Protection cover for sextant center shaft

A central shaft and protective cover technology, which is applied in the field of sextant central bearing devices, can solve the problems of increasing maintenance costs, loose nuts, and affecting measurement accuracy, so as to reduce maintenance costs, prevent accidental loosening, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

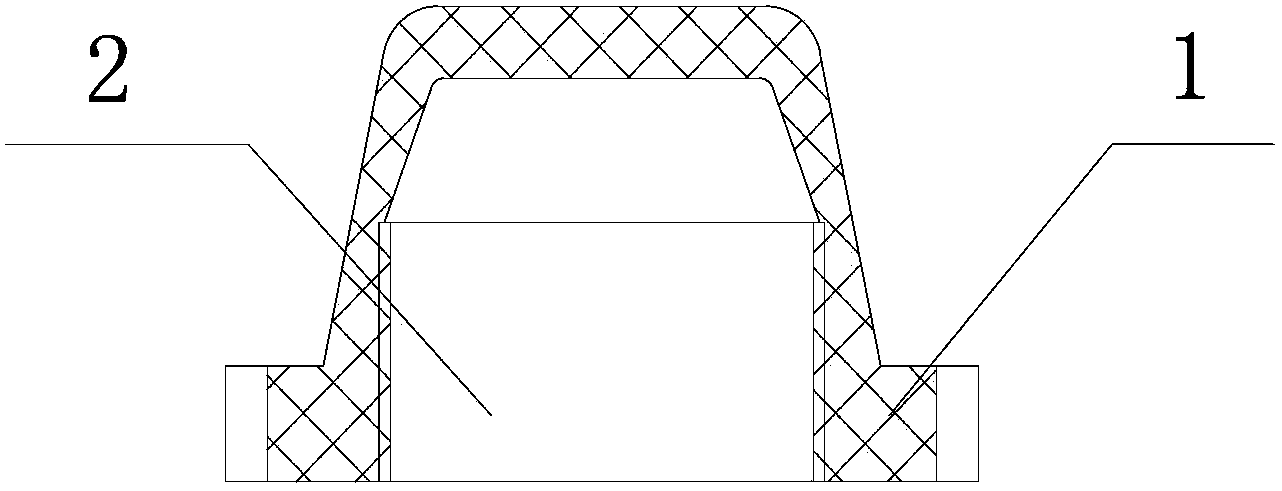

[0010] See figure 1 As shown, a protective cover for the central axis of a sextant, the cover 1 is fixed on the central axis with a nut for protecting the nut on the central axis, and the cover 1 is provided with a Groove 2 where the size of the nut wants to match; the protective cover is fixed on the nut on the central shaft by sticking; or the protective cover is fixed on the nut on the central shaft by clamping .

[0011] The specific embodiments described above have further described the purpose, technical solutions and beneficial effects of the present invention in detail. It should be understood that the above descriptions are only specific embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com