Agricultural film mulching device

A film laying device, agricultural technology, applied in the direction of application, plant protection cover, botany equipment and method, etc., to achieve the effect of reducing physical exertion, easy to place and take, and convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

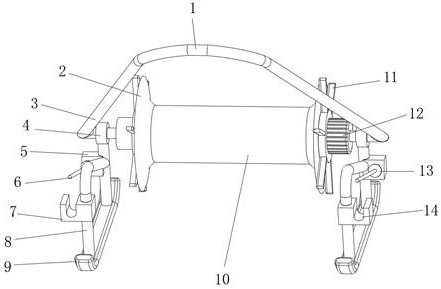

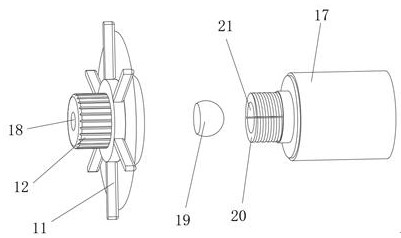

[0031] refer to Figure 1-3 , an agricultural film laying device, comprising a support tube 10, the inner wall at both ends of the support tube 10 is provided with a convex column 17, and the outer wall of one end of the convex column 17 is provided with a circular groove 21, and one of the convex column 17 The side outer wall is welded with a connecting column 20, and a side outer wall of the connecting column 20 is provided with a circular groove 21, and the inner wall of the circular groove 21 is clamped with a rotating ball 19, and one side outer wall of the rotating ball 19 is provided with a support frame 3, and supports The middle section of the frame 3 is clamped with a connecting pipe 1, and one end of the support frame 3 is connected to the inner wall of the convex column 17 through bearing rotation, and the outer wall of the connecting column 20 is threaded with a tightening sleeve 12, and one side of the outer wall of the tightening sleeve 12 is provided with The s...

Embodiment 2

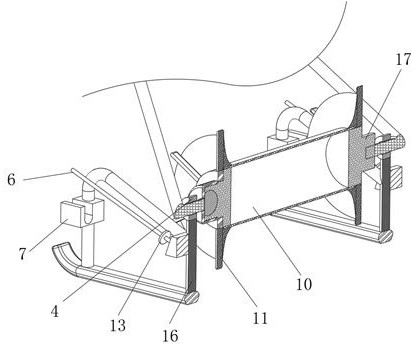

[0039] refer to Figure 4-6 , an agricultural film laying device. Compared with Embodiment 1, the outer walls of both ends of the support frame 3 are clamped with clips 22, and one end of the clips 22 is provided with a support rod 23, and the support rod 23 One side outer wall is all provided with spring 24, and one end of spring 24 is welded on the outer wall of clip 22, and the inner wall of support rod 23 is fixed with cross bar 25 by bolt, and the outer wall of one end of support rod 23 is connected with roller 15 in rotation, and support rod 23 is U. type, the outer wall of the cross bar 25 is provided with a plurality of short bars 26 equidistantly distributed, and the cross section of the short bars 26 is fan-shaped; ability, the other side of the short rod 26 is arc-shaped, which is beneficial to reduce the scratching of the short rod 26 on the plastic film; The film fits better; the set roller 15 presses down and guides the laid mulch film to prevent the wind from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com