Horizontal automatic control bagging machine

An automatic control bagging machine, horizontal technology, applied in the directions of horticulture, application, botany equipment and methods, etc., can solve the problems of complex structure, slow bagging speed, waste of labor, etc. Fast bagging and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

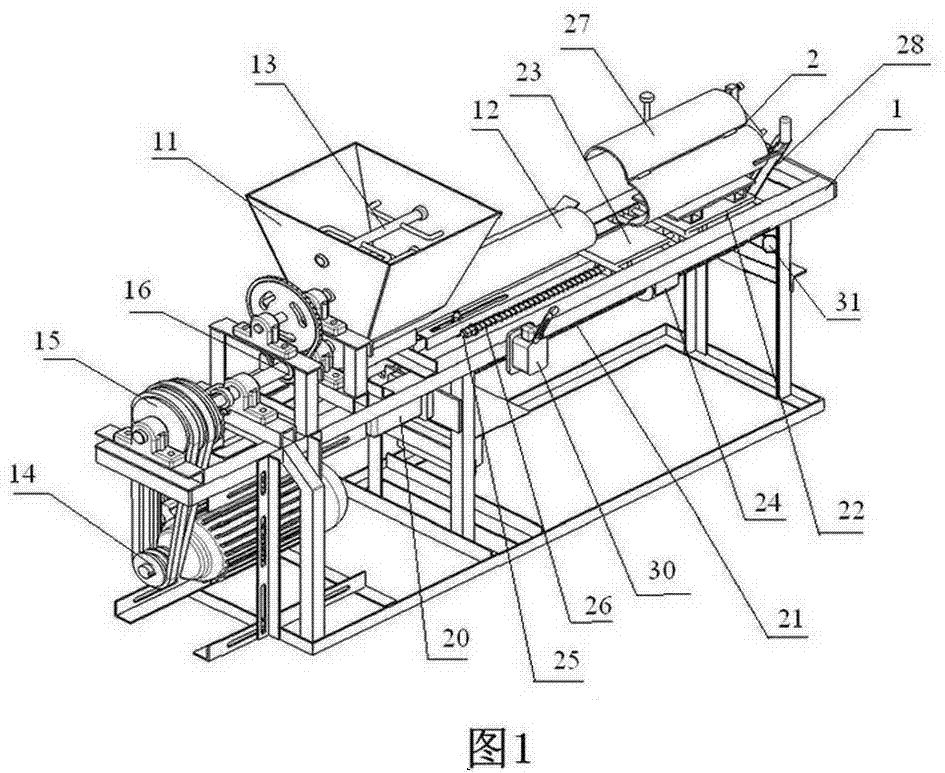

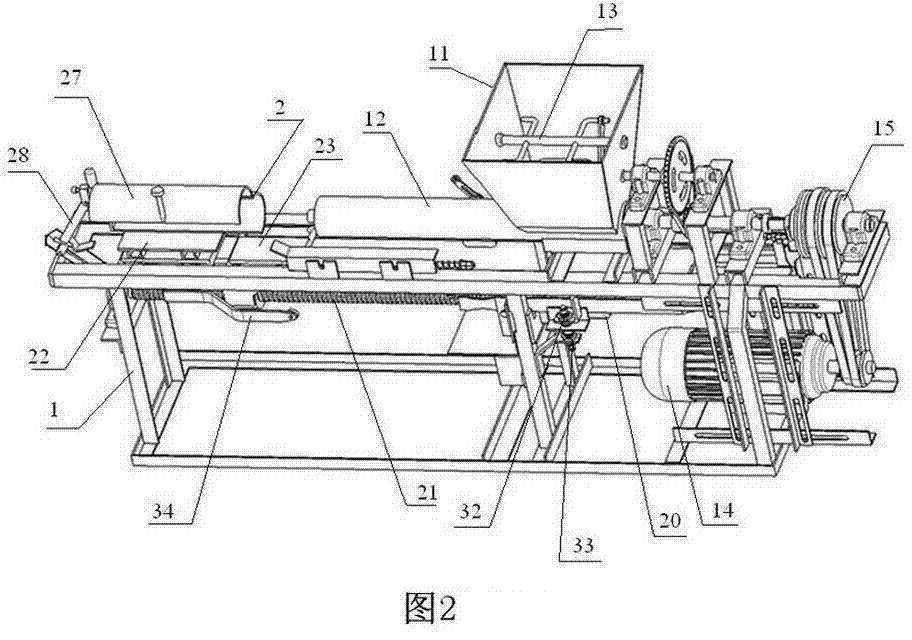

[0024] see figure 1 , figure 2 Shown:

[0025] The horizontal self-control bagging machine of the present invention is made up of frame 1, feeding device, moving device, control device and bagging tube 2, wherein feeding device and moving device are arranged on frame 1, and feeding device consists of hopper 11 and The feeder 12 is composed of an agitator 13 arranged in the hopper 11, and the feeder 12 is arranged at the lower end of the hopper 11. The feeder 12 is driven to rotate by the motor 14 through the first drive wheel 15, and the motor 14 is also connected to the first drive wheel. The second driving wheel 16 coaxially arranged at 15 drives the agitator 13 in the hopper 11 to rotate and work, and the agitator 13 rotates synchronously with the feeder 12, and the feeder 12 is a screw feeder.

[0026] The moving device is composed of a forward and reverse motor 20, a screw 21, a front block 22 and a rear block 23, wherein the forward and reverse motor 20 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com