Stamping die waste discharging mechanism and stamping die thereof

A stamping die and discharge mechanism technology, applied in the field of stamping manufacturing, can solve the problems of being stuck on the mold, inconvenient operation, and restricting stamping production efficiency, and achieve the effect of avoiding adhesion, avoiding damage, and facilitating the transportation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

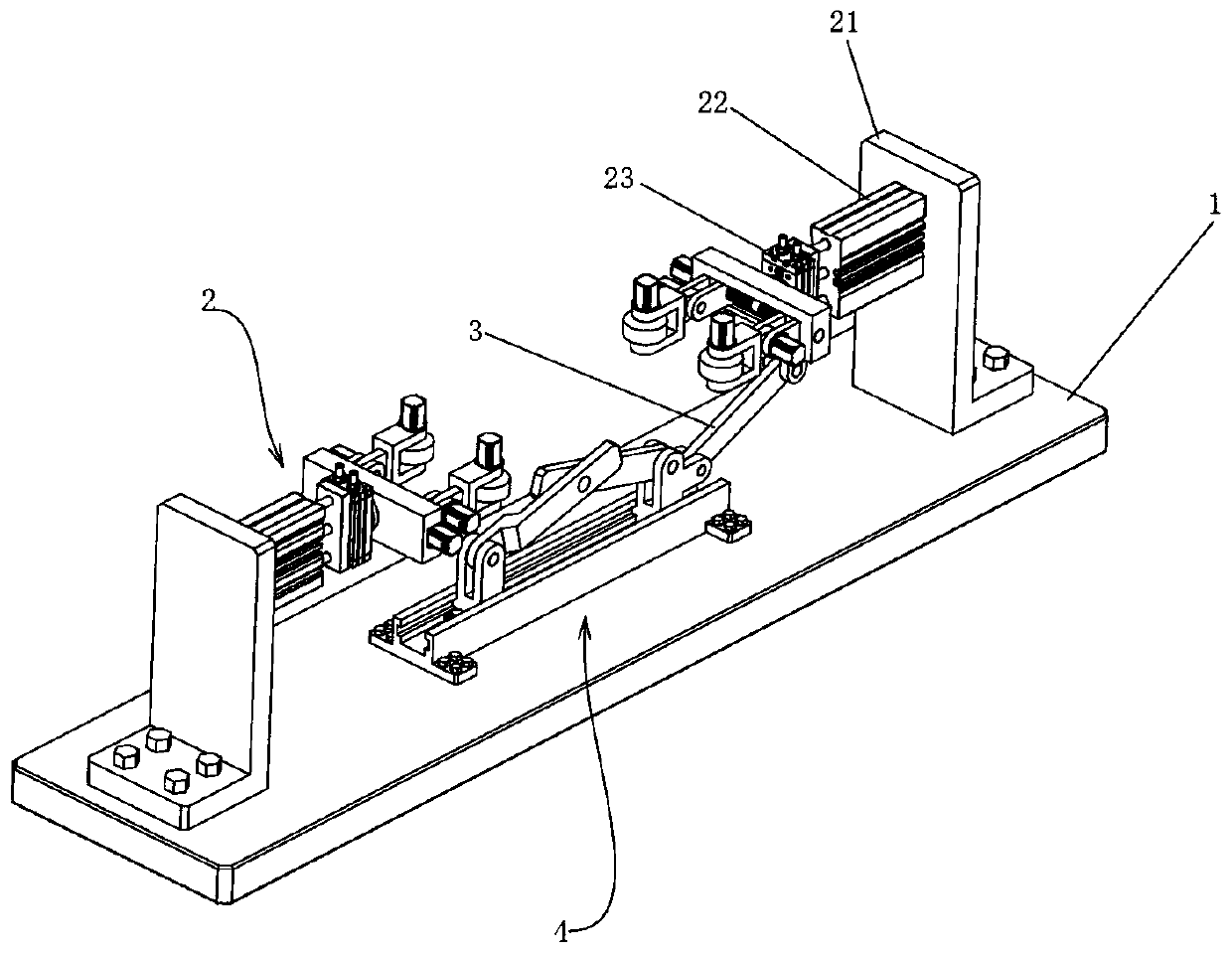

[0022] see Figure 1 to Figure 3 , the present invention provides a technical solution:

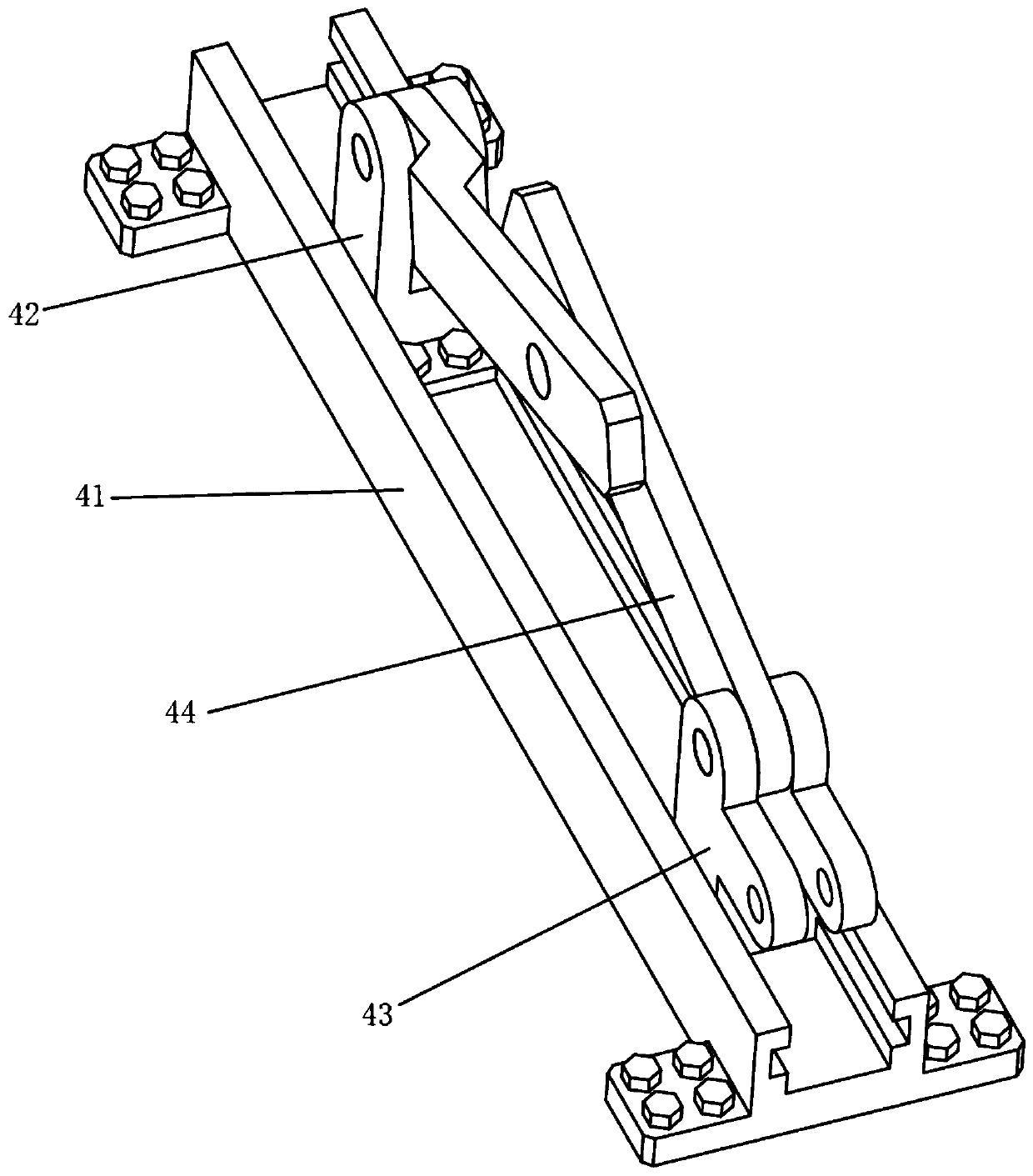

[0023] A stamping die waste material discharge mechanism, including a bottom plate 1, a conveying mechanism 2, a connecting rod 3 and a lifting mechanism 4, wherein:

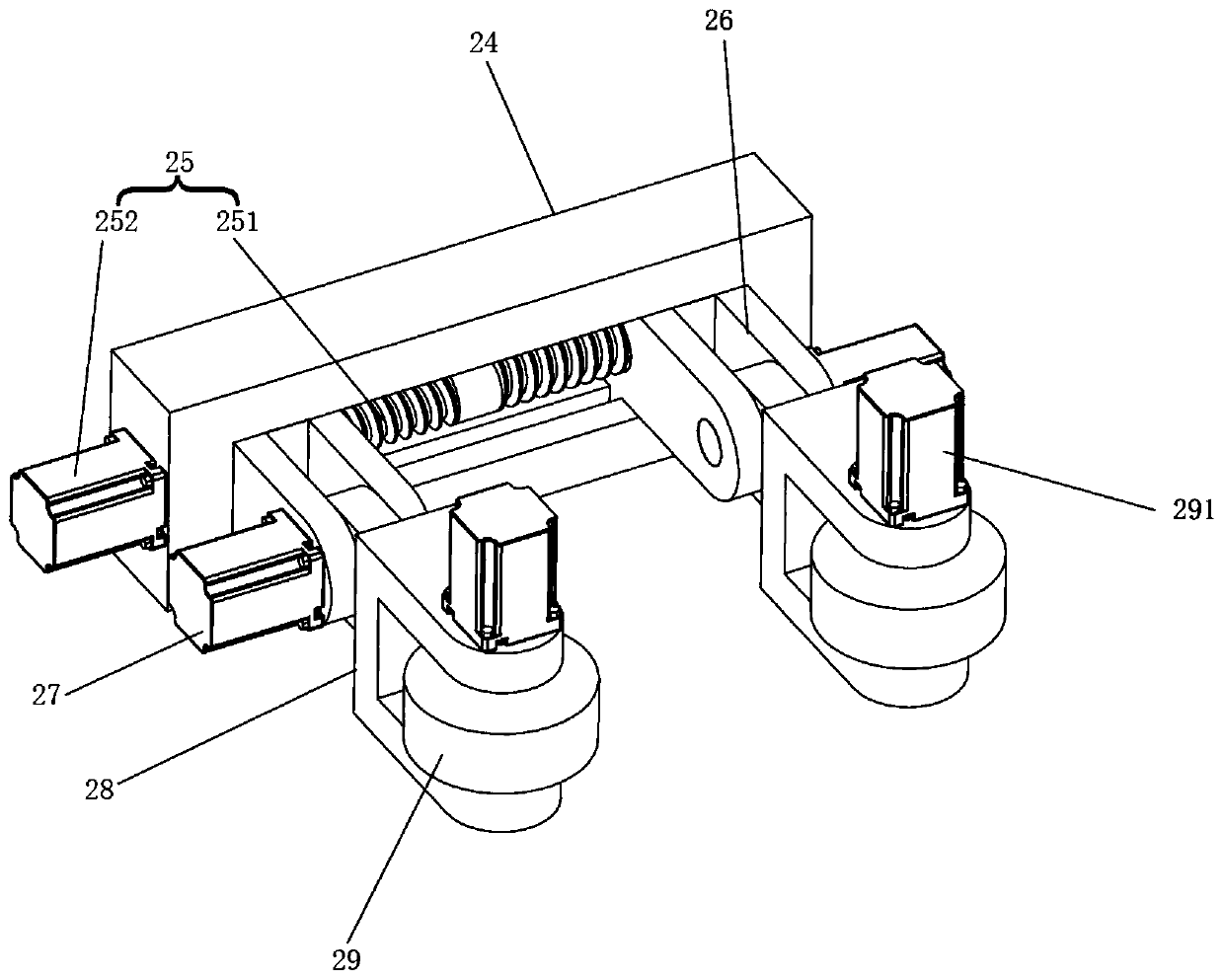

[0024] The two conveying mechanisms 2 are oppositely arranged, and the conveying mechanism 2 includes a support frame 21, a biaxial cylinder 22, a rotary cylinder 23, a mounting frame 24, a linear drive mechanism 25, a slider I 26, a steering gear 27, a roller mounting frame 28, a roller 29 and The motor I291, the support frame 21 is fixedly installed on the base plate 1 by bolts, the double-axis cylinder 22 is fixedly installed on the support frame 21 by bolts, the power output end of the double-axis cylinder 22 is fixed with a rotary cylinder 23 by bolts, and the installation frame 24 passes Bolts are fixedly installed on the power output end of the rotary cylinder 23, so the mounting frame 24 can rotate under the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com