A three-roll inner cavity dirt cleaning system and treatment method

An inner cavity and dirt technology, which is applied to the three-roller inner cavity dirt cleaning system and treatment field, can solve the problems of equipment and pipeline corrosion and damage, remove scale, and sewage pollute the environment, etc., to avoid sewage discharge, improve production efficiency, and improve operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

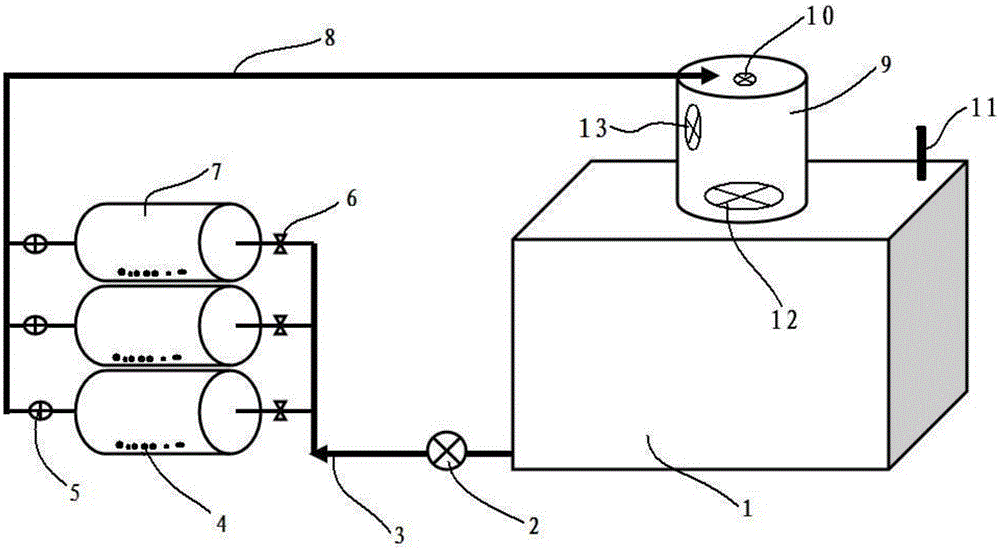

[0031] A three-roller internal cavity dirt cleaning system, including: purification pool 1, water supply pipe 3, booster pump 2, flow valve 6, descaling steel ball 4, three rollers 7, thermometer 5, return water pipe 8, stainless steel The filter screen 10, the cooling tower 9, the sedimentation tank 12 and the water supply pipe 11, the water outlet on the lower side of the purification pool 1 is connected to one end of the water supply pipe 3, and the other end of the water supply pipe 3 is connected to one end of the inner cavity of the three rollers 7. 7 Inside the cavity are placed a descaling steel ball 4 with a diameter of 8mm and three rollers. 7 The other end of the cavity is connected to the return water pipe 8, the other end of the return water pipe 8 is connected to the top water inlet of the cooling tower 9, and the bottom of the cooling tower 9 is connected to The top water inlet of the purification pool 1 is connected, and the bottom of the cooling tower is connect...

Embodiment 2

[0036] A three-roller inner cavity dirt cleaning system, including: purification pool 1, water supply pipe 3, booster pump 2, flow valve 6, descaling steel ball 4, three rollers 7, thermometer 5, return water pipe 8, stainless steel The filter screen 10, the cooling tower 9, the sedimentation tank 12 and the water supply pipe 11, the water outlet on the lower side of the purification pool 1 is connected to one end of the water supply pipe 3, and the other end of the water supply pipe 3 is connected to one end of the inner cavity of the three rollers 7. 7 Inside the cavity is placed a 15mm descaling steel ball 4 and three rollers. 7 The other end of the cavity is connected to the return water pipe 8, the other end of the return water pipe 8 is connected to the top water inlet of the cooling tower 9, and the bottom of the cooling tower 9 is connected to the The top water inlet of the purification pool 1 is connected, and the bottom of the cooling tower is connected with the top wa...

Embodiment 3

[0041] Using the above-mentioned three-roller inner cavity dirt cleaning system processing method, the steps are:

[0042] 1. Fill the purified pool with water through the water supply pipeline and start the booster pump to increase the pressure;

[0043] 2. After pressurization, the water will be sent to the flow valve of the three rollers through the water supply pipeline, and then sent to the three rollers through throttling distribution;

[0044] 3. Start the rotation of the three rollers, drive the internal descaling steel ball to rotate and rub against the walls of the inner cavity of the three rollers, so that the dirt will fall off by friction;

[0045] 4. The return water passes through the thermometer, observes the temperature change, and adjusts the water inlet volume by adjusting the three rollers water inlet flow valve to cool the three rollers;

[0046] 5. The backwater is sent to the cooling tower through the backwater pipe along with the dirt and filtered by the filter; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com