Bidirectional movement vertical type steel-bar automatic bending machine

A two-way moving, bending machine technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of small positive and negative bending angle displacement, limited bending minimum size, easy to hurt the operator, etc., to achieve stable work, simple and easy operation. The effect of low cost of operation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

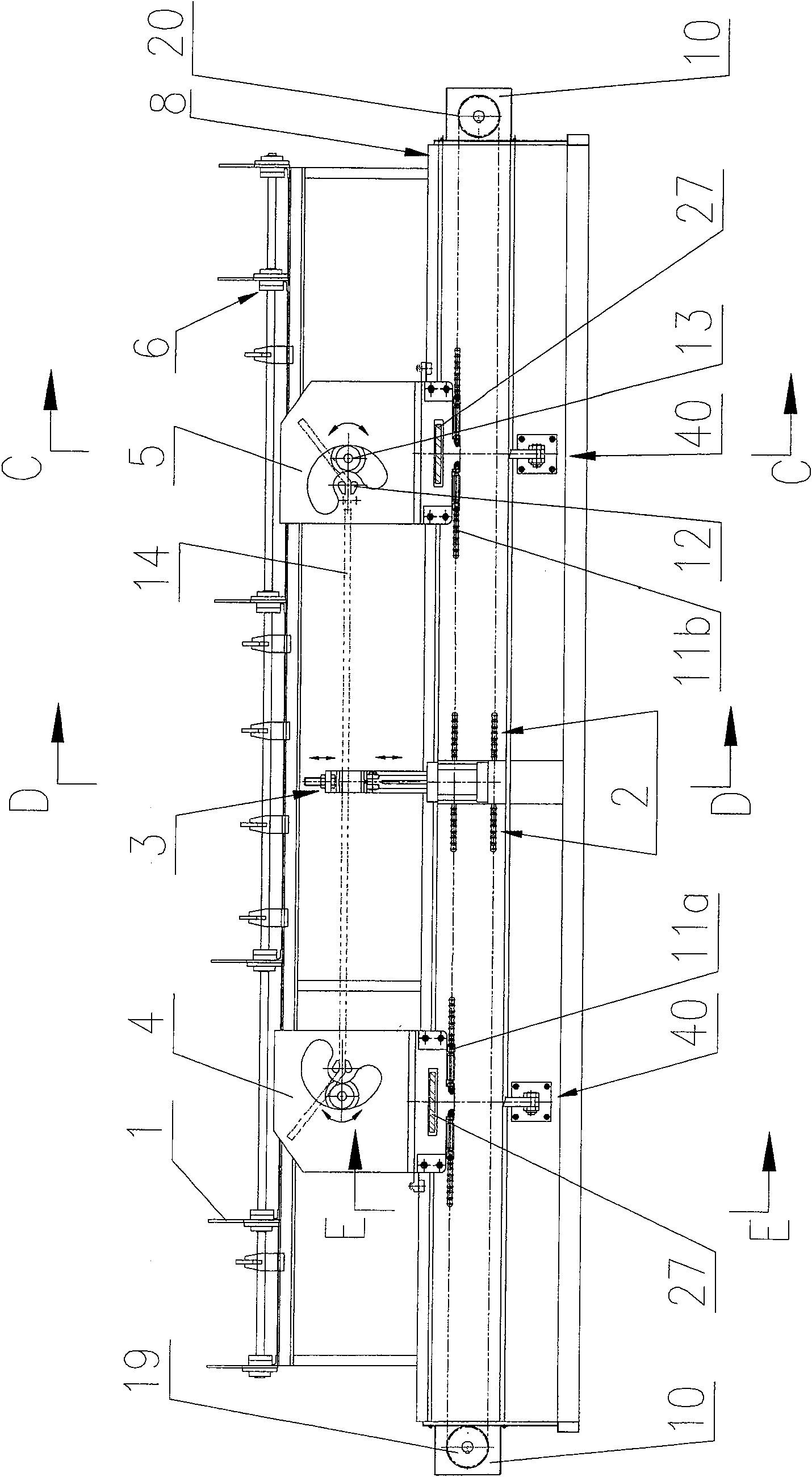

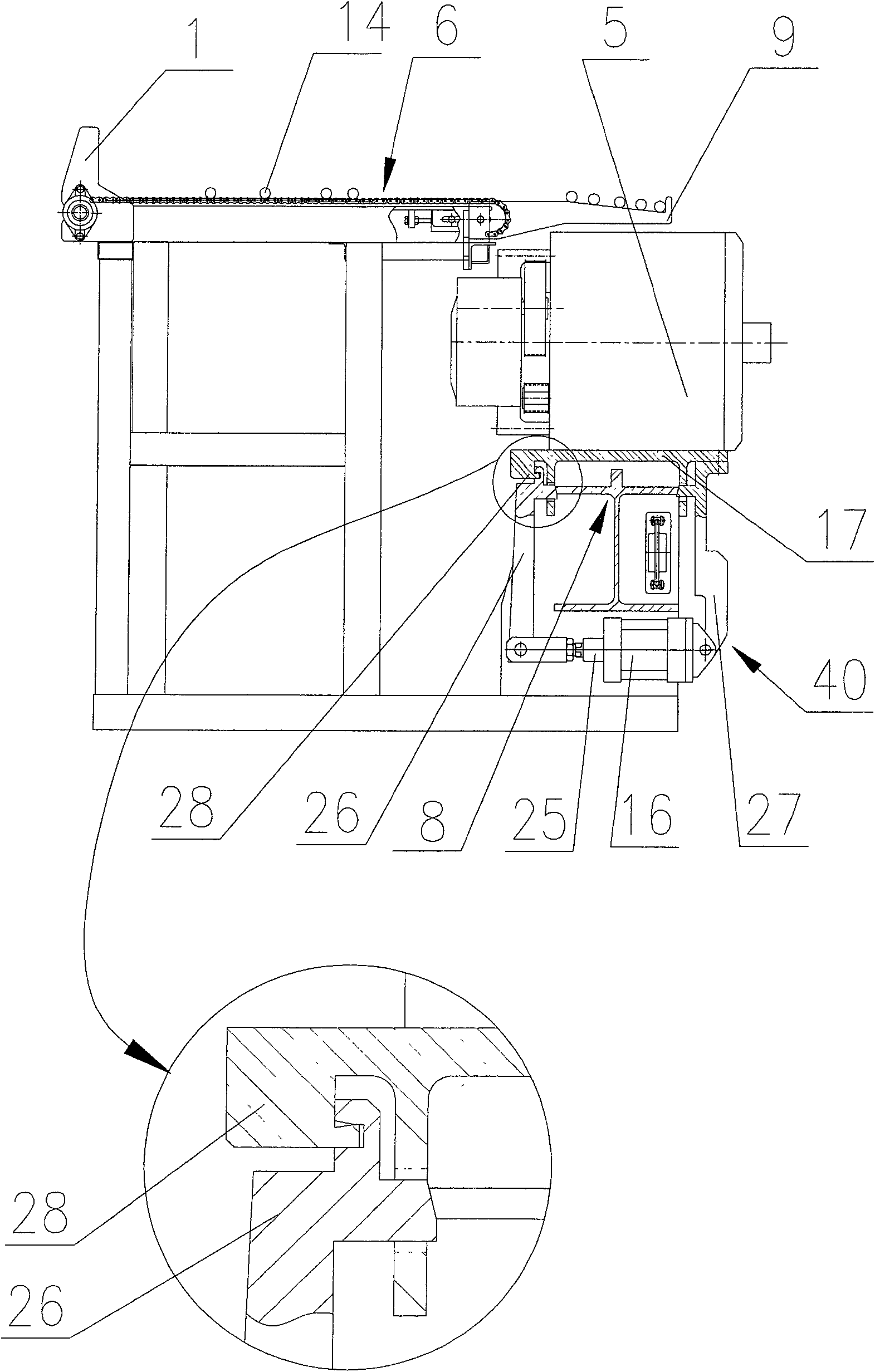

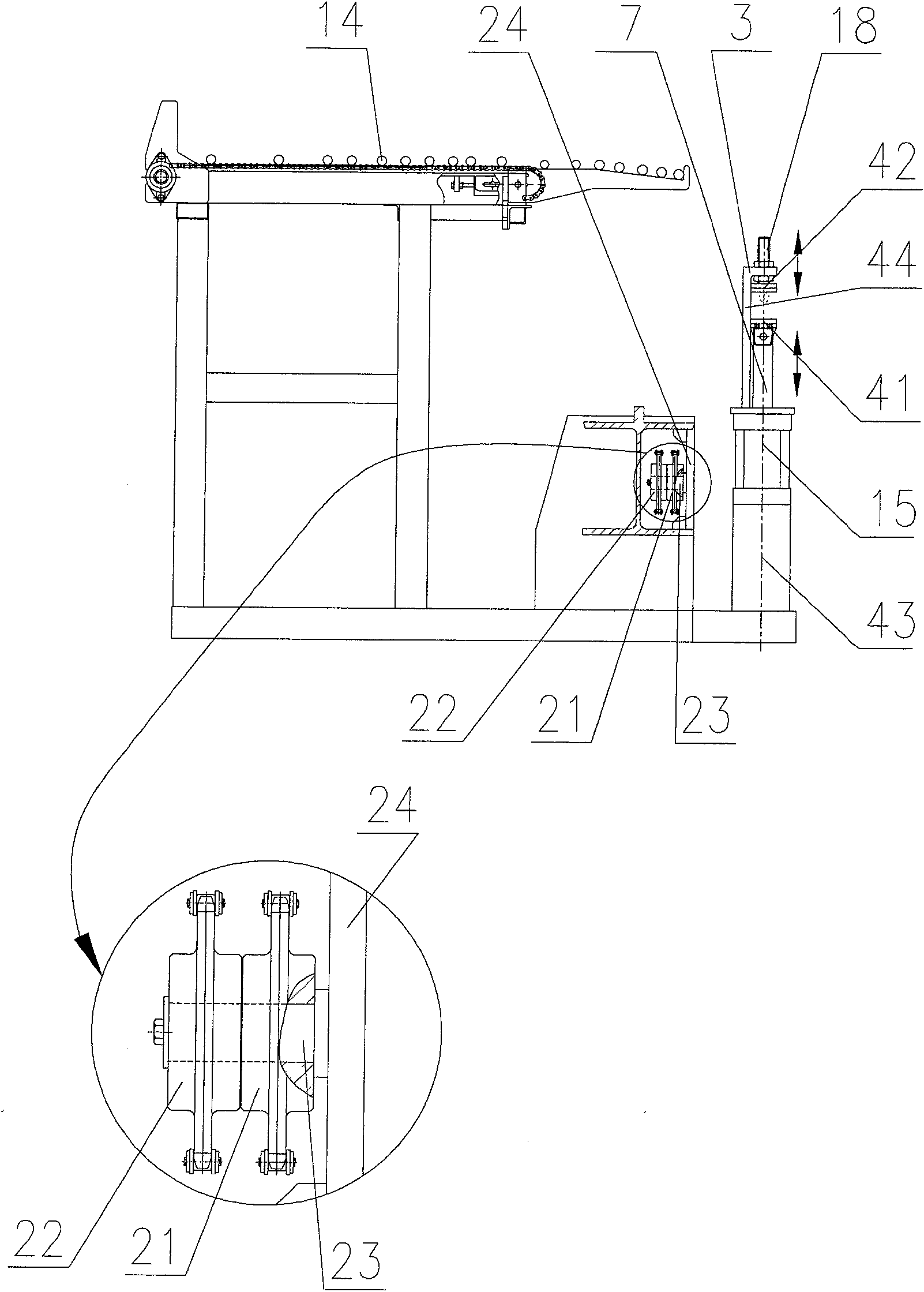

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] figure 1 is the front view of the present invention; figure 2 yes figure 1 Middle C-C sectional view; image 3 yes figure 1 Middle D-D sectional view; Figure 4 yes figure 1 Middle E-E sectional view.

[0021] The present invention provides a two-way mobile vertical automatic bending machine for steel bars. The two-way mobile vertical automatic steel bar bending machine includes: a track 8 , a steel bar automatic bending machine moving on the track 8 , and a steel bar pressing device 3 .

[0022] The steel bar pressing device 3 is arranged on one side of the track 8 .

[0023] The steel bar automatic bending machine includes the first steel bar automatic bending machine 4 and the second steel bar automatic bending machine 5 corresponding to the same structural position; the bottoms of the first steel bar automatic bending machine 4 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com