Automatic knotting assembly for plastic shaping filaments

An automatic knotting, plastic technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of low knotting efficiency and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

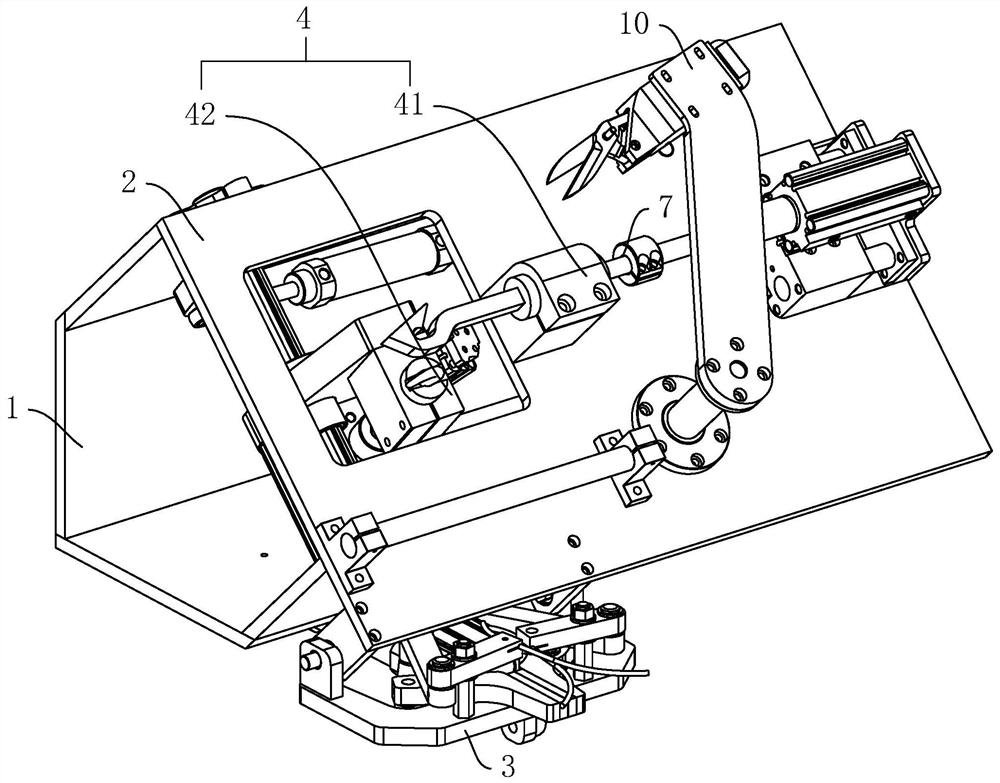

[0057] A plastic setting wire automatic knotting assembly, such as figure 1 Shown, including knotted base 1. The top of the knotting base 1 is obliquely provided with a working table 2 , and an installation chamber is formed between the knotting base 1 and the working table 2 . An installation hole is provided through the work surface 2, and the installation hole extends along a direction perpendicular to the work surface 2, and the installation hole communicates with the installation chamber.

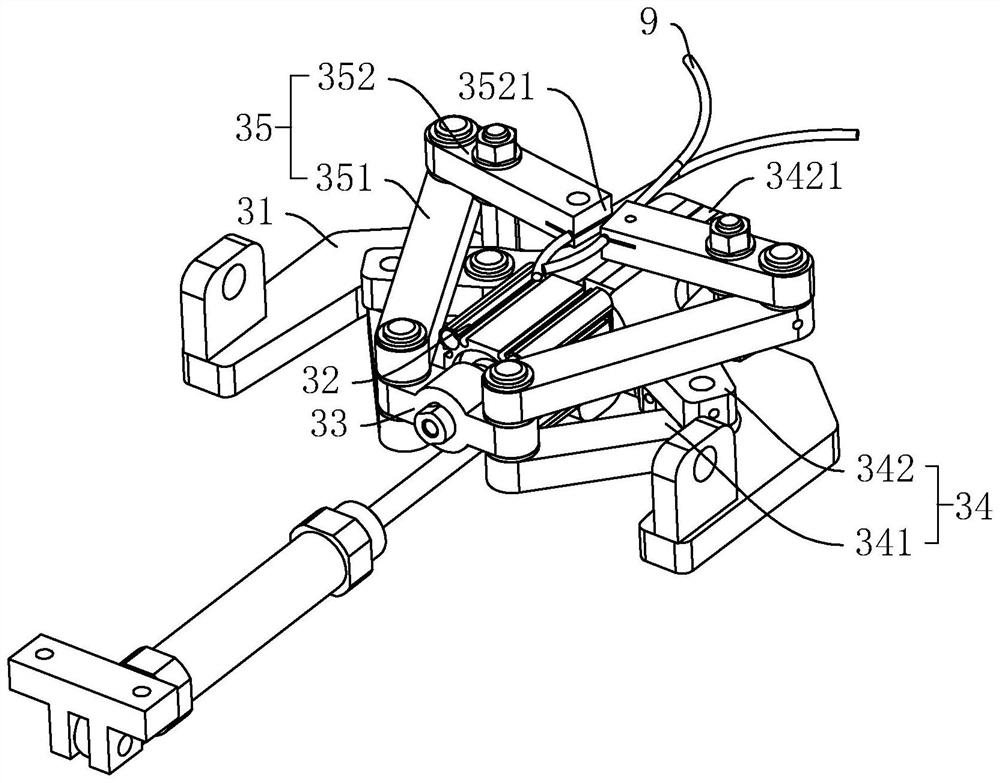

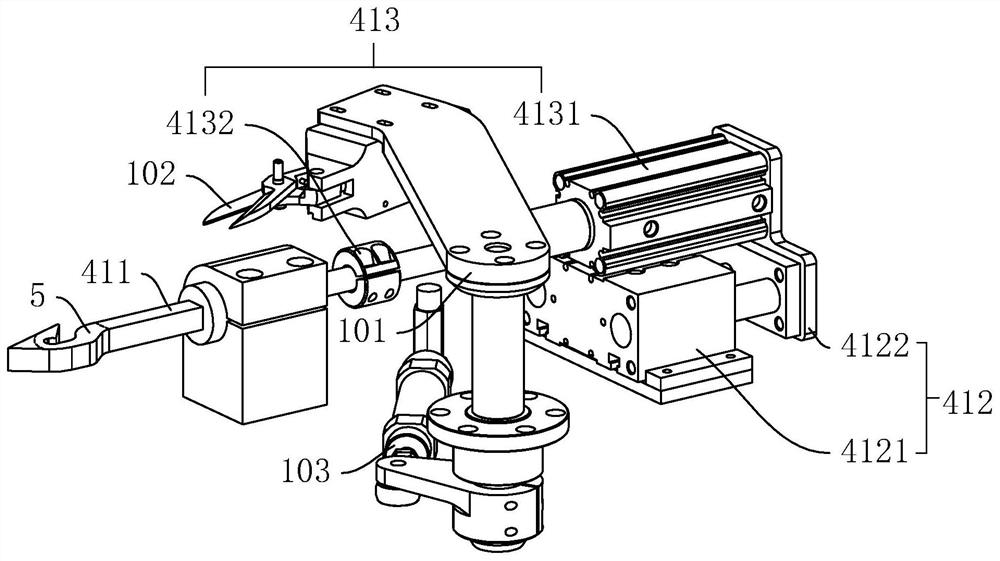

[0058] The working surface 2 is provided with a thread end clamping part 3 for clamping and fixing the hanging plastic shaping thread, a thread end knotting part 4 for knotting the hanging plastic shaping thread, and a thread end cutting part for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com