Electro-hydraulic synchronous bending machine and control method thereof

A bending machine and electro-hydraulic technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of high manufacturing cost and production cost, achieve the effect of reducing bending time, increasing lifting speed, and improving bending accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

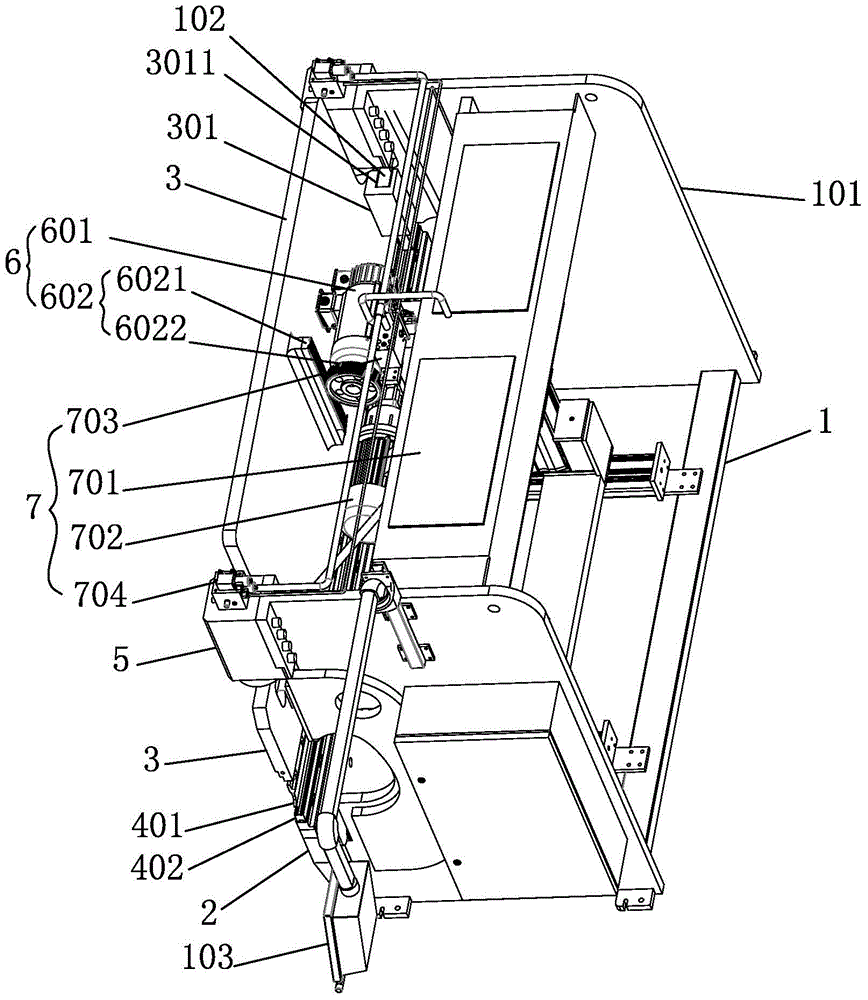

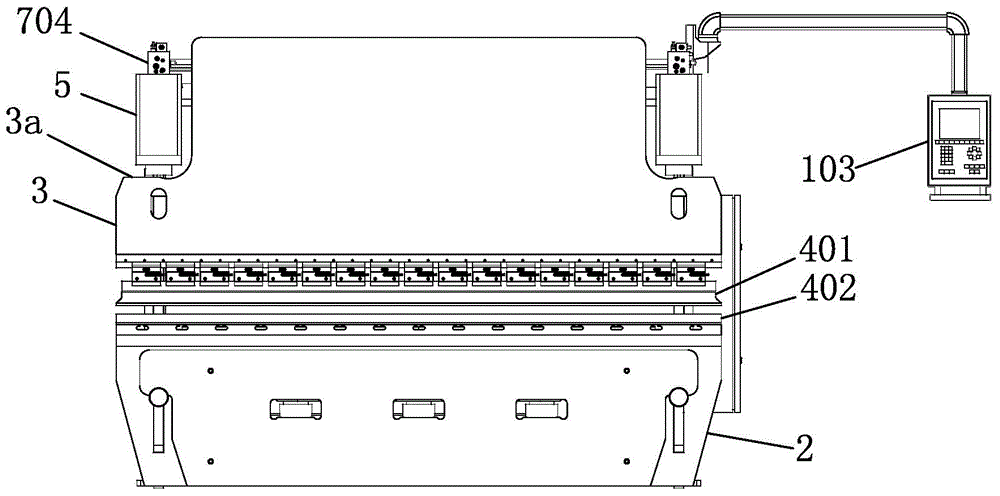

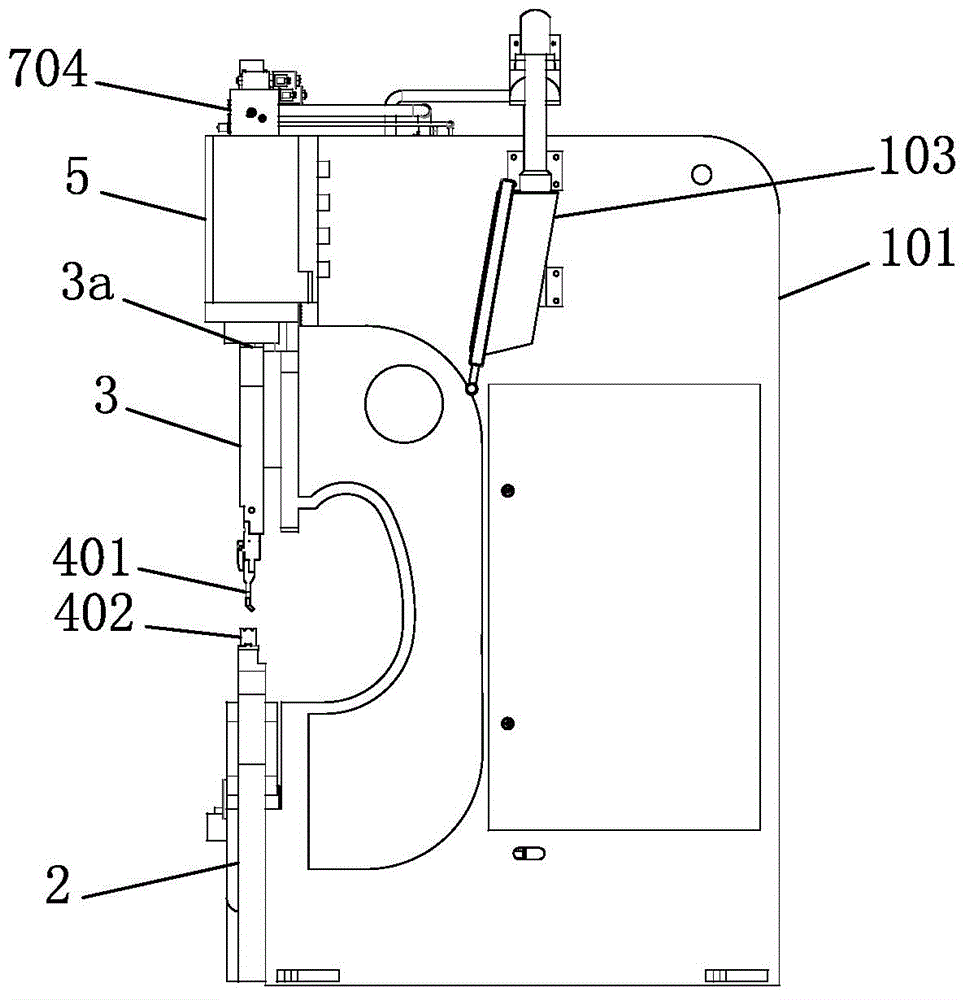

[0024] Embodiment 1: as Figure 1 to Figure 3 As shown, an electro-hydraulic synchronous bending machine includes a frame 1, a vertical plate 2 arranged on the frame 1, and a slider 3 arranged above the vertical plate 2. The lower end of the slider 3 is provided with an upper die 401, The upper end of vertical plate 2 is provided with lower mold 402, and the both sides of frame 1 is respectively provided with oil cylinder 5, and frame 1 comprises two side plates 101, and two oil cylinders 5 are fixed on the side plate 101 by bolt, two oil cylinders 5 The piston rods of the two cylinders are respectively connected to the slider 3, and the slider 3 is provided with two installation surfaces 3a, and the two installation surfaces 3a are located on the same horizontal plane, and the lower end surfaces of the piston rods of the two oil cylinders 5 are respectively connected to the two installation surfaces 301, The workpiece to be bent is placed on the lower mold 402, and the piston...

Embodiment 2

[0030] Embodiment 2: The difference from Embodiment 1 is that the transmission device 602 includes a lead screw and a screw nut, the lead screw is connected to the output shaft of the servo motor, and the screw nut is connected to the slider. The screw and nut form a ball screw structure, which has the advantages of high transmission efficiency and low noise.

[0031] A control method for an electro-hydraulic synchronous bending machine, including the following control stages:

[0032] 1) Standby stage: the bending machine is in the standby state after starting, the oil pump 702 is powered on, at this time the slider 3 is at the top dead center position, and the oil return port of the electromagnetic pressure valve 703 is opened;

[0033] 2) Fast-down stage: the control module issues a command to control the forward rotation of the servo motor 601, and the servo motor 601 drives the slider 3 to go down quickly through the transmission device 602 until the slider 3 reaches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com