Patents

Literature

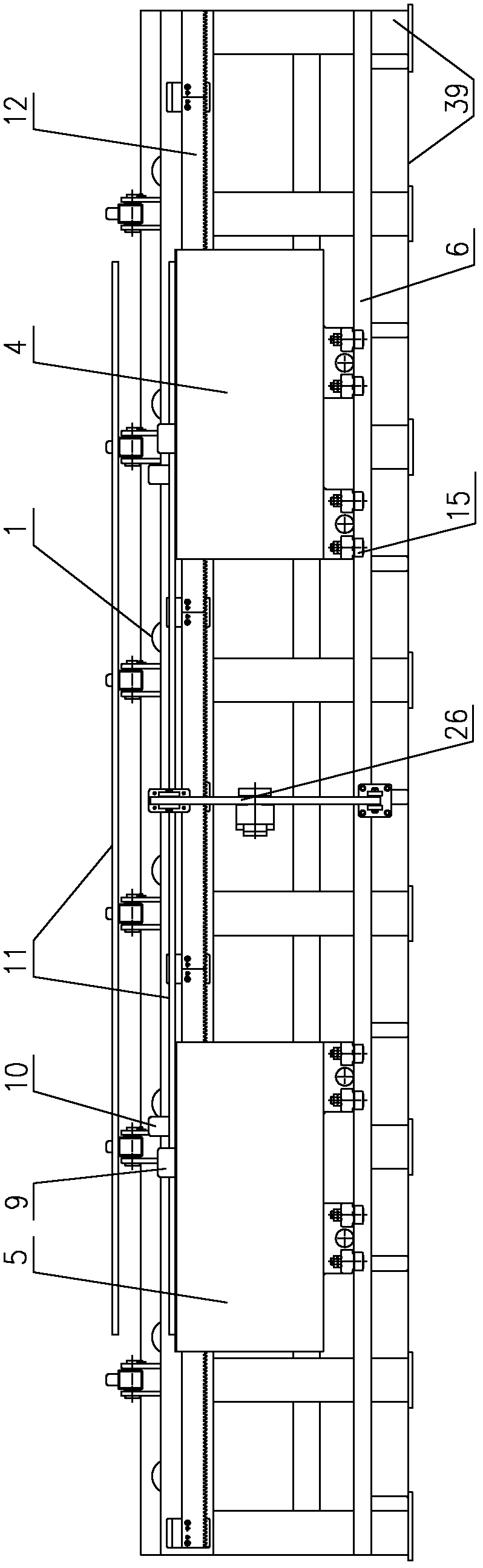

38results about How to "Reduce bending time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

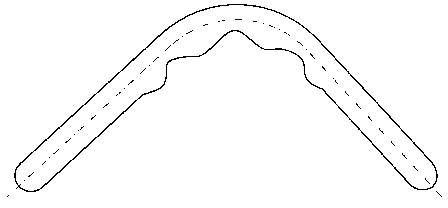

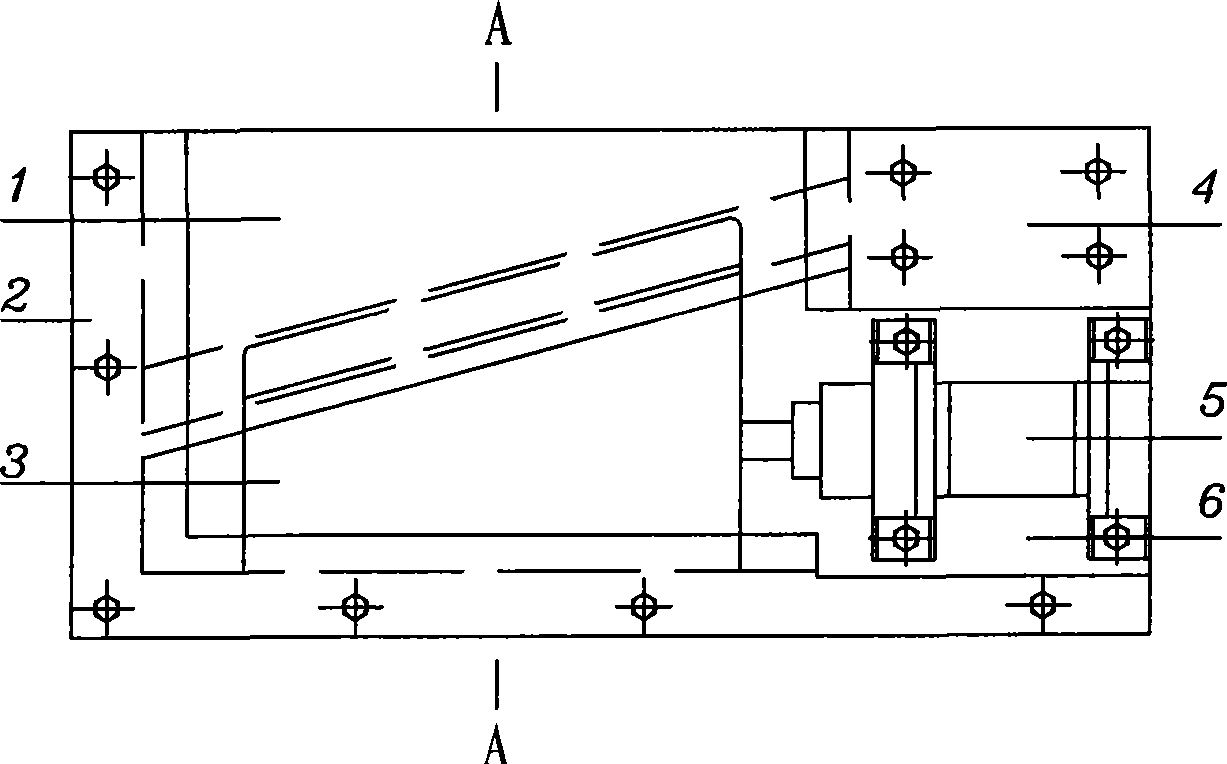

Automatic bending machine capable of continuously bending steel bars with different semi-diameters

The invention discloses an automatic bending machine capable of continuously bending steel bars with different semi-diameters, which comprises a track, a mobile driving mechanism, a turntable and a clamping mechanism, wherein the turntable and a fixed plate are connected to telescopic mobile mechanisms respectively; for the telescopic mobile mechanism connected with the turntable, the turntable is fixed at the upper end of a main shaft, and the main shaft is connected to a main shaft piston rod of a reciprocating mechanism; for the telescopic mobile mechanism connected with the fixed plate, a first supporting shaft, a second supporting shaft and a fixed plate piston rod are fixed on the bottom surface of the fixed plate; and the reciprocating mechanism connected with the fixed plate piston rod is fixed in the steel bar automatic bending machine. The automatic bending machine has the advantages of overcoming defects of the prior art, being capable of forming the steel bars with different bending semi-diameters once, obviously shortening the bending forming time of the steel bars and improving the production efficiency. The automatic bending machine also has the advantages of simple structure, convenient maintenance, smooth working, energy consumption saving and low processing cost.

Owner:TJK MACHINERY TIANJIN

Heat pipe bending method and heat pipe bending production device

The invention relates to the technical field of heat pipe radiating, in particular to a heat pipe bending method and a heat pipe bending production device. Liquid refrigerant is arranged in a heat pipe, and the heat pipe bending method includes S1 heating the heat pipe to transfer the internal liquid refrigerant into steam; and S2 bending mechanically. The heat pipe bending method is of an optimized solution on the basis of the existing bending process forming technology. During the production process of heat pipe bending, the heat pipe is heated to transfer the internal liquid refrigerant into steam, dynamic equilibrium is performed by utilizing generated steam differences and bend buckling moments, bending limit during the heat pipe bending process is increased, section shape at bending position can be prevented from generating distortion, small-radius bending is realized, and bending pass rate is increased.

Owner:SUN YAT SEN UNIV

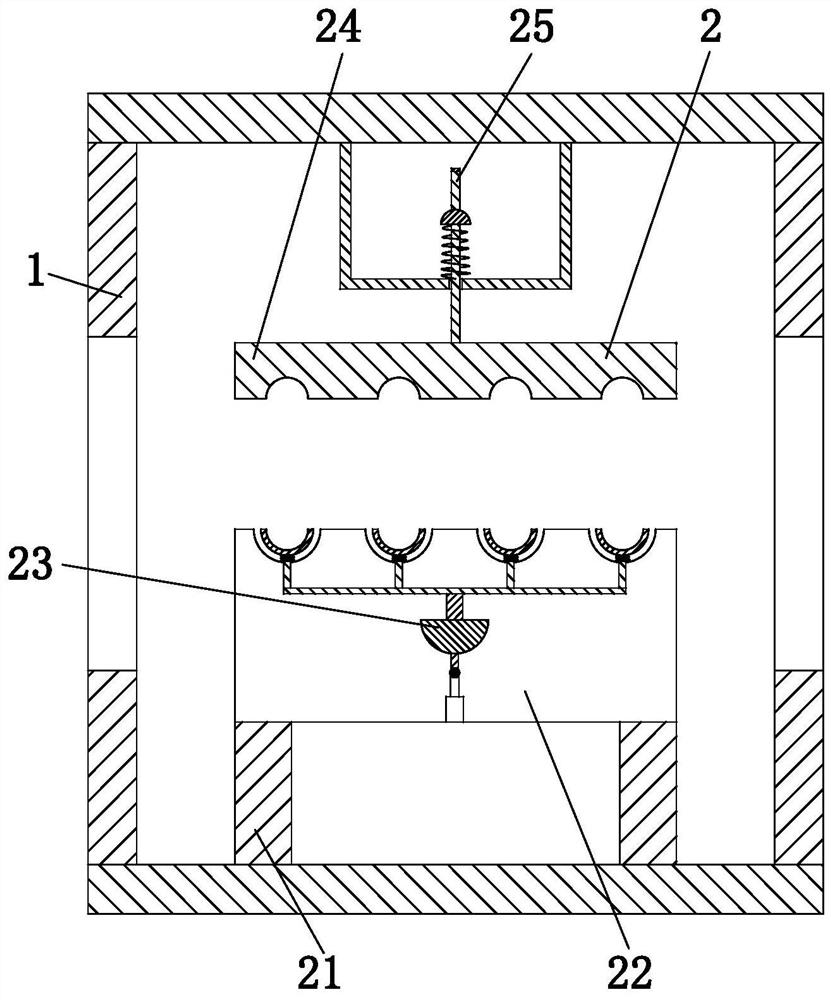

Shearing and bending mechanism

ActiveCN104128440AHigh degree of automationReduce routine maintenance timeShaping toolsEjection devicesEngineeringAutomation

The invention discloses a shearing and bending mechanism which comprises an upper die base connected under a press machine and a lower die base connected under the upper die base. A flanging convex die is connected under the upper die base, a lower cavity is formed in the bottom of the flanging convex die, a material pressing block is connected in the lower cavity, an upper cavity is formed in the top of the lower die base, a forming inserted block is connected in the upper cavity, peripheral guide pins are arranged between the material pressing block and the forming inserted block, a product material piece is arranged on the surfaces of the peripheral guide pins, a bending convex die is arranged on one side of the lower cavity of the flanging convex die, an edge cutting convex die is arranged on the other side of the lower cavity of the flanging convex die, the length of the edge cutting convex die extending downwards is longer than that of the bending convex die, a cutting inserted block is arranged on the lower die base and at the position corresponding to the edge cutting convex die, the edge cutting convex die can extrude the product material piece on the peripheral guide pins, and the bending convex die can extrude the product material piece. The shearing and bending mechanism simplifies bending procedures, improves bending automation, saves bending time and daily bending mechanism maintaining time and reduces bending cost.

Owner:ANHUI XINYUE PRECISION MACHINERY

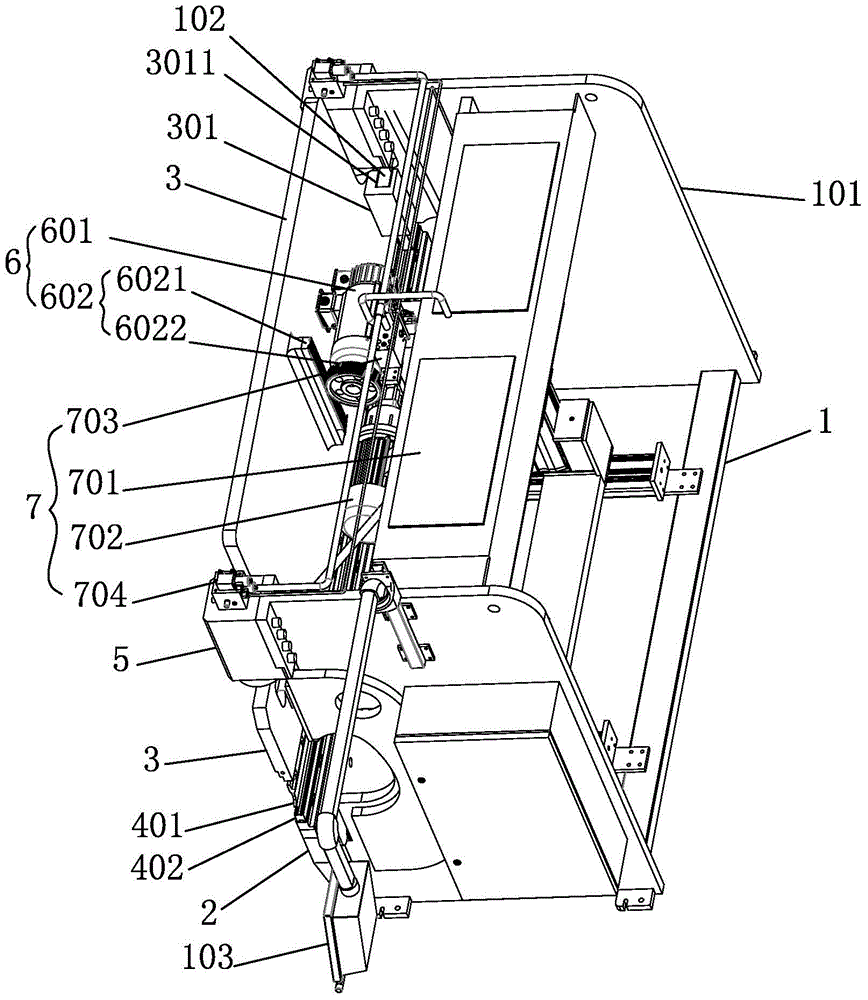

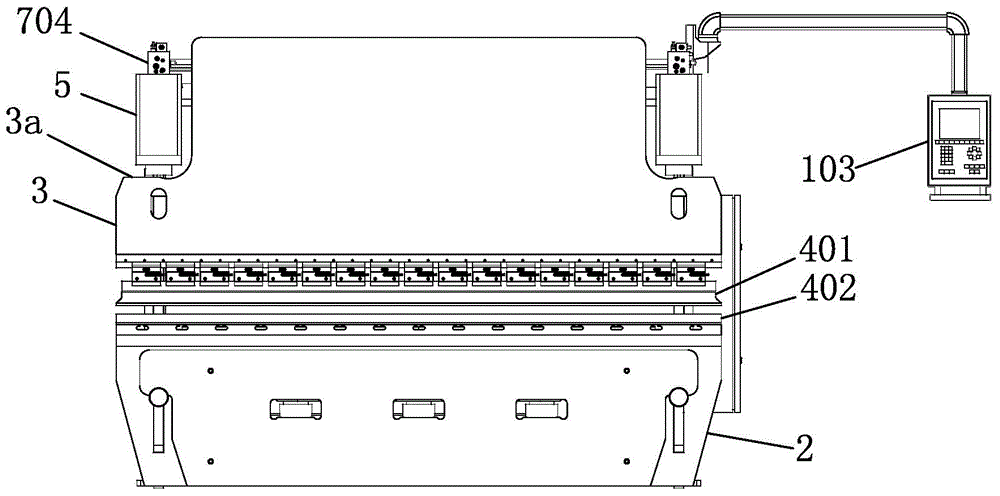

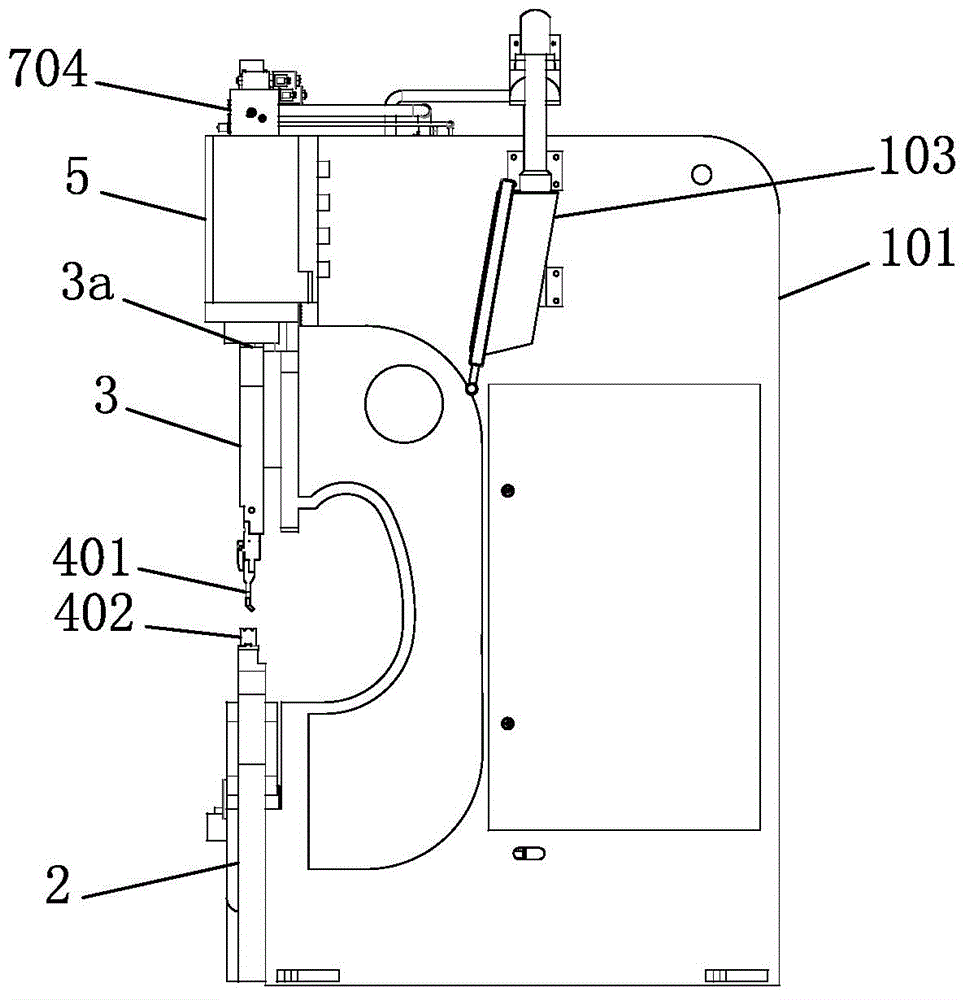

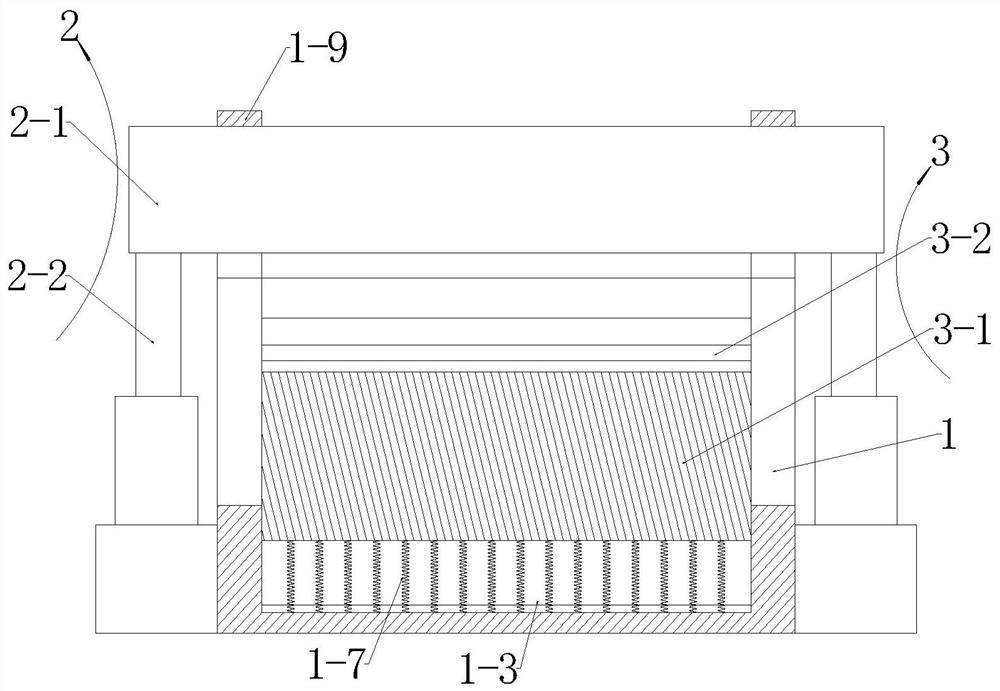

Electro-hydraulic synchronous bending machine and control method thereof

The invention discloses an electro-hydraulic synchronous bending machine and a control method thereof. The technical problem that an existing bending machine is high in manufacturing cost and production cost is solved. The electro-hydraulic synchronous bending machine comprises a machine frame and a sliding block, oil cylinders are arranged on the two sides of the rack respectively, piston rods of the two oil cylinders are connected with the sliding block, and the bending machine further comprises an electric servo driving system, a hydraulic driving system and a control system. The electric servo driving system comprises a servo motor and a transmission device arranged on the servo motor and the sliding block, and the servo motor drives the sliding block to move vertically through the transmission device. The hydraulic driving system comprises oil tanks, an oil pump, an electromagnetic pressure valve and two proportional flow valves. An oil outlet of the oil pump is communicated with an oil inlet of the electromagnetic pressure valve, a pressure oil port of the electromagnetic pressure valve is communicated with oil inlets of the two proportional flow valves, and oil outlets of the two proportional flow valves are communicated with the two oil cylinders respectively.

Owner:SHAOXING ANYAXIN AUTOMATION TECH

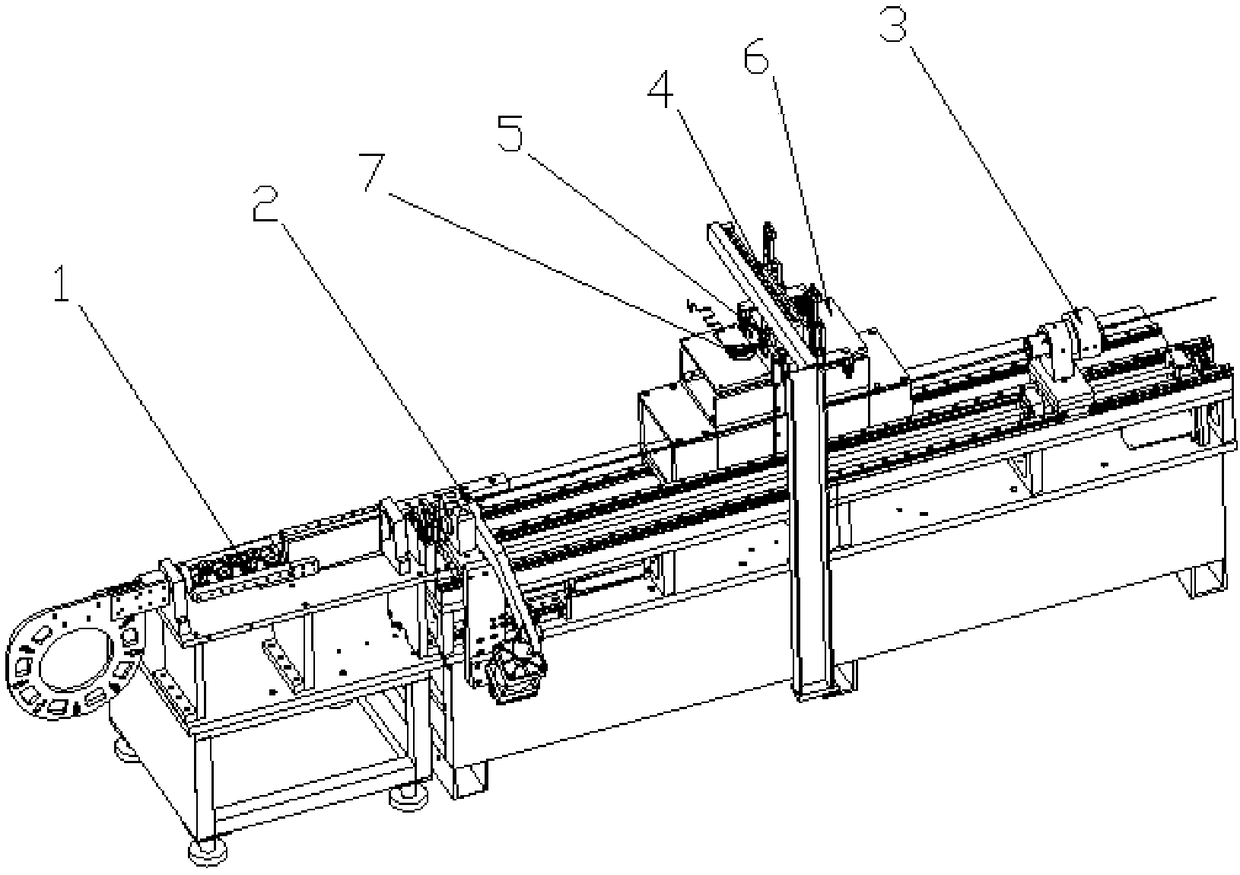

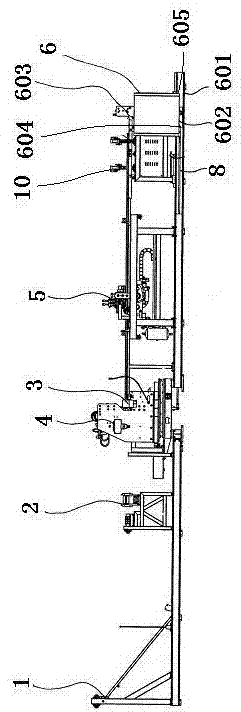

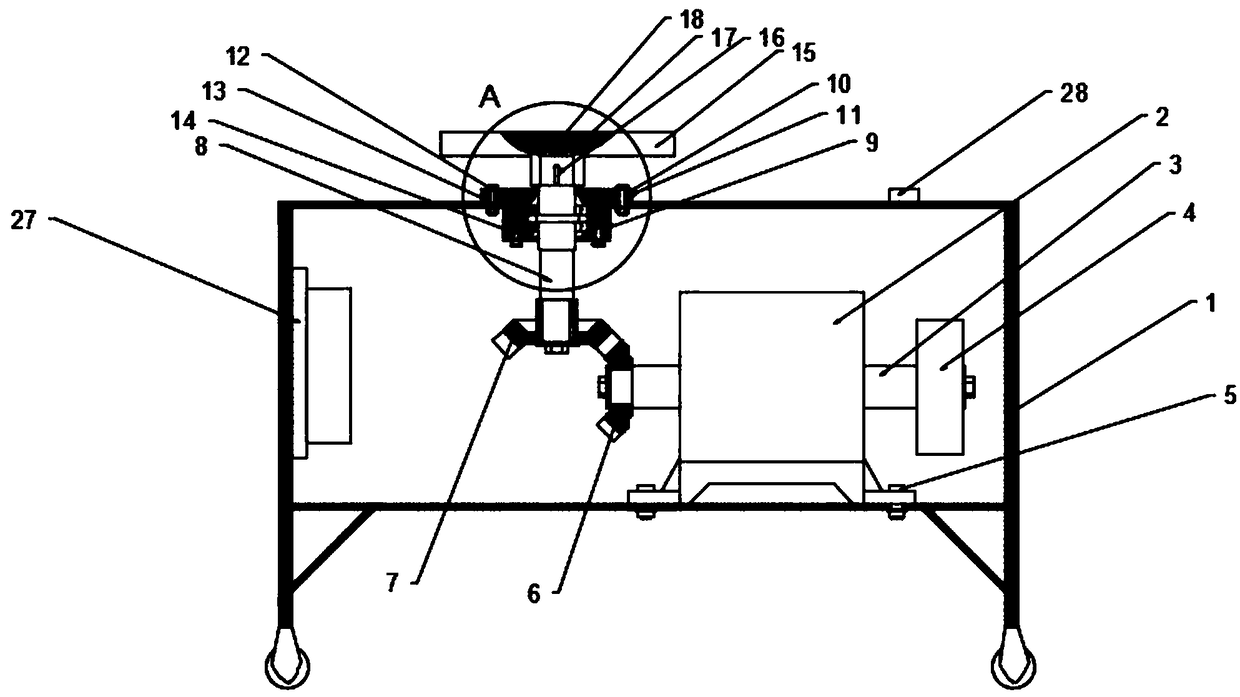

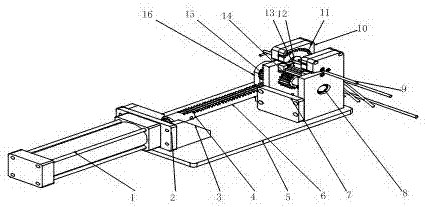

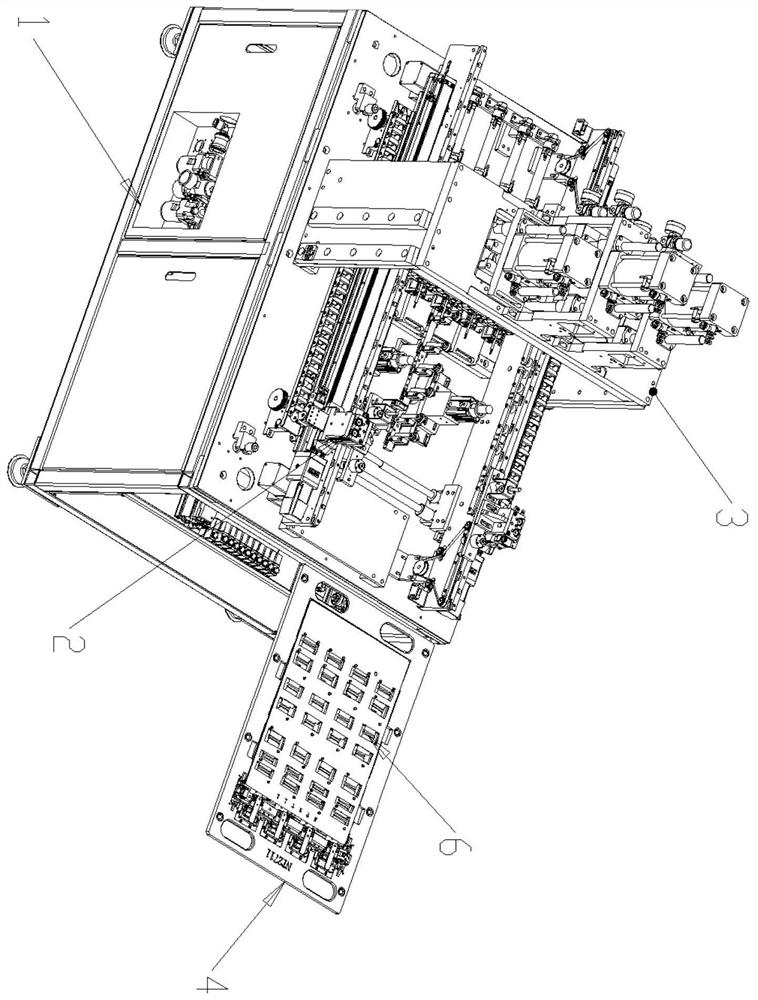

Double-head seven-axis forming machine

The invention discloses a double-head seven-axis forming machine. The double-head seven-axis forming machine comprises a bottom frame and a rack platform arranged on the bottom frame and further comprises a material counting mechanism, a linear mechanism, a cutting-off mechanism, a feeding mechanism, a wire changing mechanism used for adjusting the angle of a wire, a left forming mechanism, a right forming mechanism, and a wire pulling mechanism which are all arranged on the rack platform, wherein the left forming mechanism and the right forming mechanism are used for bending the wire; the left forming mechanism and the right forming mechanism are arranged on the left side and the right side of the wire changing mechanism correspondingly; and the wire changing mechanism is fixed to the rack platform of the double-head seven-axis forming machine. According to the double-head seven-axis forming machine, the structure is integrally designed, the process steps are simplified, the bending forming time is shortened, the structures of front stations and rear stations are compact, cooperation is tight, machining debugging is easy, convenient and easy to operate, and one-time complex linearbending operation can be achieved; the bending efficiency is high, the manufacture process is good in stability, the bending quality is greatly improved, more convenience is realized, the manual handoperation error is reduced, manpower is saved, a computer is utilized to control multiple axes to conduct an action simultaneously, and debugging is easy; and the cost is reduced, the resources are saved, and the production efficiency is improved.

Owner:GUANGZHOU CAIHONG HARDWARE SPRING CO LTD

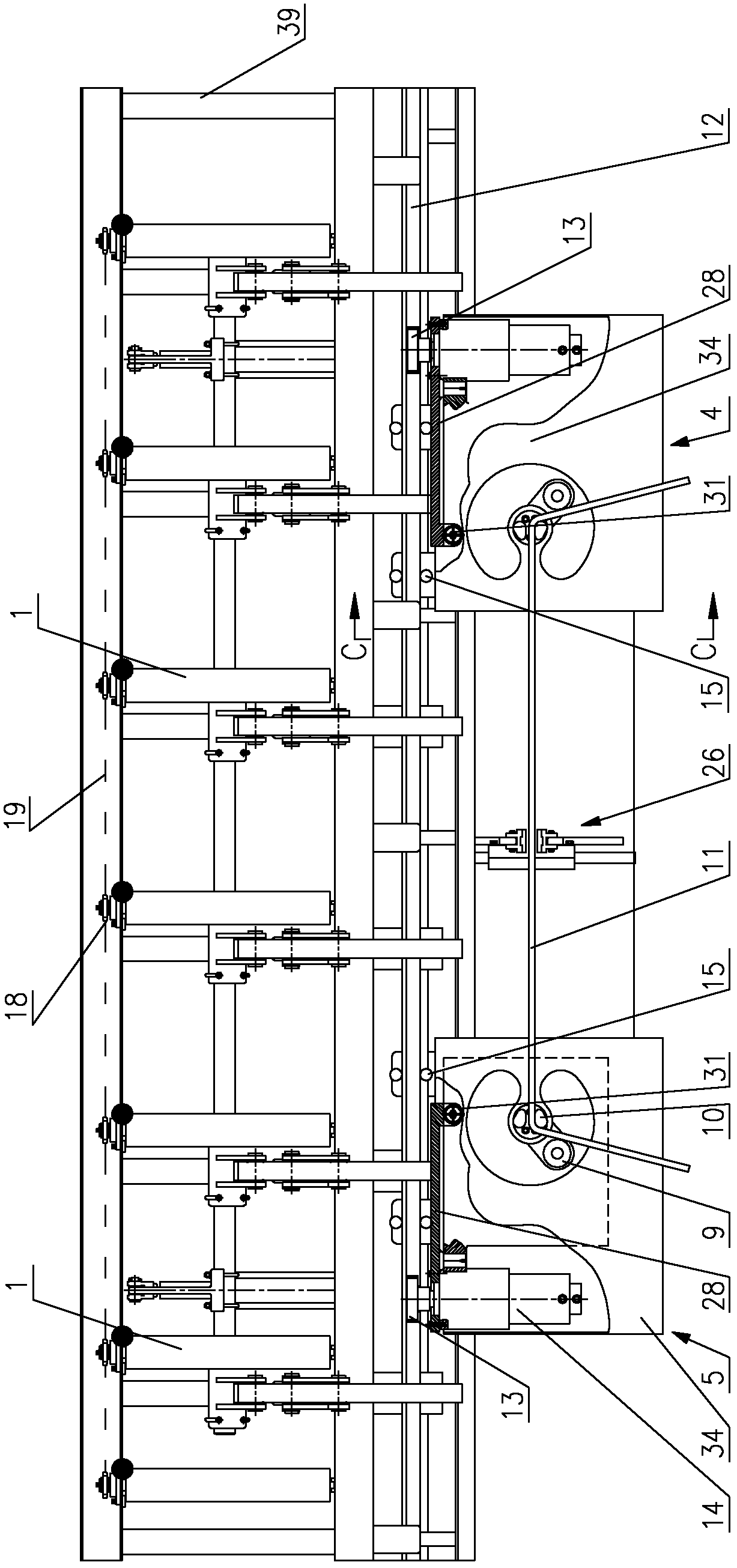

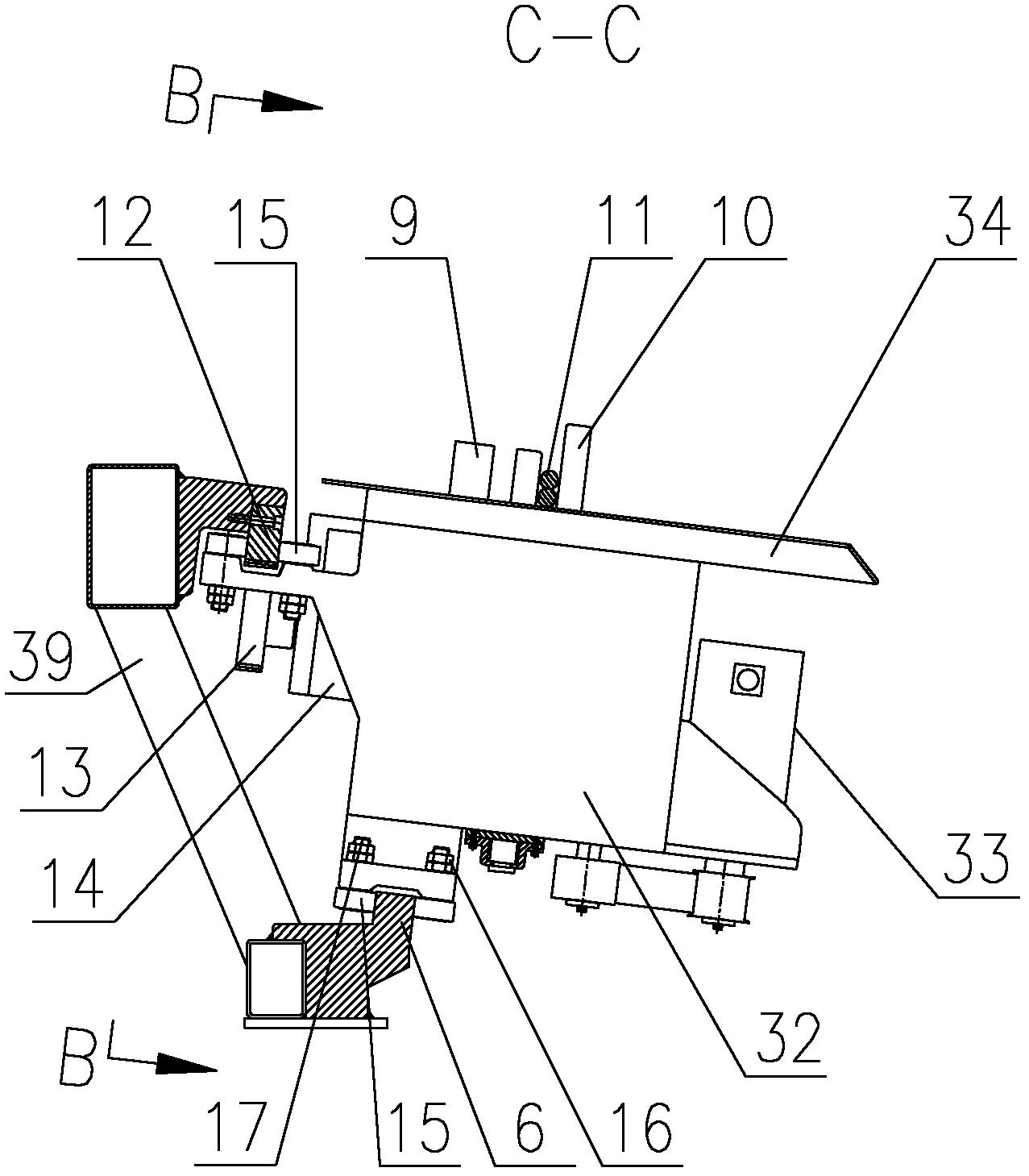

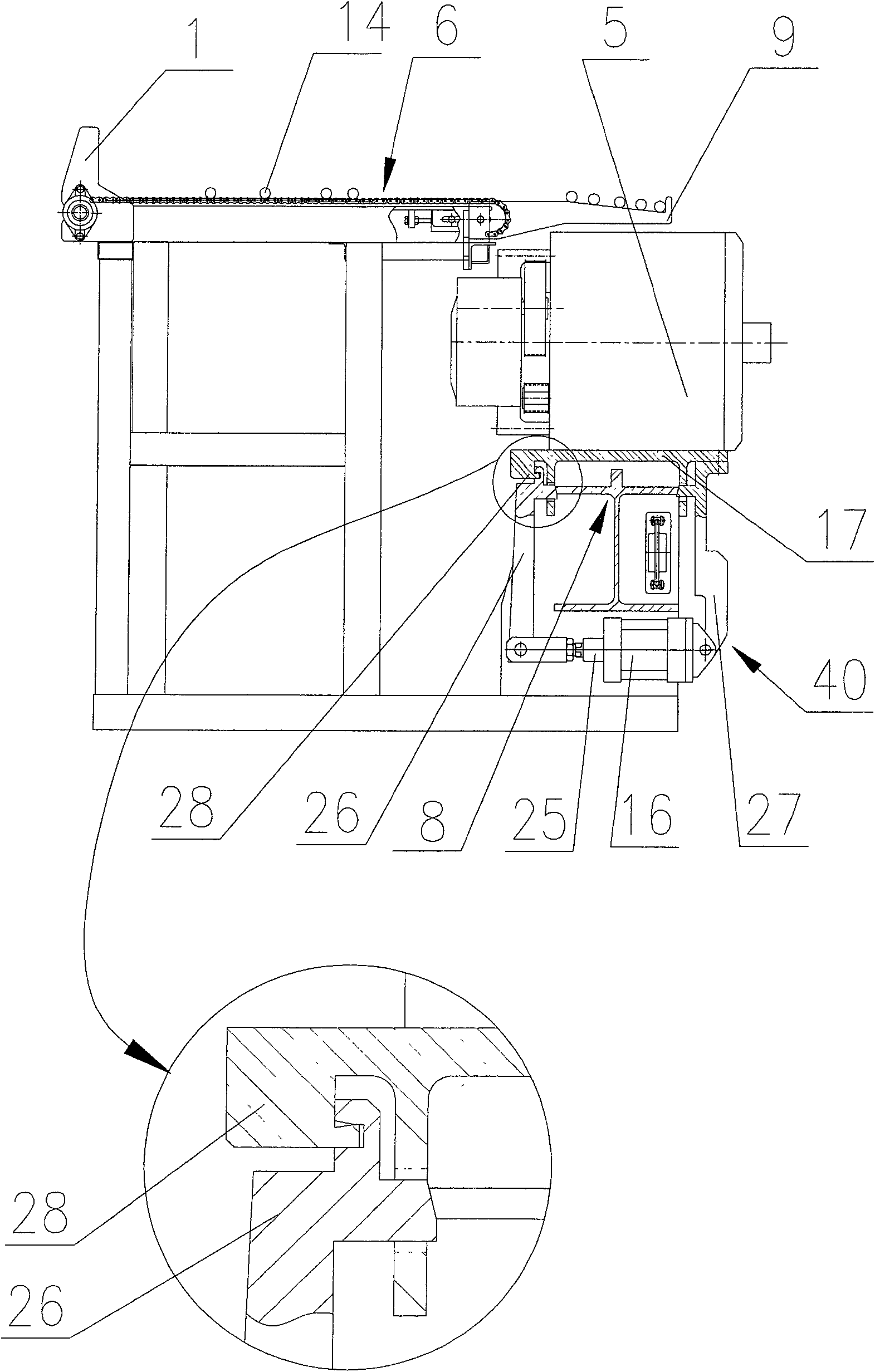

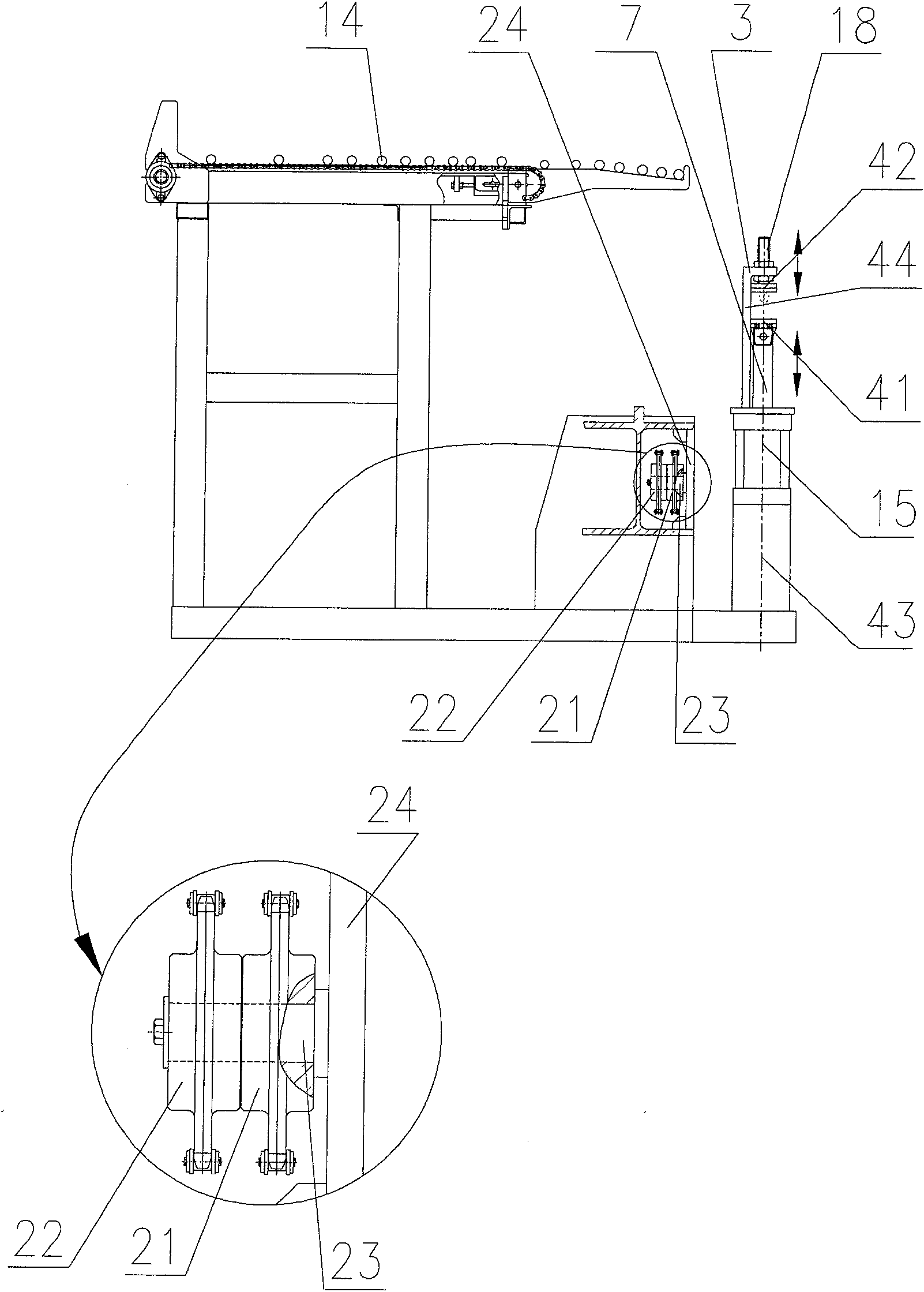

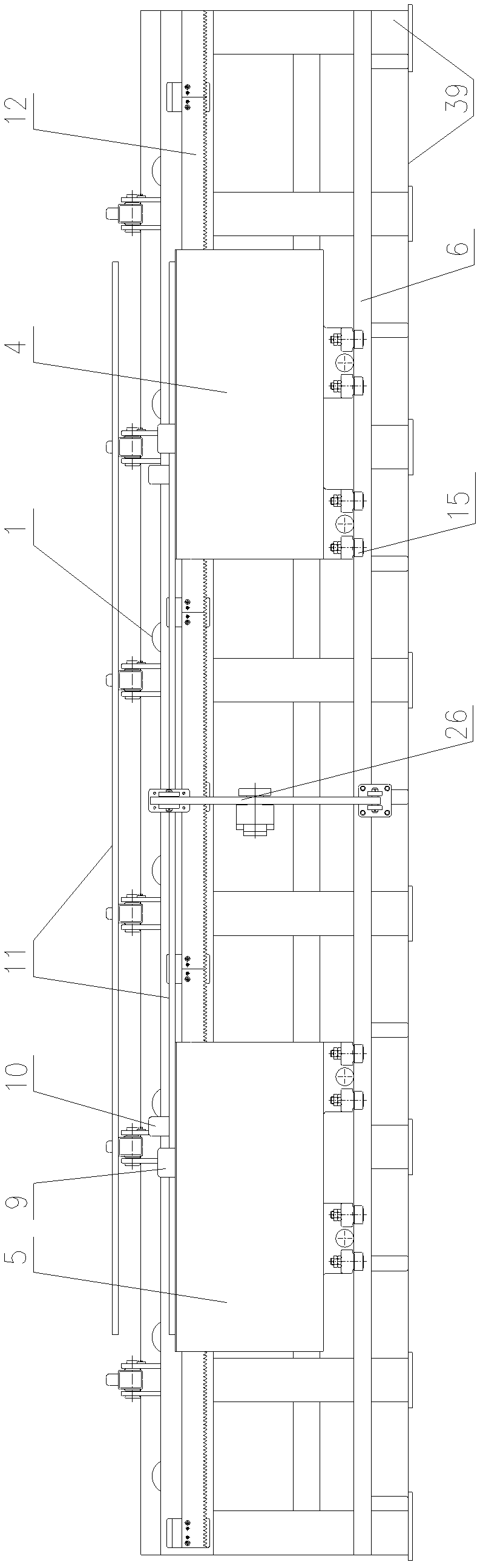

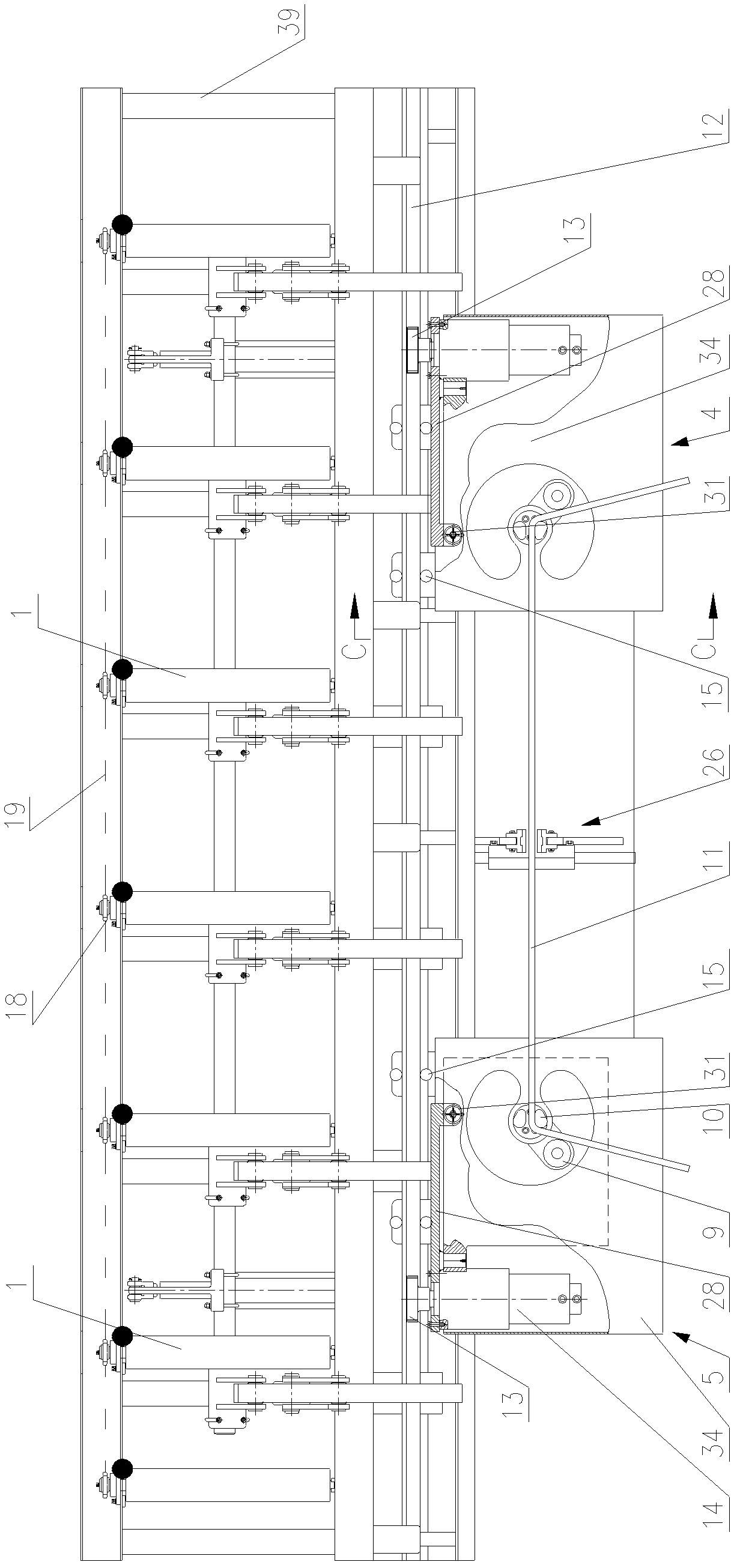

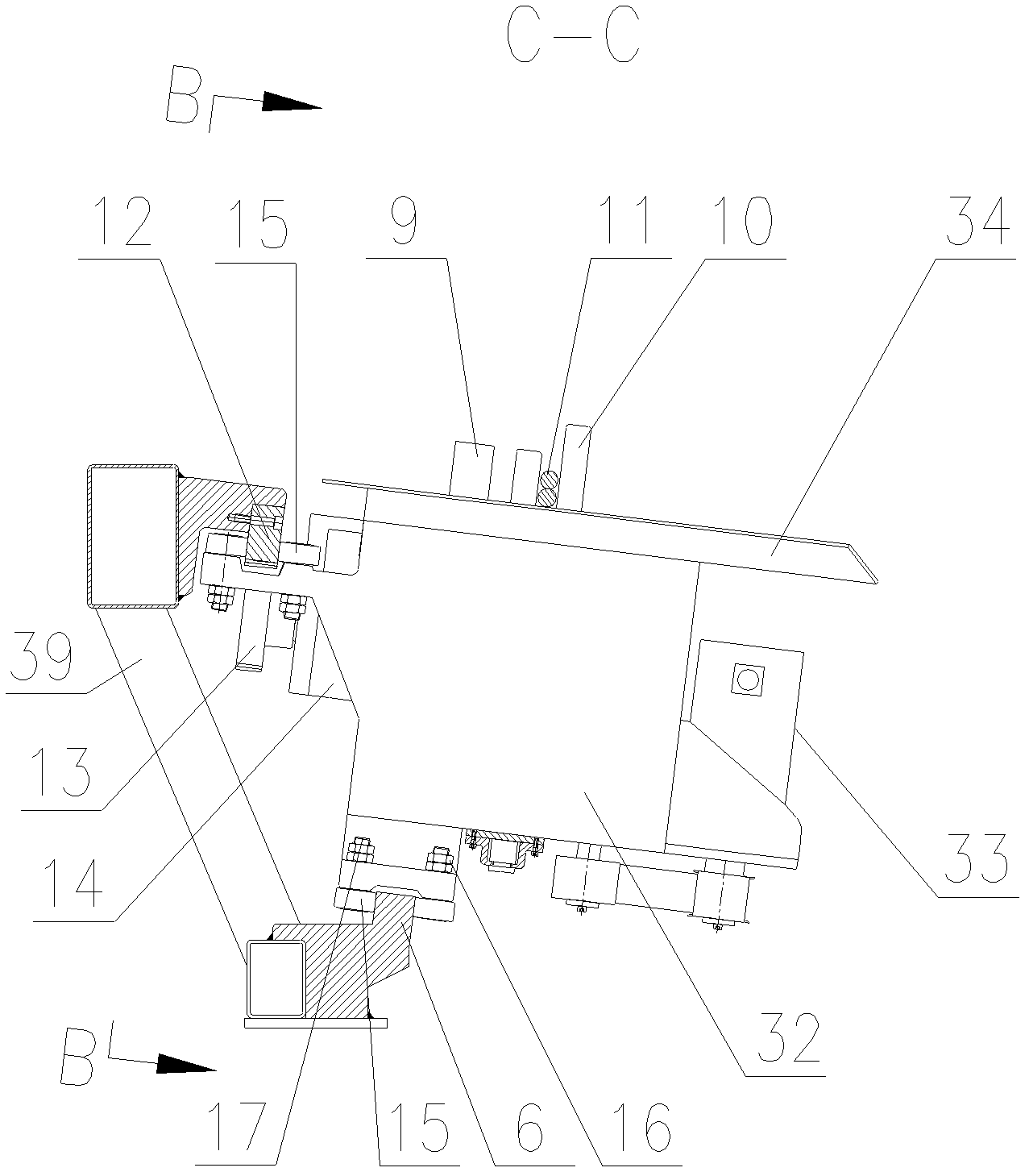

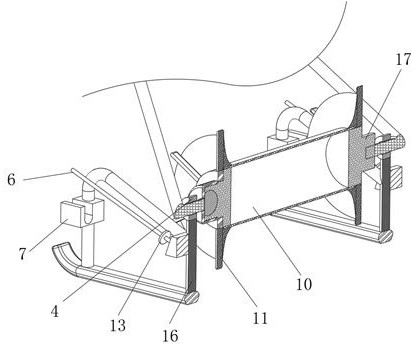

Movable inclined platform type automatic steel bar bending machine

The invention discloses a movable inclined platform type automatic steel bar bending machine, comprising a rack, a track, a gear rack and two automatic steel bar bending machines. The two steel bar bending machines are respectively provided with a gear transmission mechanism and a gear floating mechanism which move along the gear rack; the gear floating mechanism comprises a motor connecting plate and a support shaft; the motor connecting plate penetrates through and is hinged at one end of the support shaft, and the other end of the support shaft is fixed on a cabinet of each automatic steel bar bending machine; one end of the motor connecting plate is fixed on a motor flange plate in the gear transmission mechanism, and a gear in the gear transmission mechanism is meshed with the gear rack; and the other end of the motor connecting plate is supported on the cabinet of the automatic steel bar bending machine in a floating manner. The movable inclined platform type automatic steel bar bending machine has the beneficial effects that the accurate meshing between the gear and the gear rack in a travelling mechanism of the automatic steel bar bending machine can be ensured, the running is stable, the structure is simple, and an inclined platform type working table surface saves effort, is easy to operate, ensures the safety of an operator and realizes the humanized operation.

Owner:TJK MACHINERY TIANJIN

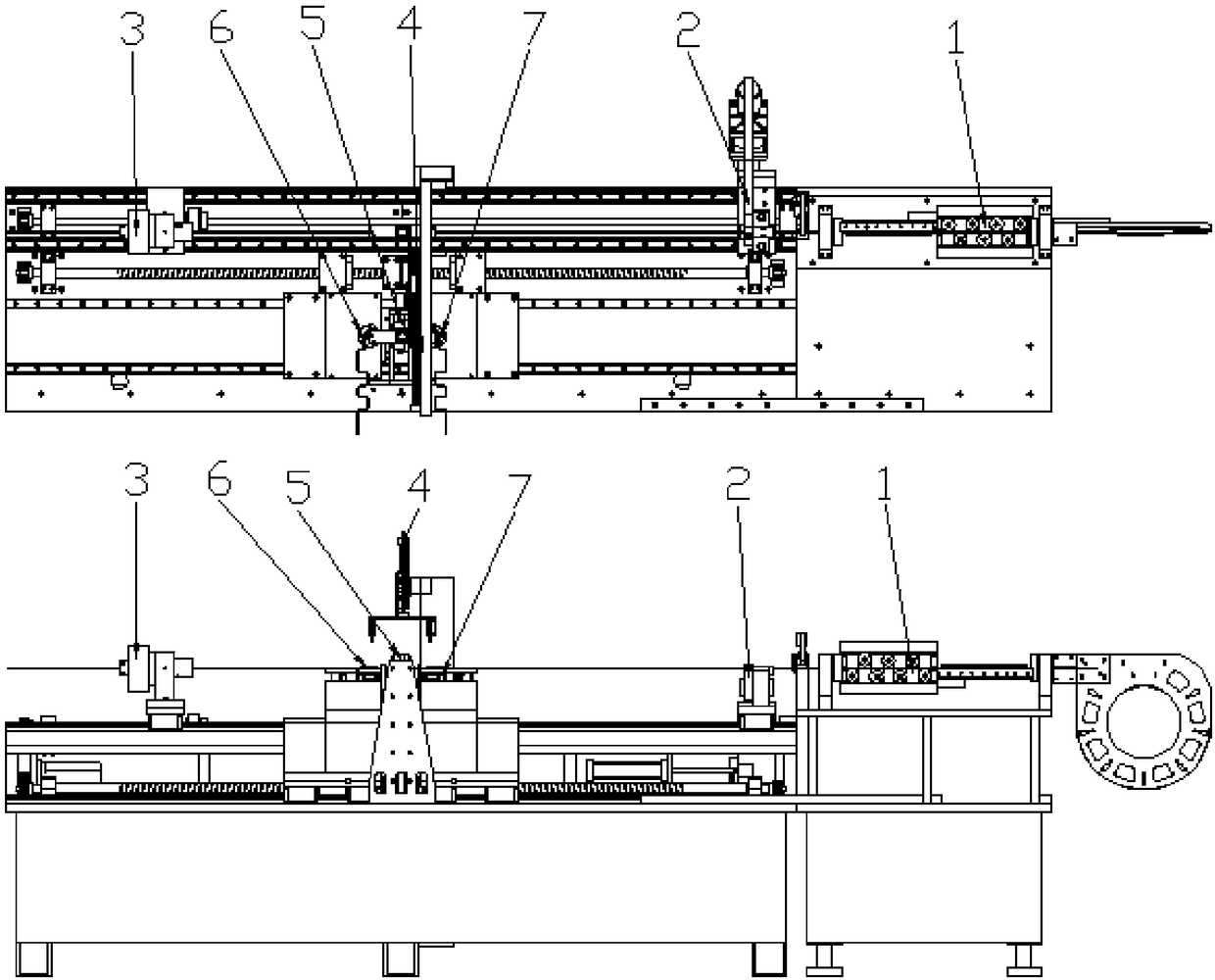

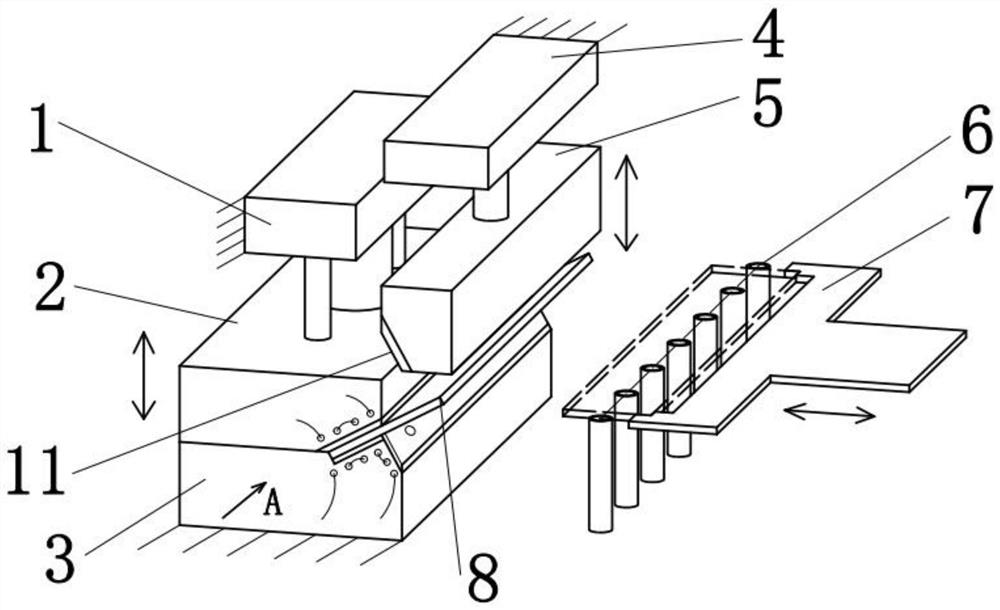

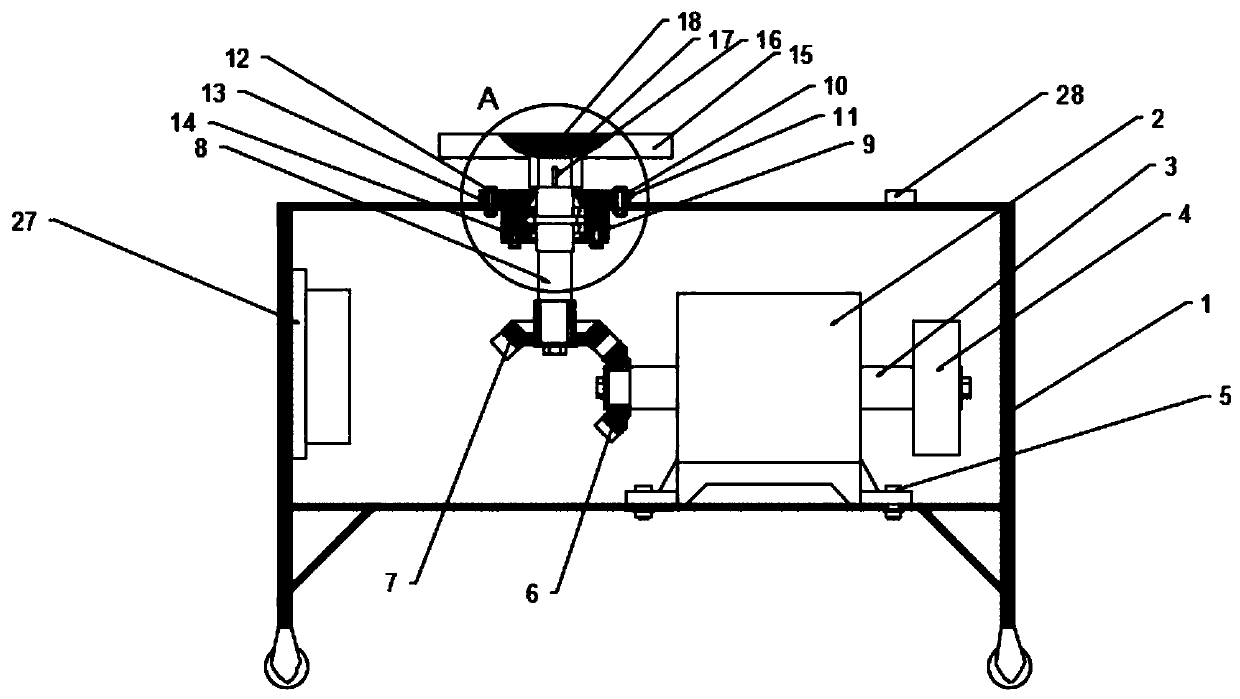

Welding forming device and welding method of breeding cage spacer nets

ActiveCN107378294AReduce bending timeIncrease productivityWelding/cutting auxillary devicesWire networkRight trapezoidWelding

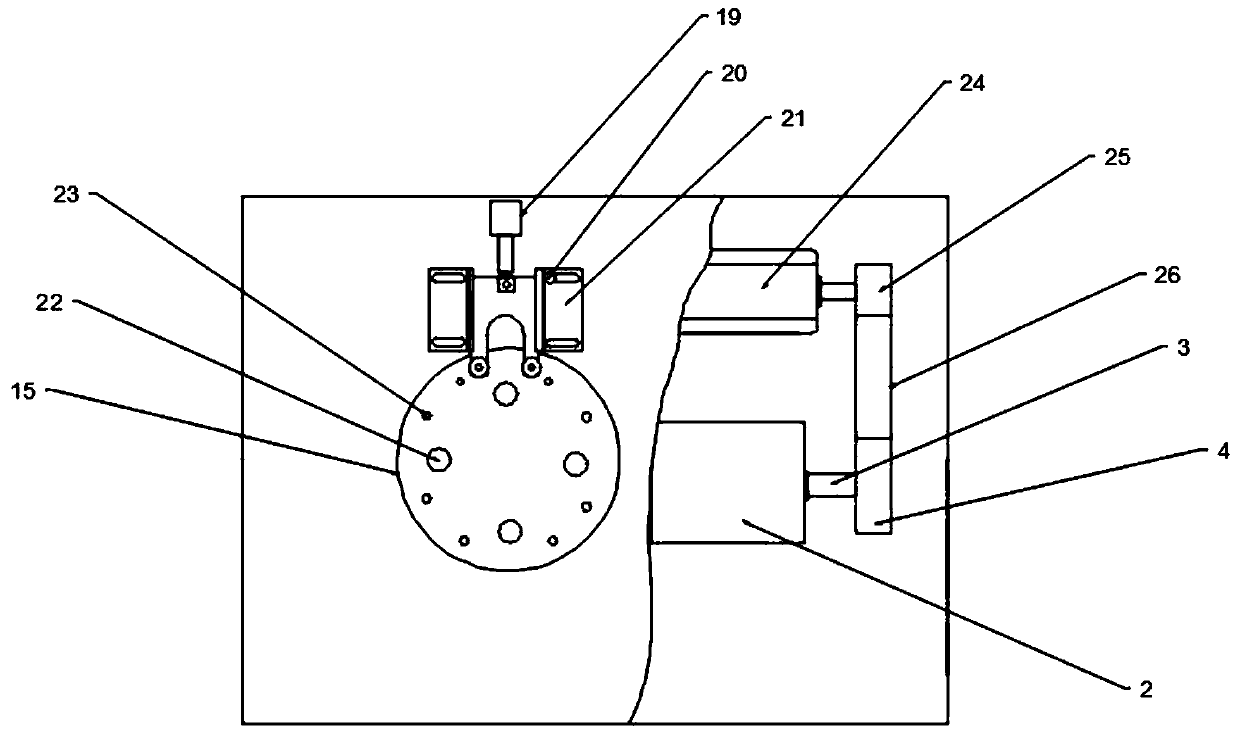

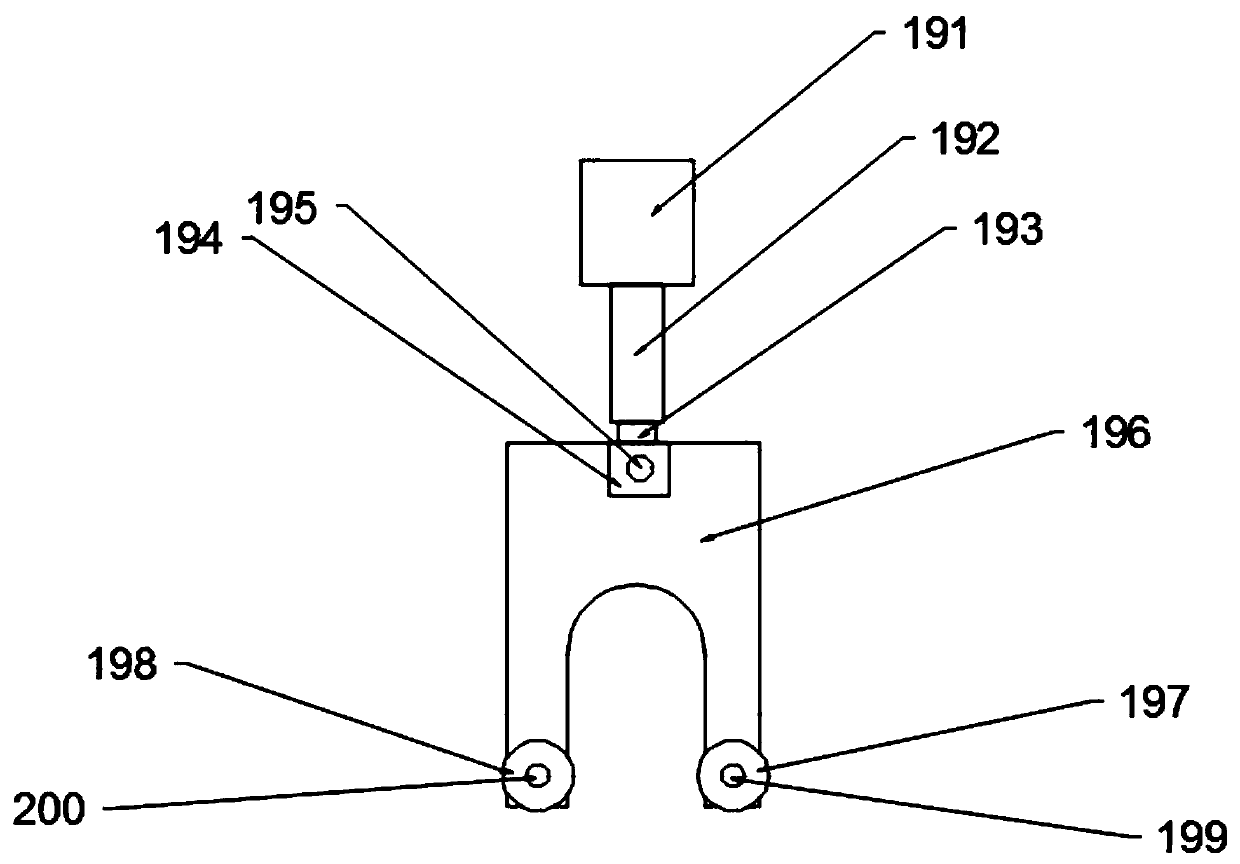

The invention belongs to the technical field of welding devices and welding methods, and discloses a welding forming device and welding method of breeding cage spacer nets. The welding forming device is mainly characterized by comprising a wire feeding mechanism, an aligning mechanism, a welding mechanism with a horizontal wire locating mechanism, a net dragging and bending mechanism and a cutting mechanism, the welding mechanism comprises a welding base and a welding rotary disc, and a welding rack is arranged on the welding rotary disc; the net dragging and bending mechanism comprises a net dragging trolley and a bending mechanism located on the net dragging trolley, a cutter of the cutting mechanism is located on a cutting rotary disc, and a synchronous connecting rod is arranged between the cutting rotary disc and the welding rotary disc. When a transverse wire perpendicular to a longitudinal wire is welded, the welding rotary disc is restored, when a transverse wire which is in oblique crossing with the longitudinal wire is welded, the position of the longitudinal wire is constant, the welding rotary disc drives the transverse wire and an upper electrode and a lower electrode to rotate, a net piece is welded into a mode that a rectangle composed of two opposite right trapezoids serves as one unit and the middle of the net piece is provided with two slant transverse wires which are parallel with each other and intersect the longitudinal wire to form a certain angle. In this way, the bending time is saved, and the production efficiency is improved.

Owner:河北骄阳焊工有限公司

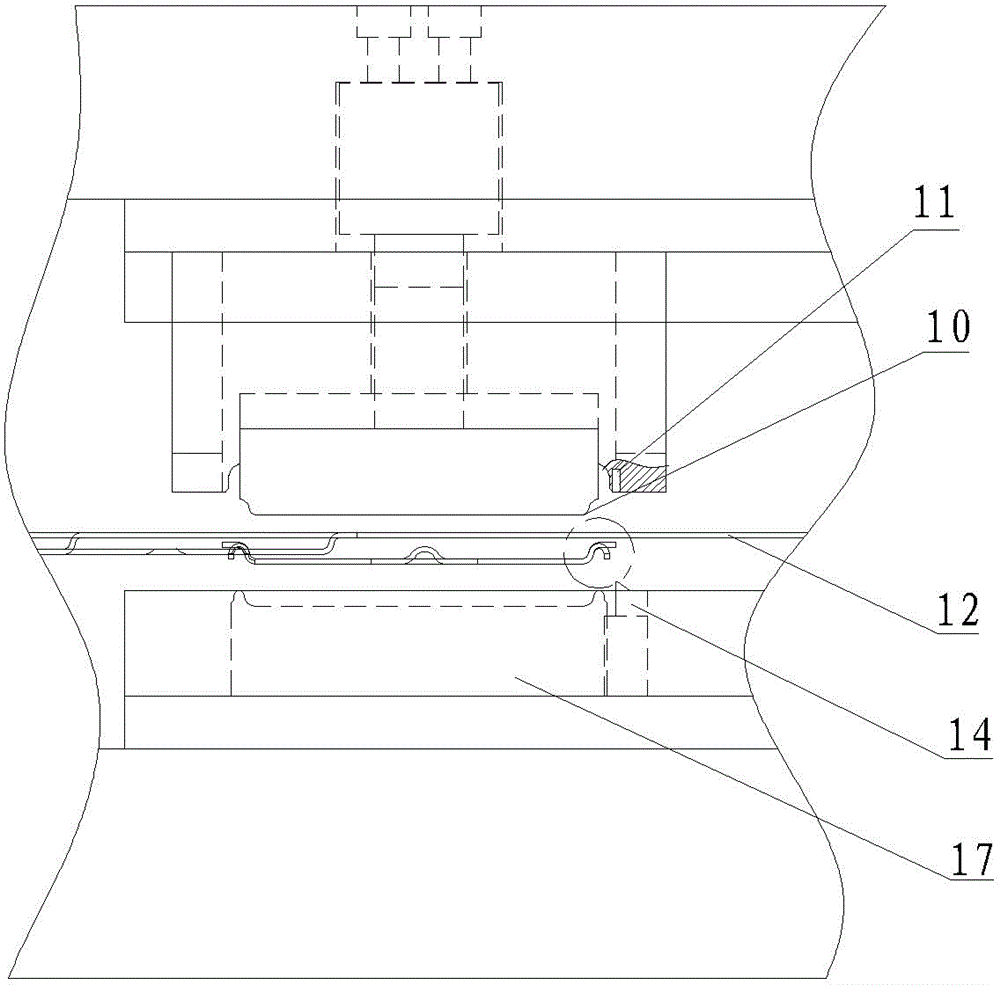

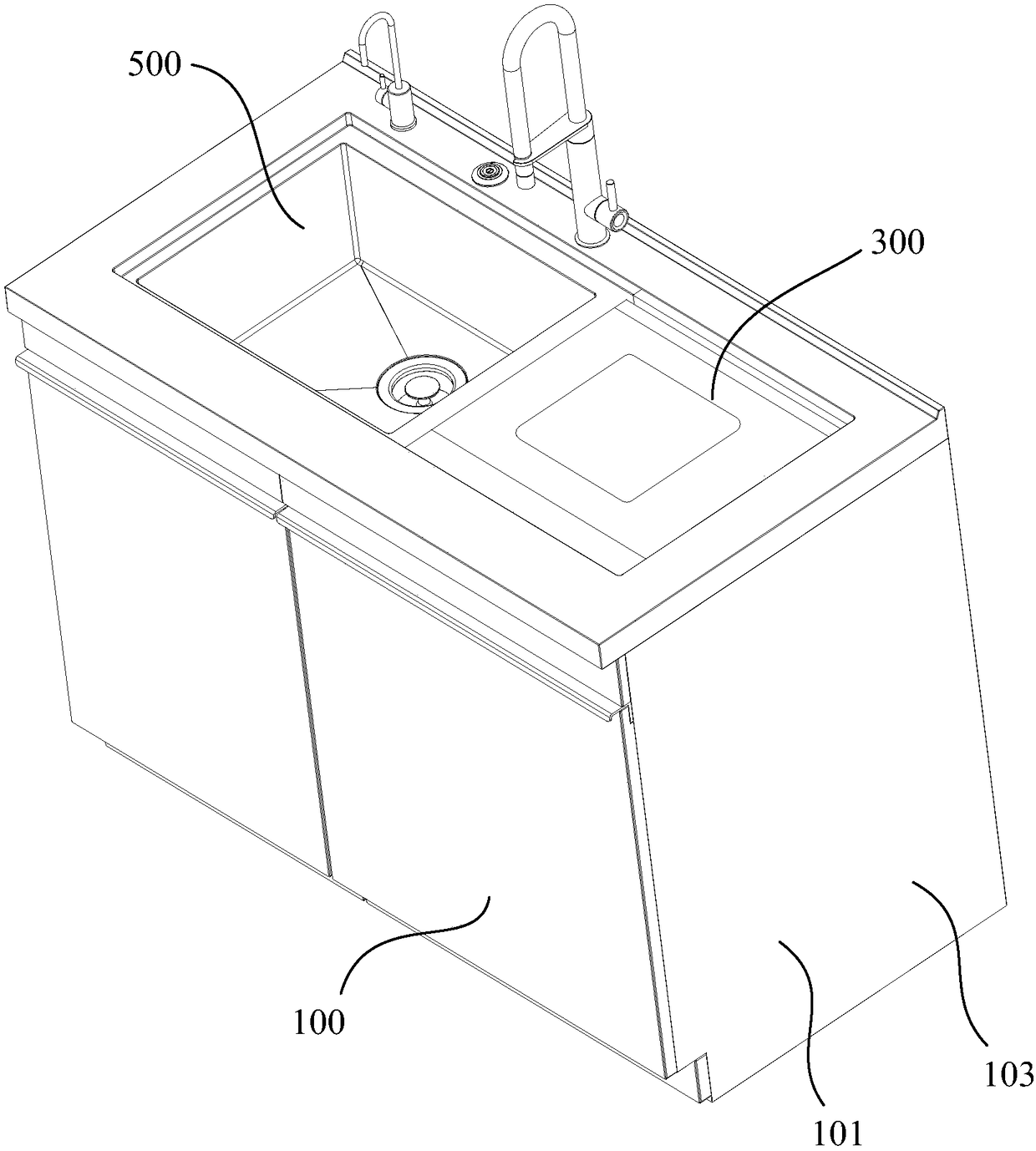

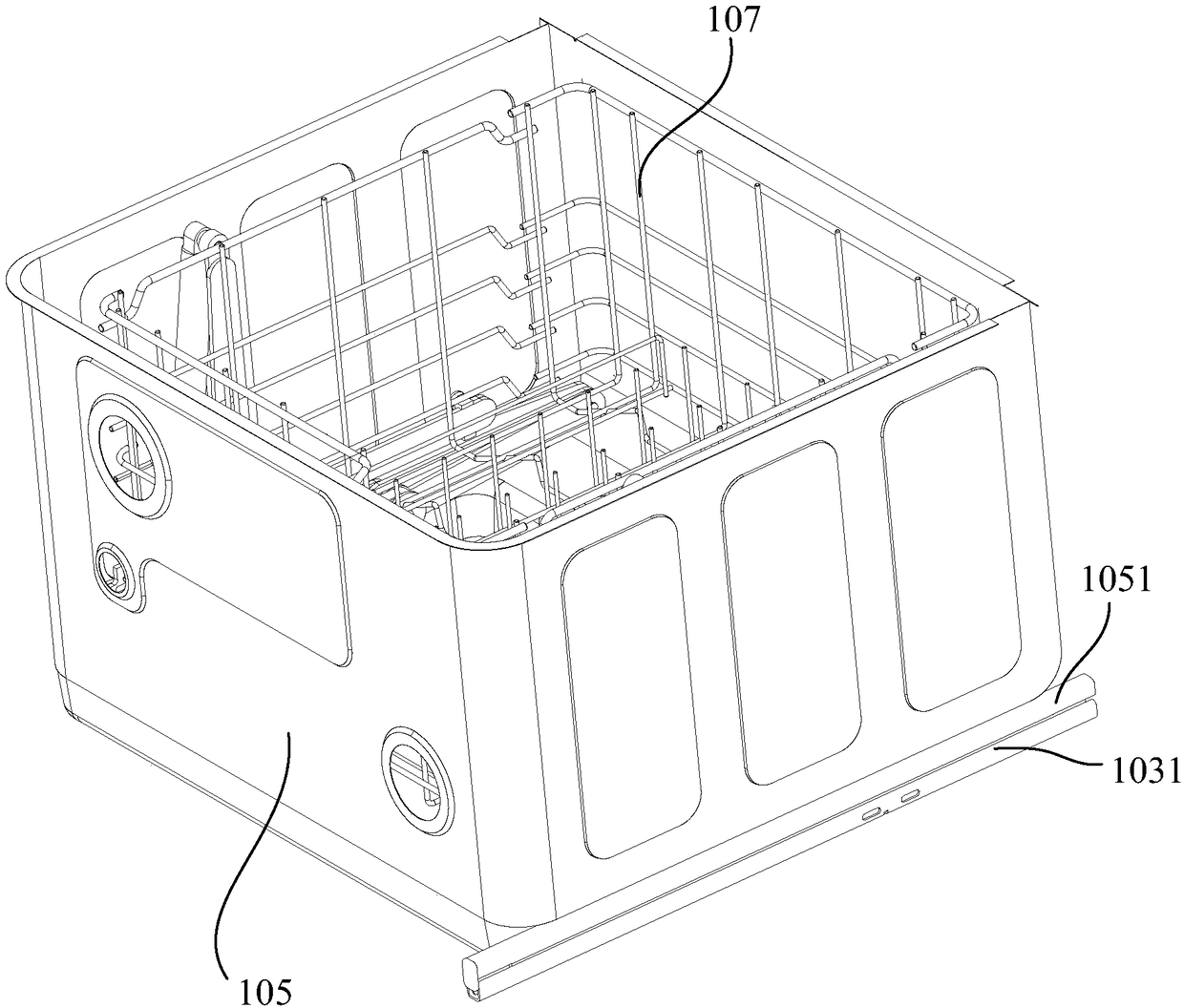

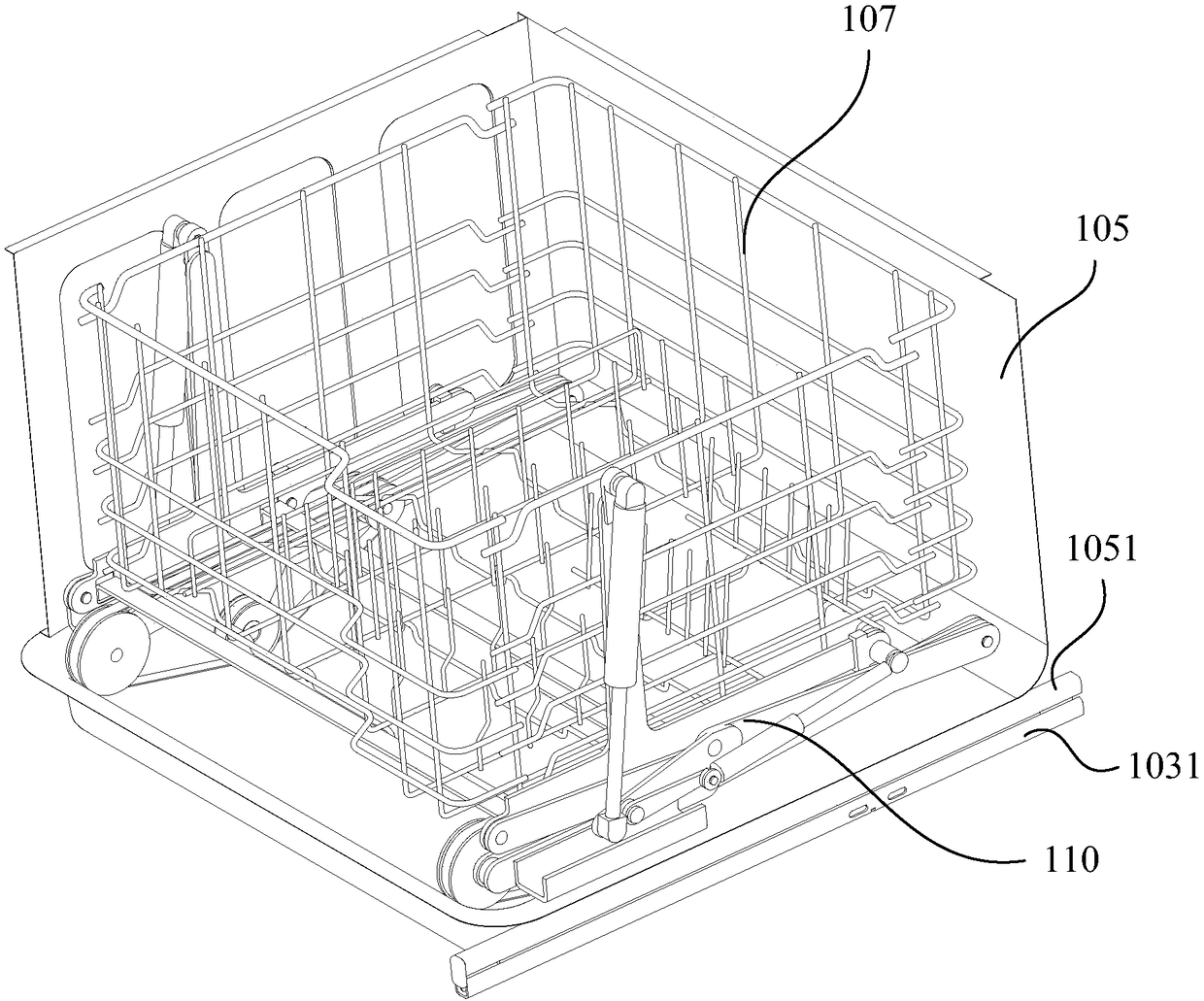

Electric appliance for kitchen and combined electric appliance for kitchen

ActiveCN108553054ALarge range of up and down activitiesLittle room for movementTableware washing/rinsing machine detailsLavatory sanitoryEngineeringElectrical equipment

The invention discloses an electric appliance for a kitchen and a combined electric appliance for the kitchen. The electric appliance for the kitchen comprises a shell, a loading basket assembly and lifting devices and is characterized in that each lifting device comprises an upper-layer connection rod structure, a lower-layer connection rod structure, an elastic power-assisting part and a synchronous driving structure. Each upper-layer connection rod structure is rotatably connected to the loading basket assembly; one end of each lower-layer connection rod structure is rotatably connected tothe end of the corresponding upper-layer connection rod structure, and the other end of each lower-layer connection rod structure is rotatably connected to the shell; one end of each elastic power-assisting part is rotatably connected to the loading basket assembly, the other end of each elastic power-assisting part is rotatably connected to the corresponding upper-layer connection rod structure,and the elastic power-assisting part provides power-assisting force in the process of lifting the loading basket assembly; each synchronous driving structure is connected to the corresponding upper-layer connection rod structure and the shell and drives the upper-layer connection rod structure and the lower-layer connection rod structure to synchronously move. According to the technical scheme, through the electric appliance for the kitchen, the stooping time of a user in the process of taking and placing goods can be shortened, and accordingly the user operates the electric appliance more conveniently.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG +1

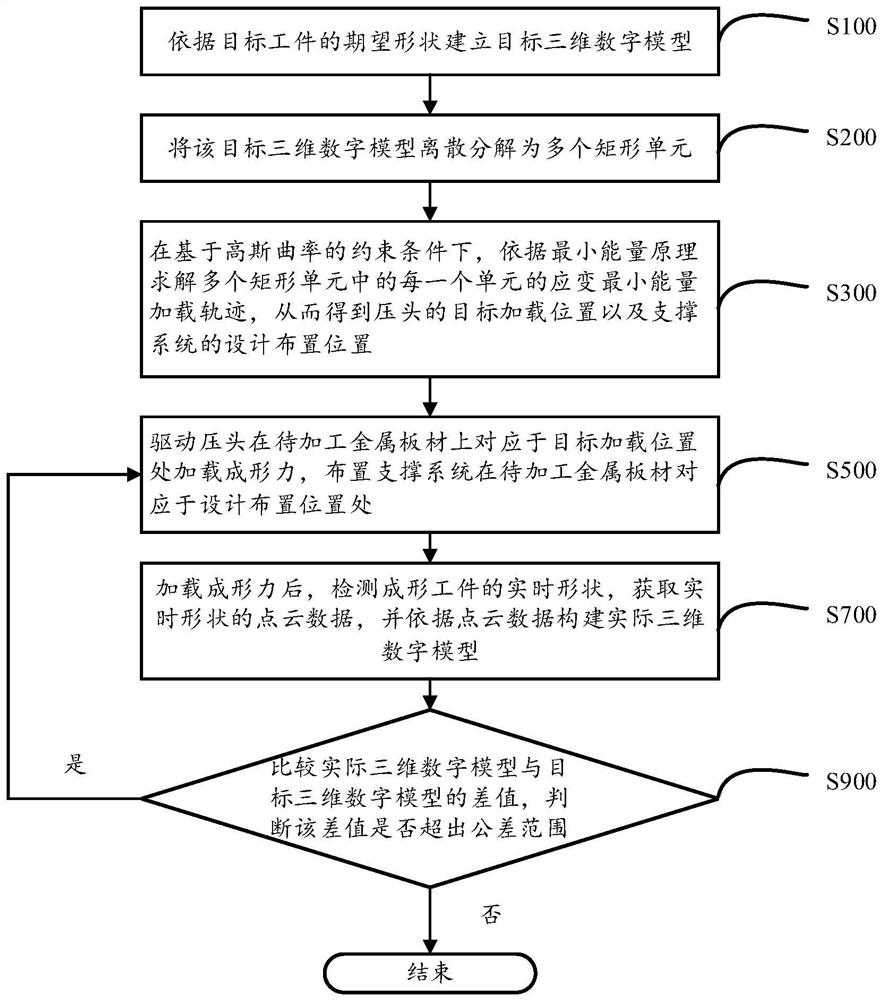

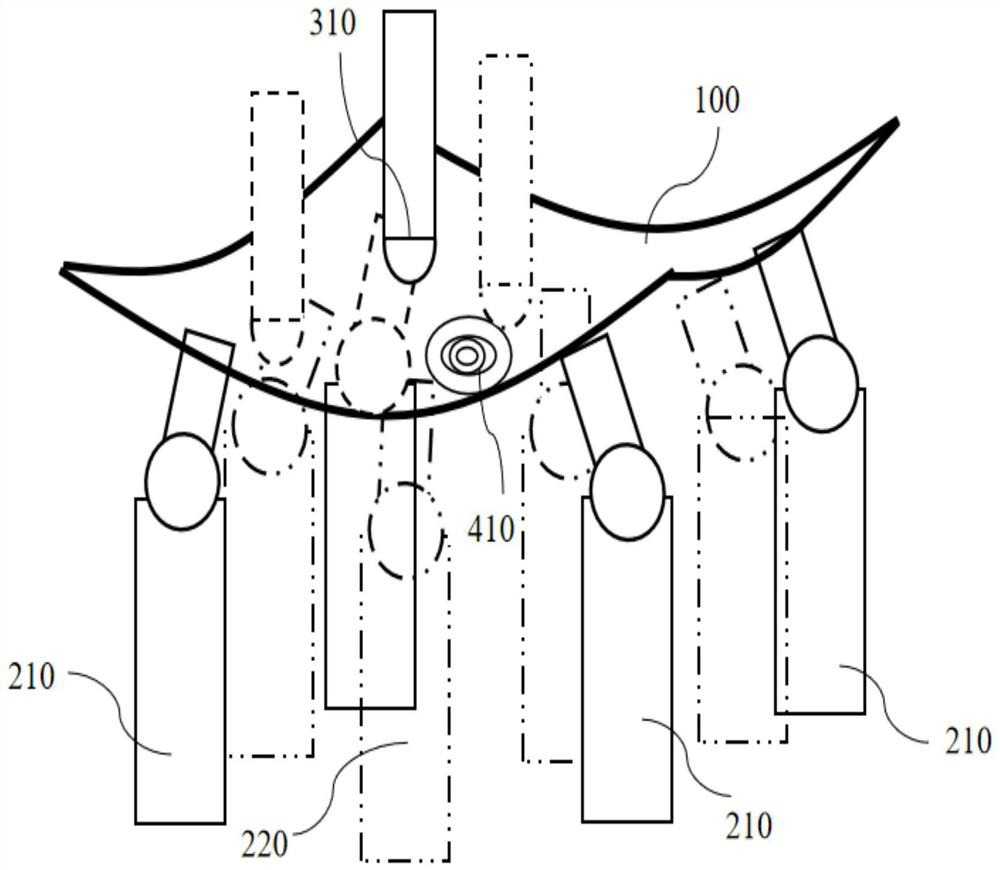

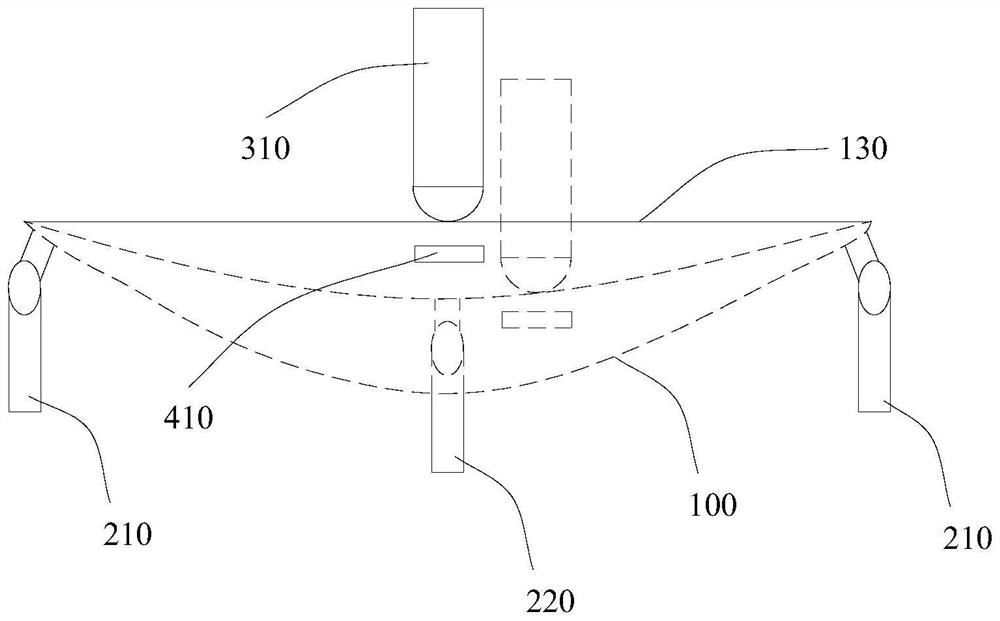

Incremental forming bending method for double-curved-surface metal plate

ActiveCN114309261AReduce bending timeSuitable for bendingIncreasing energy efficiency3D modellingSupporting systemPoint cloud

The invention discloses an incremental forming bending method for a double-curved-surface metal plate. The method comprises the following steps: establishing a target three-dimensional digital model according to an expected shape; decomposing the matrix into a plurality of rectangular units; solving a strain minimum energy loading track of each unit according to a minimum energy principle under a constraint condition based on Gaussian curvature so as to obtain a target loading position of a pressure head and a design arrangement position of a support system; the pressing head is driven to load forming force at the position corresponding to the target loading position, and the supporting system is arranged at the position corresponding to the design arrangement position; after the forming force is loaded, the real-time shape of the formed workpiece is detected, point cloud data of the real-time shape is obtained, and an actual three-dimensional digital model is constructed; and comparing the difference value between the actual three-dimensional digital model and the target three-dimensional digital model, and if the difference value exceeds the tolerance range, repeatedly driving the pressure head to load the forming force. By adopting the method, the working efficiency and the forming precision of the incremental forming bending process of the double-curved-surface metal plate can be improved.

Owner:GUANGDONG POLYTECHNIC OF IND & COMMERCE

Hardware plug foot bending mechanism and bending method

The invention relates to the technical field of hardware plug foot bending, in particular to a hardware plug foot bending mechanism and a bending method. The bending mechanism comprises a fixing jig, a driving mechanism and a bending plunger chip connected with the driving mechanism in a driving mode. The plunger chip end face of the bending plunger chip is provided with slope structures protruding outwards. Each slope structure comprises a half-bending slope for laterally bending plug feet and a pressing slope for pressing the plug feet, wherein the half-bending slope is connected with the pressing slope, and the slope structures correspond to the hardware plug feet in a one-to-one mode. According to the method, the bending plunger chip pushes and presses the hardware plug feet, the half-bending slopes abut against the hardware plug feet, the hardware plug feet are bent to be the angle of the half-bending slopes, and finally, the pressing slopes abut against the hardware plug feet until the hardware plug feet abut against the bending angle of the pressing slopes. The hardware plug foot bending mechanism and the bending method are low in cost and high in bending efficiency.

Owner:DONGGUAN GOOD MARK NEW PRECISION TECH CO LTD

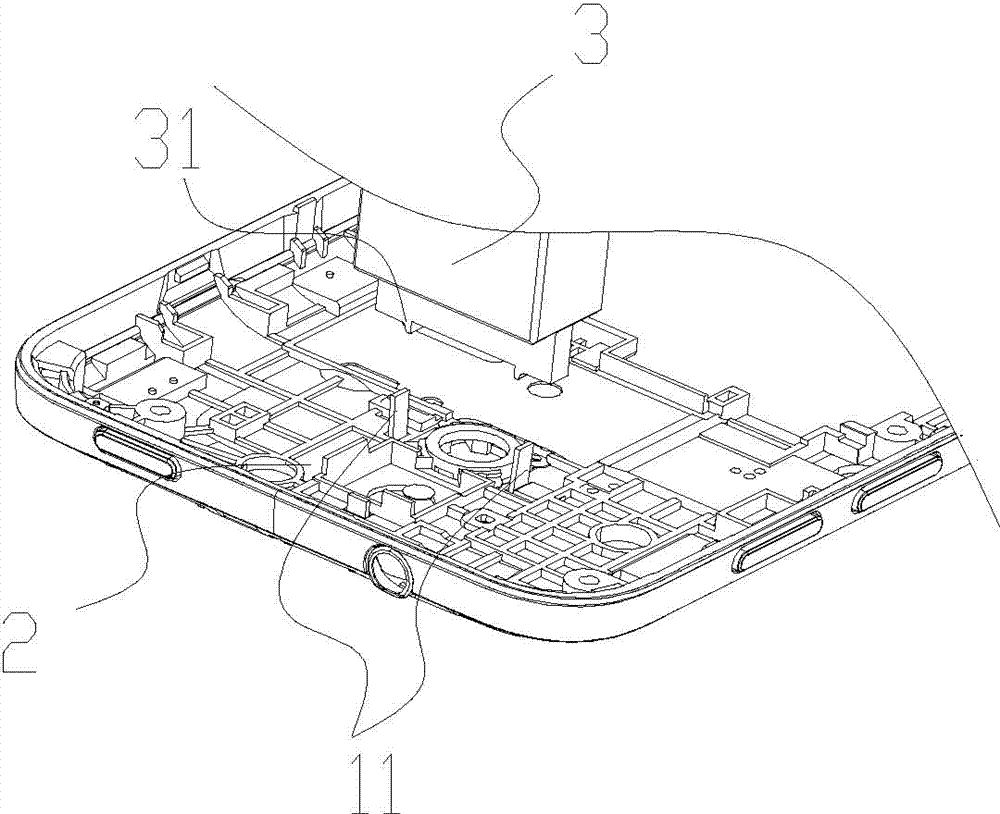

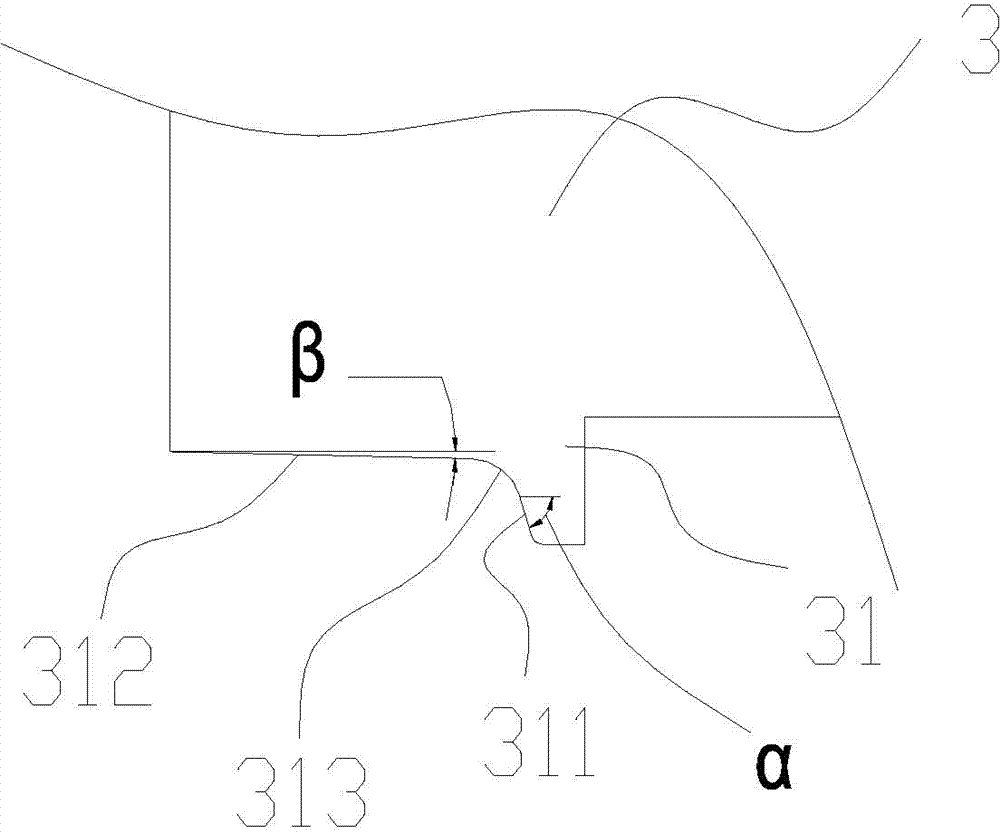

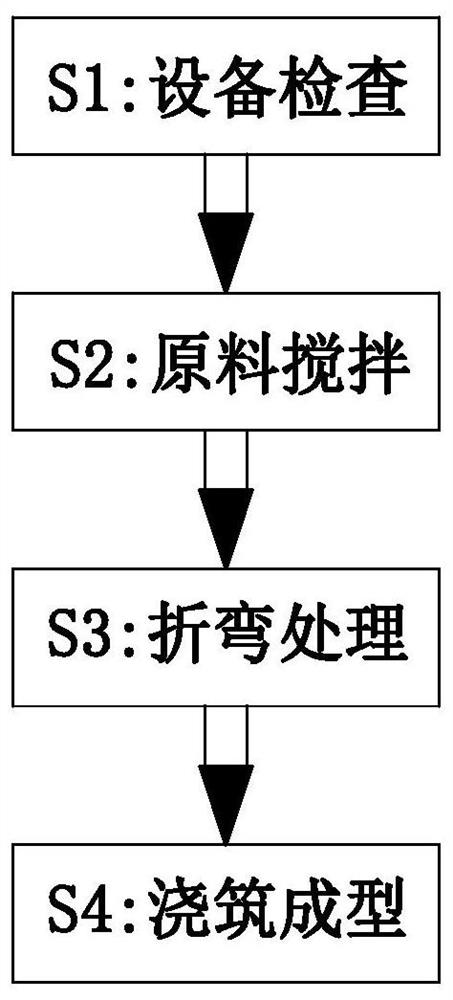

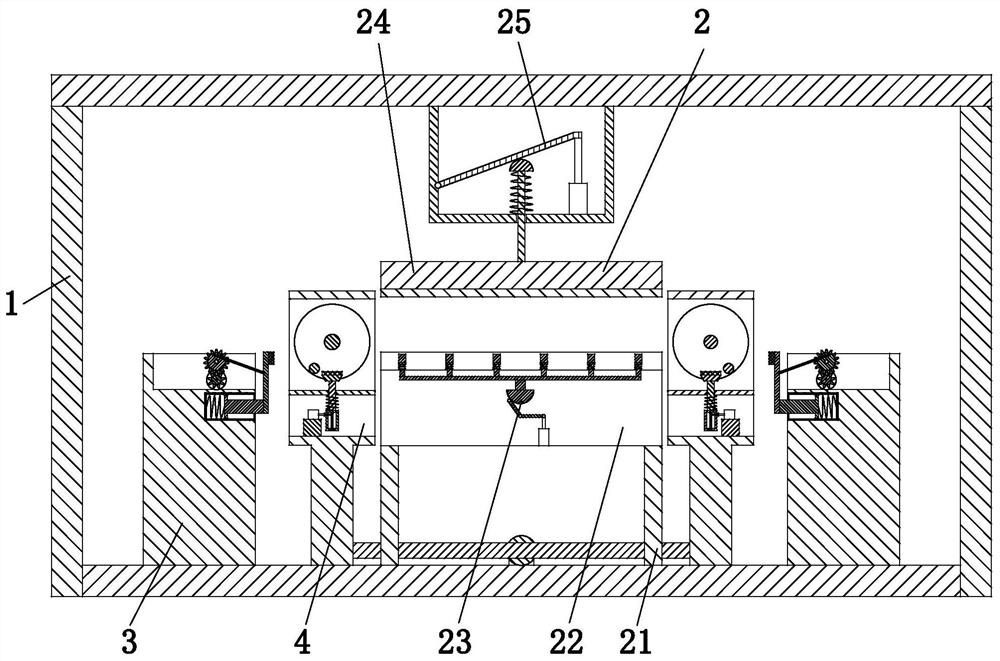

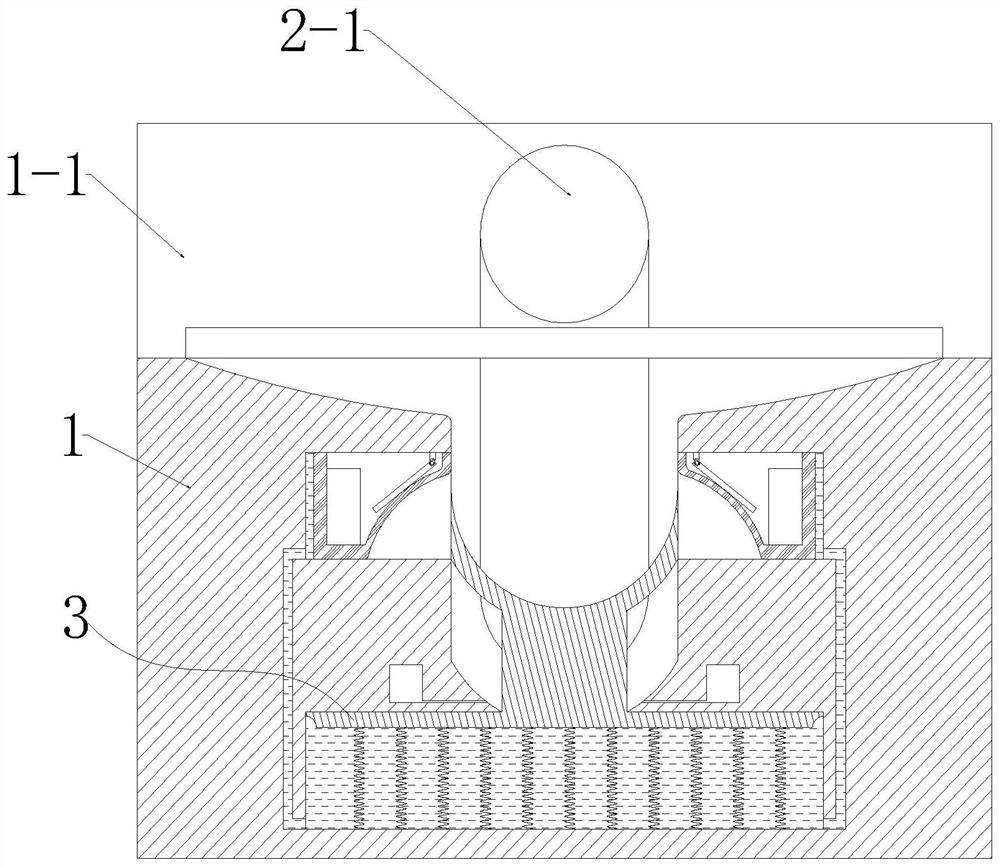

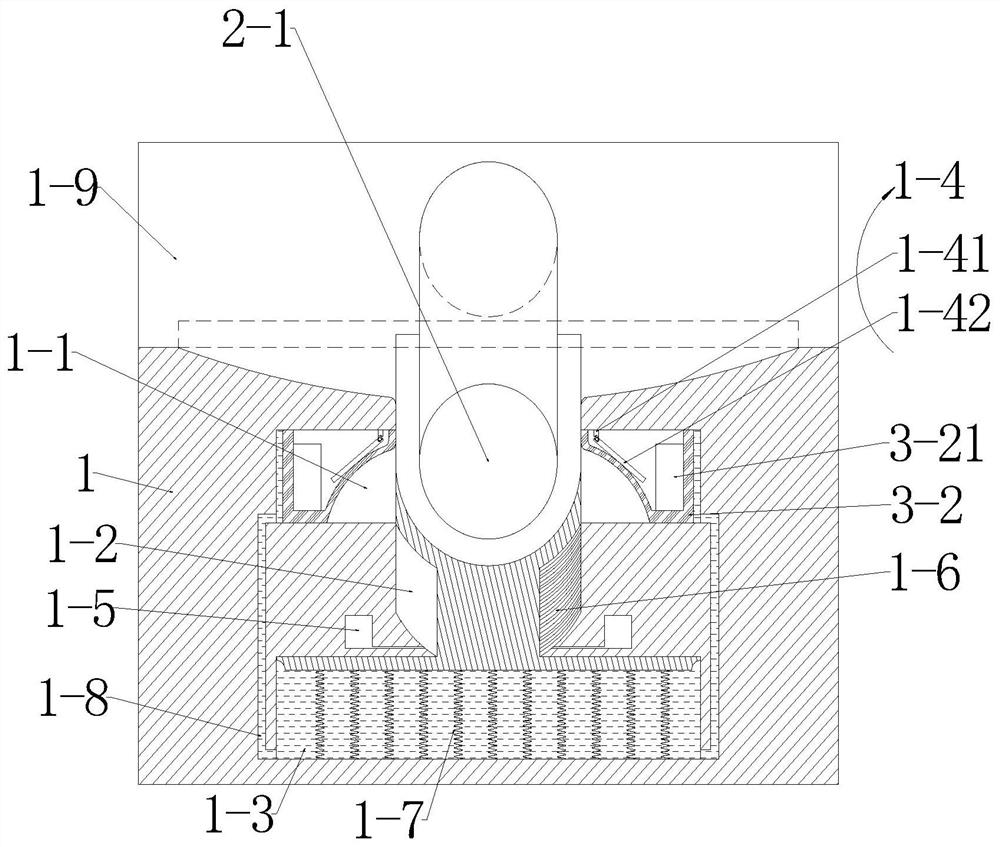

Forming and manufacturing method of building assembly type composite floor

InactiveCN112554438AReduce investmentShorten bending timeConstruction materialFloorsFloor slabConstruction engineering

The invention relates to a forming and manufacturing method of a building assembly type composite floor. The building assembly type composite floor comprises a frame body, a supporting device, aligning devices and bending devices; the supporting device is arranged in the middle of the interior of the frame body, the bending devices are symmetrically arranged at the positions, close to the rear portion, of the left side and the right side of the supporting device, and the aligning devices are symmetrically arranged on the left side and the right side of the supporting device. According to the forming and manufacturing method, the possible defects occur in an existing steel bar end bending method in the actual operation process can be solved, a, segment-shaped steel bars are bent manually through a bending machine, only one end of one steel bar can be bent at a time, the bending time consumption is long, and consequently the bending efficiency is low; and b, when the number of the reinforcing steel bars needing to be bent is large, the labor intensity of bending workers can be greatly increased through manual bending, time and labor are wasted, therefore the bending efficiency is reduced, and meanwhile certain influences are caused to benefits of enterprises.

Owner:顾胜文

Construction device for energy-saving building and working method thereof

Owner:国家电投集团江西中业兴达电力实业有限公司

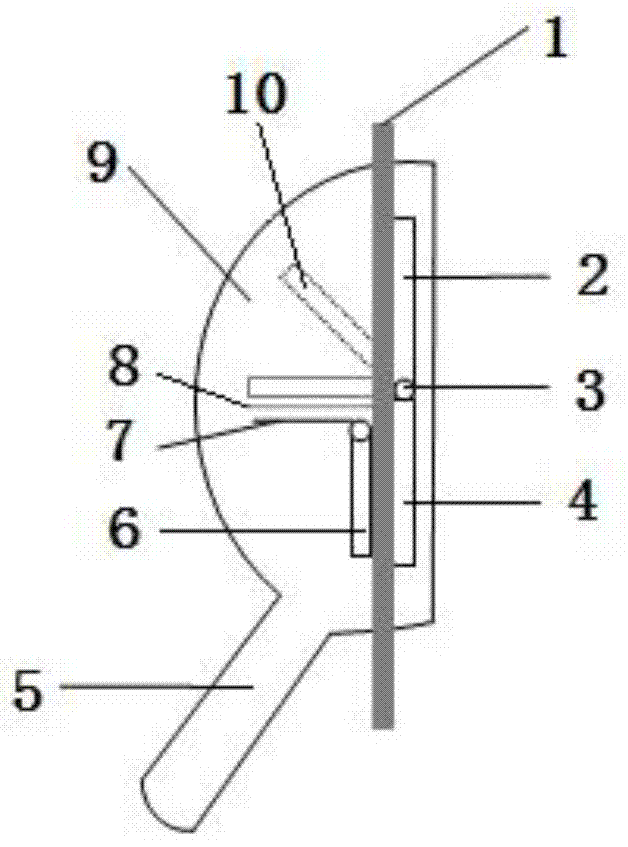

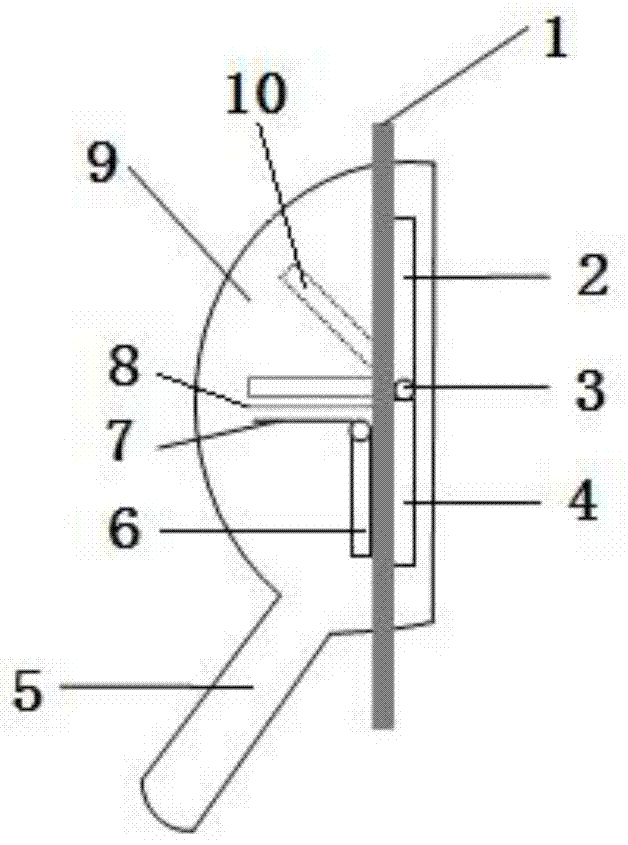

Wire bender

The invention relates to a wire bender which comprises two parts of a bottom holder and a rotating system, wherein the bottom holder consists of a grabbing handle and an angle marking plate, wherein a base line and an angle line formed by bending the wire are marked on the angle marking plate; the rotating system comprises a general fixed sheet, a pressing and rotating sheet and an elastic fixed sheet; the general fixed sheet is arranged on the angle marking plate; the pressing and rotating sheet is hinged to the angle marking plate by a rotating shaft; the pressing and rotating sheet and the straight side of the angle marking plate are arranged along the same direction; the pressing and rotating sheet and the general fixed sheet are positioned on the same straight line; the elastic fixed sheet is arranged on the angle marking plate; a fixed side of the elastic fixed sheet is arranged on the angle marking plate; the elastic fixed sheet and the general fixed sheet are arranged side by side; an elastic side of the elastic fixed sheet is arranged on the fixed side in a hinge manner. The wire bender can be used for bending a hard and straight wire for multiple angles, has the advantages of easiness and accuracy in operation, capability of improving the working efficiency and attractiveness of distribution and the like, and is particularly suitable for occasions for bending and distributing the hard and straight wires during fitted sheet electrical connection.

Owner:STATE GRID CORP OF CHINA +1

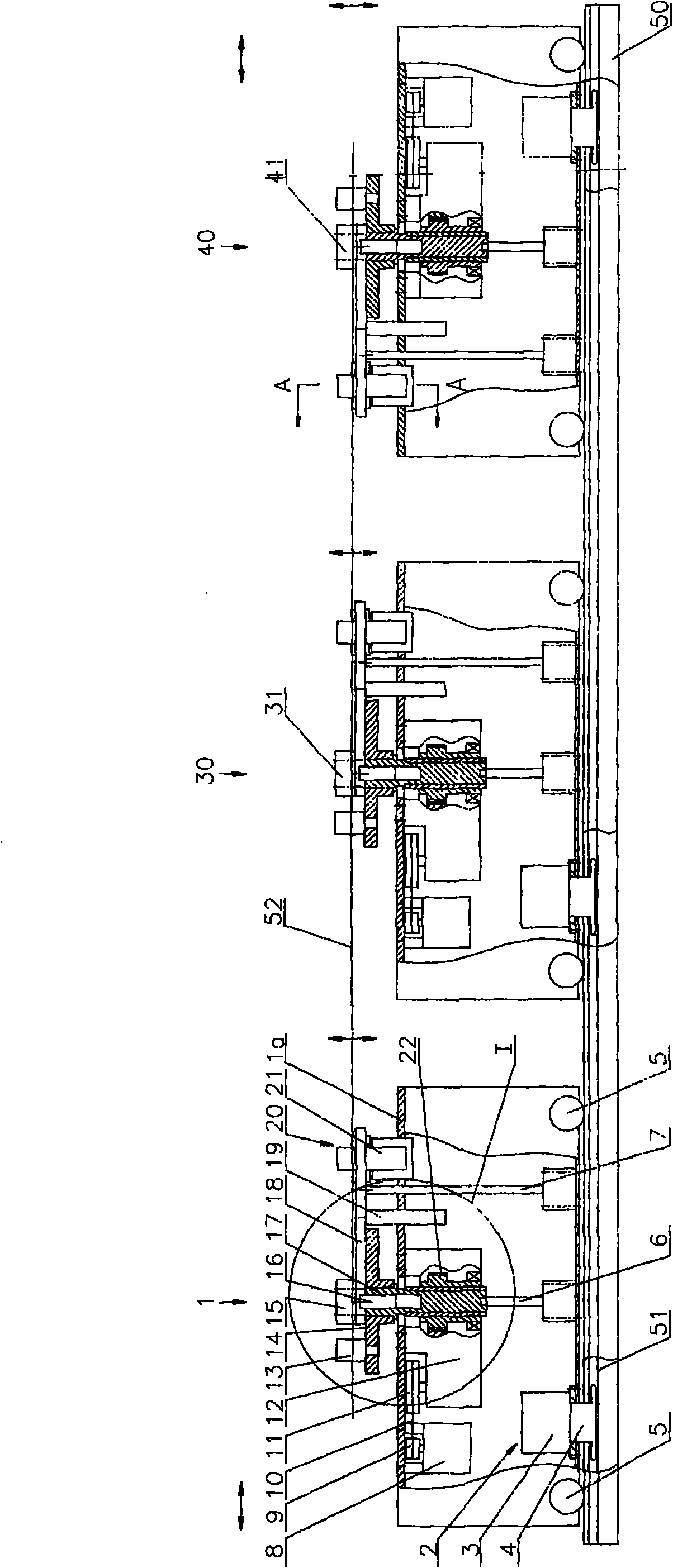

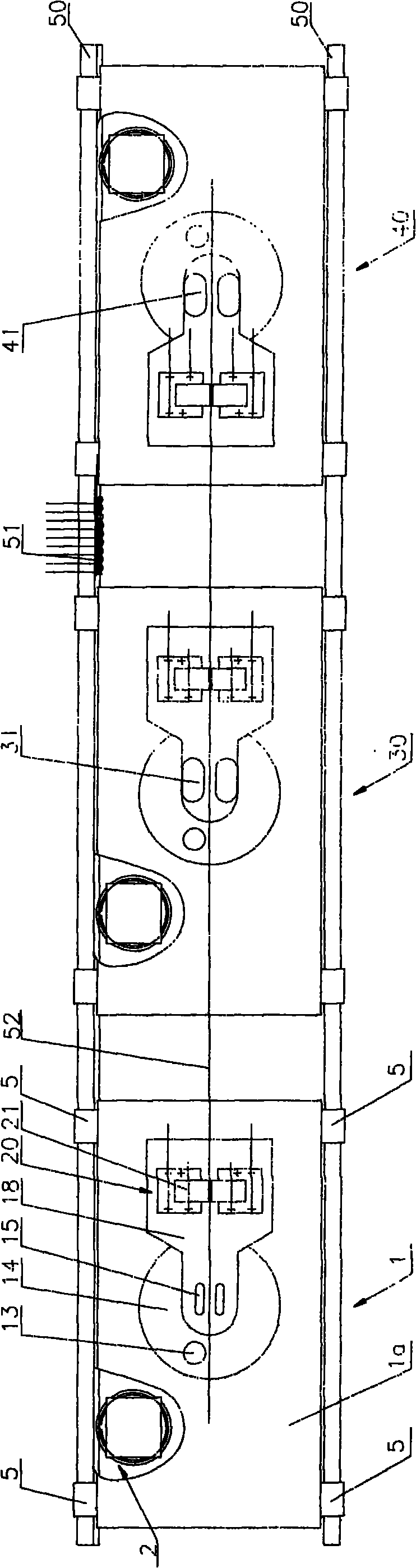

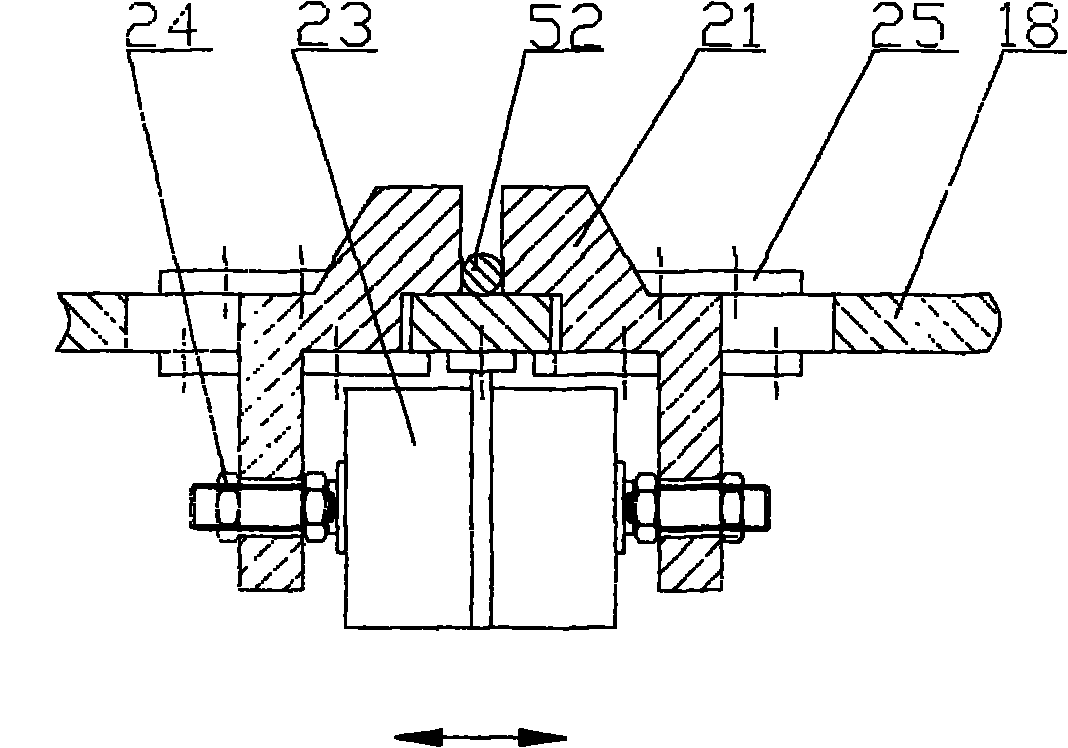

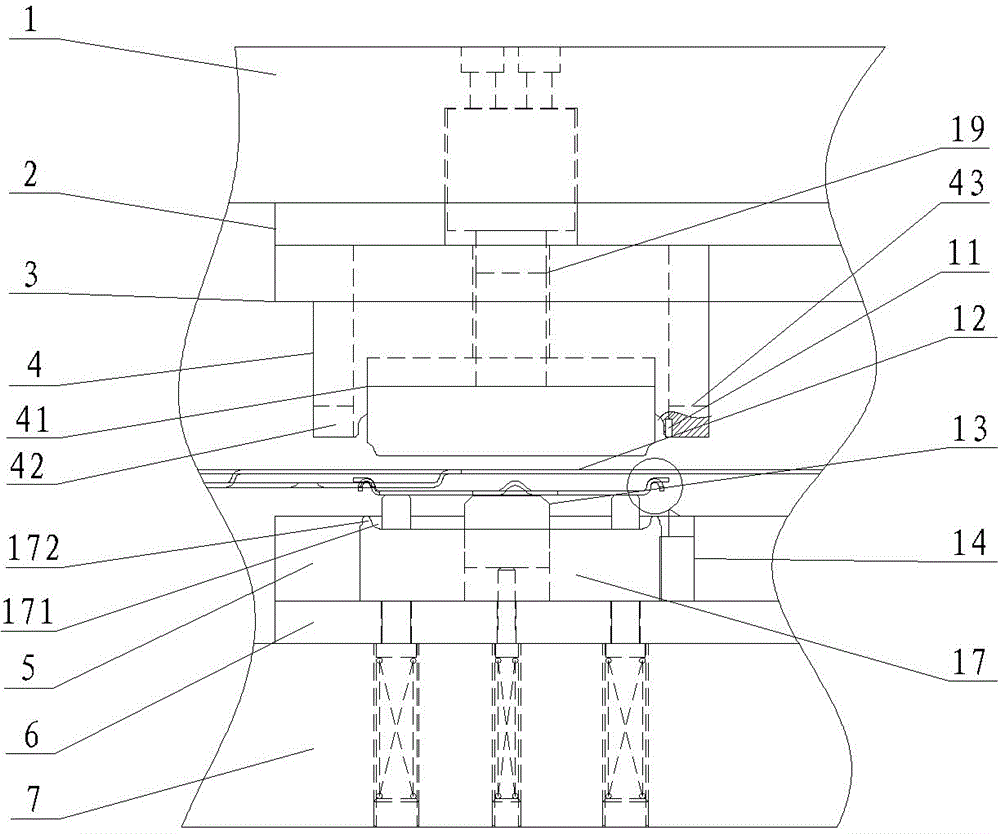

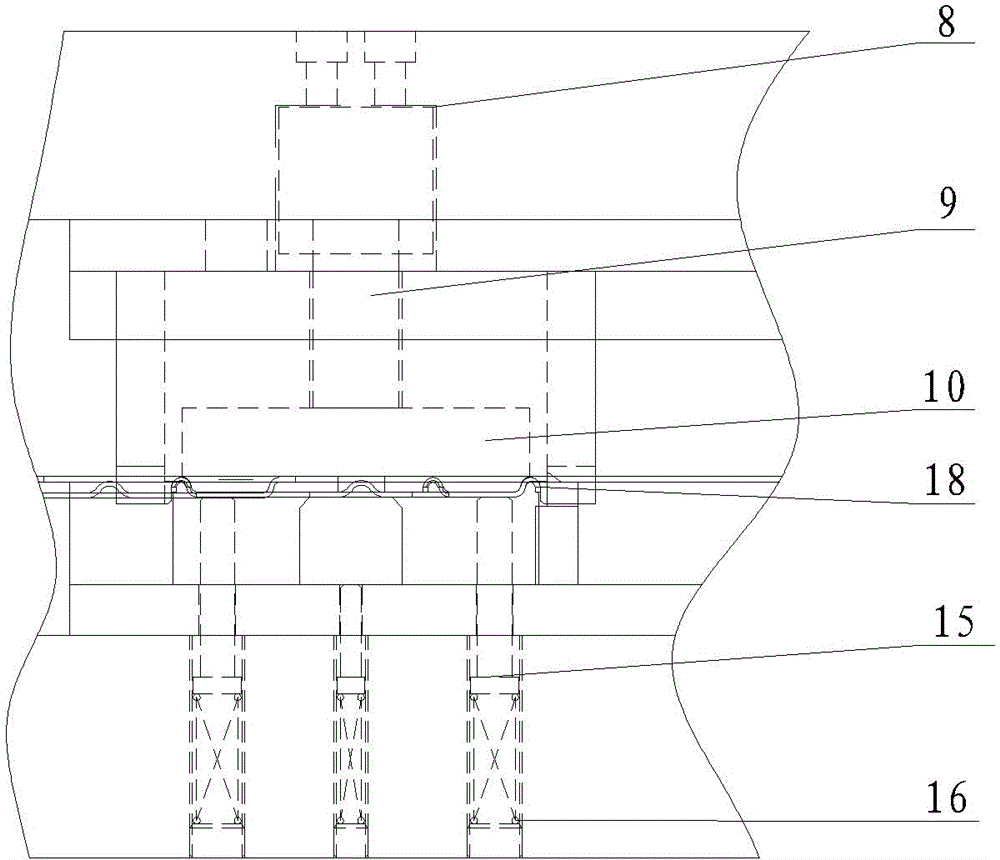

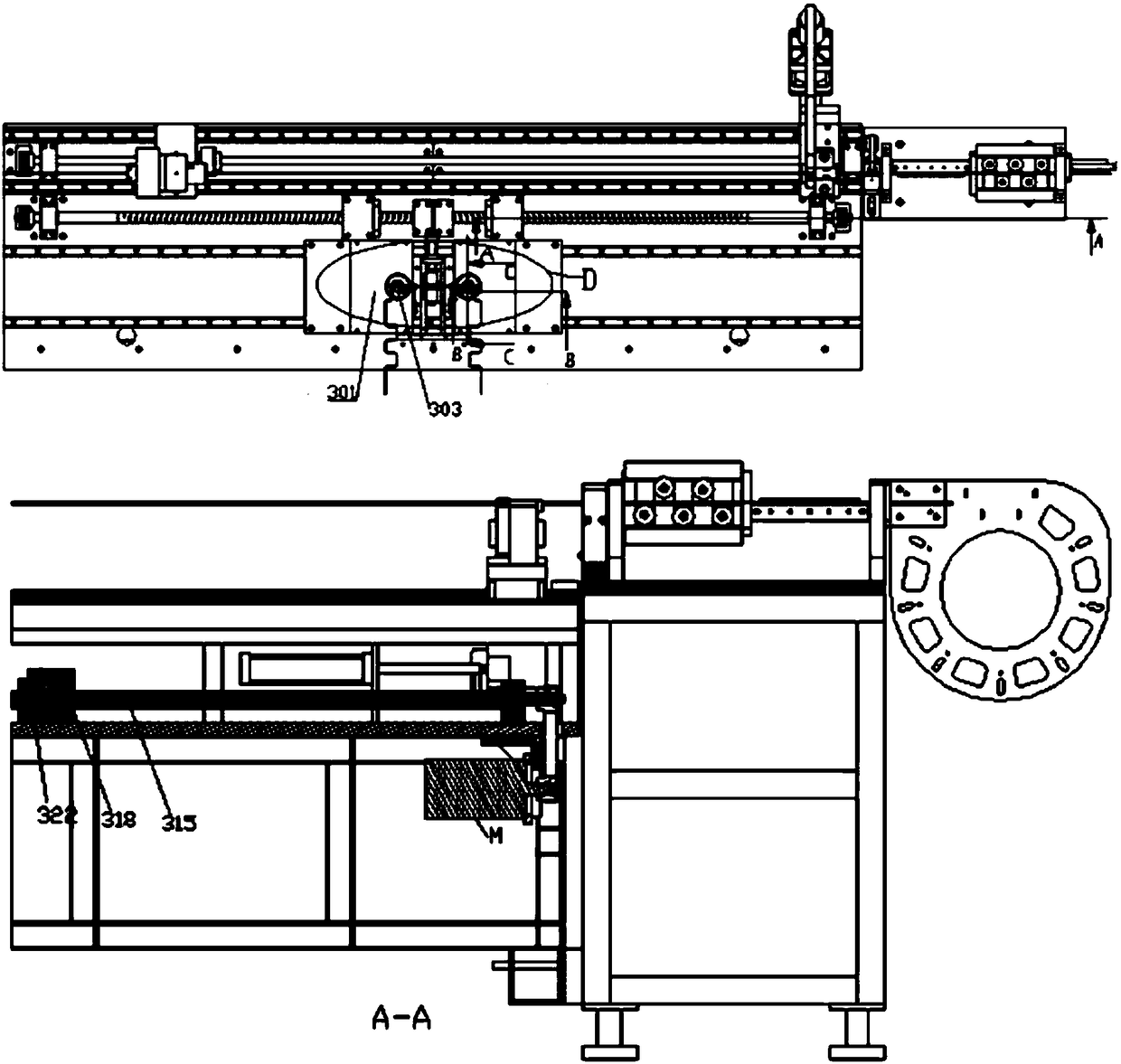

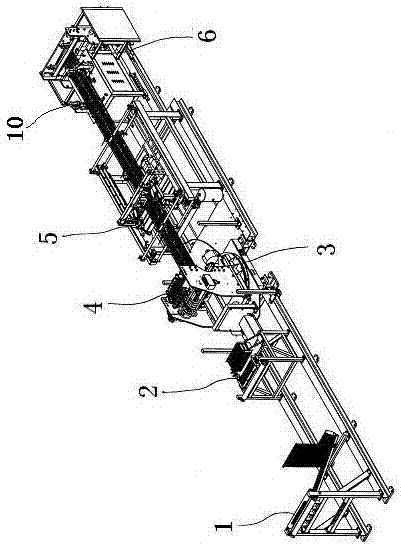

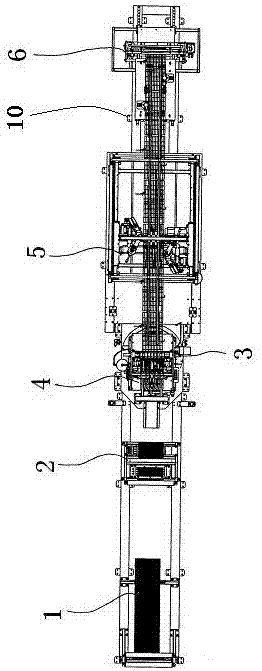

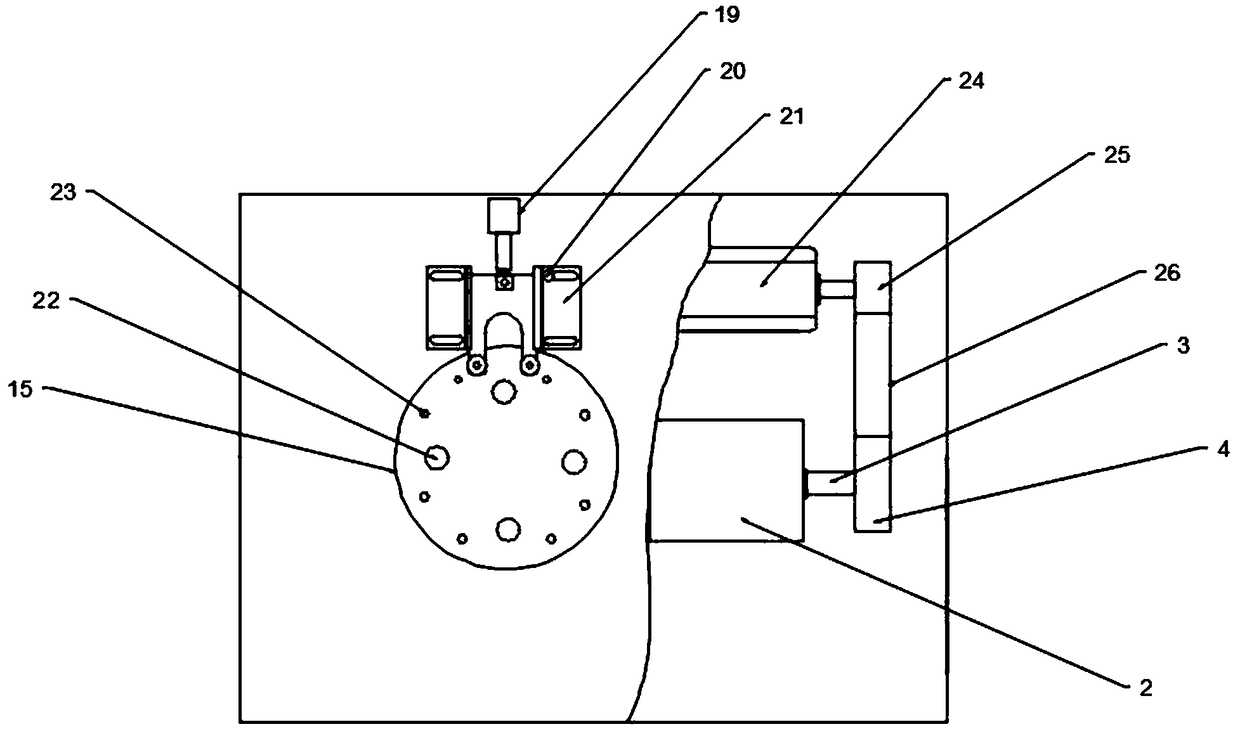

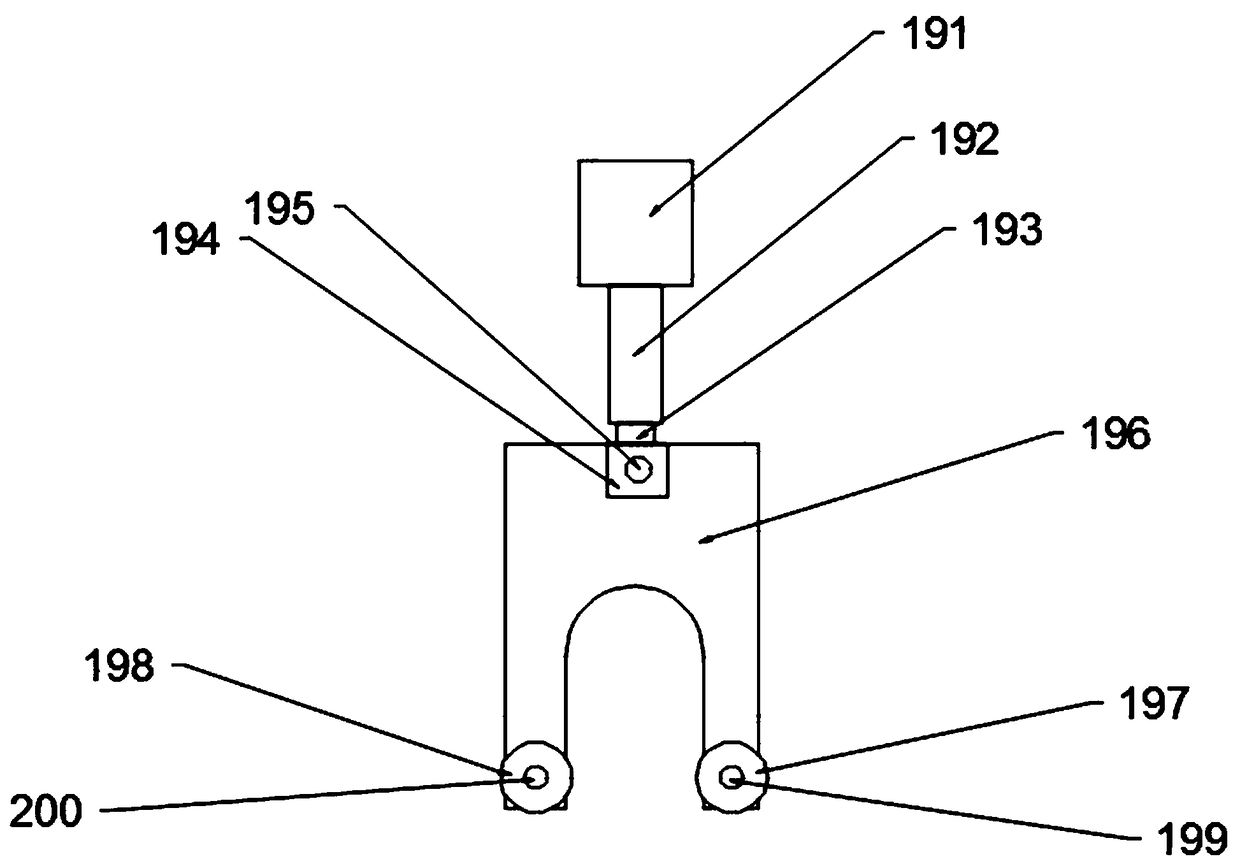

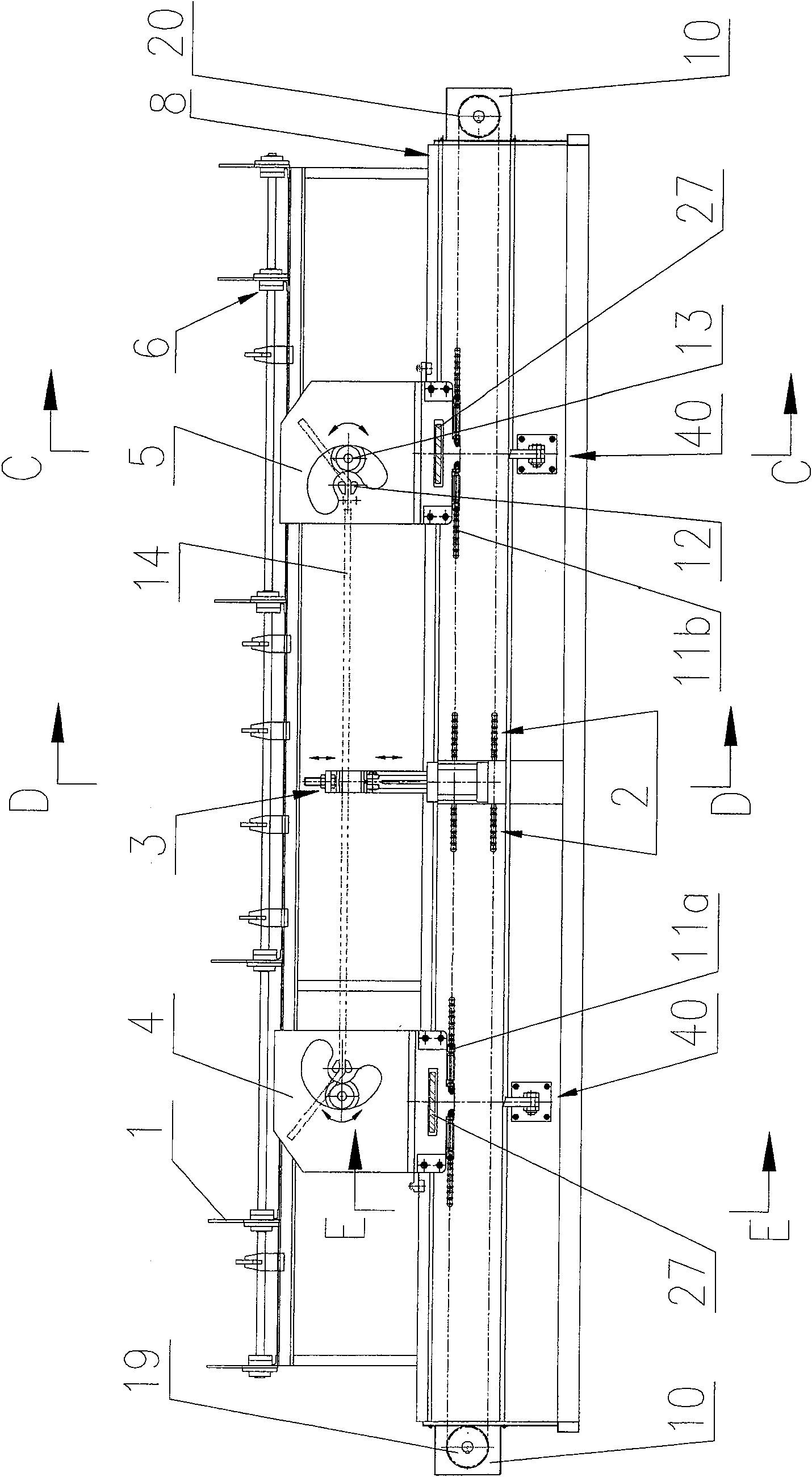

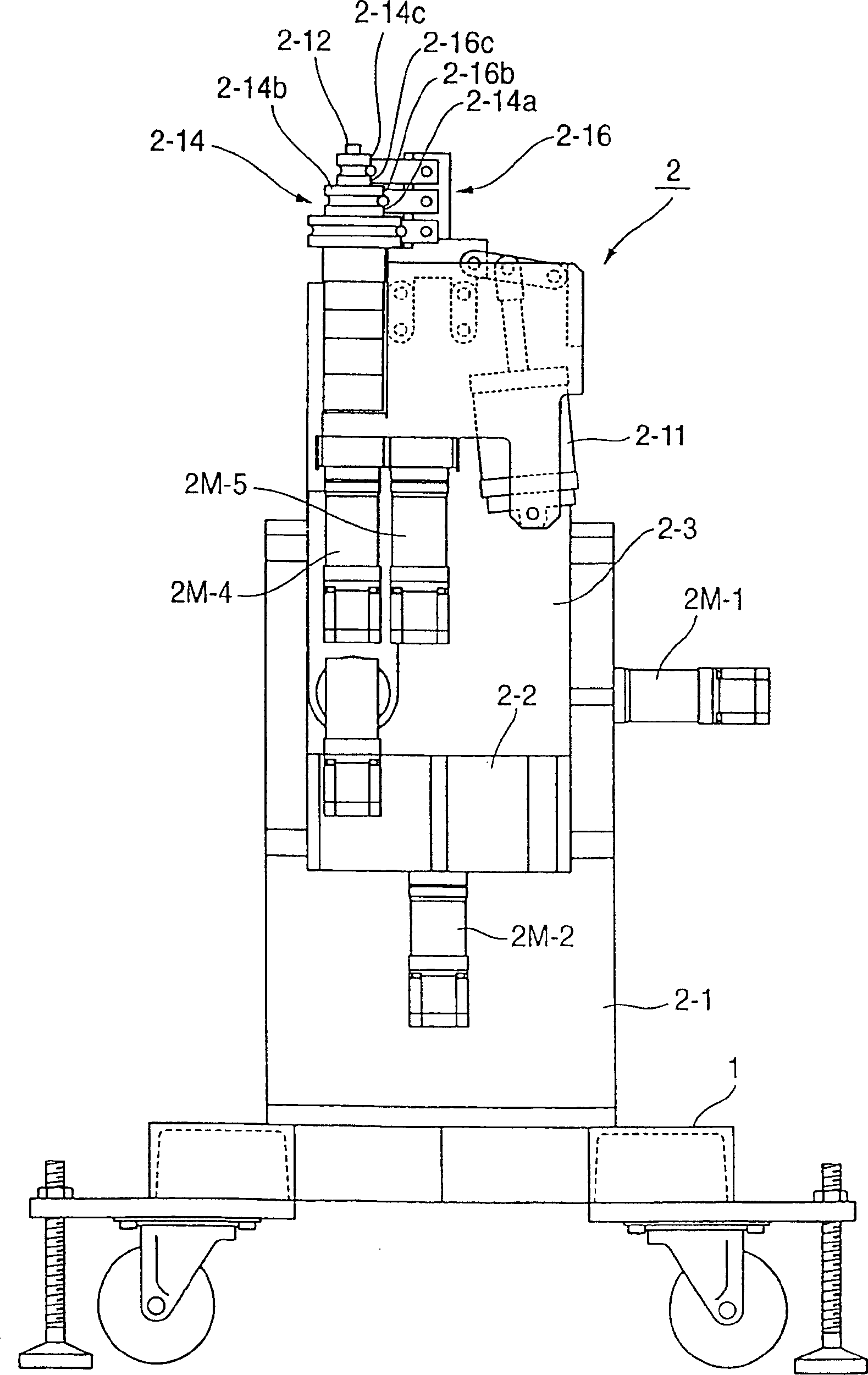

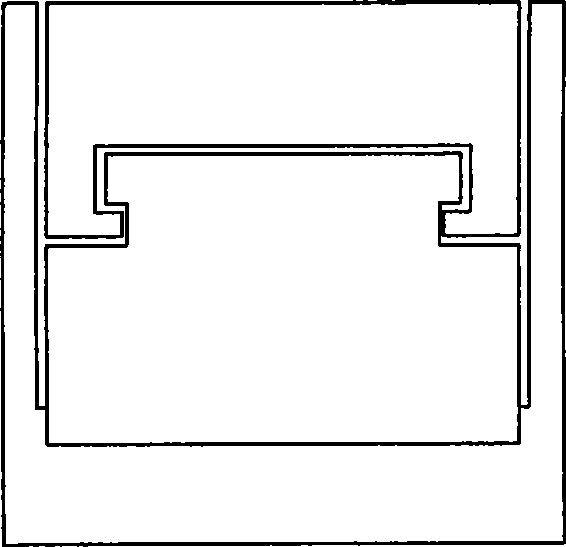

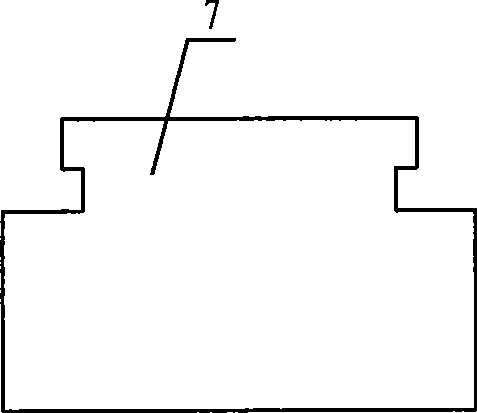

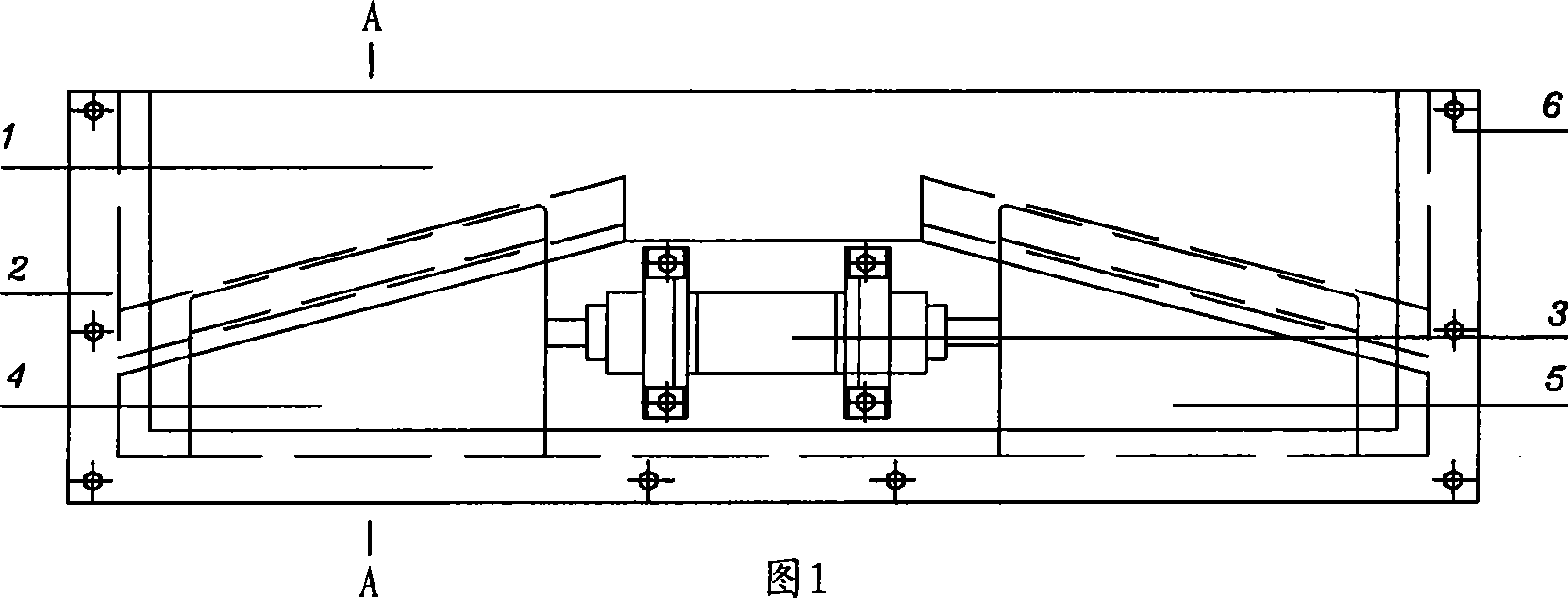

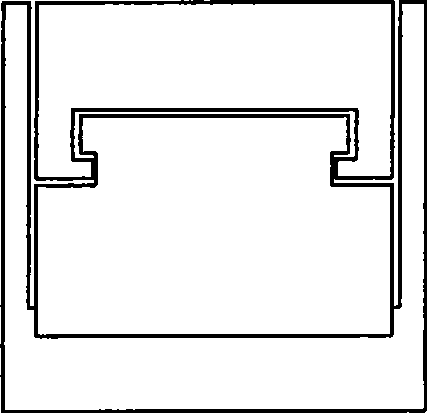

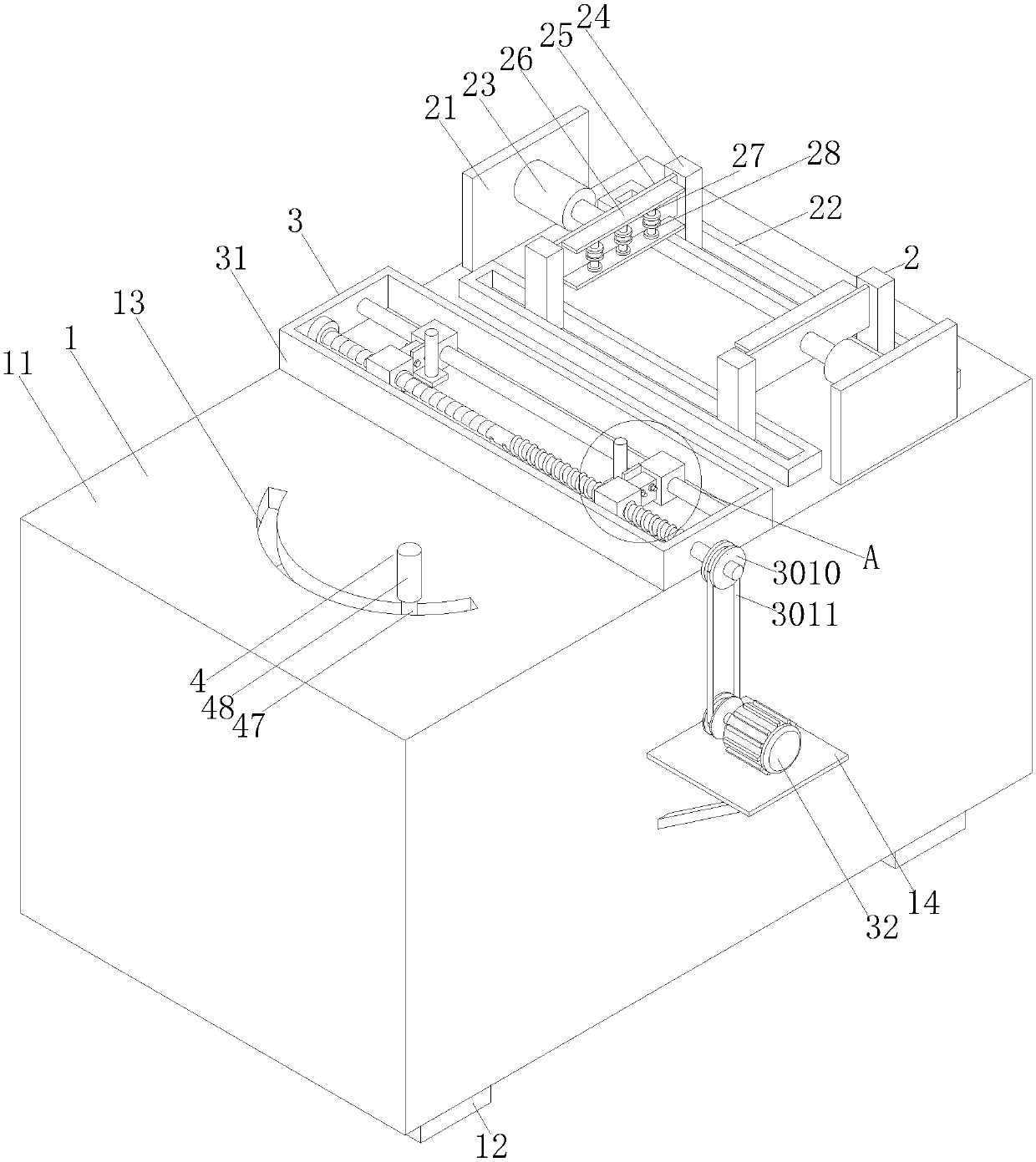

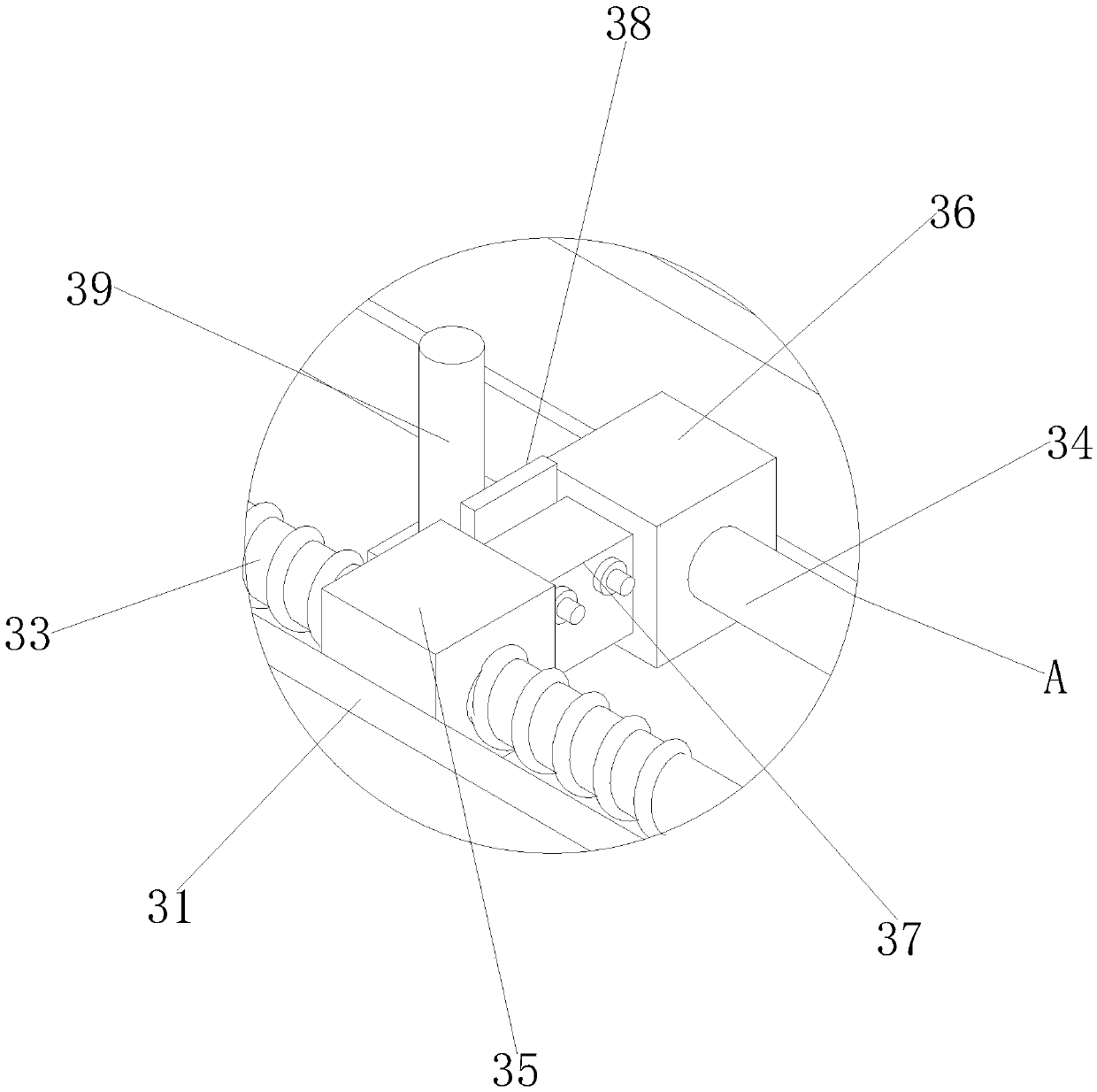

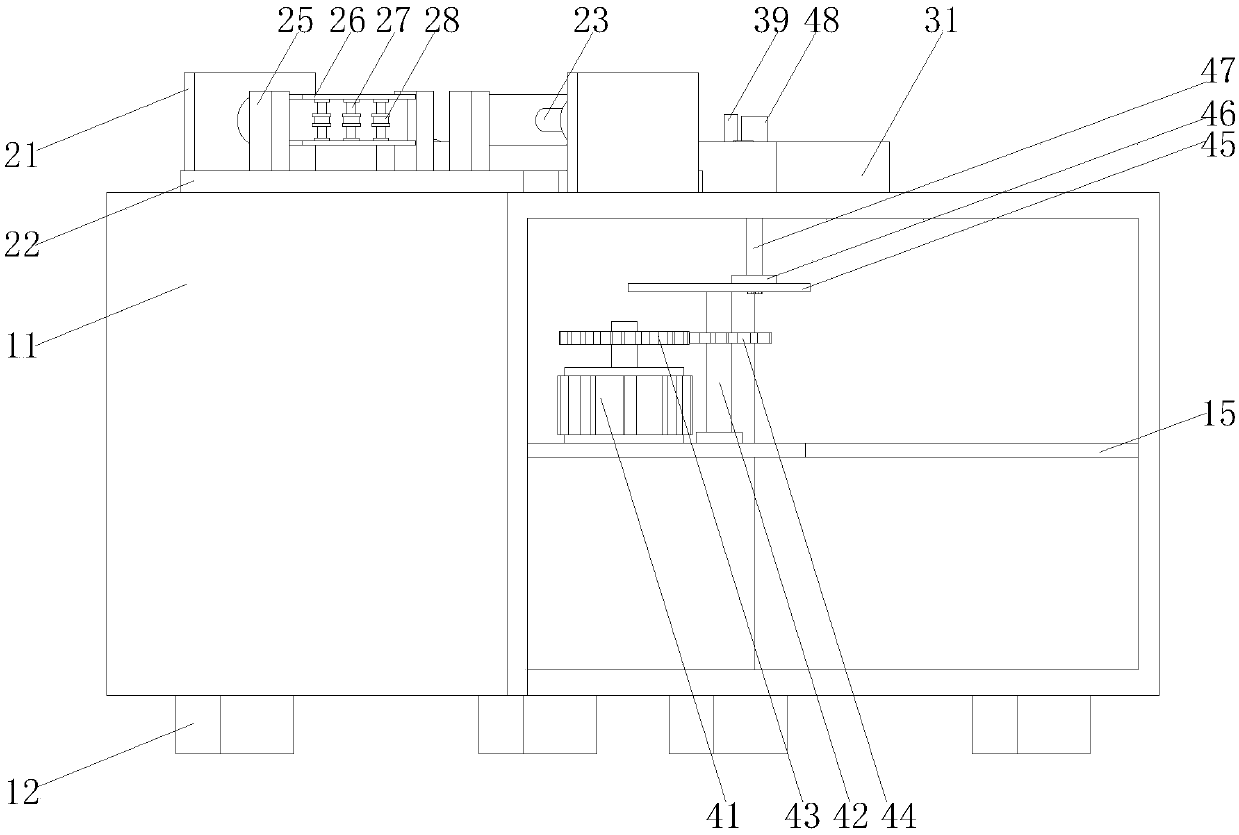

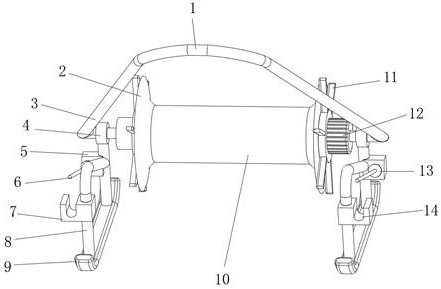

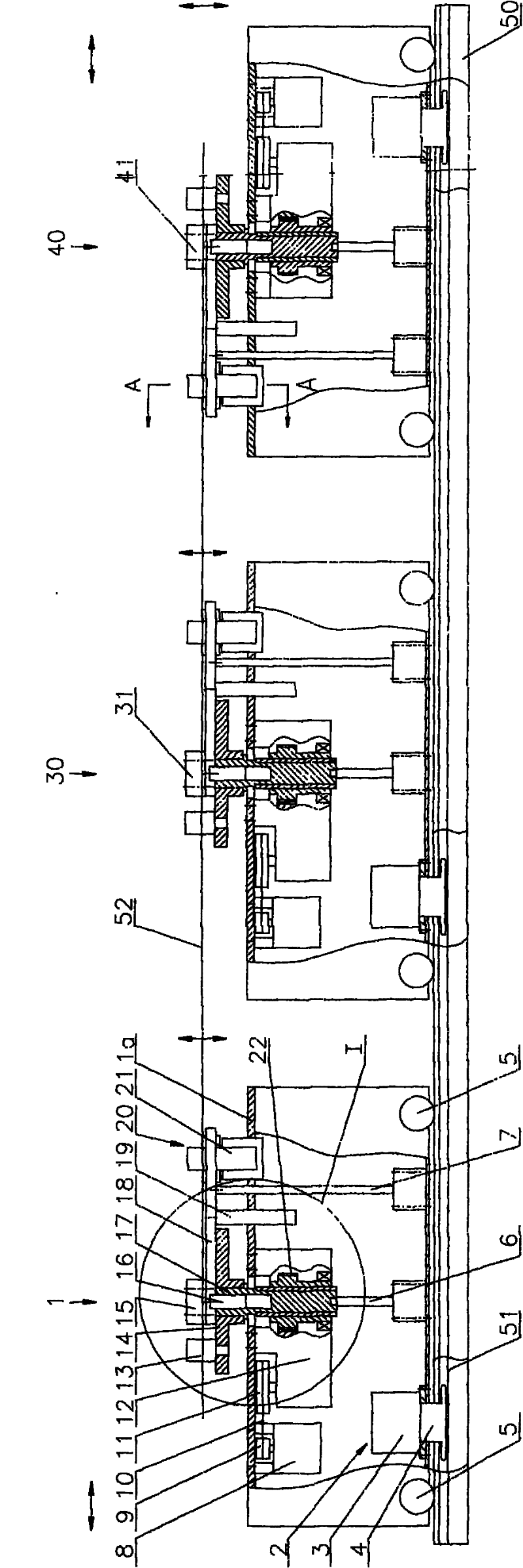

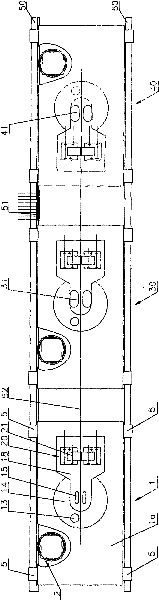

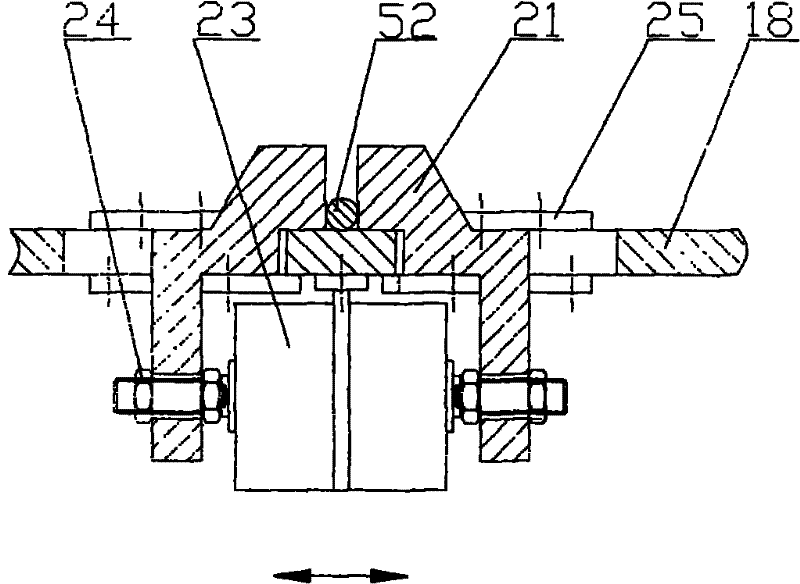

Bidirectional movement vertical type steel-bar automatic bending machine

ActiveCN100579684CEnsure safetyLarge displacement rangeWork holdersLocking mechanismArchitectural engineering

The invention discloses a bi-directional movement vertical reinforcing steel bar automatic bending machine, which comprises a rail, an reinforcing steel bar automatic bending machine which moves on the rail and a reinforcing steel bar compressing device; the reinforcing steel bar compressing device is arranged on one side of the rail; the reinforcing steel bar automatic bending machine consists of a first reinforcing steel bar automatic bending machine and a second reinforcing steel bar automatic bending machine which have the same structure and arranged on corresponding positions; the bottoms of the first reinforcing steel bar automatic bending machine and the second reinforcing steel bar automatic bending machine are provided with bi-directional traction mechanisms which have the same structure and are used for driving the bending machines to move on the rail and locking mechanisms which are used for locking the bending machines on the rail. The invention has the beneficial effects that the vertical bending pattern is easier for operation and the safety of operator can be guaranteed. The minimum bending length is 460mm and the bending angle range is extended. The two bending machines can move right and left fast at the same time for bending reinforcing steel bars to shorten the bending and forming time and promote the productivity. The invention has the advantages that the structure is simple and maintenance is convenient; work is stable and the energy is saved and the cost is low.

Owner:TJK MACHINERY TIANJIN

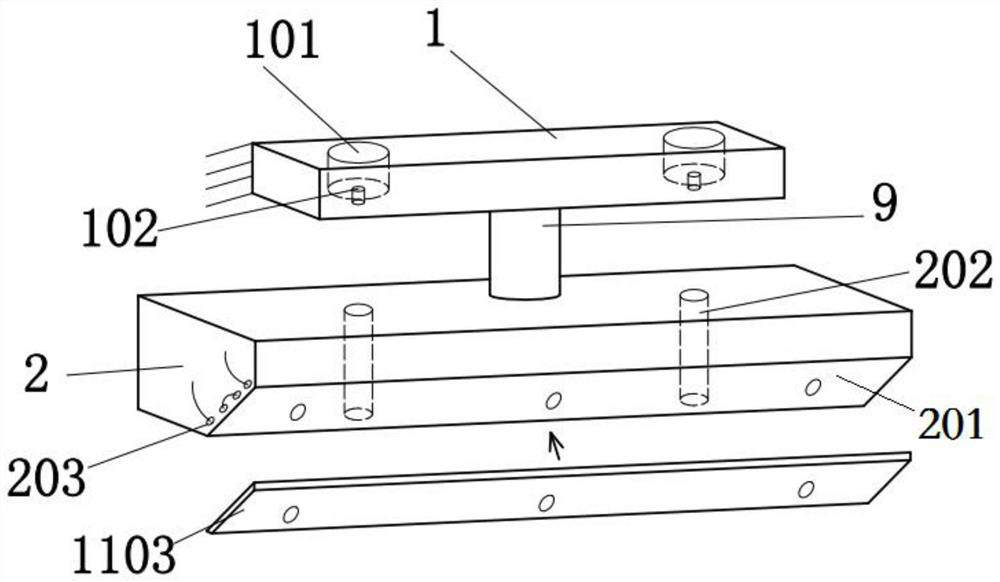

Device for thermally bending titanium alloy sheet into profiles and its thermal bending method

ActiveCN112775220BReduce distanceReduce bending timeShaping toolsMetal-working feeding devicesHydraulic cylinderTitanium alloy

The invention discloses a device for thermally bending a titanium alloy sheet into a profile and a thermal bending method thereof. The device includes an upper fixing block, a pressing block, a lower machine body, a bending upper fixing block, a bending block, a pressing hydraulic cylinder and Main bending hydraulic cylinder. First, the clamping device clamps the titanium alloy plate, and then heats the central area of the plate through the flame heating pipe. After reaching a certain temperature, the whole plate is quickly transported to the first wear-resistant plate, and the pressing block moves downward until the second The three wear-resistant plates are fixed in contact with the upper part of the plate. At the same time, the heating wires in the first heating hole and the second heating hole keep the plate warm to reduce heat loss. The bending block moves downward to bend the whole plate, and finally The clamping device clamps the heated sheet and transports the sheet away. This device can solve the demand for short-time conversion from heating to bending of the hot bending process of titanium alloy plates, reduce heat dissipation time, provide bending consistency and uniformity, and meet the needs of high-precision titanium alloy V-shaped profiles.

Owner:YANSHAN UNIV

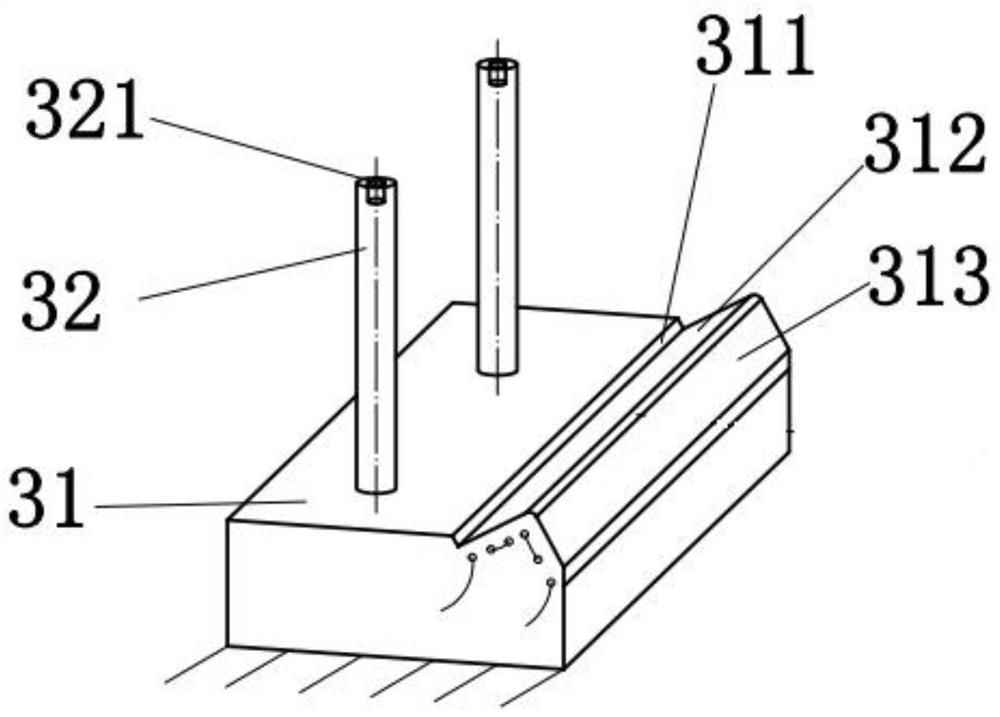

Bending processing device for large-scale wind power high-speed gearbox

ActiveCN113198879BShort bending timeSimple driveMetal-working feeding devicesPositioning devicesClassical mechanicsStructural engineering

The invention discloses a bending processing device for a large-scale wind power high-speed gear box. The bending processing device includes a base, a pressing mechanism, and a bending mechanism. The base is sequentially provided with a pressing mechanism, a pressing mechanism, and a bending mechanism. Bending mechanism, the pressing mechanism exerts pressure on the middle of the sheet, the pressing mechanism makes the bending mechanism bend the sheet, and the bending mechanism bends the sheet. The invention is scientific and reasonable, and is safe and convenient to use. The pressing mechanism exerts pressure on the middle position of the plate, so that the plate is bent from the middle position, and the pressing mechanism provides bending power for the bending mechanism while applying pressure to the plate. The two ends of the plate are extruded, so that the two ends of the plate are bent and close to each other, and the pressing mechanism and the bending mechanism cooperate with each other to quickly bend the plate into shape.

Owner:江苏卓海电气装备有限公司

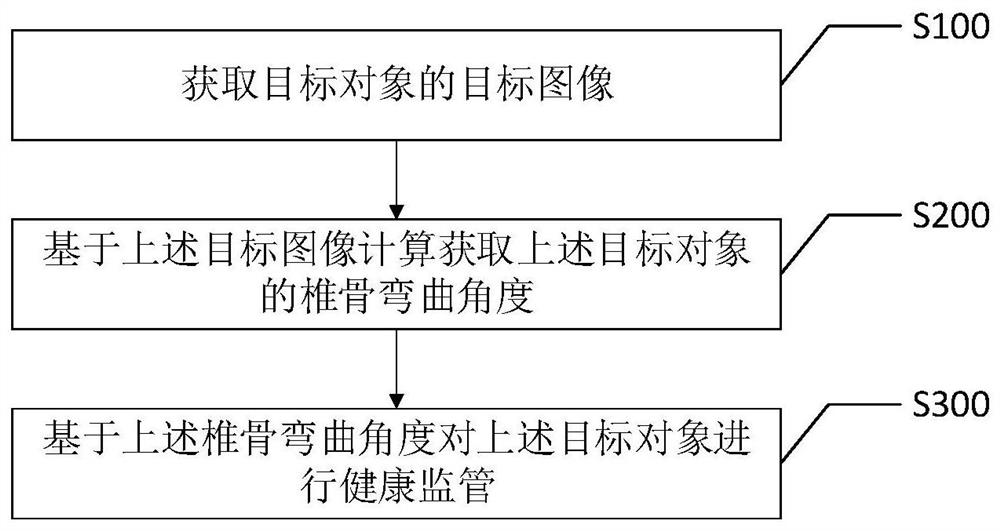

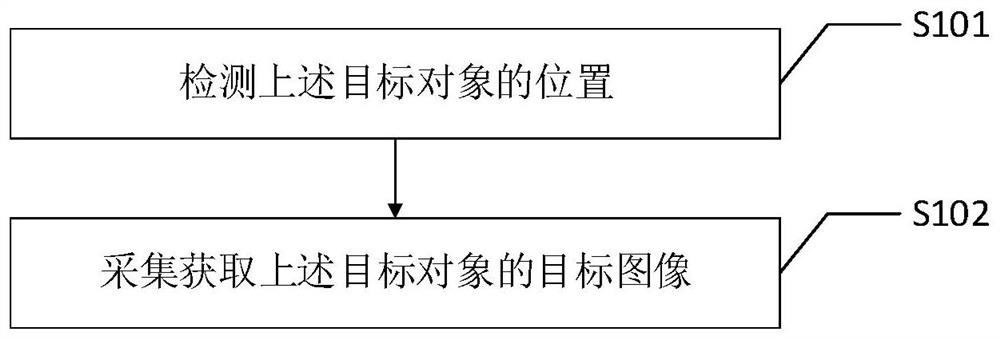

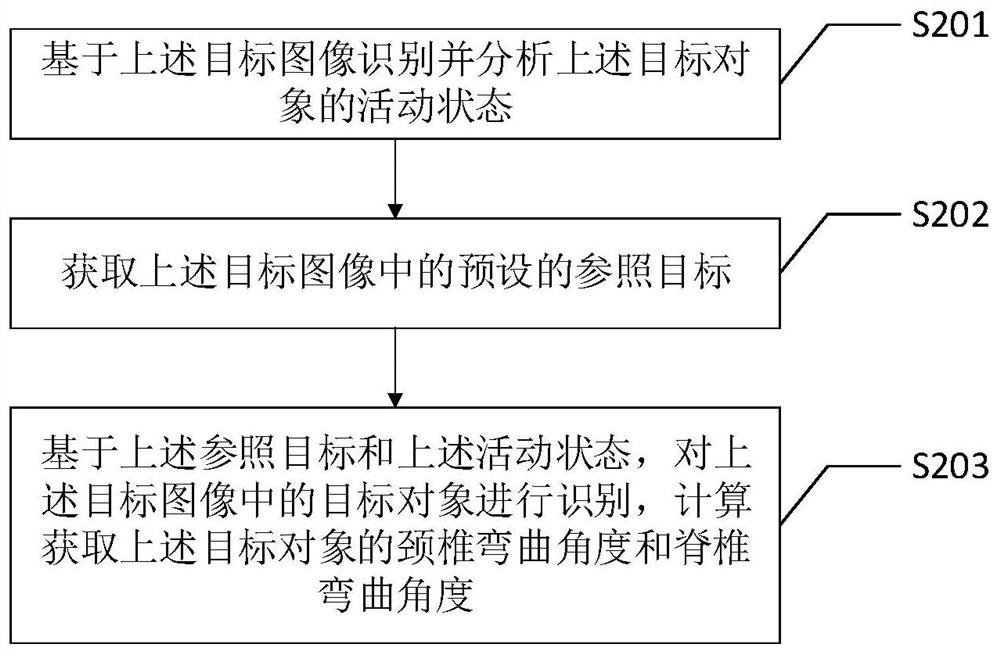

Health supervision method and device, intelligent terminal and computer readable storage medium

PendingCN114642421ARealization of health supervisionReduce bending timeDiagnostic recording/measuringSensorsEngineeringPhysical therapy

The invention discloses a health supervision method and device, an intelligent terminal and a computer readable storage medium, and the method comprises the steps: obtaining a target image of a target object; calculating and acquiring a vertebra bending angle of the target object based on the target image; and performing health supervision on the target object based on the vertebra bending angle. According to the health supervision method provided by the scheme of the invention, the target image of the user can be acquired, so that the vertebra bending angle of the user is acquired in real time, and health supervision on the user is realized. Therefore, compared with the prior art, the scheme provided by the invention is beneficial to providing a health supervision scheme for the user, helping the user pay attention to an unhealthy posture, realizing health supervision on the user, and being beneficial to reducing the vertebra bending time of the user and reducing the possibility of vertebra injury of the user.

Owner:SHENZHEN TCL NEW-TECH CO LTD

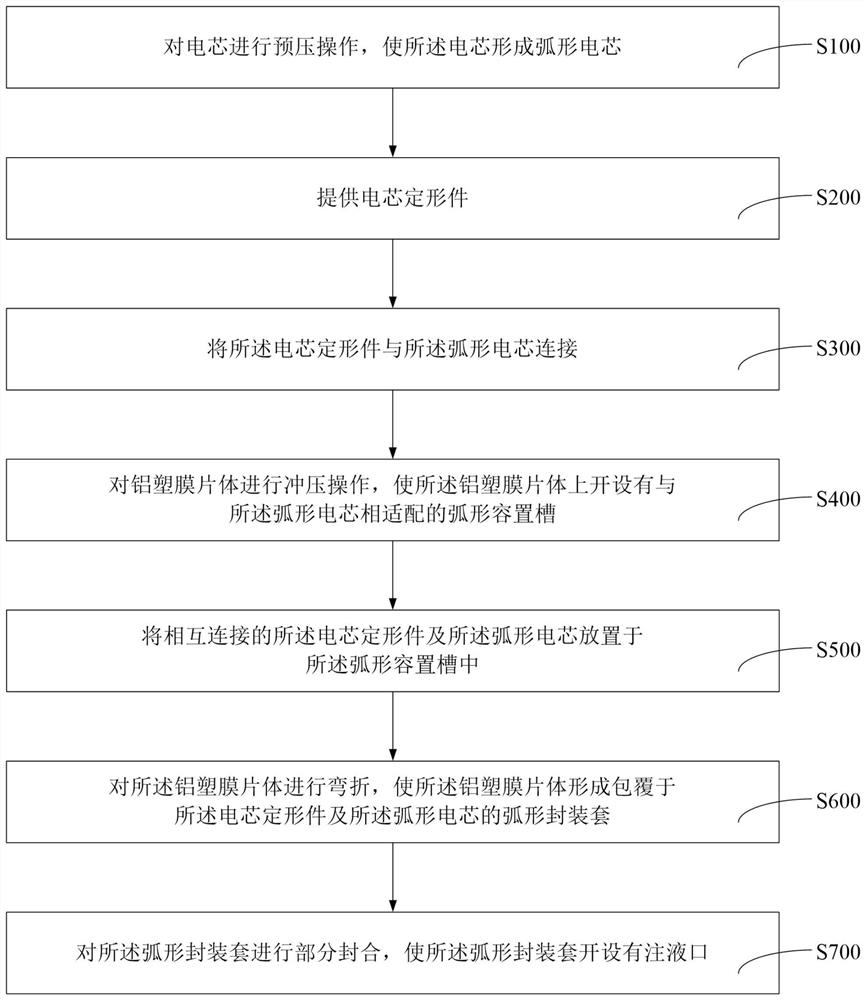

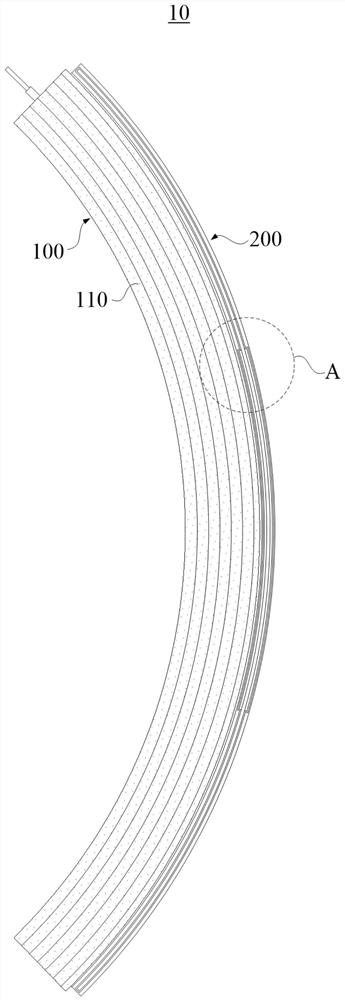

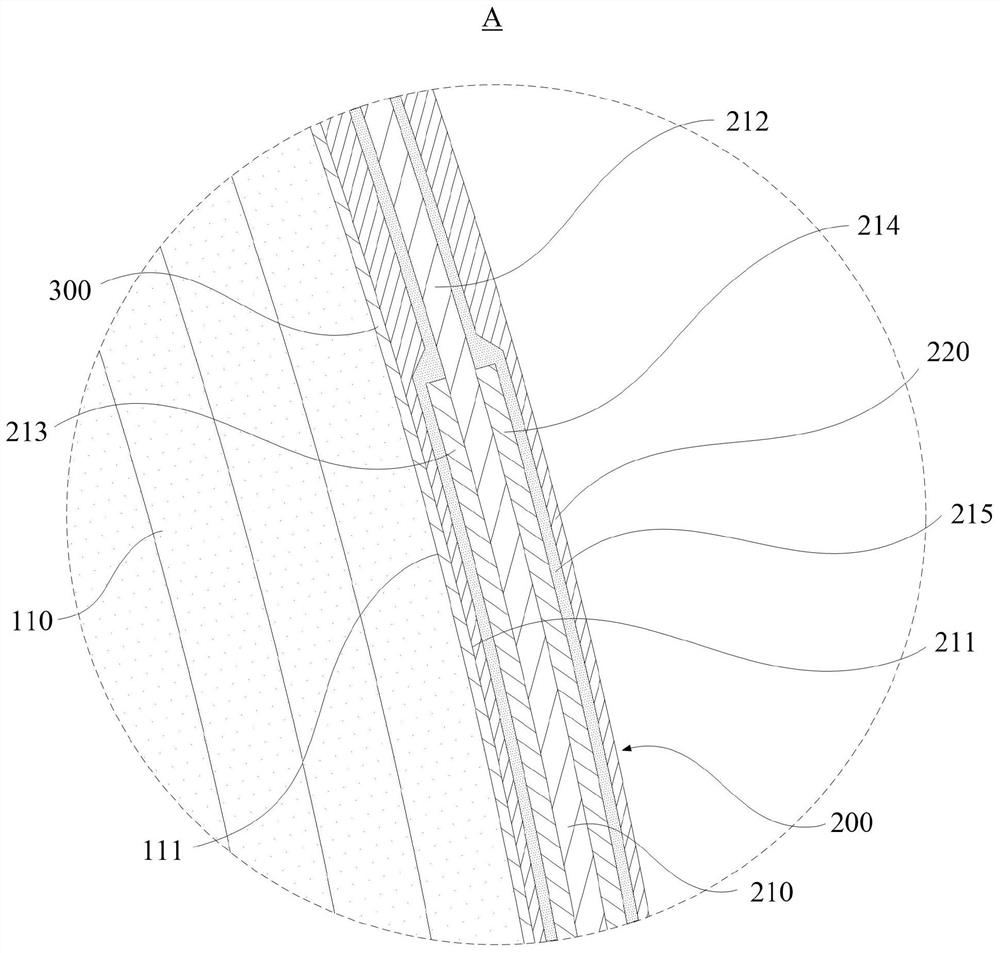

Shaping processing method for arc-shaped battery, and arc-shaped battery

ActiveCN113258122AReduce bending timeImprove processing efficiencyFinal product manufactureSecondary cells manufactureStructural engineeringPlastic film

The invention provides a shaping processing method for an arc-shaped battery, and the arc-shaped battery. The shaping processing method for the arc-shaped battery comprises the following steps: carrying out pre-pressing operation on a battery cell so as to allow the battery cell to form an arc-shaped battery cell; providing a shaped battery cell; connecting the shaped battery cell with the arc-shaped battery cell; performing stamping operation on an aluminum-plastic film sheet body so as to allow an arc-shaped accommodating groove matched with the arc-shaped battery cell to be formed in the aluminum-plastic film sheet body; placing the shaped battery cell and the arc-shaped battery cell which are connected with each other in the arc-shaped accommodating groove; and bending the aluminum-plastic film sheet body to allow the aluminum-plastic film sheet body to form an arc-shaped packaging sleeve covering the shaped battery cell and the arc-shaped battery cell. According to the invention, the flat battery cell is quickly bent and pressed into an arc-shaped structure through pre-pressing operation, so the processing time of bending and pressing is favorably shortened; the arc-shaped battery cell is fixed through the shaped battery cell, so the arc-shaped battery keeps self radian in the processes of transportation and circulation; and as bending operation does not need to be carried out on an packaged aluminum-plastic film, wrinkles caused by bending operation can be effectively avoided.

Owner:HUIZHOU HENGTAI TECH

A shearing and bending mechanism

The invention discloses a shearing and bending mechanism which comprises an upper die base connected under a press machine and a lower die base connected under the upper die base. A flanging convex die is connected under the upper die base, a lower cavity is formed in the bottom of the flanging convex die, a material pressing block is connected in the lower cavity, an upper cavity is formed in the top of the lower die base, a forming inserted block is connected in the upper cavity, peripheral guide pins are arranged between the material pressing block and the forming inserted block, a product material piece is arranged on the surfaces of the peripheral guide pins, a bending convex die is arranged on one side of the lower cavity of the flanging convex die, an edge cutting convex die is arranged on the other side of the lower cavity of the flanging convex die, the length of the edge cutting convex die extending downwards is longer than that of the bending convex die, a cutting inserted block is arranged on the lower die base and at the position corresponding to the edge cutting convex die, the edge cutting convex die can extrude the product material piece on the peripheral guide pins, and the bending convex die can extrude the product material piece. The shearing and bending mechanism simplifies bending procedures, improves bending automation, saves bending time and daily bending mechanism maintaining time and reduces bending cost.

Owner:ANHUI XINYUE PRECISION MACHINERY

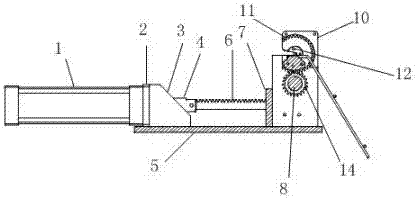

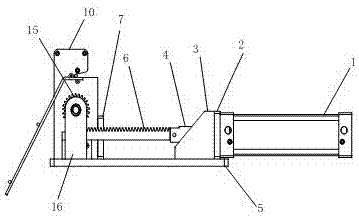

Pneumatic bending machine

The invention discloses a pneumatic bending machine. The machine comprises a pneumatic, etc., wherein a pneumatic flange is mounted at one side of the cylinder; a cylinder inclination supporting part is fixed to the other side of the cylinder flange; the cylinder flange, the cylinder inclination supporting part, a reinforcing plate, a two-stage gear cover plate and a main shaft support are fixed to a combining panel; one end of a rack is connected to the cylinder through a rack connector, and the other end of the rack is engaged with a driving gear; a main shaft passes through a transmission gear and the driving gear and is mounted on the main shaft support; at least one bending product passes through the two-stage gear cover plate; a two-stage gear is mounted between the two-stage gear cover plate and a two-stage gear fixing shaft; a bending cutter head is positioned above the transmission gear and is fixed to the two-stage gear. With the adoption of the pneumatic bending machine, the bending is automatically carried out, so that the time of bending a workpiece is reduced, and the operation is convenient.

Owner:宿迁威生金属制品厂

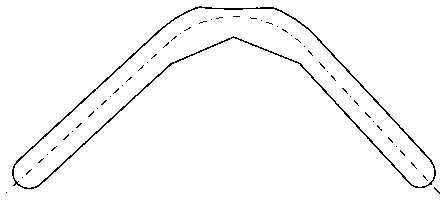

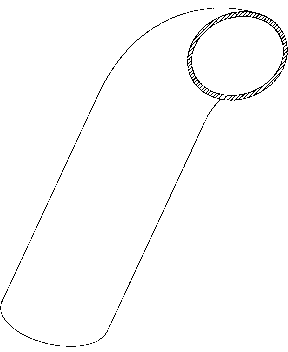

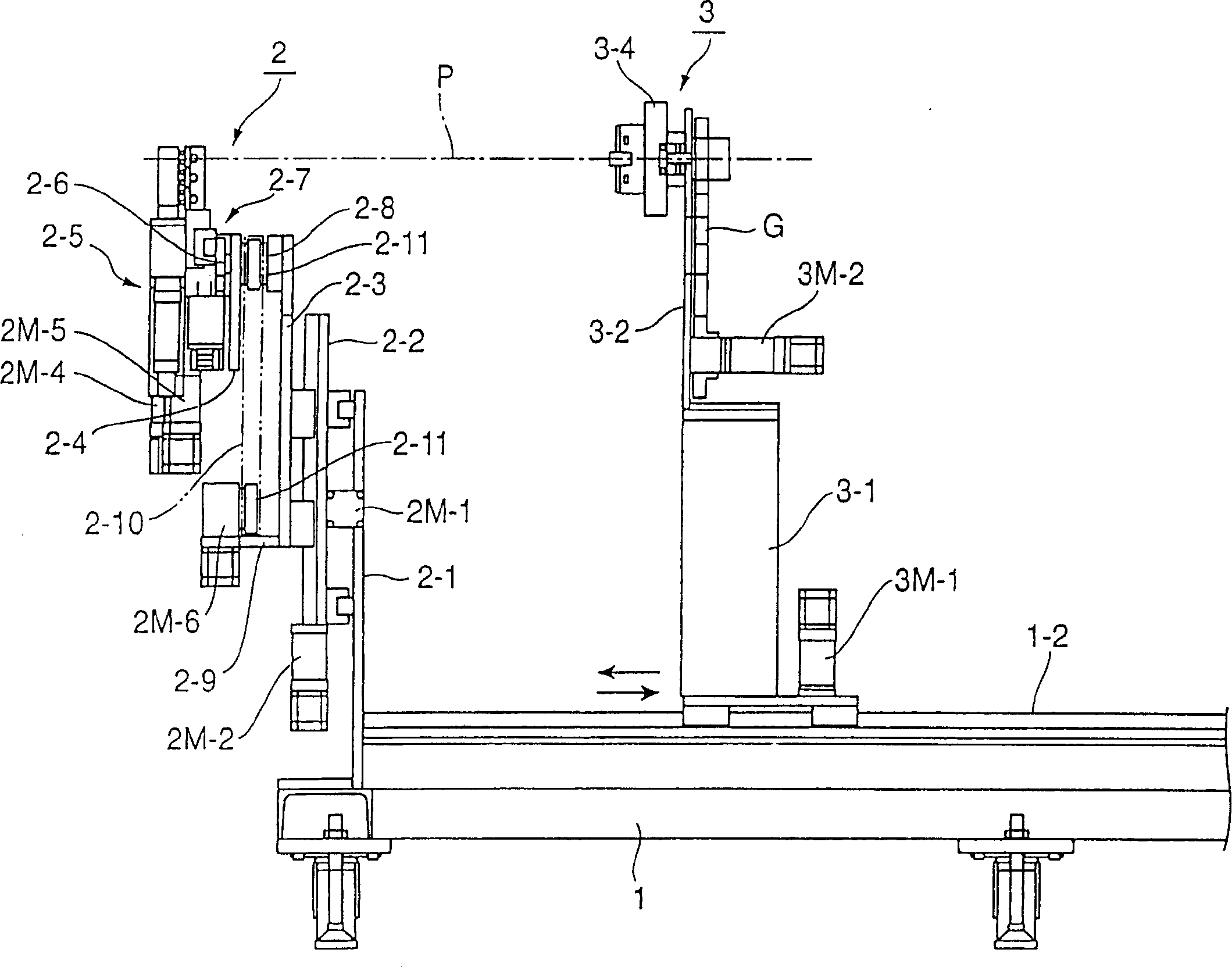

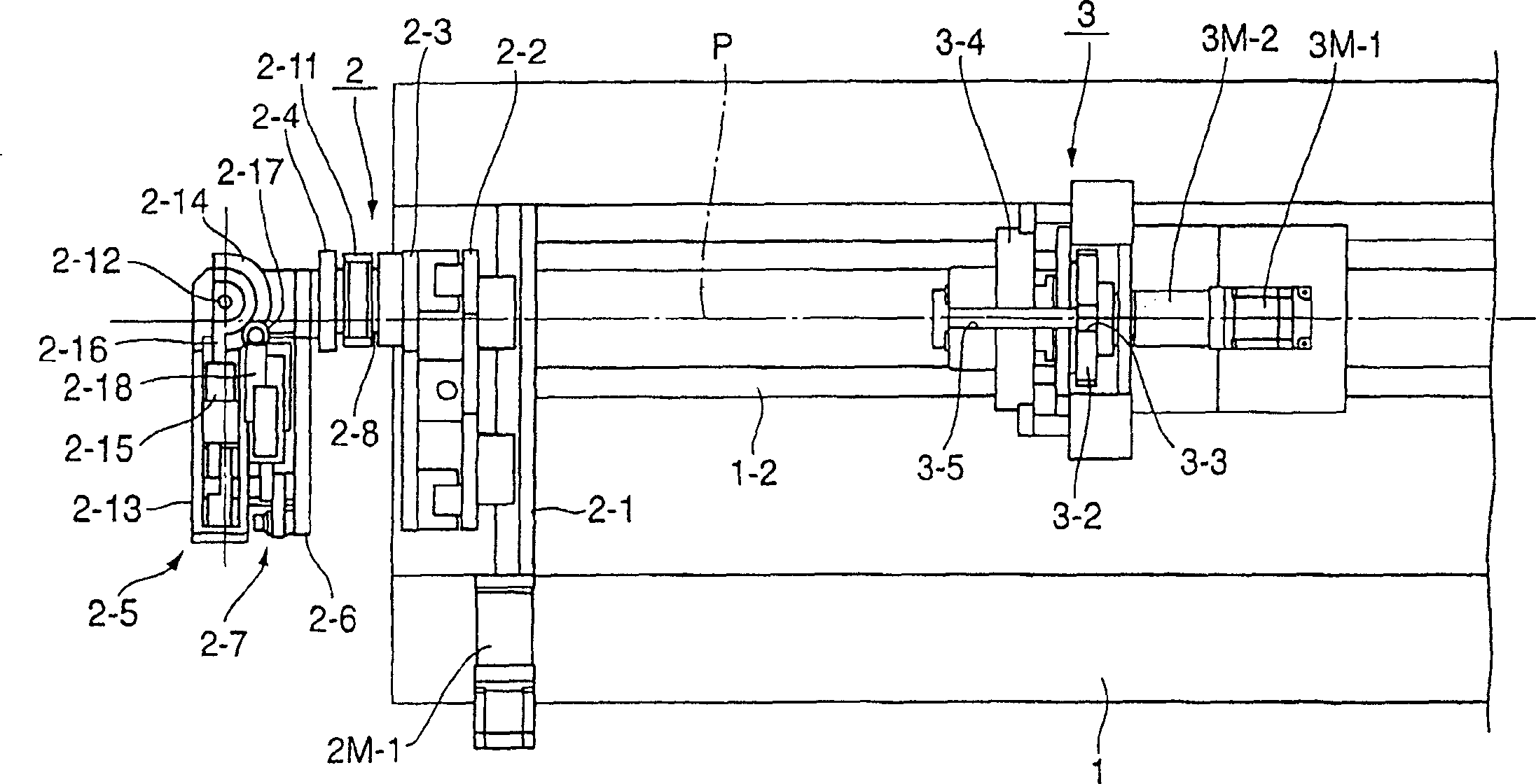

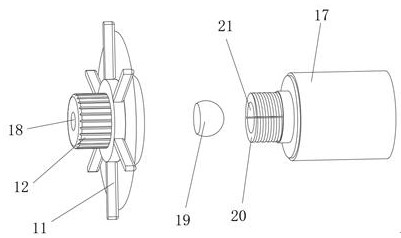

Bending device for tube

A tube bending device having draw-bending and compression-bending functions and capable of bending in all processes in a unit of device is provided. The device performing bending by rotating the tube at a predetermined angle with the tube pressured against a circumferential surface of a bending die, the device including a movable type of tube bending unit movable in a longitudinal direction of a tube to be processed or a fixed type of tube bending unit and a tube twisting unit for rotating the tube freely at a predetermined angle with a center of the tube being an axis core is characterized in that the tube bending unit has one or both of draw-bending and compression-bending functions and is provided rotatably in a vertical plane about an axis parallel to the axis core of the tube so that the displacement amount in a tube twisting operation can be reduced.

Owner:USUI CO LTD

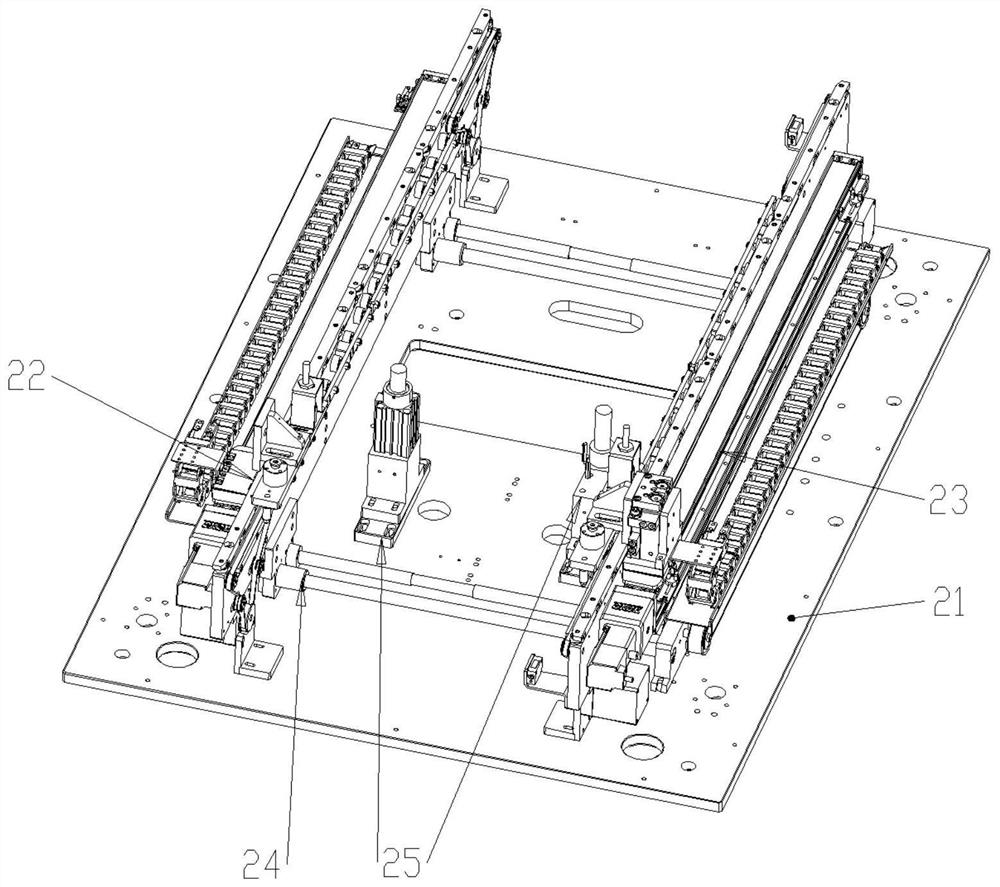

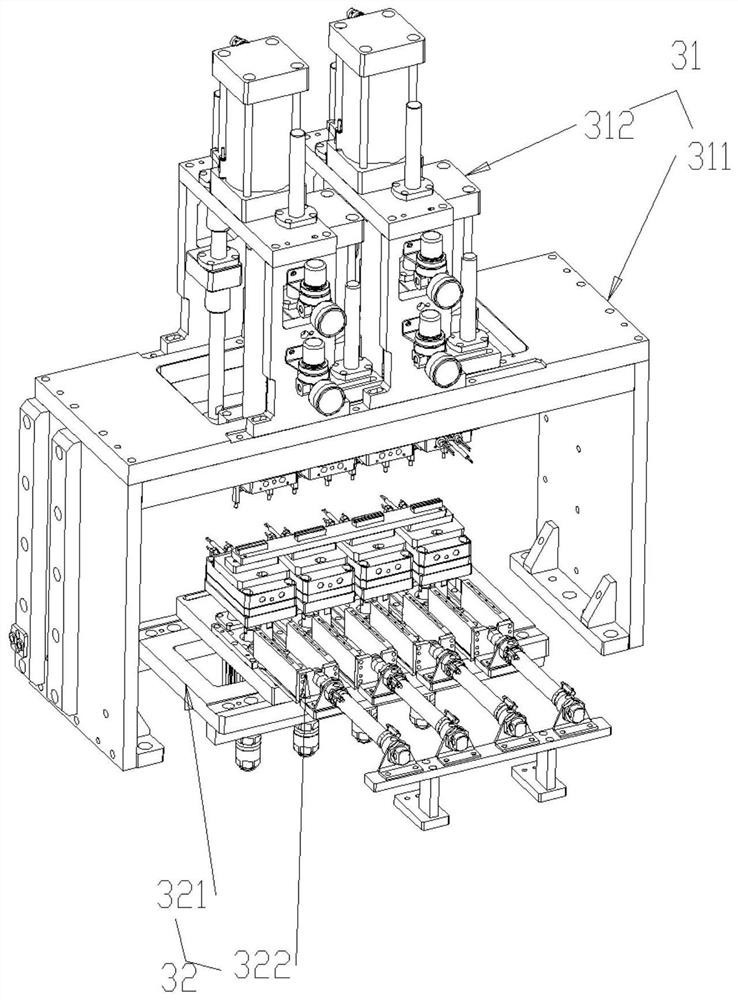

Automatic bending machine for continuously bending FPC board

PendingCN114051320AImprove bending qualityHigh strengthPrinted circuit manufactureStructural engineeringMechanical engineering

The invention discloses an automatic bending machine for continuously bending an FPC board and a working method thereof. The automatic bending machine comprises a rack, a conveying structure, a bending structure and a carrier structure; the conveying structure comprises a fixed base plate, a first side conveying structure, a second side conveying structure, a width adjusting structure and a carrier positioning structure. The bending structure comprises an upper die structure assembly and a lower die structure assembly; and the carrier structure comprises a placing plate, a pressing plate, a limiting pin, an end part positioning structure and a shifting roller structure. According to the invention, the multiple sets of FPC boards needing to be bent are sequentially placed on the carrier structure and reach the bending structure to be bent under the conveying effect of the conveying structure, after each time of bending, the positions of the FPC boards on the carrier structure are repositioned through the material shifting roller structure, and therefore the working efficiency and the bending quality of the bending machine are greatly improved.

Owner:苏州市锐翊电子科技有限公司

Movable inclined platform type automatic steel bar bending machine

Owner:TJK MACHINERY TIANJIN

Tube turning clamping and shrinking device

The invention relates to a pipeline turning clamping and contracting device which consists of a translational inclined wedge-shaped block, two guide grooves and a hydraulic cylinder. The two sides of the translational inclined wedge-shaped block are respectively contained in the two guide grooves, and the translational inclined wedge-shaped block is embedded with an embedded inclined wedge-shaped block which can slide in the translational inclined wedge-shaped block; the hydraulic cylinder is fixed on a lower cover board, one end surface of the embedded inclined wedge-shaped block is fixed on the hydraulic cylinder, and the other end surface is contained in one guide groove. The device has the following advantages: the invention relates to a pipeline clamping and contracting device, in which the inclined wedge-shaped block is pulled and pushed hydraulically, the clamping and contracting of the pipeline is controlled by the hydraulic cylinder, and any other external force is not needed. A special bend operation button or handle is not needed to set, thus leading to simple operation and shortening the pipeline bending time greatly.

Owner:MCC TIANGONG GROUP

Tube translation clamping and shrinking device

The invention relates to a pipeline translational clamping and contracting device which consists of a translational inclined wedge-shaped block, a guide groove and a hydraulic cylinder. The translational inclined wedge-shaped block consists of two connected inclined wedge-shaped blocks, the two sides of the translational inclined wedge-shaped block are respectively contained in the guide groove, and the two inclined wedge-shaped blocks in the translational inclined wedge-shaped block are respectively embedded with an embedded inclined wedge-shaped block which can slide in the inclined wedge-shaped blocks; the hydraulic cylinder is fixed on a lower cover board, the two ends of the hydraulic cylinder can come out of the cavity at the same time, one end of the two embedded inclined wedge-shaped blocks is respectively fixed at the two ends of the hydraulic cylinder, and the other end surface is contained in the guide groove respectively. The device has the following advantages: the invention relates to a pipeline clamping and contracting device, in which the inclined wedge-shaped blocks are pulled and pushed hydraulically, the clamping and contracting of the pipeline is controlled by the hydraulic cylinder, and any other external force is not needed. A special bend operation button or handle is not needed to set, thus leading to simple operation and shortening the pipeline bending time greatly.

Owner:MCC TIANGONG GROUP

Novel minitype construction steel bar bending device

The invention discloses a novel minitype construction steel bar bending device. The novel minitype construction steel bar bending device used comprises a foundation mechanism, a preliminary fixing mechanism, a medium stabilizing mechanism and a bending mechanism, wherein the preliminary fixing mechanism, the medium stabilizing mechanism and the bending mechanism are arranged on the foundation mechanism; the foundation mechanism comprises a worktable; cushion blocks are fixedly mounted at the bottom of the worktable; a bending groove is formed in the top part of the worktable; a motor fixing plate is fixedly mounted on the front face of the worktable; a mounting plate is fixedly mounted in the worktable; and the preliminary fixing mechanism comprises side plates and sliding rails. The novelminitype construction steel bar bending device disclosed by the invention has the advantages that the structure is simple and reasonable, the size of the device is small, and the device is convenientto mount and use; when the device is used, a worker can complete the bending operation of construction steel bars, so that the manpower is saved; and meanwhile, by adopting a mechanical bending way,the time required to bend the construction steel bars is shortened, the bending quantity of the construction steel bars can be improved, the bending efficiency is high, the labor intensity of workersis reduced, and building operations are facilitated.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP

a twister

Owner:STATE GRID CORP OF CHINA +1

Agricultural film mulching device

InactiveCN112544317AReduce bending timeReduce physical exertionPlant protective coveringsAgricultural engineeringPlastic mulch

The invention discloses an agricultural film mulching device. The agricultural film mulching device comprises a supporting pipe, convex columns are arranged on the inner walls of the two ends of the supporting pipe, and circular grooves are formed in the outer walls of one ends of the convex columns; connecting columns are fixedly connected to the outer walls of one sides of the convex columns, and circular grooves are formed in the outer walls of one sides of the connecting columns; rotating balls are clamped to the inner walls of the circular grooves, a supporting frame is arranged on the outer walls of one sides of the rotating balls, and a connecting pipe is clamped to the middle section of the supporting frame; the two ends of the supporting frame are rotationally connected to the inner walls of the convex columns through bearings, tightening sleeves are in threaded connection with the outer walls of the connecting columns, and second limiting blocks are arranged on the outer walls of one sides of the tightening sleeves; and the outer walls of the two ends of the supporting pipe are fixedly connected with first limiting blocks. When the agricultural film mulching device is used, a worker can hold the supporting frame with one hand, in the process of moving the whole device, the mulching film rotates with the supporting pipe as the center and is unfolded, at the moment, theworker can cover the edge of the mulching film with the other hand, and therefore laying of the mulching film can be completed by one person.

Owner:六安科科达尔生物科技有限公司

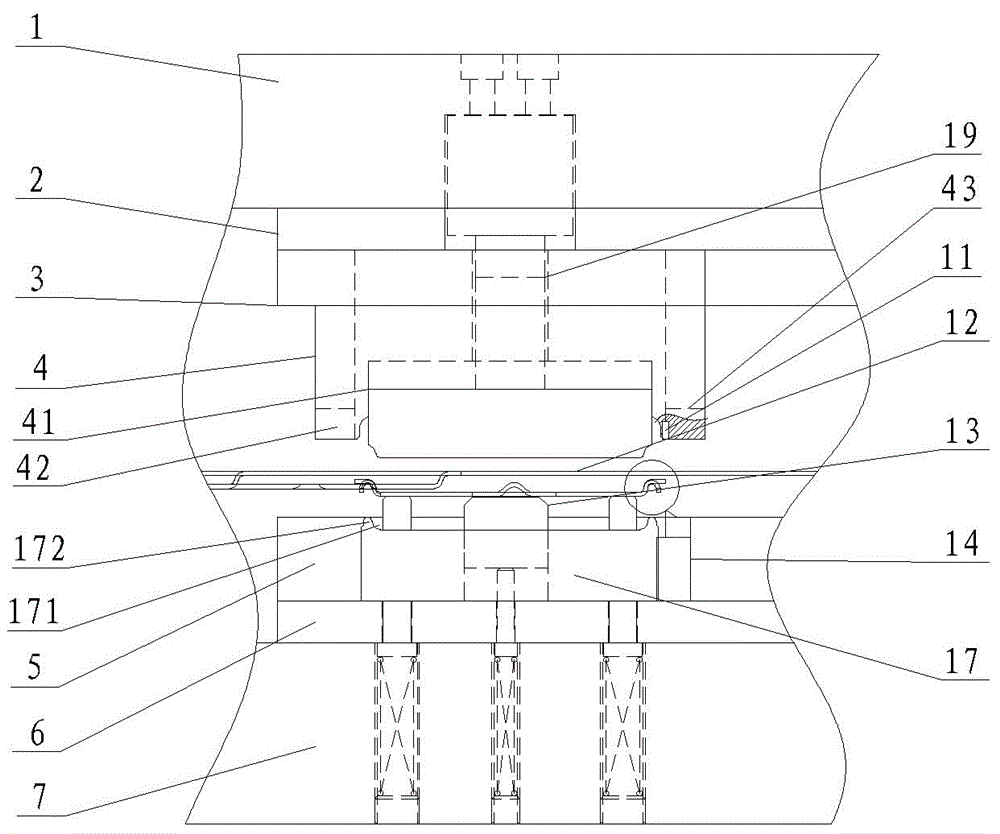

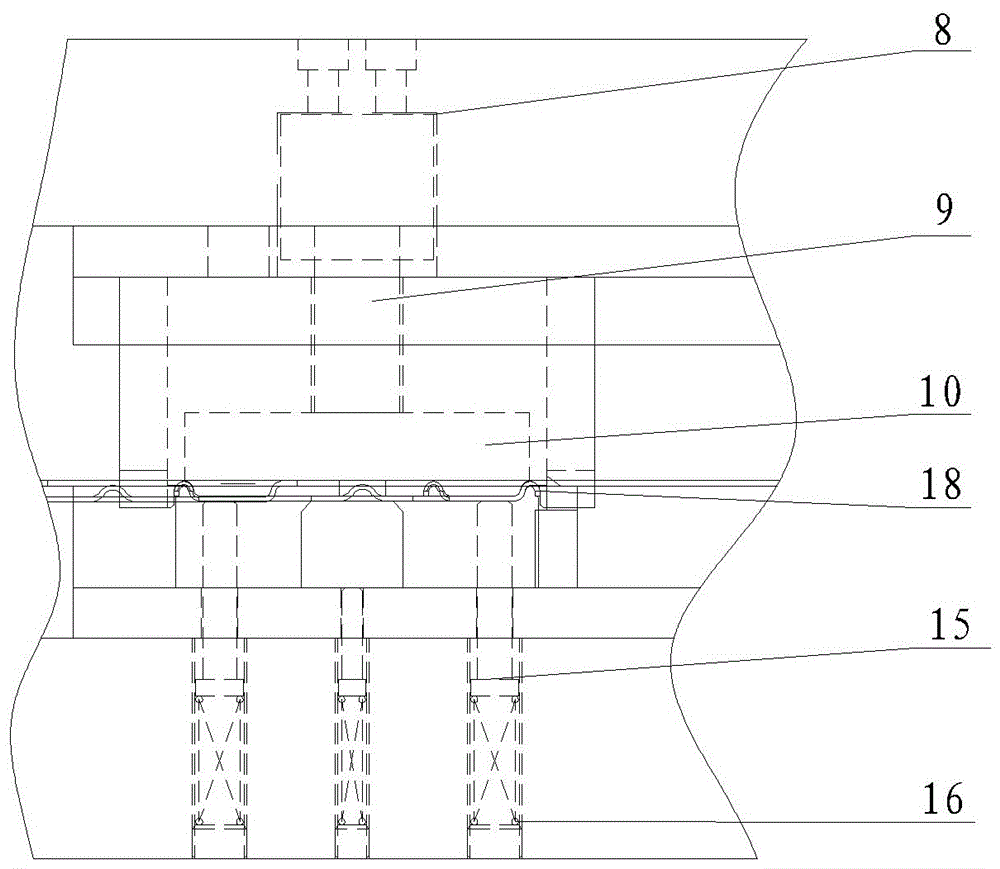

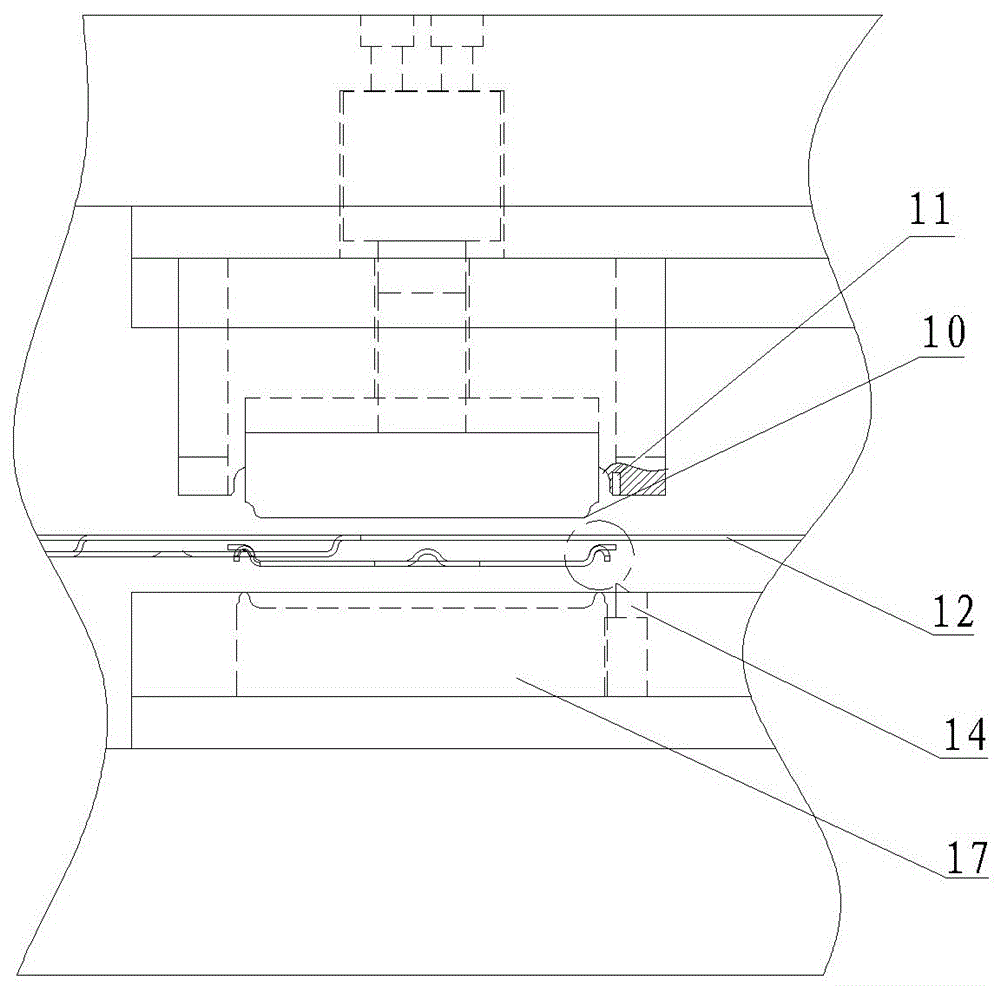

Automatic bending machine capable of continuously bending steel bars with different semi-diameters

The invention discloses an automatic bending machine capable of continuously bending steel bars with different semi-diameters, which comprises a track, a mobile driving mechanism, a turntable and a clamping mechanism, wherein the turntable and a fixed plate are connected to telescopic mobile mechanisms respectively; for the telescopic mobile mechanism connected with the turntable, the turntable is fixed at the upper end of a main shaft, and the main shaft is connected to a main shaft piston rod of a reciprocating mechanism; for the telescopic mobile mechanism connected with the fixed plate, afirst supporting shaft, a second supporting shaft and a fixed plate piston rod are fixed on the bottom surface of the fixed plate; and the reciprocating mechanism connected with the fixed plate piston rod is fixed in the steel bar automatic bending machine. The automatic bending machine has the advantages of overcoming defects of the prior art, being capable of forming the steel bars with different bending semi-diameters once, obviously shortening the bending forming time of the steel bars and improving the production efficiency. The automatic bending machine also has the advantages of simplestructure, convenient maintenance, smooth working, energy consumption saving and low processing cost.

Owner:TJK MACHINERY TIANJIN

A construction device and working method for an energy-saving building

Owner:国家电投集团江西中业兴达电力实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com