Spinning machine

A technology for spinning machines and spun yarns, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve problems such as longer time, long time for jointing operations, and difficulty in catching spun yarns. The effect of reducing time-consuming and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

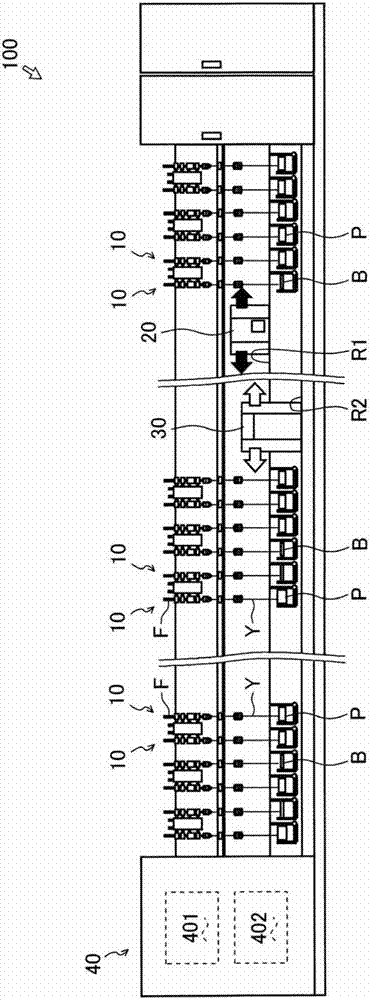

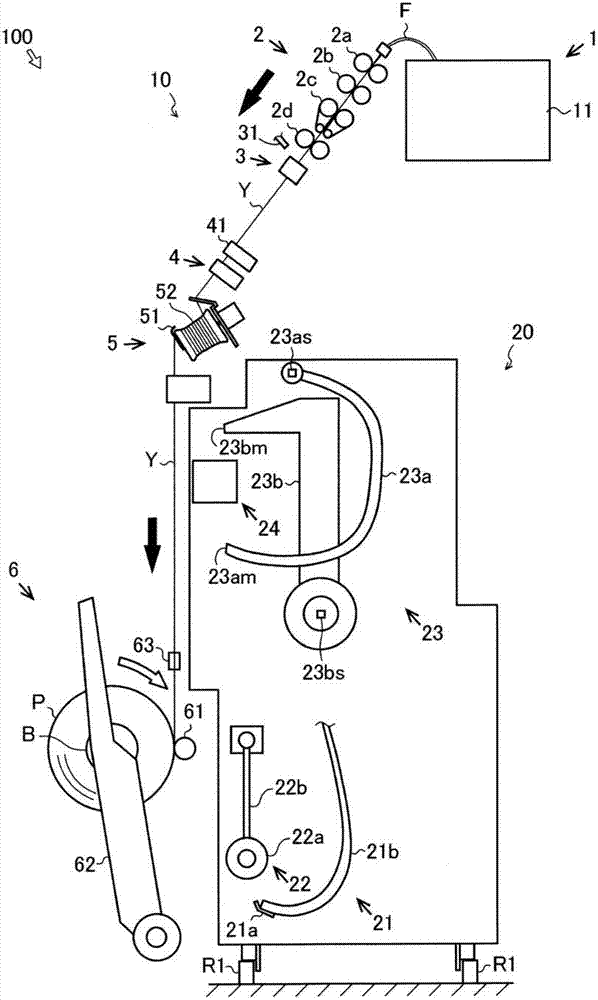

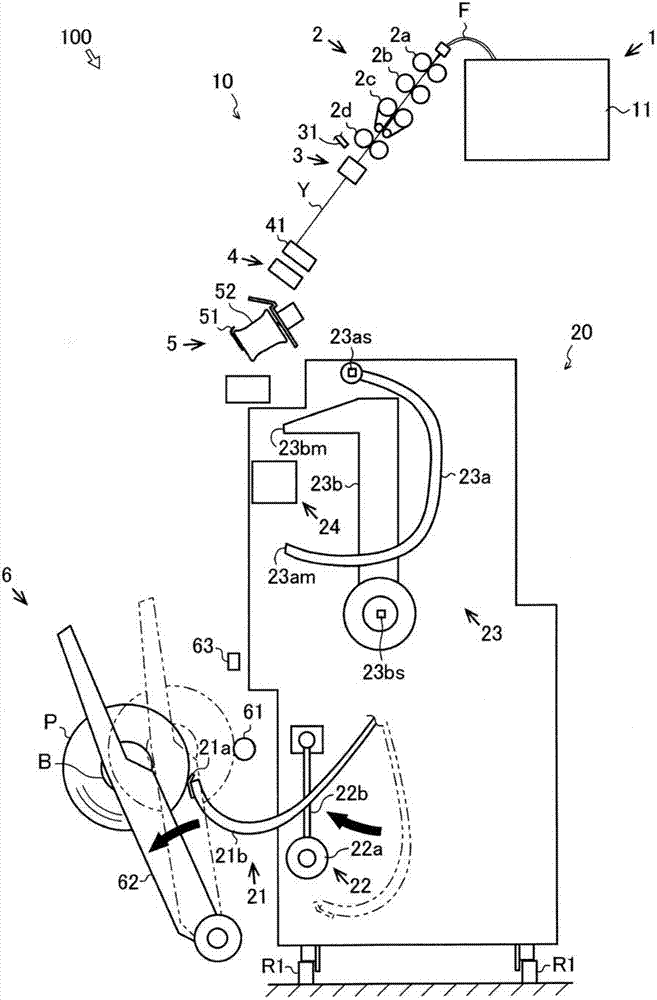

[0037] First, refer to figure 1 The spinning machine 100 will be briefly described. A blacked-out arrow shown in the figure indicates the traveling direction of the work vehicle 20 . In addition, blank arrows shown in the figure indicate the traveling direction of the doffing cart 30 .

[0038] The spinning machine 100 includes a plurality of spinning units 10 . The spinning machine 100 is provided with a work cart 20 , a doffing cart 30 , and a control device 40 .

[0039] The spinning unit 10 is capable of drafting a fiber bundle F, and can manufacture a spun yarn Y by twisting the drafted fiber bundle F. The spinning unit 10 can manufacture a package P by winding the spun yarn Y. In addition, the detailed structure of the spinning unit 10 will be described later.

[0040]The work cart 20 can travel along a rail R1 extending in the direction in which the spinning units 10 are arranged. When the spun yarn Y becomes discontinuous in one spinning unit 10, the operation ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com