A Method for Reducing Electromagnetic Vibration and Noise of Automotive Claw Pole Generator Based on Magnetic Pole Eccentricity

A technology of electromagnetic vibration and generator, applied in the direction of salient poles, magnetic circuit shape/style/structure, etc., can solve the problems of no public reports of technical solutions, etc., to weaken torque ripple, improve air gap magnetic density distribution, reduce electromagnetic Effects of Vibration and Noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The method of reducing the electromagnetic vibration noise of the automotive claw pole generator based on the eccentricity of the magnetic pole in this embodiment is:

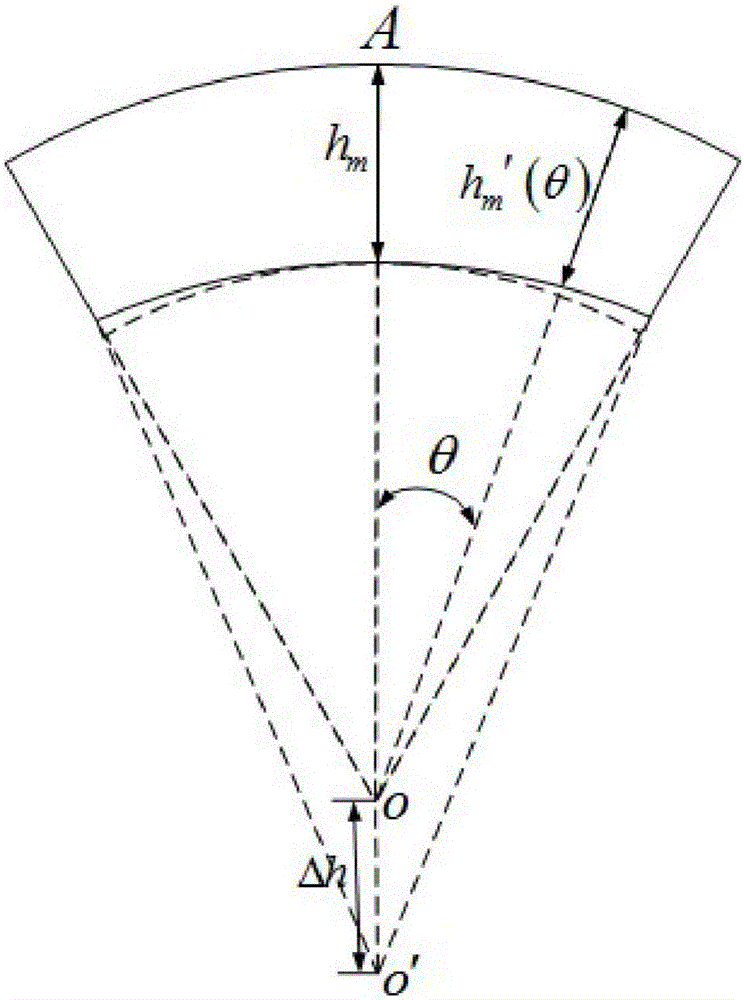

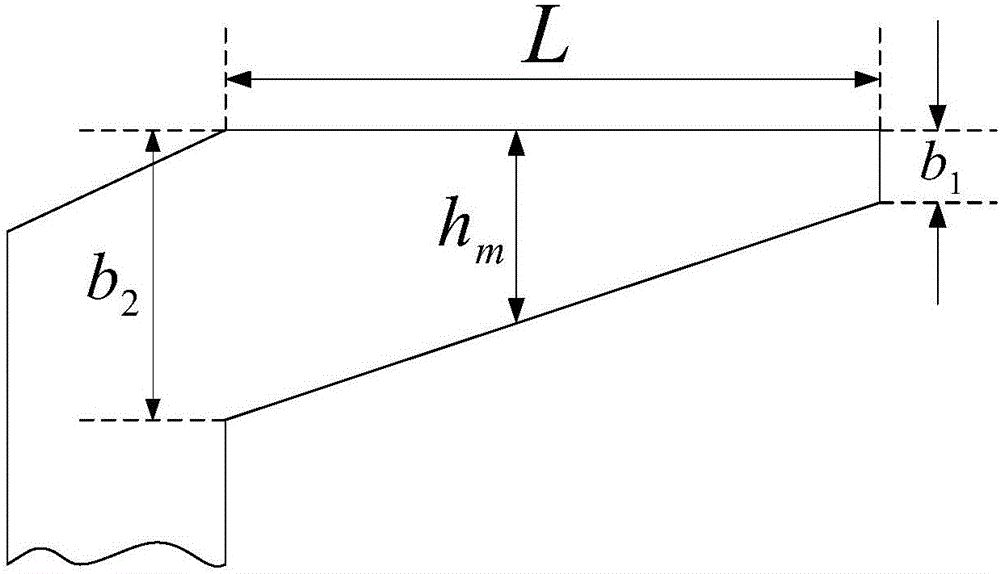

[0013] Such as figure 1 As shown, it is assumed that the plane where the axially protruding end of each claw pole of the N pole and S pole of the claw pole generator is located on the radial section is the S plane; the axial protruding end of the claw pole is on the S plane There are outer arc lines and inner arc lines ( figure 1 The inner circular arc line represented by the middle solid line); make: the center of the outer circular arc line is point O, the midpoint of the outer circular arc line is point A, and the center point of the inner circular arc line is point O′, then point O′ is It is located on the extension line of the line connecting OA at the end of point O, and the distance from point O is Δh. The S section is the section at any position along the axial direction of each claw pole. Loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com