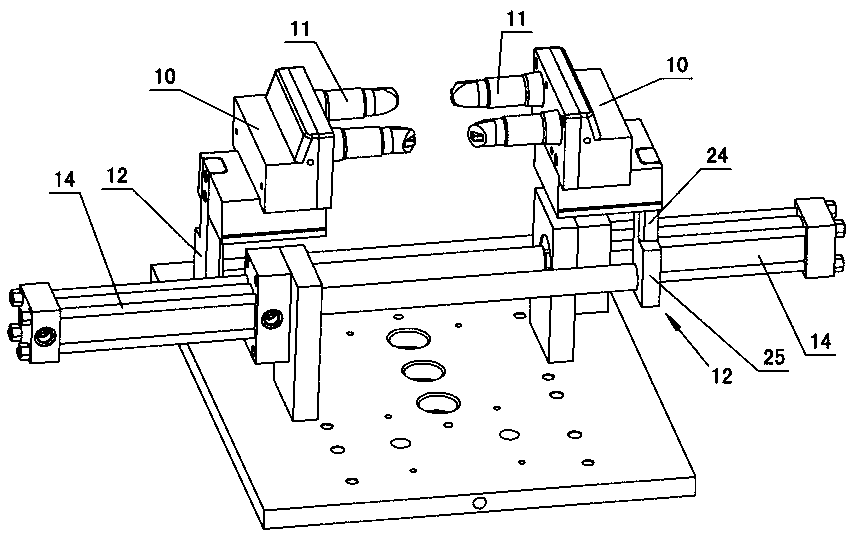

[0012] The invention relates to a J-shaped water trap rotary demoulding mechanism, such as figure 1 — Figure 5 As shown, it includes the lower doubler plate 1, the mold foot 2 is installed on the lower doubler plate, the thimble base plate 3 and the thimble panel 4 are arranged between the mold feet, the ejector rod 22 is installed between the thimble base plate and the thimble panel, and the movable mold is installed on the mold foot Frame 5, the movable mold cavity 6 is installed on the movable mold frame, there is a fixed mold cavity on the movable mold cavity, there are cores in the fixed mold cavity and the dynamic mold cavity, and there is injection molding between the fixed mold cavity, the dynamic mold cavity and the core. The J-shaped trap 7 is characterized in that: the left and right sides of the movable mold frame 5 are shaped with growth-type left and right slides 8, the growth-type left and right slides are equipped with left and right beading bars 9, and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com