Compression roller mechanism in rotary ironing machine

A technology of a drum ironing machine and a pressing roller mechanism, which is applied to ironing machines, washing devices, textiles and papermaking, etc., can solve problems such as poor flatness, save quantity, avoid displacement, and improve ironing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

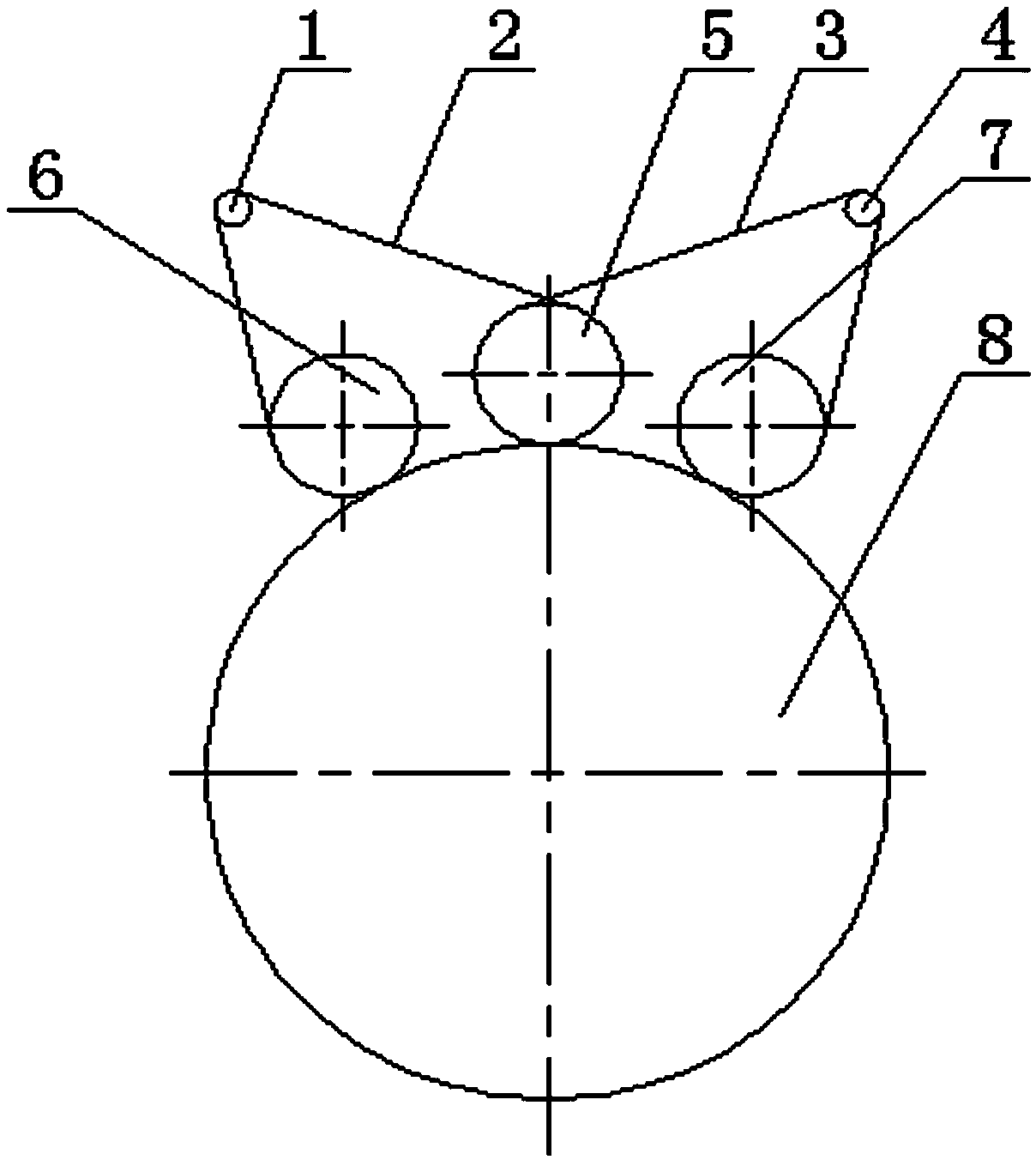

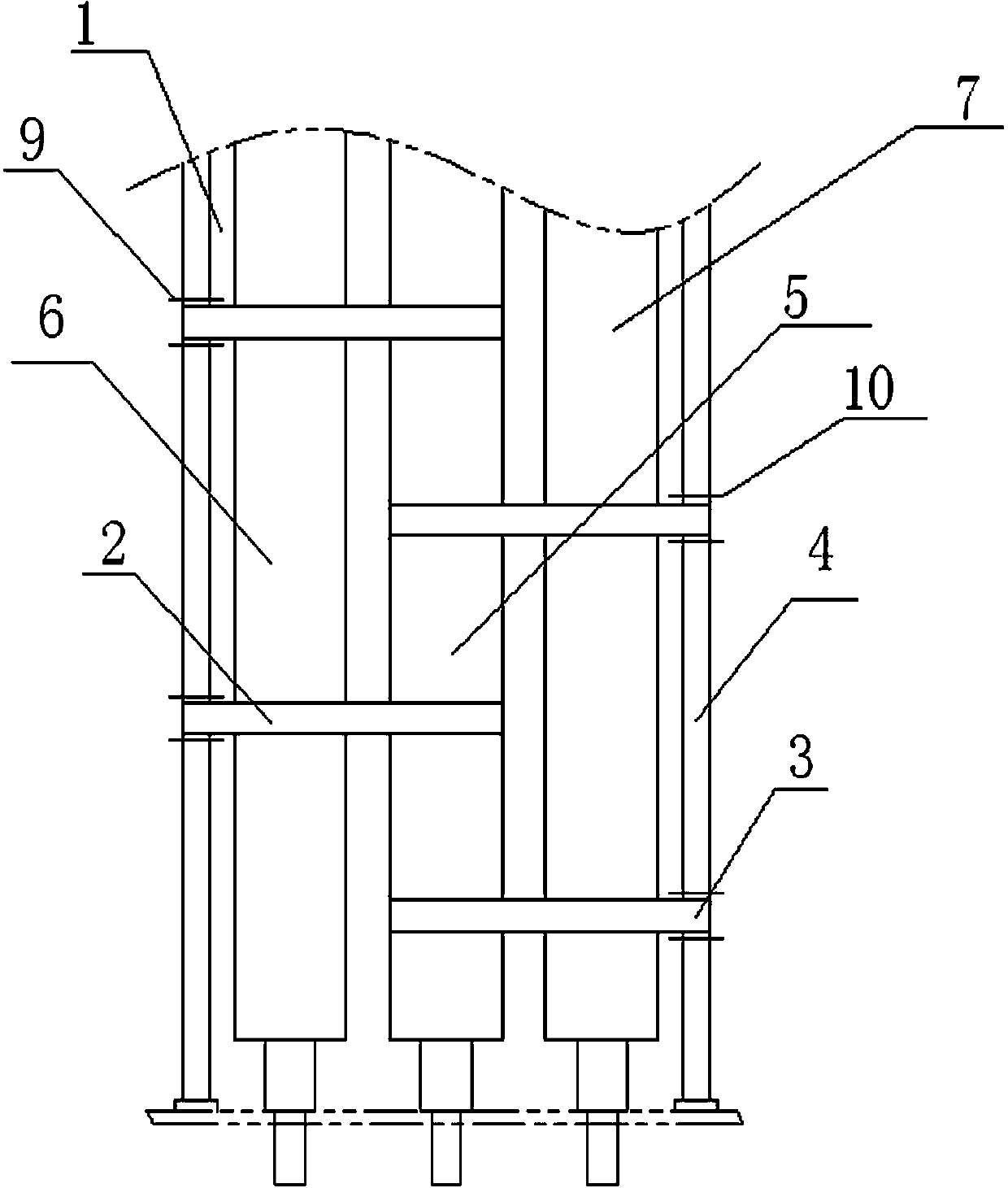

[0009] Embodiment one, in figure 1 with figure 2 Among them, the present invention provides a pressure roller mechanism in a drum ironing machine, which includes a pressure roller set and an ironing cylinder 8, the pressure roller set is attached to the ironing cylinder 8 by its own gravity, and the pressure roller set includes a left press Roller 6, middle pressure roller 5 and right pressure roller 7, middle pressure roller 5 is located on the longitudinal axis of ironing cylinder 8, left pressure roller 6 and right pressure roller 7 are respectively positioned at the left and right sides of middle pressure roller 5, on the left A left fixed pipe 1 is arranged above the roller 6, a right fixed pipe 4 is arranged on the upper part of the right pressure roller 7, and several left guide belts 2 are wound between the left pressure roller 6, the middle pressure roller 5 and the left fixed pipe 1. In this embodiment, two left guide belts 2 are wound between the left pressure rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com