System and method for preventing and controlling potential hazards in gas extraction

A technology for hidden safety hazards and gas extraction, which is used in gas discharge, safety devices, mining devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

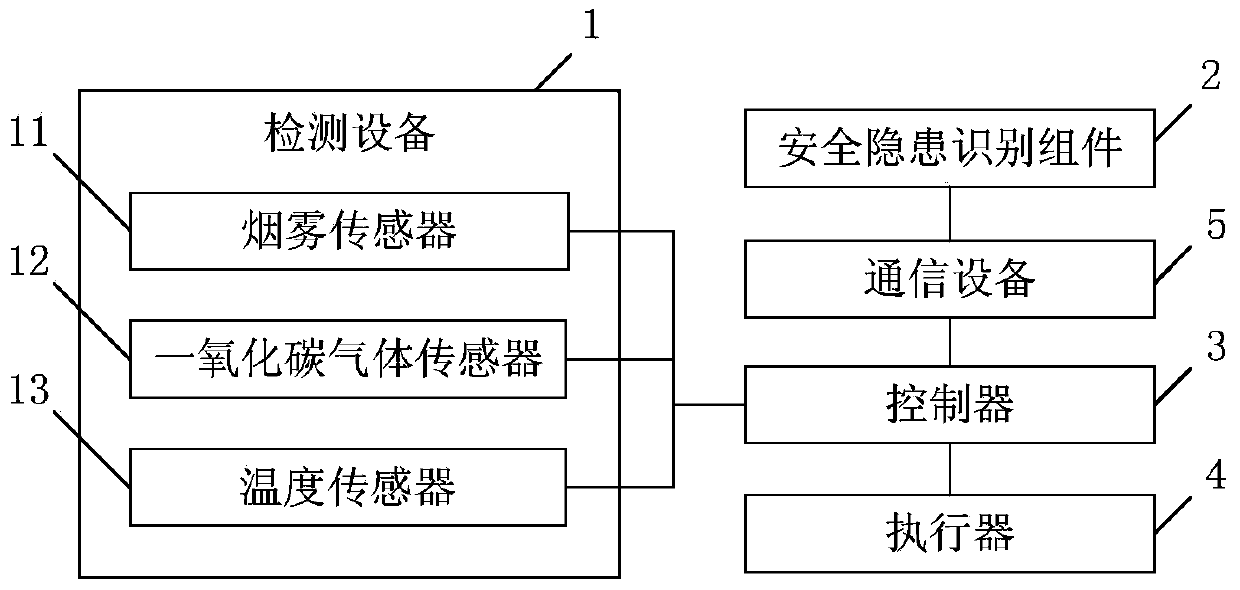

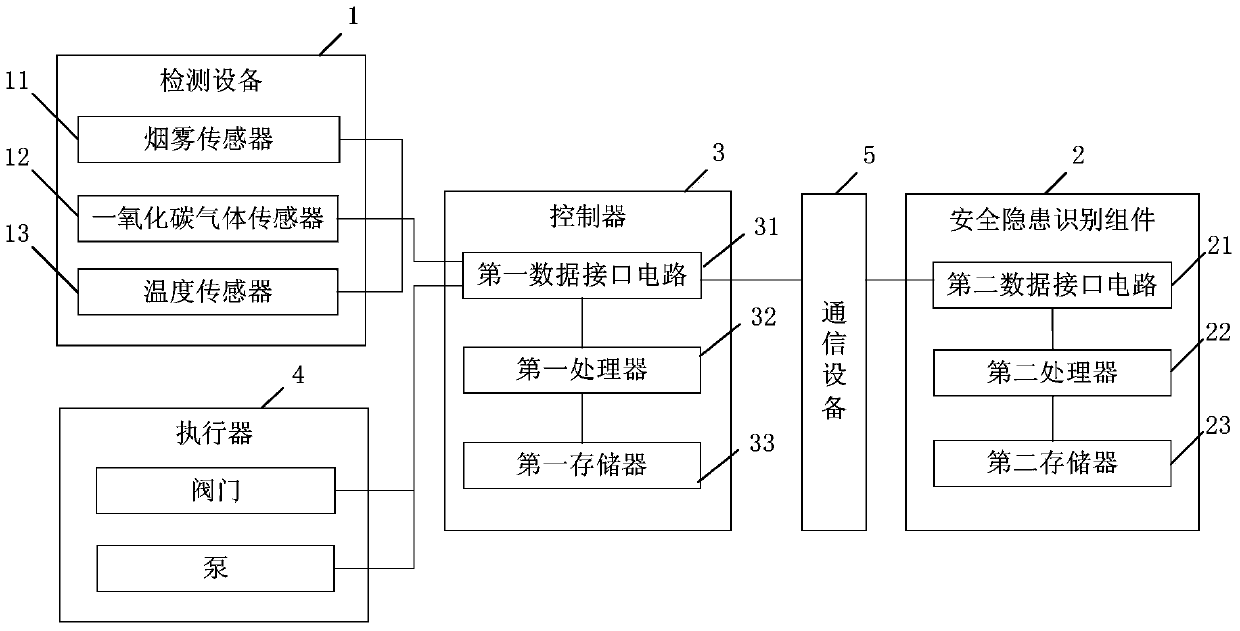

[0022] figure 1 It is a schematic structural diagram of the gas drainage safety hazard prevention and control system provided in Embodiment 1 of the present invention, figure 2 It is another structural schematic diagram of the safety hazard prevention and control system for gas drainage provided by Embodiment 1 of the present invention. Such as figure 1 and figure 2 As shown, the safety hazard prevention and control system for gas drainage may include: a detection device 1 , a safety hazard identification component 2 , a controller 3 , an actuator 4 and a communication device 5 .

[0023] Wherein, the detection device 1 is used to detect safety hazard parameters, and the safety hazard parameters include smoke concentration, carbon monoxide gas concentration and temperature. The controller 3 is respectively connected with the detection device 1 and the potential safety hazard identification component 2 for receiving potential safety hazard parameters, and sending the poten...

Embodiment 2

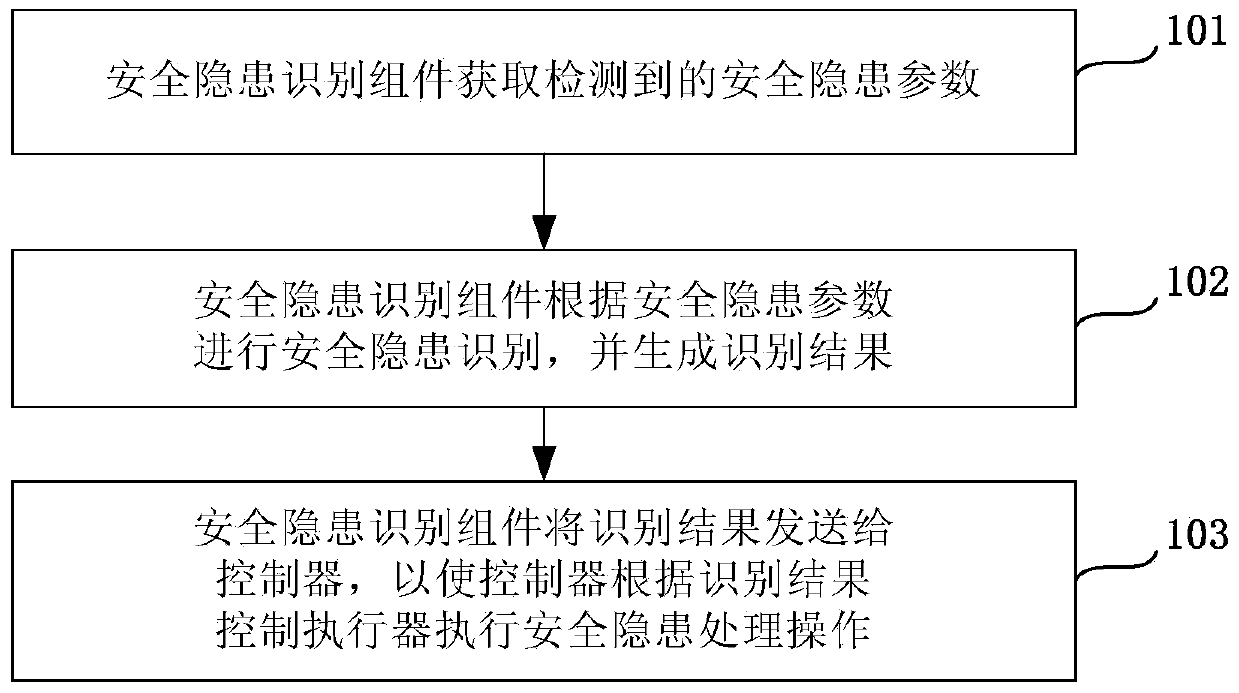

[0043] image 3 It is a flow chart of the method for preventing and controlling potential safety hazards in gas drainage provided by Embodiment 2 of the present invention. This method can be executed by the potential safety hazard identification component in the system for preventing and controlling potential safety hazards in gas drainage, and is realized by means of software / hardware. Such as image 3 As shown, the prevention and control methods for gas drainage safety hazards may include:

[0044] Step 101, the potential safety hazard identification component obtains the detected safety hazard parameters, the safety hazard parameters include smoke concentration, carbon monoxide gas concentration and temperature.

[0045] The safety hazard parameters are detected by the detection equipment installed under the mine. Specifically, the smoke concentration can be detected by the smoke sensor installed in the fire-prone area in the mine passage, for example, the smoke sensor ins...

Embodiment 3

[0066] Figure 5 A schematic diagram of the structure of the safety hazard prevention and control device for gas drainage provided by Embodiment 3 of the present invention, Figure 6 Another structural schematic diagram of the safety hidden danger prevention and control device for gas drainage provided by Embodiment 3 of the present invention. Such as Figure 5 and Figure 6 As shown, this embodiment also provides a safety hazard prevention and control device for gas extraction, which may include: a safety hazard parameter acquisition module 100 , a safety hazard identification module 200 and a recognition result sending module 300 .

[0067] Among them, the safety hazard parameter acquisition module 100 is used to obtain the detected safety hazard parameters, the safety hazard parameters include smoke concentration, carbon monoxide gas concentration and temperature, and the safety hazard identification module 200 is used to perform safety hazard identification according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com