Stir-frying cooking utensil

A cooking utensil and frying technology, which is applied in the field of cooking utensils, can solve the problems of large differences in taste and quality, and achieve the effect of uniform taste and increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

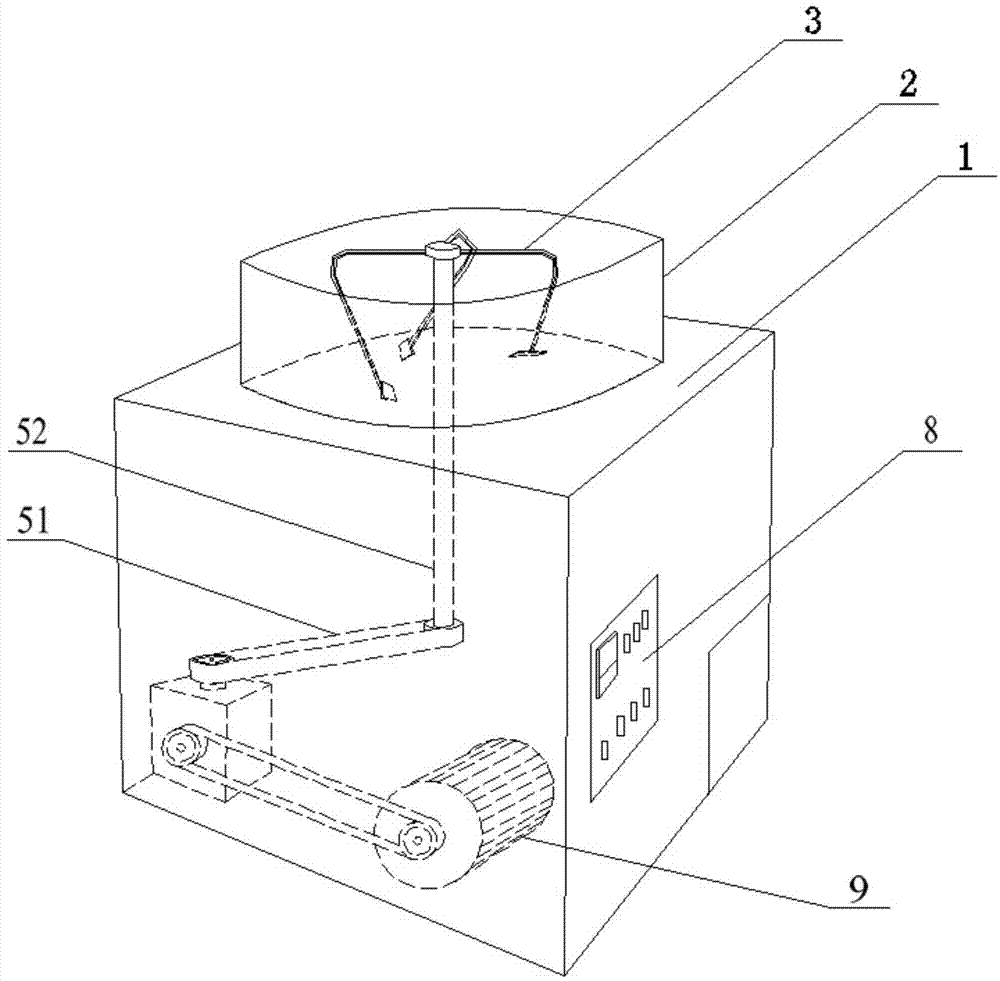

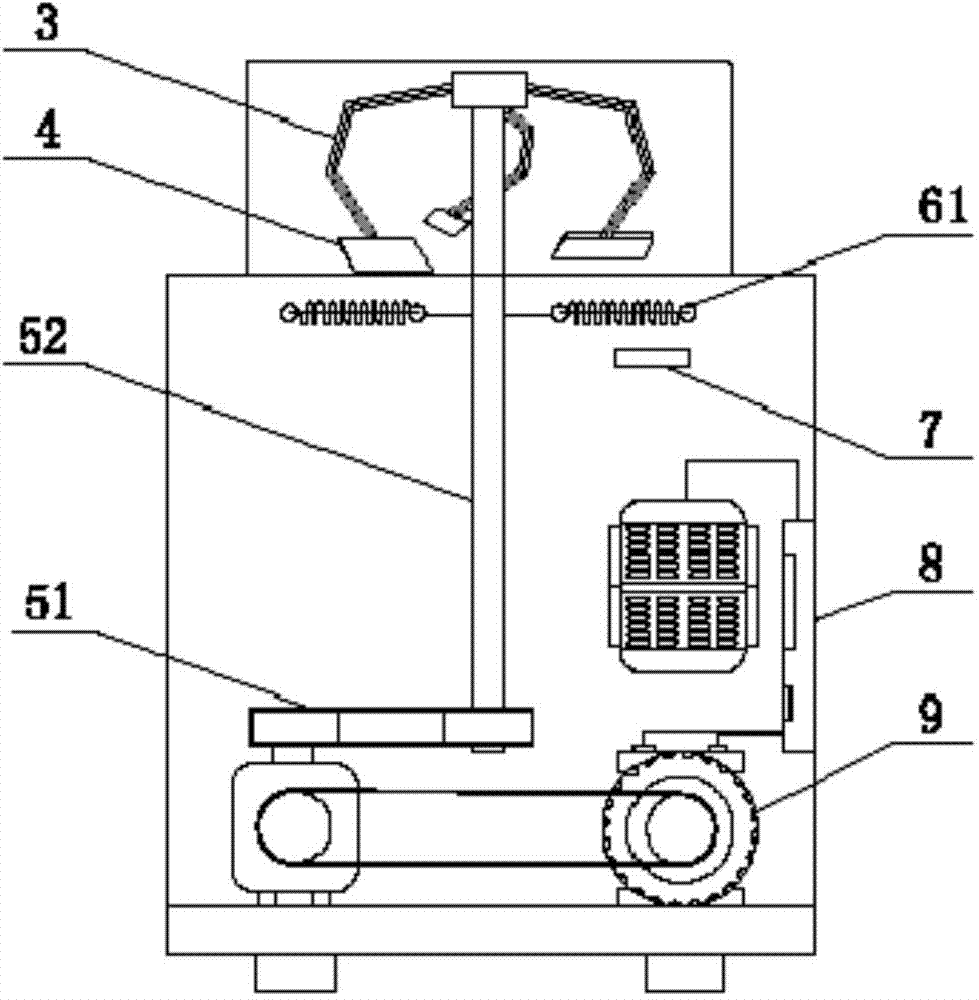

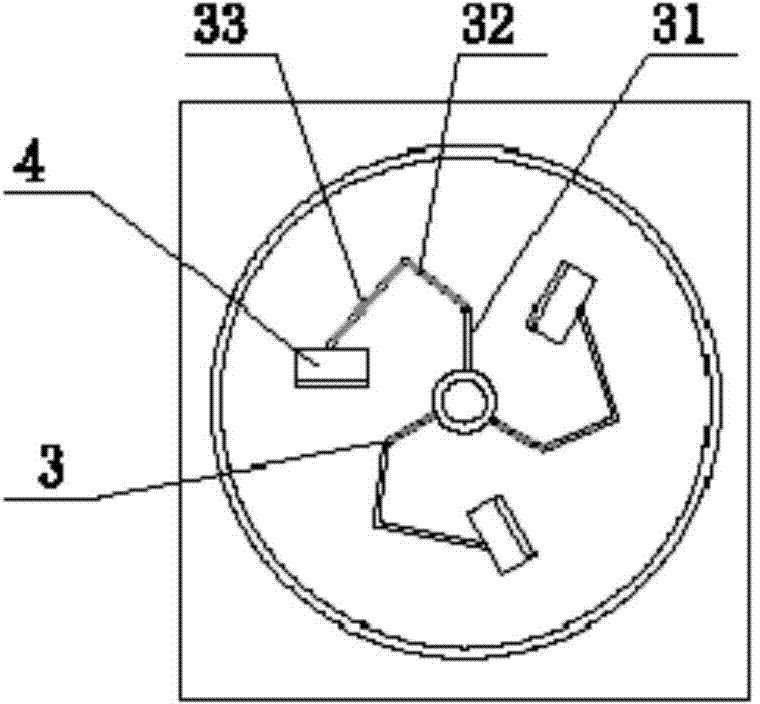

[0023] Example 1, such as Figure 1-3 As shown, a frying cooker includes a furnace body 1, a wok 2 arranged on the furnace body and a stir-frying arm 3 arranged in the wok, and a heating device for providing a heat source to the wok 2 is arranged in the furnace body 1 And the power unit that provides power to the stir-fry arm 3, the power unit is connected with the stir-fry arm 3 through a transmission device;

[0024] A control panel 8 is arranged on the outside of the furnace body 1, and the control panel 8 includes a display screen for displaying the operating status of the cooker and an operating console for controlling the power unit. The display screen is a current and voltage meter indicator light, and control buttons are arranged on the console.

[0025] A weighing device and a temperature control device are arranged below the wok 2, and the data measured by the weighing device are displayed on the furnace body 1 through a display screen. The temperature control devi...

Embodiment 2

[0030] Example 2, such as Figure 4 , 5 As shown, a frying cooker includes a furnace body 1, a wok 2 arranged on the furnace body and a stir-frying arm 3 arranged in the wok, and a heating device for providing a heat source to the wok 2 is arranged in the furnace body 1 And the power device that drives the stir-frying arm 3 to move, the power device is connected with the stir-fry arm 3 through the transmission device; the heating device is a steam heater 62, and a sensor 7 is arranged below the steam heater. The steam heater 62 is airtightly arranged at the bottom of the pot, and its steam is supplied by an external steam boiler 100 . In actual use, one steam boiler can provide steam to multiple frying cookers at the same time, and the use of steam heating can ensure that the heating of the frying pan 2 is more uniform, and the taste of the fried beef jerky is more consistent. All the other undescribed parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com