Environment-friendly all-around quick painting equipment

A kind of painting equipment and all-round technology, applied in the field of painting, can solve the problems of not having harmful formaldehyde adsorption function, paint is harmful to human health, affecting the speed of painting, etc., and achieves the effect of simple structure, reduced labor intensity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

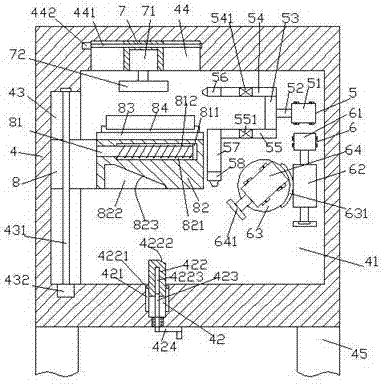

[0035] When automatic painting and automatic circular repairing work are required, the workpiece is installed in the clamping turntable 84, and then the first driving device 432 drives the first screw 431 to reverse, so that the first screw 431 drives the first sliding block 8 And the painting station 82 on the right side of the first sliding joint block 8 moves upwards along the first sliding joint groove 43 until the top end surface of the workpiece abuts against the forward painting head 72. At this time, the first control valve 541 is controlled to open and the second control valve The valve 551 is closed, and at the same time, the second screw rod 441 is driven to rotate left and right by the second driving device 442, thereby realizing the left and right motion painting work. At this time, the rotation of the handle 424 drives the third screw rod 423 to reverse, so that the third screw rod 423 drives the top block 422 moves upward until the convex block 4221 moves to the ...

Embodiment 2

[0037] When it is only necessary to complete the work of spraying paint on the top of the workpiece, the workpiece is installed in the clamping turntable 84, and then the first screw rod 431 is driven to reverse by the first driving device 432, so that the first screw rod 431 drives the first sliding block 8 and the first screw rod 431. The painting platform 82 on the right side of the sliding block 8 moves upwards along the first sliding groove 43 until the top end surface of the workpiece abuts against the forward painting head 72. At this time, the first control valve 541 is controlled to open and the second control valve 551 is closed. At the same time, the second driving device 442 drives the second screw rod 441 to rotate left and right. After the painting is completed, the first driving device 432 drives the first screw rod 431 to rotate, so that the first sliding block 8 is located in the first sliding groove 43. The bottom position, and finally take out the workpiece. ...

Embodiment 3

[0039] When it is only necessary to repair the paint work in the circumferential direction, the workpiece is installed in the clamping turntable 84, and the third screw rod 423 is driven to reverse by the rotating handle 424, so that the third screw rod 423 drives the top block 422 to move upward, so that the top block 422 is gradually extended. to the fourth sliding groove 822 until the second slope surface 4222 abuts against the right section of the first slope surface 823. At this time, the first control valve 541 is controlled to be closed and the second control valve 551 is opened. Continue to pass through the rotating handle 424 Drive the third screw rod 423 to reverse, so that the third screw rod 423 drives the top block 422 to move upwards. At this time, the second slope surface 4222 cooperates with the first slope surface 823, so that the painting table 82 overcomes the active force of the tension spring 812 and gradually faces to the right. Move sideways until the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com