Double-power double-winding voltage-reduction two-time voltage-regulation rectifier transformer set suitable for different voltage levels

A technology of voltage regulating transformer and rectifier transformer, which is applied in the direction of transformer/inductor coil/winding/connection, emergency power supply arrangement, electrical components, etc., and can solve the problems of power supply in isolated grids that do not allow networking, so as to save investment costs and Effects of operation and maintenance management costs, improvement of system reliability, and simplification of system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

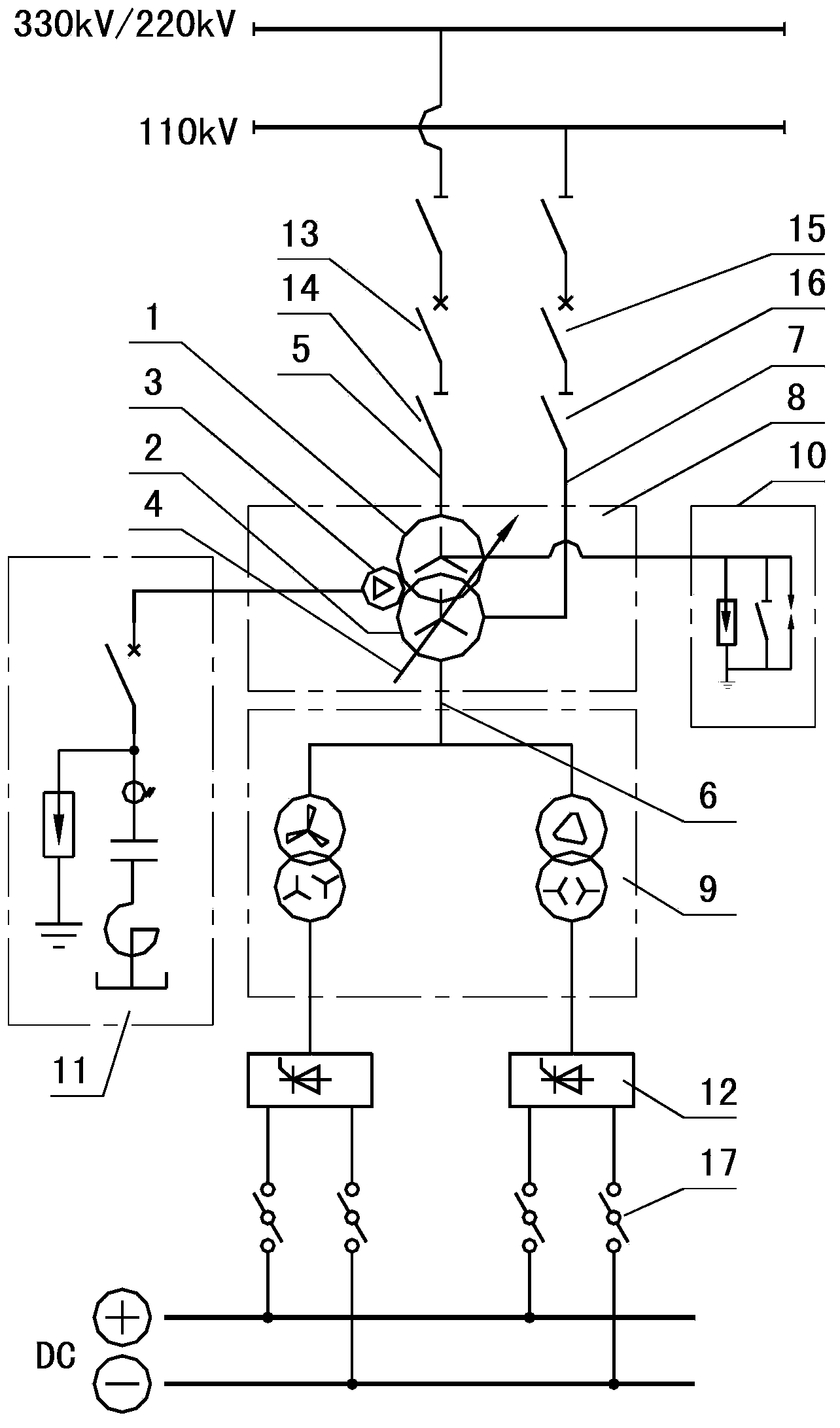

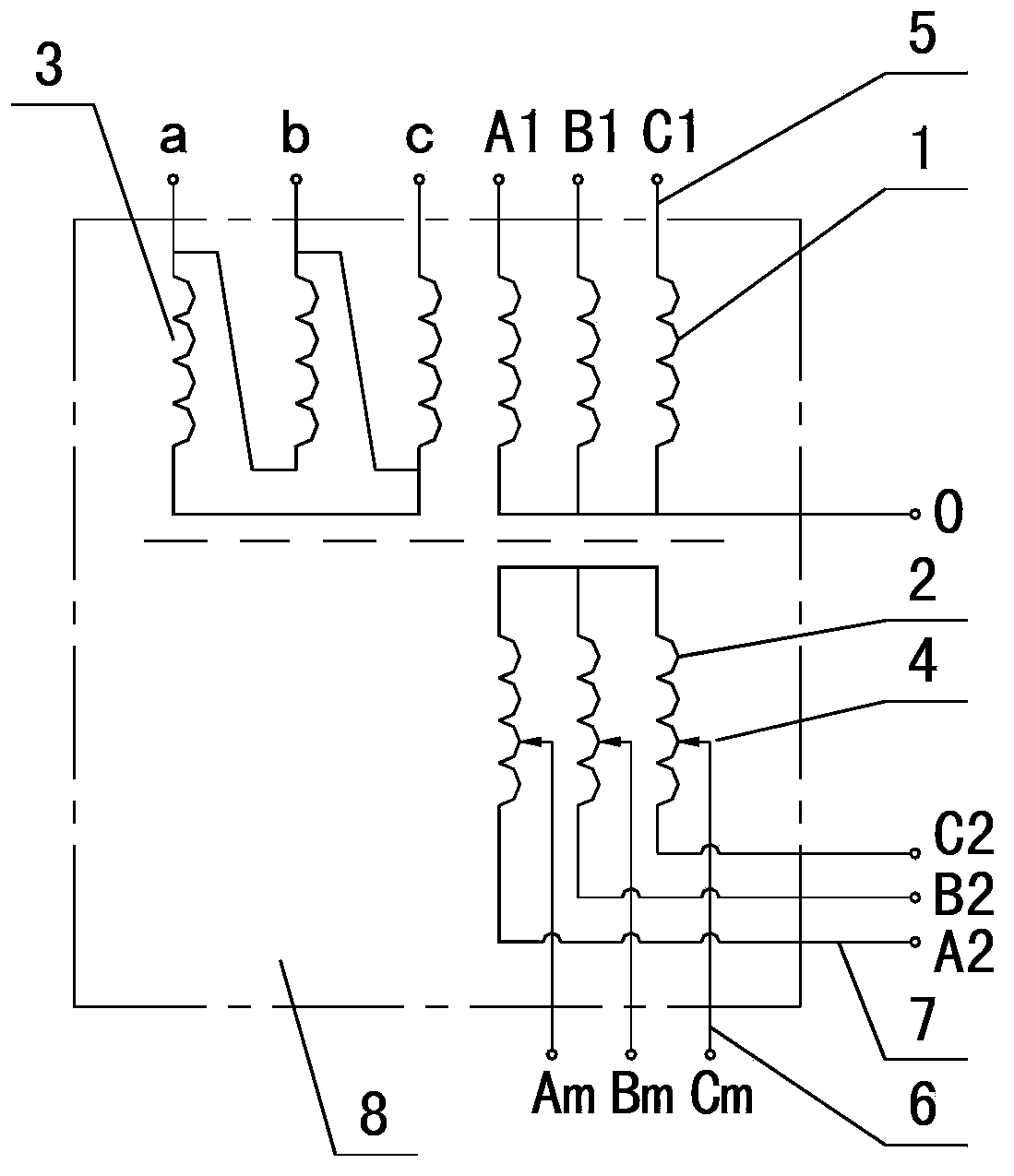

[0029] Such as figure 1 As shown, the dual-power dual-winding step-down voltage-regulating rectifier transformer group system of the present invention mainly includes: voltage-regulating transformer primary winding 1, voltage-regulating transformer secondary winding 2, voltage-regulating transformer reactive power compensation winding 3, secondary voltage-regulating on-load Voltage regulating switch 4, voltage regulating transformer primary winding high voltage lead 5, voltage regulating transformer secondary winding lead 6, voltage regulating transformer secondary winding backup power lead 7, voltage regulating transformer 8, rectifier transformer 9, neutral point grounding device 10, Reactive power compensation device 11, rectifier 12, modulating primary side circuit breaker 13, modulating primary side isolating switch 14, modulating secondary standby power side circuit breaker 15, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com