Heat pipe bending method and heat pipe bending production device

A technology for manufacturing devices and heat pipes, which is applied in the fields of heat pipe bending methods and heat pipe bending manufacturing devices, can solve problems such as inability to use mandrel rods, section distortion, and difficult processing, and achieve the goals of preventing distortion, facilitating control, and improving the wrinkle limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

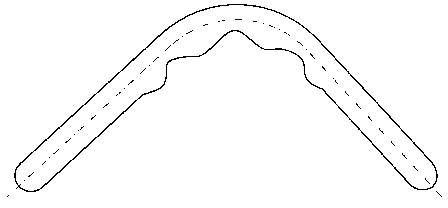

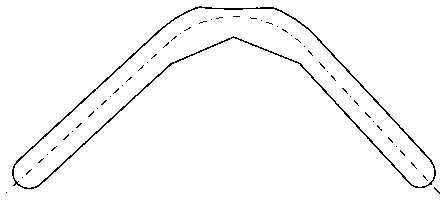

[0031] Such as Figure 4 As shown, a heat pipe bending manufacturing device includes a heating system for heating the heat pipe 50, a mechanical bending system for bending the heat pipe 50, a cooling system for cooling the bent heat pipe 50, and controlling the above-mentioned A control system in which the system performs sequential work.

[0032] The mechanical bending system includes a frame (not shown in the figure), a driving mechanism (not shown in the figure), a support mold 11 , a clamping mold 12 and a bending mold 13 . The supporting mold 11 is fixed on the frame, and the clamping mold 12 and the bending mold 13 are all connected on the driving mechanism. The clamping die 12 and the bending die 13 are driven to swing by the driving mechanism to realize the bending action. The drive mechanism can be in the form of an air cylinder or a hydraulic cylinder connected to a connecting rod mechanism, or in the form of a crank connecting rod mechanism driven by a motor, both...

Embodiment 2

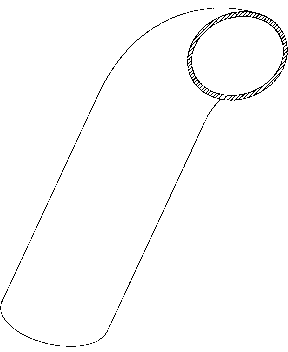

[0045] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the supporting mold 11, the clamping mold 12, and the bending mold 13 are provided with semicircular grooves matching the heat pipe 50; the driving mechanism adopts a hydraulic press As a power source, the hydraulic press is connected to the link mechanism to drive the clamping die 12 and the bending die 13 to swing.

[0046]The heat pipe 50 in this embodiment adopts a round copper tube with a diameter of 6.0mm, a wall thickness of 0.30mm, and a length of 200.0mm, and the two ends of the round copper tube are closed, and the inside is vacuumized and filled with 1.0ml of pure water as the working medium . A thermocouple 41 is attached to the side of the heat pipe 50 .

[0047] The operation steps of this embodiment are as follows:

[0048] S1: if Figure 5 As shown, the grooves of the support mold 11 and the bending mold 13 are snapped t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com