Method of sealing low/reverse piston fluid circuit within an automatic transmission case

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

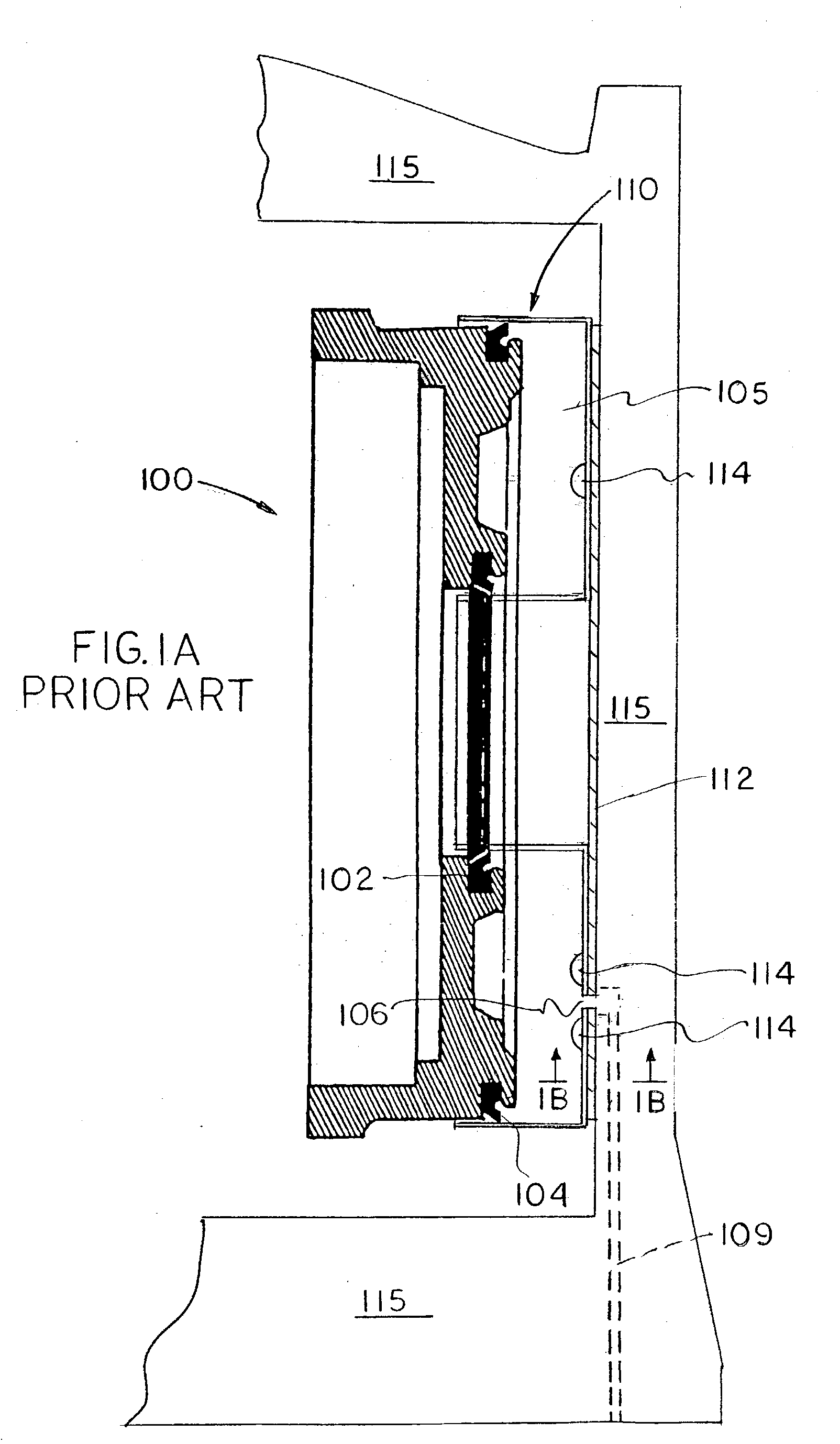

[0019] Prior to describing the present invention in detail, it may be useful to briefly review the structure and function of the low / reverse piston and piston retainer of the Chrysler A604 transmission wherein the present invention is utilized. Although the following disclosure is directed primarily to the Chrysler A604 transmission for purposes of explanation, it will be understood that the present inventive concept is applicable to transmissions of other manufacturers having a similar configuration and, as such, are considered to be within the scope of the present invention.

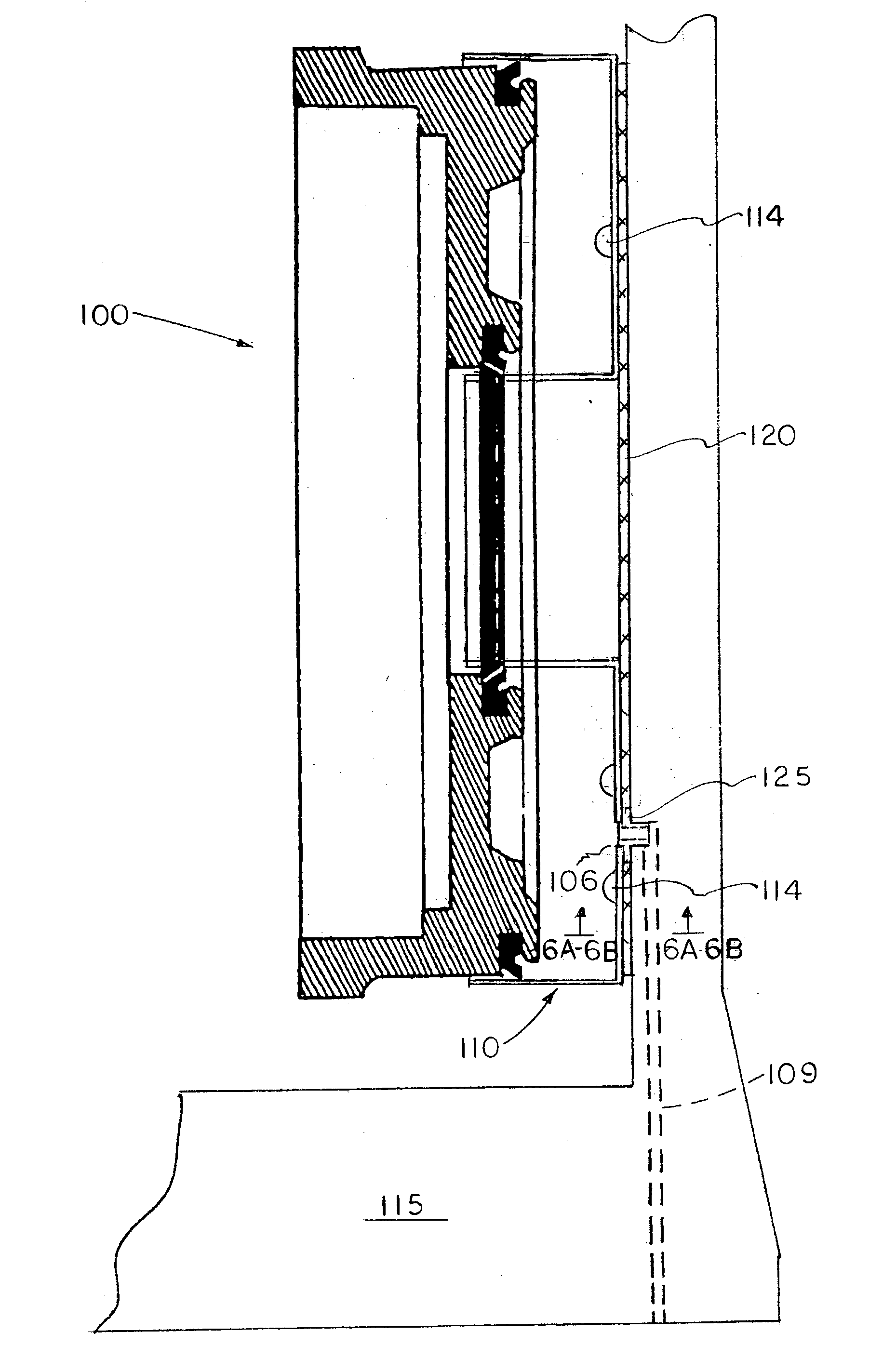

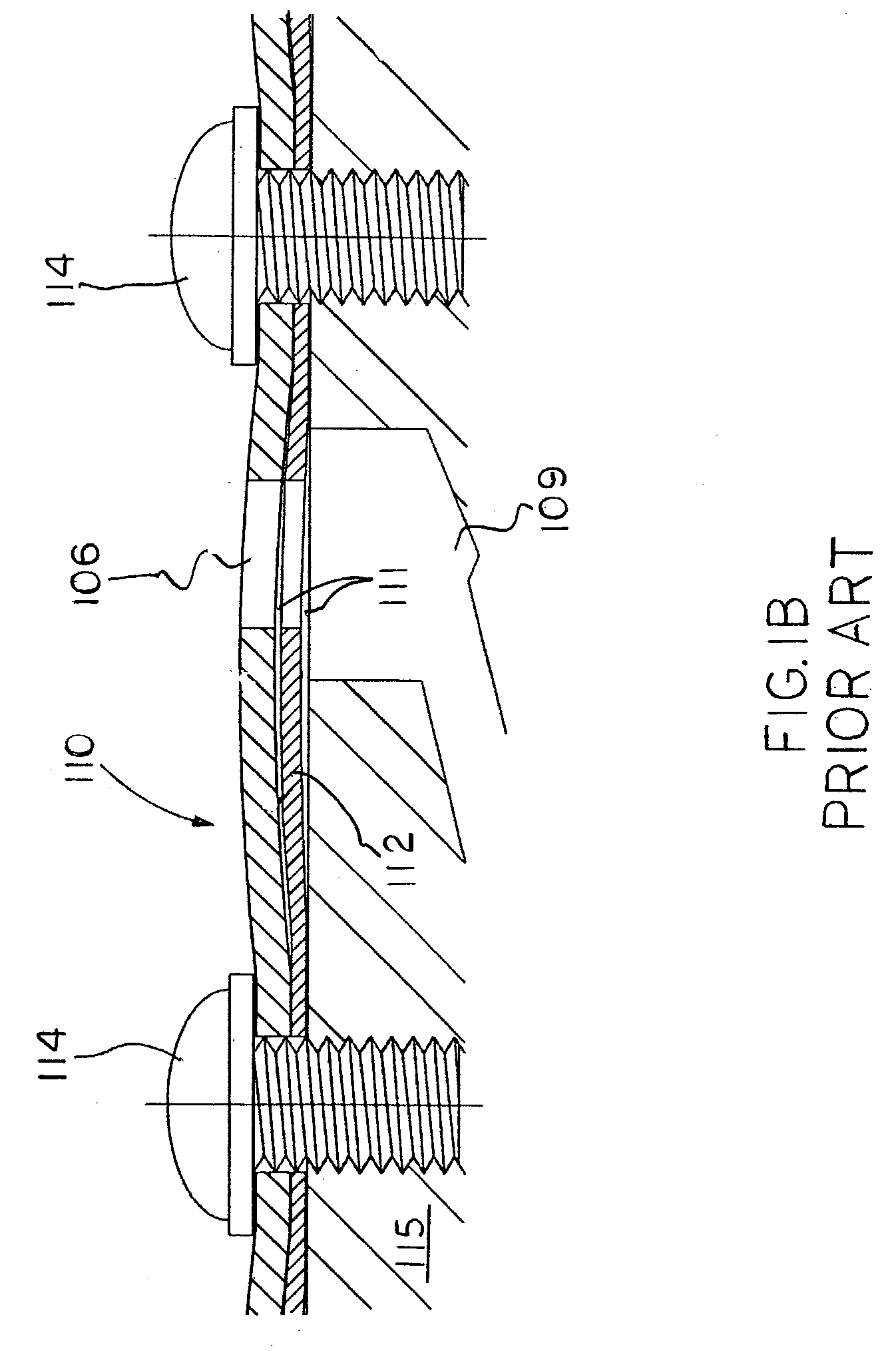

[0020] With reference to the drawings there is shown therein a prior art Chrysler A604 low / reverse piston, indicated generally at 100, installed within a piston retainer, indicated generally at 110, and illustrated in FIG. 1A. The OEM piston retainer 110 is a stamped sheet metal construction, which is designed to receive the low / reverse piston 100 in sliding engagement therein. Internal and external lip seals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com