Spinning broken yarn knotting knife

A technology for knotting knife and yarn breaking, applied in the field of textile components, can solve the problems of affecting the knotting efficiency, affecting the knotting of broken yarns, inconvenient use, etc., and achieves the effects of easy implementation, reduced production cost, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

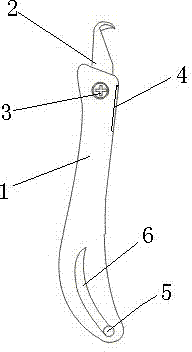

[0011] like figure 1 As shown, a textile yarn breaking knife includes a plastic handle 1 and a knotting knife head 2, the knotting knife head 2 is fixed on the top of the plastic handle 1 through a movable shaft 3, and one side of the plastic handle 1 is provided with a The slot 4 of the knotting cutter head 2, when not in use, the knotting cutter head 2 can be bent into the slot on one side of the plastic handle 1 along the movable rotating shaft 3, so as to prevent the knotting cutter head 2 from accidentally injuring people. The handle 1 is in the shape of a long arc, which can replace the traditional mold steel. The length can be processed according to the needs, saving a lot of cost. The tail of the plastic handle 1 is widened, and the tail is provided with a hanging hole 5 for hanging, which is convenient for hanging. The plastic handle 1 An anti-slip groove 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com