A derrick moving device

A technology for moving devices and derricks, which is applied in the field of special trailers for new drilling rig derricks, can solve the problems of uneconomical, complex structure, time-consuming and labor-intensive, etc., and achieve the effect of simple structure, convenient operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

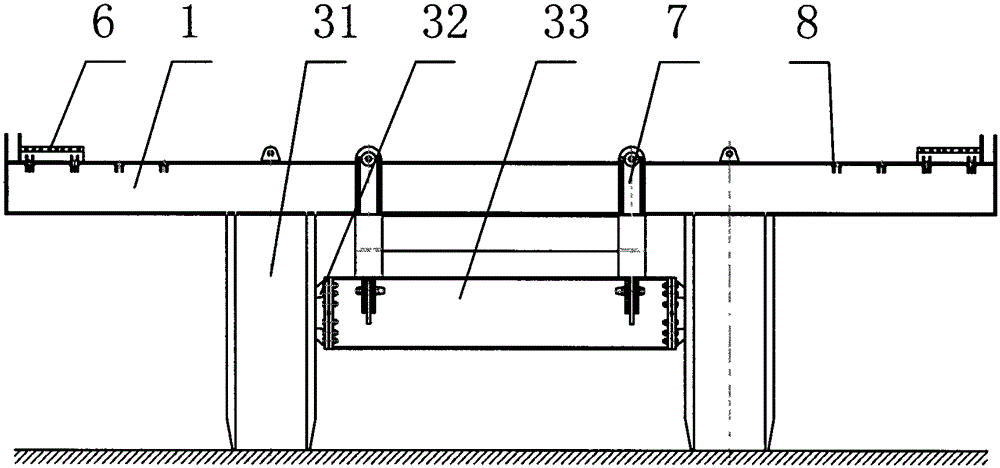

[0028] exist figure 1 , figure 2 , Figure 7 , Figure 8 , Figure 9 and Figure 10 Among them, a derrick transfer device is mainly composed of a load-bearing beam 1, a vehicle frame assembly 2, an axle assembly 3, an outrigger assembly 4 and a draw pin 5, and the outrigger assembly 4 is arranged on the axle assembly 3 The vehicle frame assembly 2 lower ends of the front and rear direction. The axle assembly 3 is mainly composed of tires 31, half shaft assembly 32 and half shaft connecting beam 33, wherein the half shaft connecting beam 33 is bolted to the half shaft assembly 32, and the use of this detachable connection is mainly for the convenience of Repair axle assembly 2 parts. Vehicle frame assembly 2 is fixedly connected on the semi-axis connecting beam 33, and the connection between them can adopt the detachable connection of pin shaft, and also can adopt the non-detachable connection mode of welding connection. The front end of the vehicle frame assembly 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com