Decoration frame of high-precision capacitive touch screen

A technology of capacitive touch screen and decorative frame, which is applied in electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as affecting the graphics process and reducing the accuracy of circuit graphics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

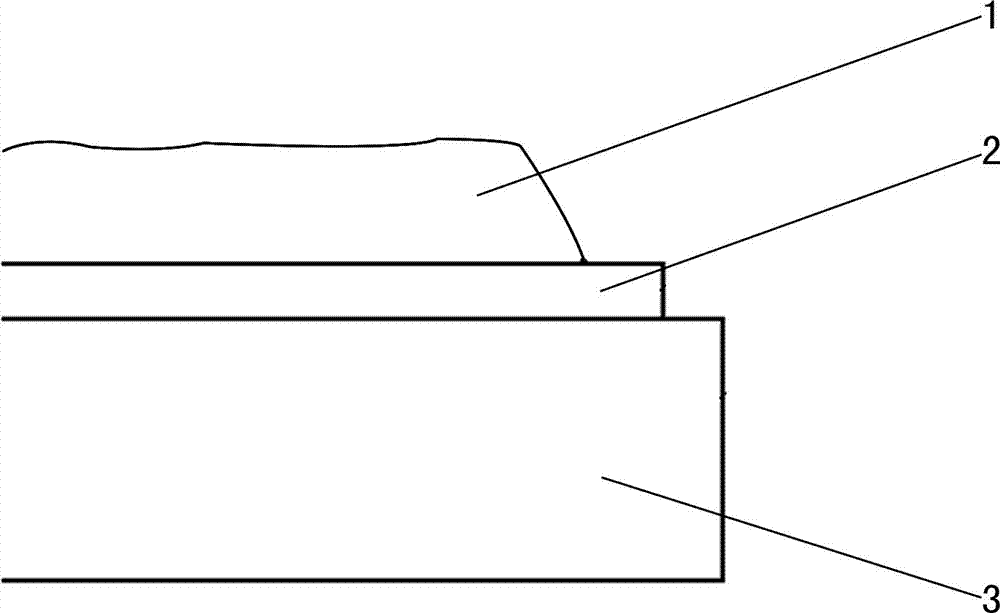

[0046] like figure 1 and figure 2 As shown, the decorative frame of this high-precision capacitive touch screen includes a main body layer 1 and a scattering layer 2, and the scattering layer 2 and the main body layer 1 are sequentially arranged on a transparent substrate 3; the scattering layer 2 is a white paint with a haze greater than 80%. layer, the scattering layer 2 is made by the yellow light process, the thickness of the scattering layer 2 is 4 μm; the main layer 1 is an ink layer, the main layer 1 is within the range of the scattering layer 2, and the thickness of the main layer 1 is 4 μm.

[0047] The total thickness of the main body layer 1 and the scattering layer 2 is 8 μm, which is far thinner than the prior art 30 μm, and is suitable for the manufacture of an integrated capacitive touch screen; the scattering layer 2 is made by the yellow light process, and the lines on the edge of the scattering layer 2 are relatively smooth. Therefore, the decorative frame...

Embodiment 2

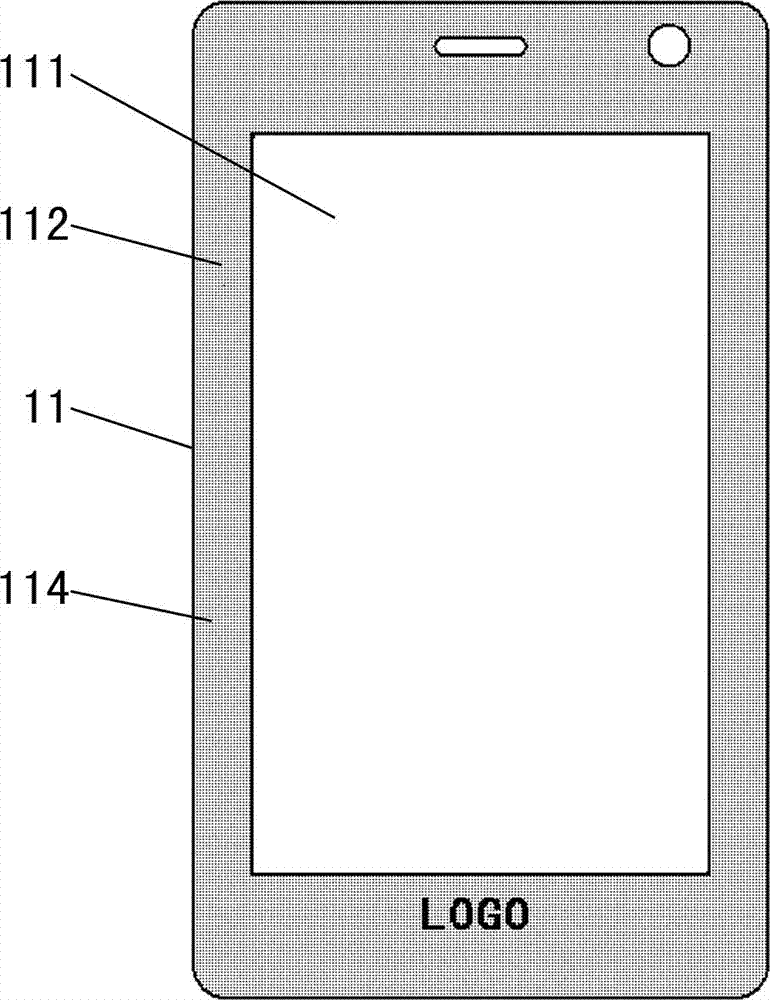

[0050] like image 3 and Figure 4 As shown, the front and back schematic diagrams of an integrated capacitive touch screen with a white decorative frame, the integrated capacitive touch screen only uses a transparent substrate 11, and the inner side of the transparent substrate 11 can be divided into a middle area 111 and a peripheral area 112. A sensing column composed of a plurality of triangular sensing electrodes 113 is fabricated in the middle area 111 , and a touch action of a touch object such as a finger can be sensed according to a known capacitive touch sensing principle. The peripheral area 112 is provided with a white decorative frame 114, such as Figure 5 , Image 6 As shown, the white decorative frame 114 includes a main body layer 1141 and a white scattering layer 1142; the scattering layer 1142 and the main body layer 1141 are sequentially arranged on the transparent substrate 11, the main body layer 1141 is within the range of the scattering layer 1142, an...

Embodiment 3

[0082] Schematic diagram of the front and back of the white all-in-one capacitive touch screen, such as Figure 14 , 15 , Figure 17 , Figure 18 As shown, the capacitive touch screen uses only one transparent substrate 22 , and the inner surface of the transparent substrate 22 can be divided into a middle area 221 and a peripheral area 222 . A sensing array composed of X sensing electrodes 223 and Y sensing electrodes 224 is formed in the middle area 221 , which can sense touch actions of touch objects such as fingers through known capacitive touch sensing principles. At the intersection of the X sensing electrodes 223 and the Y sensing electrodes 224, a jumper connection structure 225 is provided, wherein the adjacent Y sensing electrodes 224 are connected to each other through a bottom connection 2251 made of a transparent conductive film (ITO), An insulating block (layer) 2252 is fabricated on the bottom connection 2251 , and adjacent X sensing electrodes 223 straddle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com