Hardware plug foot bending mechanism and bending method

A bending mechanism and hardware technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high cost of machinery and equipment, long time required for bending, low bending efficiency, etc., to reduce the cost of machinery and equipment The effect of reducing cost, shortening bending time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application is further described in conjunction with the following examples.

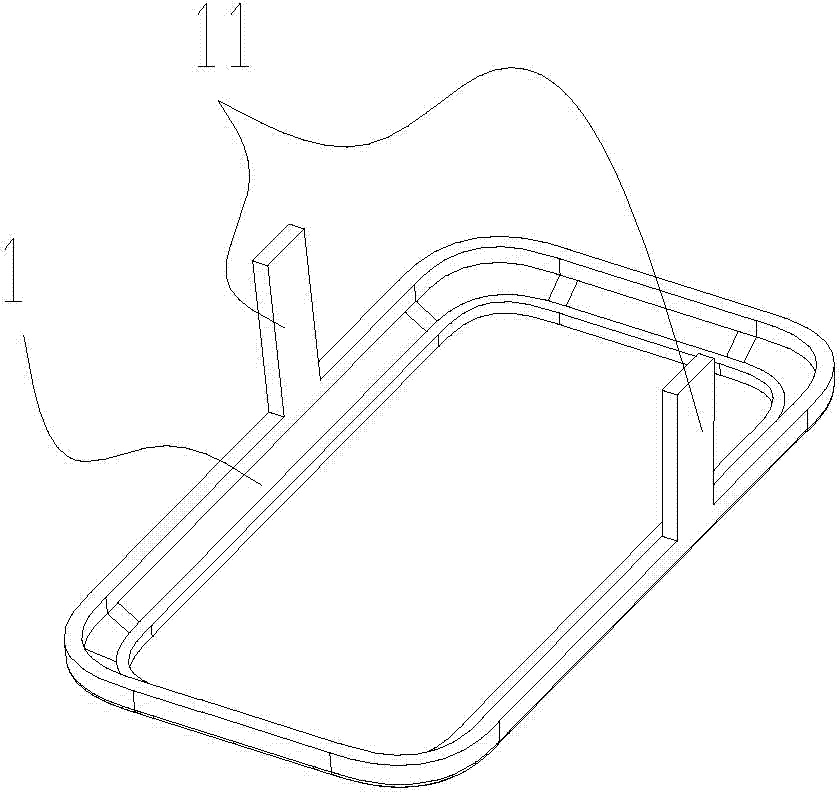

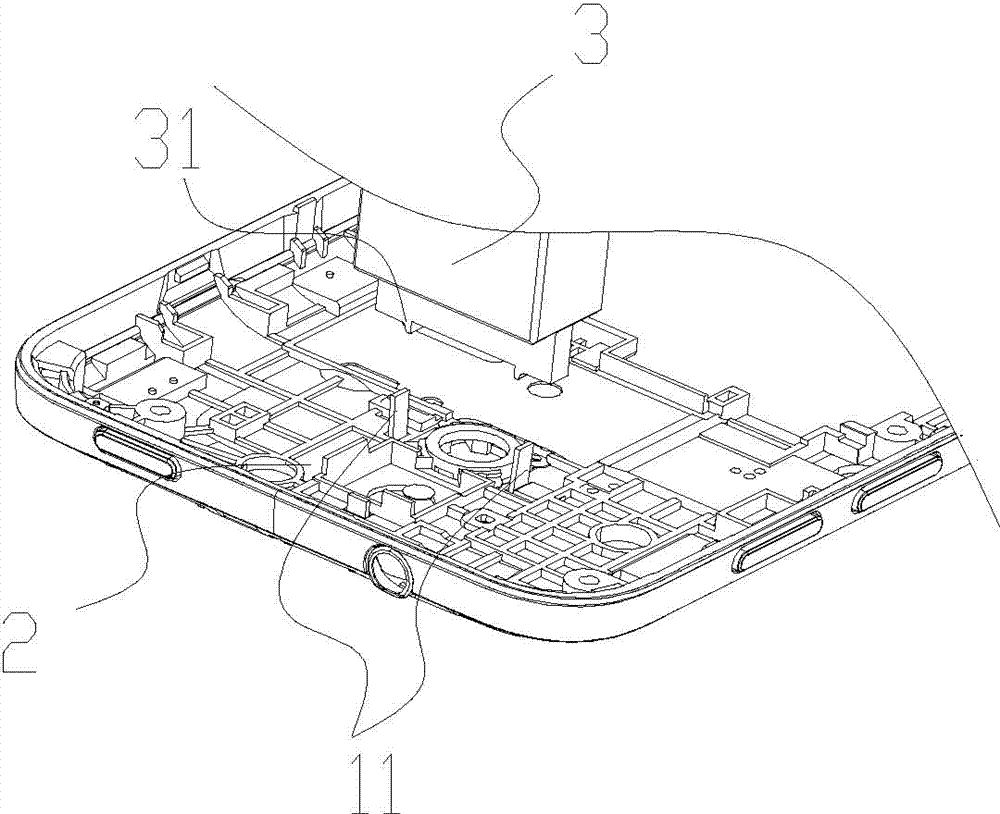

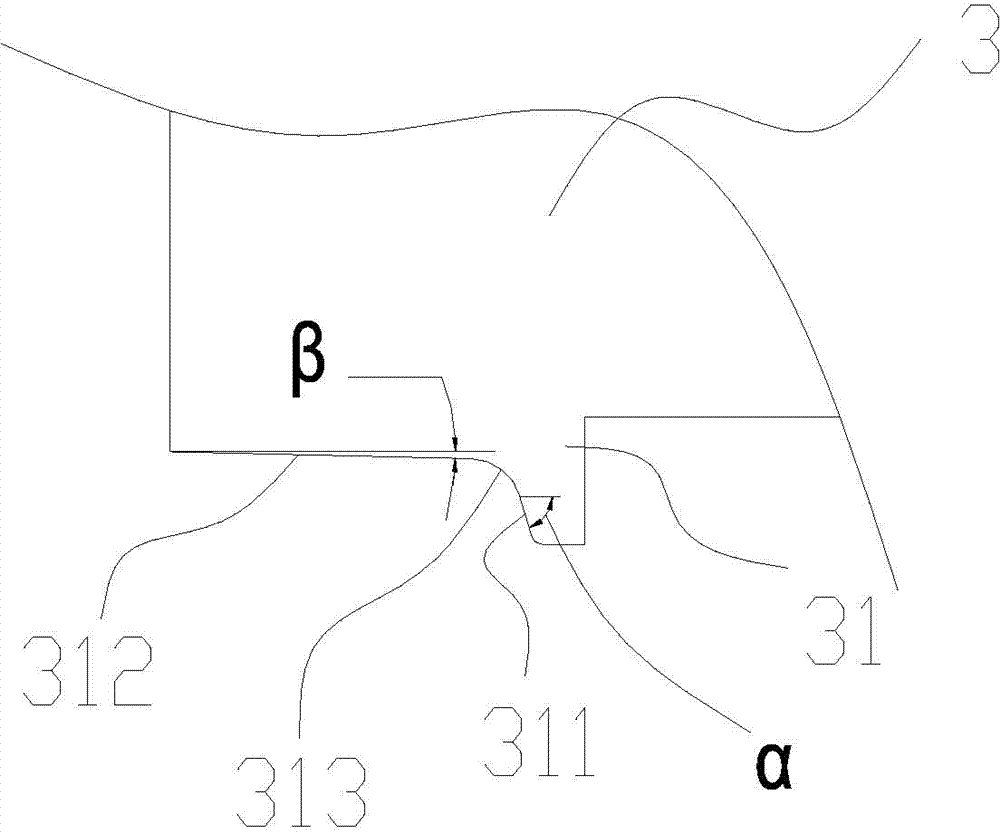

[0028] A specific implementation of a hardware pin bending mechanism of the present application, such as figure 2 , including fixing fixtures for fixing products with hardware 1 already installed, the figure 2 The pin 11 of the hardware 1 is clearly visible. The hardware 1 is located below the product and is covered in this figure. The above-mentioned technical features belong to the prior art. The innovation of this application is that the bending mechanism also includes a driving mechanism and The bending punch 3 drivingly connected with the driving mechanism, the punch end surface of the bending punch 3 is provided with two slope structures 31, and the slope structure 31 includes a half-bending slope 311 for side bending pin 11 and a A flattening slope 312 for flattening the pin 11 , an arc-shaped transition slope 313 is provided between the half-bending slope 311 and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com