Gap self-regulating device for multiple-disc wet brake

A wet brake and brake technology, applied in the direction of slack adjuster, etc., can solve the problems such as the inability to provide compensation clearance, the risk of affecting the normal operation of the brake, and the difficulty of ensuring stable interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

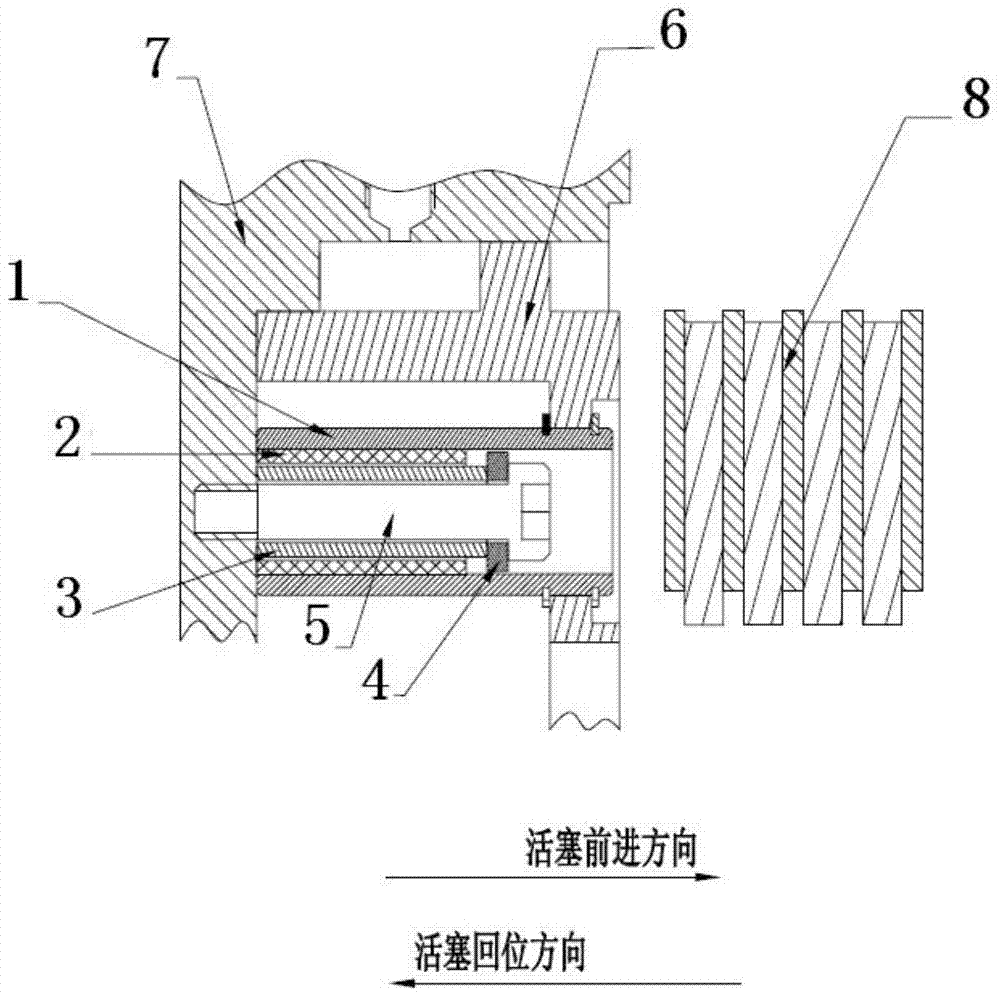

[0010] Such as figure 1 As shown, the main components suitable for the multi-disc wet brake clearance self-adjusting device are: bushing 1, elastic body 2, sliding sleeve 3, retaining shoulder 4, compensation guide pin bolt 5; elastic body 2 is installed on the bushing with interference 1; the compensating guide pin bolt 5 is installed with the shoulder 4, the sliding sleeve 3 and the elastic body 2 in sequence;

[0011] When the multi-disc wet brake is working, the piston 6 moves axially and presses against the friction pair 8 so that the initially set braking gap between the piston 6 and the friction pair 8 will be eliminated, generating braking torque for braking.

[0012] With the repeated braking of the multi-disc wet brake, the friction pairs 8 will wear out, and there is still a wear gap between the friction pairs 8 when the piston 6 moves to the initially set braking gap. In order to generate the braking torque, the piston 6 must continue to move axially to eliminate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com