Automatic bending machine for continuously bending FPC board

A bending machine, automatic technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems that affect the product position accuracy and dimensional accuracy, increase the loss of parts and maintenance costs, reduce work efficiency, etc., to improve The effect of bending position accuracy, improving product yield, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

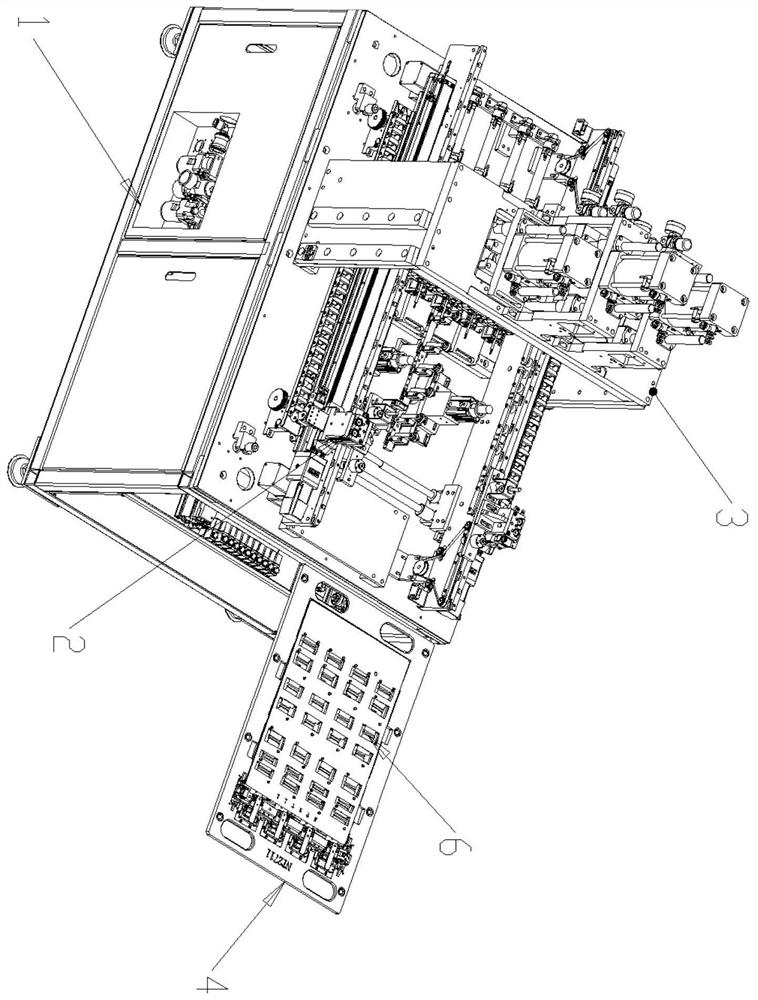

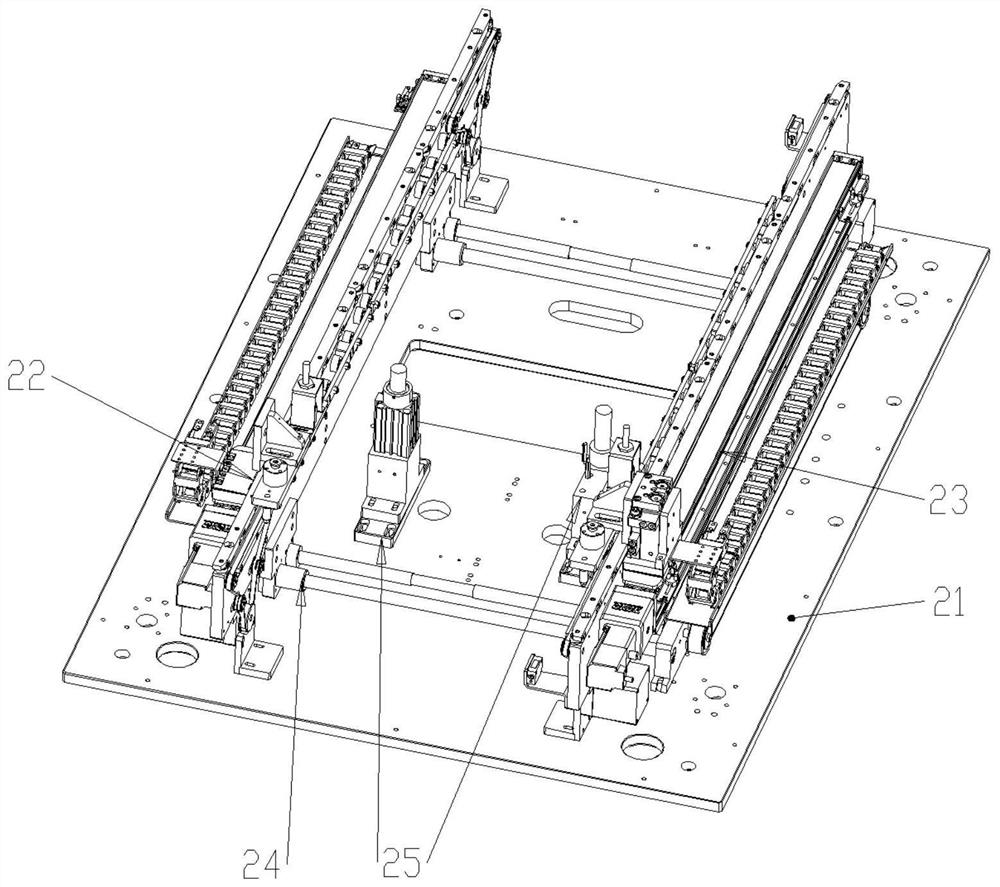

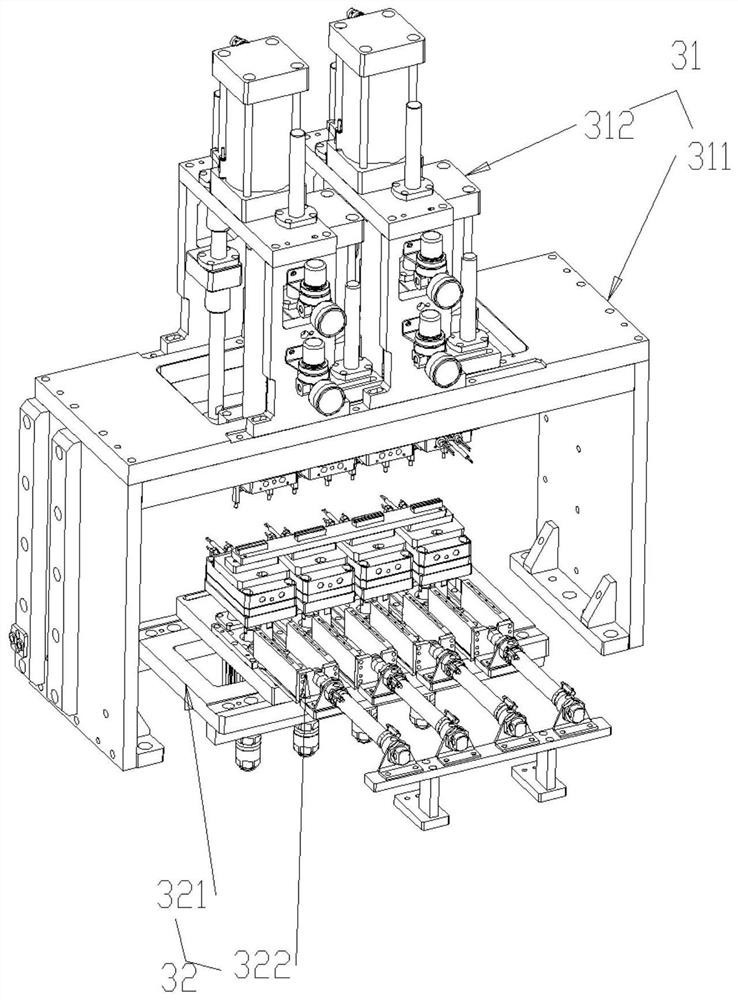

[0035] Such as figure 1 Shown is a perspective view of the present invention, including a frame 1, a transmission structure 2, a bending structure 3, and a carrier structure 4, the transmission structure 2 is arranged on the frame 1, and the bending structure 3 is arranged on the frame 1 In the upper middle position, the carrier structure 4 moves along the conveying structure 2, and performs bending work at the position of the bending structure 3; wherein, as figure 2 Shown is a perspective view of the transmission structure 2, including a fixed base plate 21, a first side transmission structure 22, a second side transmission structure 23, a width adjustment structure 24, and a carrier positioning structure 25. The first side transmission structure 22. The second side transmission structure 23 is relatively arranged on both sides of the fixed substrate 21, and the width adjustment structure 24 is arranged on the fixed substrate 21 and respectively connected to both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com