Bending device for tube

A bending device and tube technology, applied in the field of high-efficiency bending devices for long tubes, can solve the problems of increasing the processing capacity, the bending time cannot be shortened, etc., to achieve the effect of shortening the bending time, improving the accuracy and efficiency, and reducing the displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

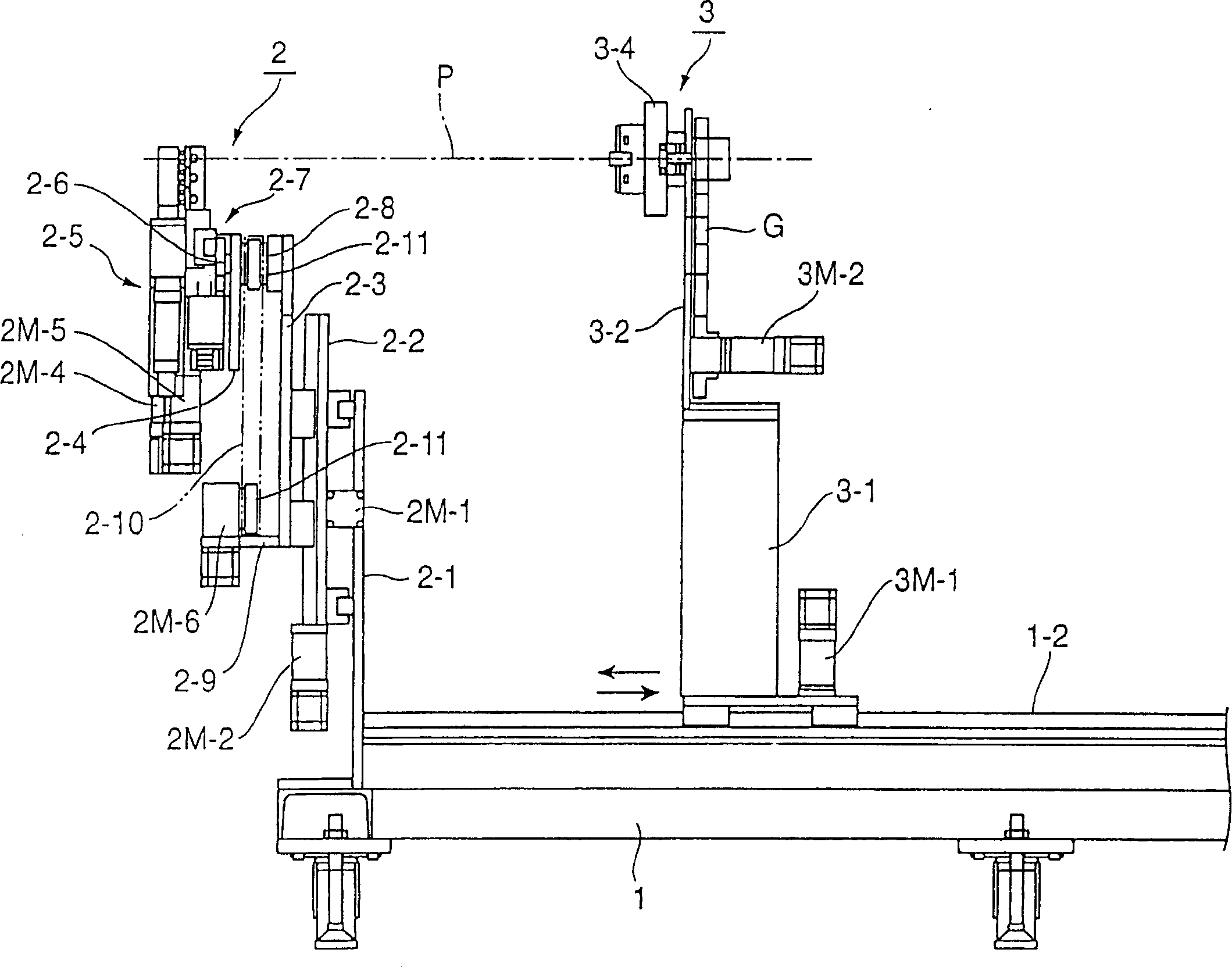

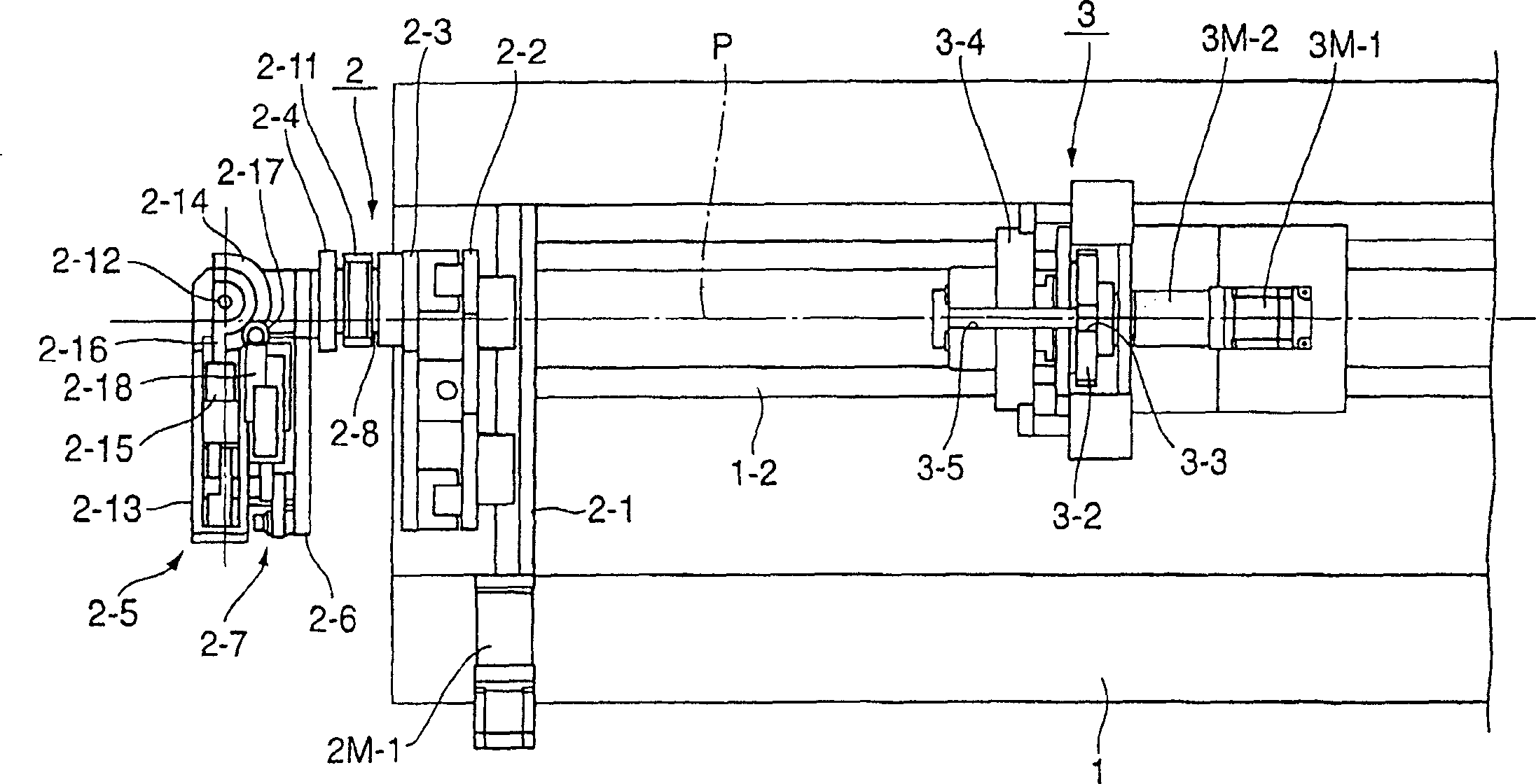

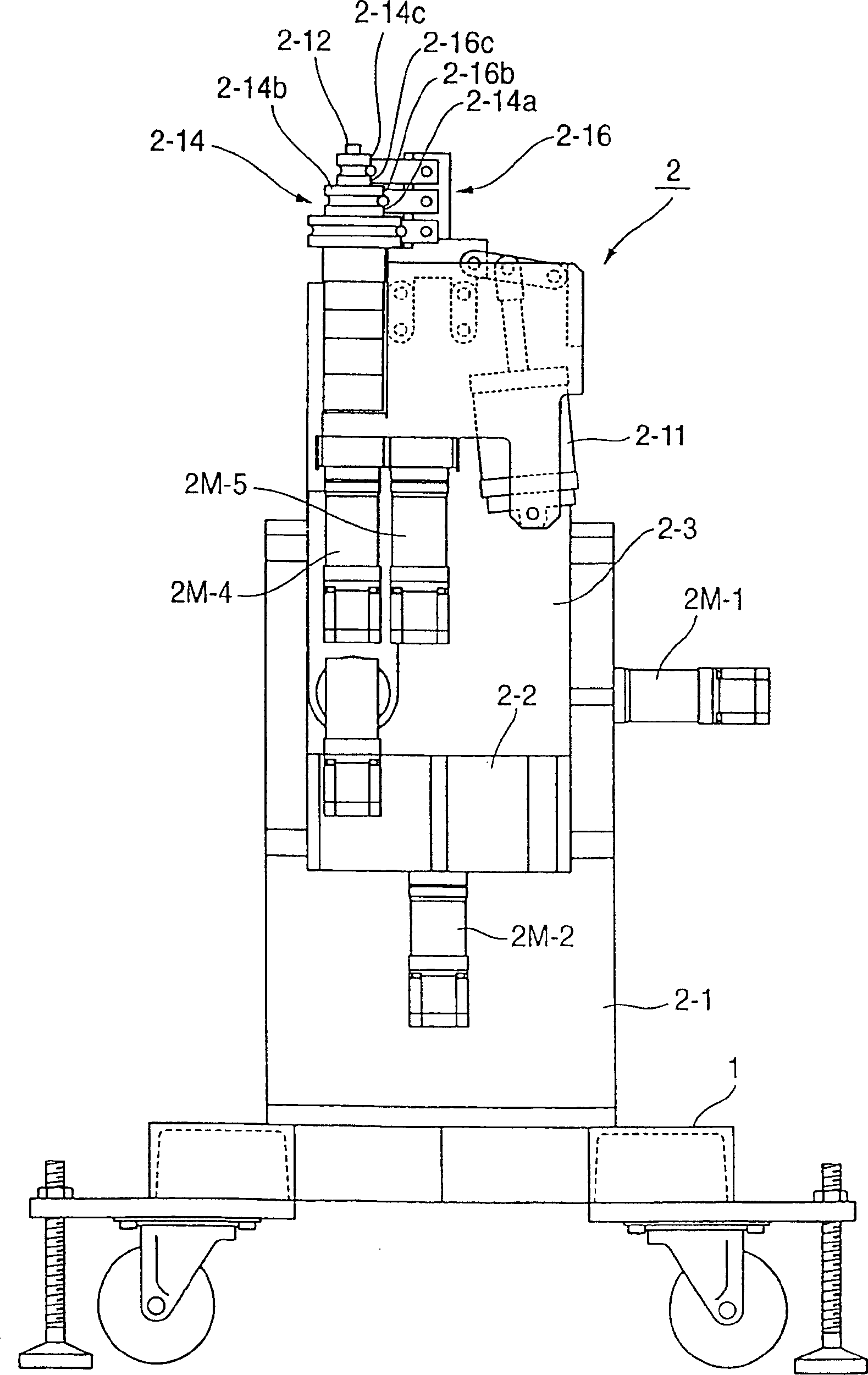

[0016] In the present invention, 1 denotes the base, 2 denotes the pipe bending assembly, 3 denotes the pipe twisting assembly and P denotes the processed pipe. Among them is a bending device composed of a pair of bending components with two functions of tension bending and compression bending, which will be described here by way of example.

[0017] That is to say, the pipe bending device according to the present invention includes a pipe bending assembly 2 and a pipe twisting assembly 3. Figures 1 to 6 The demonstration shows the pipe bending device with Figure 7 In both cases of the pipe bending device shown, the two components are mounted on the base 1 . exist Figures 1 to 6 In the illustrated pipe bending device, the pipe bending assembly 2 is fixedly mounted on the base 1, and the pipe twisting assembly 3 is placed on the base 1 so as to be movable along the axis center of the pipe P being processed. On the other hand, in Figure 7 In the shown pipe bending appara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com