Automatic bending machine capable of continuously bending steel bars with different semi-diameters

A technology of bending radius and bending machine, which is applied in the field of steel bar automatic bending production line, can solve the problems of not being able to meet the requirements of different bending radii for steel bar processing, waste of labor, low efficiency, etc., and achieve shortening of forming time, energy saving and stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

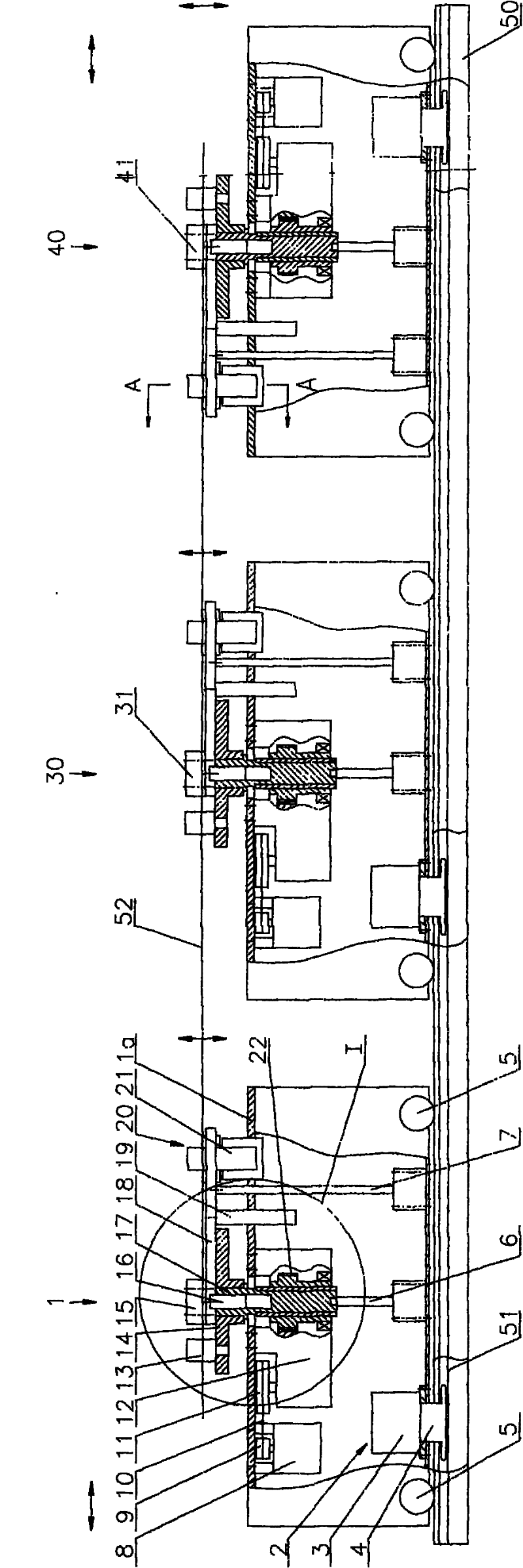

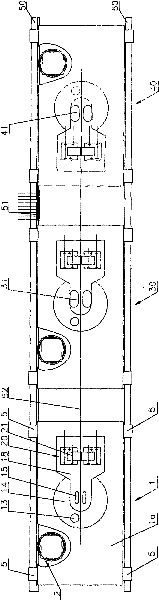

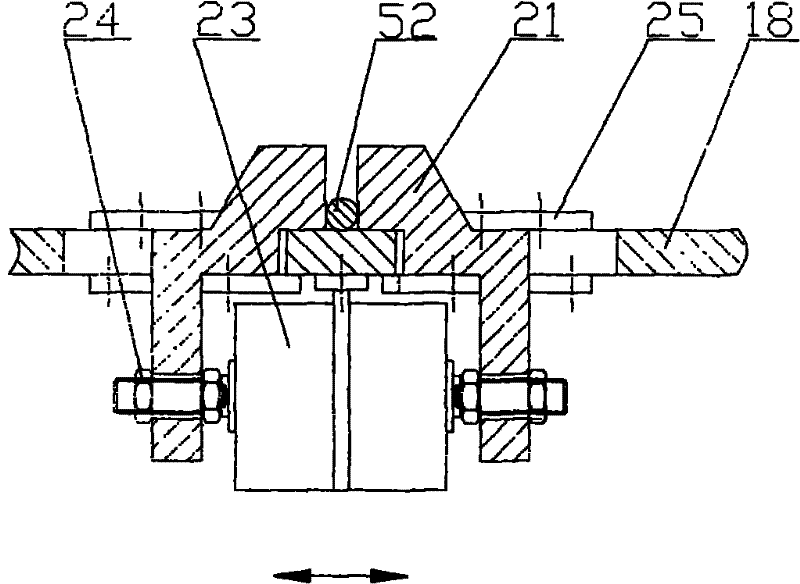

[0016] figure 1 is the front view of the present invention; figure 2 yes figure 1 top view of image 3 yes figure 1 Middle A-A sectional view; Figure 4 yes figure 1 Enlarged view of middle part I.

[0017] The present invention provides an automatic steel bar bending machine with different radii for continuous bending. The automatic steel bar bending machine includes: two parallel rails 50; the bottom of the automatic steel bar bending machine is provided with a mobile drive mechanism 2 driven by a motor to walk along the rails; The steel bar automatic bending machine is provided with a turntable 14 supporting the bending shaft 13 ; a fixing plate 18 supporting the first central shaft 15 and a steel bar clamping mechanism 20 .

[0018] The rotating disk 14 and the fixed plate 18 are respectively connected to telescopic moving mechanisms capable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com