Feeding device

A feeding device and an integrated technology, which is applied in the directions of packaging, transportation and packaging, and external frames, can solve the problem that the forklift cannot lift the anchor rod upwards, and achieve the effect of improving transportation efficiency and strengthening load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

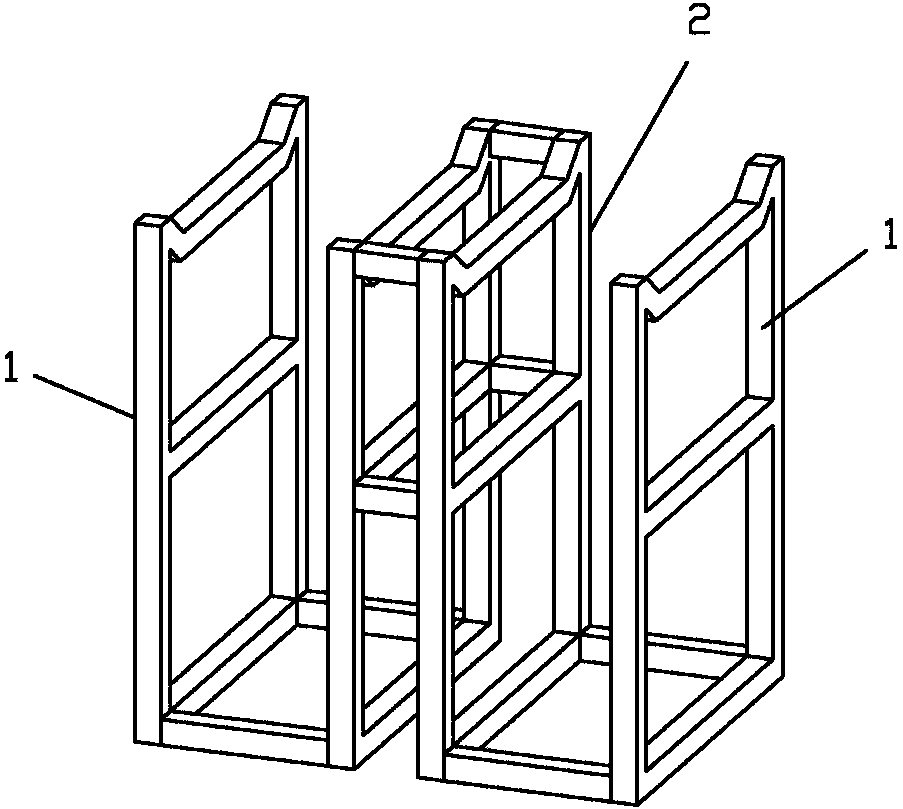

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but does not constitute any limitation to the present invention. figure 1 As shown, the present invention includes a bracket, and the bracket is composed of a middle bracket 2 and a bracket 1 on both sides, and the middle bracket 2 and the bracket 1 on both sides are only connected as a whole at the bottom. For the convenience of collecting the blanks of the anchor rods, the tops of the middle bracket 2 and the side brackets 1 adopt a "U"-shaped groove with the same cross-section, and the blanks of the anchor rods cut out are automatically rolled into the grooves. In order to strengthen the supporting strength, the middle support 2 can also be formed by connecting two basic units, which have the same structure as the side support 1 . In the present invention, the middle bracket 2 and the two side brackets 1 are only connected at the bottom. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com